#Polypropylene (PP) Resin Market

Link

Polypropylene (PP) Resin Size, Share, Trends and industry analysis now available from IndustryARC.

0 notes

Text

Electric Vehicle Plastics Market: An In-Depth Exploration and its Contribution to a Circular Automotive Industry

The global electric vehicle plastics market size was estimated at USD 13.33 billion in 2030 and is anticipated to grow at a compound annual growth rate (CAGR) of 28.0% from 2024 to 2030. The industry is projected to witness significant growth in terms of consumption, on account of high application scope and increasing demand from the growing population. The Polypropylene (PP) resin demand in the Asia Pacific region is estimated to grow at the fastest CAGR over the forecast period. Strong government support & initiatives regarding emissions and increasing investment by manufacturers are propelling the growth of the region.

Electric Vehicle Plastics Market Report Highlights

The Asia Pacific region is estimated to grow at the fastest CAGR from 2022 to 2030. Increasing demand from the growing population coupled with environmental concerns among others are anticipated to drive market growth in the region

The battery segment is anticipated to register the fastest CAGR from 2022 to 2030. Batteries are one of the significant components of an EV and, in comparison to combustion engines, battery vehicles do not produce any emissions and are eco-friendly. The growing demand for EVs has promising growth for EV batteries

The exterior application segment accounted for the largest revenue share in 2021 and is estimated to continue its dominance over the forecast period due to the high demand in aesthetics

The BEV vehicle type segment led the industry in 2021 and it is anticipated to continue growing over the forecast period as PHEVs have higher maintenance costs than BEVs

For More Details or Sample Copy please visit link @: Electric Vehicle Plastics Market Report

Furthermore, EVs are efficient and require less maintenance as compared with traditional vehicles. These factors are expected to boost the demand for EVs, which is expected to drive the demand for plastics over the forecast period. Increasing utilization of plastics in EVs is anticipated to boost industry growth positively over the forecast period. Plastics have proven to perform well under harsh conditions through their resistance to shock, moisture, oxidation, and further maintaining their chemical and mechanical properties. Plastics will be crucial material for manufacturing lightweight and energy-efficient EVs. Based on resin type, PP is expected to witness major demand during the projected years.

Polypropylene is used in many components of the vehicle including bumpers, carpet fibers, cable insulation, and others. Properties, such as good heat, chemical & fatigue resistance, and others, are anticipated to drive the demand for PP in the industry. Major manufacturers are adopting expansion strategies, such as new product development, production facility expansions, mergers & acquisitions, and joint ventures. For instance, in October 2021, DuPont launched a new extension of its existing Zytel HTN range, named as Zytel 500 series. These products are developed to provide enhanced retention properties in e-mobility oils, electrically friendly characteristics, and a high Comparative Tracking Index (CTI).

EVPlastics #ElectricVehicles #SustainableDriving #EcoFriendlyCars #ElectricVehicleTech #CleanTransportation #GreenMobility #EVInnovation #PlasticsInEVs #FutureOfTransport #SustainableMaterials #EcoAutoDesign #EVManufacturing #PolymerInnovation #ZeroEmissionVehicles #GreenTechAuto #CleantechPlastics #EVDesign #EcoFriendlyPlastics #CircularAutoEconomy

#EV Plastics#Electric Vehicles#Sustainable Driving#Eco-Friendly Cars#Electric Vehicle Tech#Clean Transportation#Green Mobility#EV Innovation#Plastics In EVs#Future Of Transport#Sustainable Materials#Eco Auto Design#EV Manufacturing#Polymer Innovation#Zero Emission Vehicles#Green Tech Auto#Cleantech Plastics#EV Design#Eco-Friendly Plastics#Circular Auto Economy

2 notes

·

View notes

Text

Purging Compound Market: Unlocking Growth Opportunities and Challenges

Introduction

Purging compounds are specially formulated materials that are used to clean plastic processing equipment and eliminate material cross-contamination between different plastic grades or formulations. They essentially "push out" any residual plastic left in the machine after a production run and prepare the equipment for the next material. These compounds are available for most major commercial plastics like polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), nylon, polycarbonate and others.

Composition and Mechanism of Action

Typical purging compounds contain a base resin that matches the type of plastic being purged, along with additives that facilitate better flow and cleaning properties. For example, a polypropylene compound would use PP as the base but contain wax or silicone components. During the purging cycle, the compound is melted and forced through the machine much like the product plastic. Its excellent flow properties help displace any remaining contamination deeply seated in crevices or hard to reach areas. The additives also act as release agents that effectively strip colorants, filler particles or remnants of the previous material from machine surfaces in one pass.

Purging for Color Changes

One of the most common uses of compounds is when changing between different color batches of the same plastic on an injection molding or blow molding line. Even trace quantities of unintended color carried over can mean rejecting large production runs. Purging removes any discoloration completely to ensure bright, consistent color from the first piece produced after a changeover. It is a more economical solution than completely dismantling and cleaning the machine each time. Compounds are also available in various colors to provide a visual cue of when the purging cycle is complete.

Purging for Grade Changes

While color changes require fine purging, changing between unrelated plastic formulations or grades demands deeper level of purification. Even minuscule cross-contamination risks incompatibility issues, performance inadequacies or regulatory failures in products. Specialty compounds have been formulated to get into microscopic nooks and remove adhesion of incompatible polymers. Some advanced varieties can even dissolve into prior material rather than simply displace it. Such high performance purging allows confident switching between engineering resins, filled plastics and other dissimilar materials.

Meeting Industry Quality Standards

Purging is critical in many highly regulated industries like food packaging, medical devices, automotive and barrier films where the tiniest trace of an unintended contaminant could have safety or functionality repercussions. Compounds help manufacturers meet purity levels mandated by ISO 9000, cGMP or customer specifications by leaving machines in pristine condition. They are even applied between production lots of the same material to prevent cross-contact at the molecular level. The assurances of correct purging reassure compliance auditors and quality certifiers.

In summary, these compounds have become an indispensable tool that facilitates optimal machine utilization, consistent quality production, regulatory adherence and reduced environmental footprint in plastics processing. Their continually improving performance and formulation diversity are critical enablers powering growth of the global plastics industry. With plastics demand set to rise consistently, purging compounds will play a greater strategic role in the coming years.

0 notes

Text

Carbon Fiber Reinforced Plastic Market - Forecast(2024 - 2030)

Carbon Fiber Reinforced Plastic Market Overview:

Carbon fiber reinforced plastic market size is forecast to reach $30.5 billion by 2030, after growing at a CAGR of 9.41% during 2024-2030, owing to the increasing adoption of carbon fiber reinforced plastics over conventional metallic alloys in various end-use industries such as automotive, aerospace, wind energy, and others. This is mainly due to the tensile strength carried by CFRP, which falls between 1500 and 3500 MPa, whereas its metallic counterparts such as aluminum and steel only possess tensile strength of 450–600 MPa and 750–1500 MPa, respectively. Growing demand from the aerospace industry and a rising preference for fuel-efficient and lightweight vehicles are the major factors driving the carbon fiber reinforced plastic (CFRP) market during the forecast period

Report Coverage

The report: “Carbon Fiber Reinforced Plastic (CFRP) Market – Forecast (2020-2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the carbon fiber reinforced plastic (CFRP) Industry.

By Type: Thermoplastic (Polyether Ether Ketone (PEEK), Polypropylene, Nylon, Acrylic Resins, Polyamide Resins, PET, Polyphenylene Sulfide (PPS), Polyethylene, Polyurethane, Polyethersulfone, Polyetherimide (PEI), and Others), and Thermosetting (Epoxy Resin, Polyester Resin, Vinyl Ester Resin, Phenolic, Polyimide Resins, and Others)

By Application: Automobiles, Industrial, Aviation & Aerospace, Marine, Defense, Electrical & Electronics, Medical, Sports Equipment, Wind Energy, Civil Engineering, and Others

By Geography: Americas, Europe, Asia Pacific, RoW

Request Sample

Key Takeaways

Europe dominates the carbon fiber reinforced plastic (CFRP) market, owing to the increasing demand and production of lightweight vehicles in the region. According to OICA, in 2018 the production of light commercial vehicles has increased by 2.5 % in Europe.

The carbon fiber reinforced plastics are being widely used to manufacture sport equipment such as golf shafts, bicycles, skis, surfboards, helmets, racquets, hockey sticks, baseball bats and several other products. Its low maintenance cost and corrosion resistance properties are the major factor driving the market in the sports sector.

The properties associated with CFRP such as good conductivity, flame resistance, high strength and vibration damping has facilitated their inclusion in several electrical and electronic products such as household appliances, audio systems, enclosures, electrical installations, interconnects, brushes and EMI shielding.

The X-Ray permeability, biological inertness coupled with high strength has paved the way for CFRP applications in Medical sector. Imaging equipment, orthopedics and surgical outfits are some of the common medical devices that employ CFRP.

Due to the COVID-19 Pandemic most of the countries has gone under lockdown, due to which operations of various industries such as automotive, defense, and aerospace has been negatively affected, which is hampering the carbon fiber reinforced plastic (CFRP) market growth.

By Type – Segment Analysis

The thermosetting segment held the largest share in the carbon fiber reinforced plastic (CFRP) market in 2019, owing to the superior characteristics of thermosetting CFRP over thermoplastic CFRP. Unlike thermoplastics, they retain their strength and shape even when heated. This makes thermosetting plastics well-suited to the production of permanent components and large, solid shapes. Furthermore, these components have outstanding high strength-to-weight ratio performance, enhanced dielectric strength, low thermal conductivity. Thus, thermoset CFRP find their use in varied applications owing to their heat resistant characteristics, excellent dimensional and chemical stability properties when exposed to high heat and more.

Inquiry Before Buying

By Application – Segment Analysis

The defense application held the largest share in the carbon fiber reinforced plastic (CFRP) market in 2019 and is growing at a CAGR of 9.42%, owing to its ability to reduce a weight of an object to a large extent while providing superior strength. Thus, there is an increasing demand of carbon fiber reinforced plastics from the defense industries to manufacture specialty components for missile systems, radar panels, body armors, helmets, rocket motor casing, artificial limbs, ballistics, nuclear submarine, propulsion systems and many more. Some of the materials used in military composites include Kevlar, fiberglass and carbon fiber. Countries like Russia, India and Japan are increasingly using composites in submarines, jets, sonar domes and truck components. U.S., U.K., India, and China are the major spenders on defense equipment and maintenance of army. M80 Stileto is the largest U.S. naval vessel built using carbon-fiber composites. Armored vehicles have conventionally used steel armor for protection; however, weight of these large trucks creates logistical problems. Therefore, the adoption of CFRP is increasing in these vehicles. U.S. DOD aims to replace UH-60 Black Hawk with Bell Helicopter’s V-280 which incorporates carbon fibers in its wings, fuselage, and tail. The need for agility at the time of sudden attacks and upgrading the defense technologies has led to the shift from conventional materials to fiber reinforced materials, which is anticipated to propel the carbon fiber reinforced plastic market during the forecast period.

By Geography – Segment Analysis

Europe region held the largest share in the carbon fiber reinforced plastic (CFRP) market in 2019 up to 34%, owing to the increasing defense, and aerospace sectors in the region. The CFRP are particularly attractive to defense applications because of their exceptional strength, better stiffness-to-density ratios and superior physical properties. Also, CFRP provides relatively stronger and stiffer fibers in a tough resin matrix. According to International Trade Administration (ITA), the Norwegian Government presented a core defense spending budget of USD 6.9 billion in 2019. The Norwegian defense budget accounted for 1.62% of Norway’s GDP in 2018. French civil aerospace industry in 2018 grew to €50.36 billion, out of total non-consolidated aerospace and defense aerospace revenues of €65.4 billion. This is a 1.2% increase over 2017. Also, France has put forth an agreement with the U.K government of $2.1 billion to build a prototype combat drone, which will further boost CFRP market growth. Thus, the increasing aerospace and defense industry in Europe is likely to influence the growth of the carbon fiber reinforced plastic market in Europe.

Drivers – Carbon Fiber Reinforced Plastic (CFRP) Market

Growing Wind Power Sector

As a consequence of drastic increase in energy demand, the conventional sources of energy are depleting very fast. Hence, the need to expand and utilize the renewable energy sources like wind power is growing. The wind power sector is increasing, as use of renewable energy sources results in less emission of greenhouse and other harmful gases such as SO2. The modern wind turbine are being increasingly used in wind power sector as they are cost-effective, more reliable and have scaled up in size to multi-megawatt power ratings. Wind Energy installations in APAC increased by 23.6%. This region is set to witness high growth for wind energy equipment and materials majorly driven by commitments of government of India and China towards green energy. Carbon fiber reinforced plastic is used primarily in the spar, or structural element, of wind blades longer than 45m/148 ft, both for land-based and offshore systems. Carbon fiber has known benefits for reducing wind turbine blade mass due to the significantly improved stiffness, strength, and fatigue resistance per unit mass compared to fiberglass. Due to the increasing adoption of wind power energy source, the demand for the carbon fiber reinforced plastic is also increasing, which acts as a driver for the carbon fiber reinforced plastic market during the forecast period.

Schedule a Call

Stringent Government Regulation on Emission

Carbon fiber reinforced plastics are being extensively used in the automotive industries to reduce fuel consumption as well as emissions and to manufacture lightweight vehicles. Several governments across the world have imposed stringent standard emission and fuel economy regulations for vehicles. These standard regulations have compelled automotive OEMs to increase the use of lightweight materials such as carbon fiber reinforced plastics to assist in increasing the fuel economy of a vehicle while ensuring safety and performance. The emission regulation for light-duty cars such as Corporate Average Fuel Economy (CAFÉ) and Greenhouse Gas Emission standards sets fuel consumption standards for the vehicles. These regulations by the governments have made sure that the car manufacture henceforth might need to be manufacturing much lighter vehicles to obey as per these norms, which acts as a driver for the carbon fiber reinforced plastic market during the forecast period.

Challenges – Carbon Fiber Reinforced Plastic (CFRP) Market

High Cost of Carbon Fiber Reinforced Plastics

The cost of the carbon fiber reinforced plastics is at times supposedly higher. When compared with other traditional materials such as steel and aluminum, lightweight materials such as carbon fiber reinforced plastics (CFRP) and glass fiber reinforced plastics (GFRP) are costly. Composites of carbon fiber cost almost 1.5 to five times more than steel. High cost of fiber production inhibits large volume deployment. Therefore, precursor and processing costs need to be reduced. The high price of carbon fibers in many applications constrains the potential use of composites. Hence, the high cost of carbon fiber reinforced plastics may hinder with the carbon fiber reinforced plastics market growth during the forecast period. However, cost effective production methods coupled with high volume processing, assembly techniques and automation processes will lead to reduction of price in the near future.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the carbon fiber reinforced plastic (CFRP) market. In 2019, the market of carbon fiber reinforced plastic (CFRP) has been consolidated by the top five players accounting for 40% of the share. Major players in the carbon fiber reinforced plastic (CFRP) market are SGL Carbon SE, Teijin Ltd., Toray Industries Inc., Cytec Industries Inc., Mitsubishi Rayon Co. Ltd., Farmosa Plastics Corporation, Nippon Carbon Co. Ltd., DowAksa Advanced Composites Holdings BV, Hexcel Corporation, and Hyosung Advanced Materials.

Buy Now

Acquisitions/Technology Launches

In May 2016, Dowaska, Under secretariat of Defense Industries (SSM) and Turkish Aerospace Industries (TAI) have jointly opened The DowAksa Global Composites Center with an objective to advance Turkey’s carbon fiber and other reinforcement composites manufacturing mainly for aerospace applications in both defense and commercial aviation and the infrastructure, marine, wind energy and transportation sector.

In March 2018, Toray Industries, Inc. developed a new fabrication technology for Carbon Fiber Reinforced Plastics that enables both improved dimensional accuracy and energy savings.

In November 2018, Toray Industries, Inc. developed new carbon fibers that realized both higher tensile strength and tensile modulus named “TORAYCA® MX series”.

In September 2019, Teijin Limited acquired Benet Automotive, a leading automotive composite and component supplier in the Czech Republic. The acquisition benefits Teijin’s composite technologies business.

In December 2019, SGL Carbon and Solvay entered into a joint development agreement to develop composite materials based on large-tow intermediate modulus carbon fiber for aerospace primary structures.

In May 2020, Toray Industries, Inc. developed a high tensile modulus carbon fiber and thermoplastic pellets that are ideal for injection molding employing. Toray announced to push ahead with research and development to commercialize the fiber and pellets within the next three years.

#Carbon Fiber Reinforced Plastic Market#Carbon Fiber Reinforced Plastic Market Share#Carbon Fiber Reinforced Plastic Market Size#Carbon Fiber Reinforced Plastic Market Forecast#Carbon Fiber Reinforced Plastic Market Report#Carbon Fiber Reinforced Plastic Market Growth

0 notes

Text

Exploring Emerging Applications: Thermoformed Plastics Market Dynamics

Thermoformed Plastics: An Essential Part of Modern Packaging

Introduction to Thermoforming

Thermoforming is a plastic forming process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The key advantages of thermoforming are its ability to produce complex, high-volume shapes in a single continuous process. Some common thermoformed products include food and medical packaging, containers, automotive interior parts, signs and displays.

Sheet Forming Process

In the thermoforming process, plastic sheet material such as PVC, polystyrene, polyethylene, polypropylene, or acrylic is used. The sheet is first heated to high temperature using infrared heaters until it softens and sag. It is then placed over a matched mold cavity and a vacuum is applied from below, forcing the softened sheet tightly against the mold surface. The sheet cools and hardens to the exact shape of the mold profile before being trimmed and ejected. This allows consistent high-volume production of parts with complex 3D shapes.

Applications in Food Packaging

Thermoformed plastics play a crucial role in food packaging where packaging needs to be inexpensive yet functional. Common examples include:

- Meat and produce trays - Polystyrene and polypropylene trays of varying sizes are used in supermarkets for packaging sliced meats, cheeses, fruits and vegetables.

- Cereal liner bags - PET and polypropylene sheets are thermoformed into shape-retaining liner bags that fit inside cereal boxes for moisture and freshness protection.

- Egg cartons - Recyclable polystyrene cartons thermoformed into compartments provide protection for transporting eggs.

- Takeout containers - Disposable clamshell containers made from polystyrene or polypropylene are used ubiquitously for serving and carrying out foods from restaurants and fast food outlets.

- Yogurt and snack cups - PET, polypropylene or polylactic acid (PLA) cups are thermoformed for packaging single-serve yogurt, pudding, juice boxes and snack products.

Sustainability Considerations

As concerns grow around plastic waste and sustainability, thermoformers are increasingly focusing on use of recycled resins and design of packaging for recyclability. Some key trends include:

- Incorporation of post-consumer recycled (PCR) content in packaging to promote circular economy.

- Mono-material thermoformed containers made of PET, PP or PE for improved sorting and recycling.

- Reduced plastic thickness and shaping features to minimize material usage.

- Compostable thermoformed products made from PLA or paper for composting or recycling streams.

The future of thermoformed plastic packaging lies in sustainable design, efficient processes, and alternative biodegradable resins to balance performance, cost and environmental impact. Continued innovation is ensuring this technology remains relevant in a changing regulatory

landscape.

In Summary, thermoformed plastics have become integral components of modern packaging solutions, offering versatility, durability, and cost-effectiveness. This manufacturing process involves heating plastic sheets and molding them into various shapes to create packaging for a wide range of products. From food and beverages to consumer goods and medical supplies, blow moulding plastics provide lightweight and customizable packaging options that protect products during storage and transportation. Their ability to conform to specific shapes and sizes, along with their transparency and barrier properties, make them ideal for showcasing and preserving goods while reducing packaging waste. As a vital element in modern packaging, blow moulding plastics continue to play a crucial role in meeting the evolving needs of industries worldwide.

0 notes

Text

Introducing Ratana: Timeless Elegance in Outdoor Living

Ratana, a name that has become synonymous with luxurious and timeless outdoor living, has captured the hearts of homeowners and design enthusiasts alike. As a proud partner of Patio Productions, we're thrilled to showcase the exceptional craftsmanship and elegance that define the Ratana brand.

Click Here to Shop Ratana Now!

About Ratana

Ratana's journey began in 1980 when the Leung family founded the company as "Ratana Home and Floral." Initially focused on handcrafted gift items, the business quickly pivoted to meet the rising demand for high-quality rattan furniture. Over the years, Ratana has expanded its reach, establishing itself as a global player in the outdoor furniture market, catering to both residential and commercial sectors.

Today, Ratana's comprehensive line of contract and hospitality specification furniture can be found worldwide, gracing the interiors of 5-star luxury hotels, top-ranked restaurants, international golf courses, and even global Olympic venues. This widespread acclaim is a testament to Ratana's unwavering commitment to excellence and their ability to seamlessly blend European contemporary design with American comfort.

Shop Ratana If...

- You appreciate furniture that combines elegance and durability.Ratana's products are crafted using high-quality 6063 aluminum, renowned for its excellent extrudability, corrosion resistance, and ability to be formed into intricate shapes.

- You value weather-resistant materials.Ratana's Durarope and Durastrap are made of Polypropylene (PP) and Polyolefin (POE), offering remarkable UV resistance and a tensile strength that is 7 times stronger than traditional 13mm flat resin.

- You prioritize comfort and breathability.Ratana's reticulated (extremely open cell) cushions feature excellent drainability and water pass-through properties, ensuring a comfortable and refreshing outdoor experience.

“Ratana is known for their exquisite designs and substantial quality. We offer a firm, comfortable seat cushion with reticulated foam that provides excellent drainability. All of our collections offer deep seating and dining so you are able to design your backyard living space with ease. Fabric choses not only offer Sunbrella, but also include Outdura, and Bella Dura to give you optimal selection.”

Stacie Riley, Representative, Ratana

What We Like About Ratana

Diva 2-Seater Section Set with Corner Table by Ratana

There’s a lot to like about Ratana! Here are a few of our favorite highlights:

- Their frames are constructed using powder-coated aluminum - a durable alloy which is lightweight, sturdy, and rust proof.

- Their rope blend is hand-woven, incredibly fade resistant to withstand the rigors of sun and rain.

- Their cushions are antimicrobial and tear resistant, come with distinctive and easy to clean Sunbrella, Outdura, and Bella Dura fabrics.

- Ratana's ability to cater to a wide range of styles, from traditional to transitional and contemporary, is truly impressive. Its products seamlessly enhance the enjoyment of home and casual living experiences, making them a top choice for homeowners and designers alike.

"Ratana offers distinct and elegant designs suitable for everyone's needs. Its lightweight and smooth aluminum surfaces make it easy to move around."

Dua Rashid, Sales Associate, Patio Productions

"Ratana will give a commercial quality performance. It has collections featuring chic boho styling, and collections with mid-century and contemporary lines. Materials in collections feature Sunbrella fabrics, durable powder-coated aluminum frames, polypropylene and polyolefin braided ropes."

Andres Herera, Sales Associate, Patio Productions

Our Favorite Ratana Collections

Copacabana Collection

Copacabana Sofa Set by Ratana

If you’re looking for a clean, open, contemporary design and modular configuration, then Copacabana collection is what you need! Copacabana collection boasts a sleek black contracted-graded powder-coated aluminum furniture frames, seamlessly complemented by the warm hues of brown braided Durarope™. This collection also comes with premium, tailored deep cushioning, which meets both comfort and durability.

Lamego Collection

Lamego Sofa Set by Ratana

For those interested in the fusion of classical charm and modern sophistication, look no further than the Lamego collection! Inspired by the architectural grandeur of Lamego, Portugal, each piece is a testament to timeless elegance.

Featuring crisscrossed woven cobalt graphite Durastrap™, meticulously designed to echo the city's iconic church towers. Built to endure the elements, the weather-resistant powder-coated aluminum frames, reinforced with synthetic EVA rubber, ensure lasting beauty and resilience.

Visit our website or stop by our San Diego showroom to explore the full Ratana collections today! Our team offers design services, trade programs, custom cushions, and accessories to create your dream outdoor living space. Don't hesitate to reach out to us for all your outdoor furniture needs!

Read the full article

0 notes

Text

Polypropylene Filament Yarn Prices, Trend, Supply & Demand and Forecast | ChemAnalyst

Polypropylene Filament Yarn (PPFY) prices have been subject to fluctuations influenced by various market dynamics. Understanding these trends and the factors that drive them is crucial for businesses operating within the textile and manufacturing industries. PP filament yarn, a versatile material derived from polypropylene polymer, serves as a fundamental component in the production of a wide array of textile products, including ropes, geotextiles, upholstery, and packaging materials. Its popularity stems from its durability, lightweight nature, and resistance to moisture and chemicals.

One of the primary determinants impacting PP filament yarn prices is the fluctuation in raw material costs. Polypropylene, the base material for filament yarn production, is subject to price fluctuations driven by factors such as crude oil prices, supply-demand dynamics, and geopolitical tensions. As polypropylene is a byproduct of petroleum refining, any shifts in oil prices directly influence the cost of producing polypropylene resin, consequently affecting PP filament yarn prices. Moreover, supply disruptions or fluctuations in crude oil availability can exacerbate these price volatilities, leading to significant impacts on filament yarn costs.

Get Real Time Prices of Polypropylene Filament Yarn (PPFY) : https://www.chemanalyst.com/Pricing-data/polypropylene-filament-yarn-ppfy-1160

Market demand and supply dynamics play a pivotal role in shaping PP filament yarn prices. The textile industry's demand for filament yarns is influenced by factors such as consumer preferences, fashion trends, and industrial requirements. Periods of high demand, often associated with seasonal variations or economic growth, can exert upward pressure on PP filament yarn prices due to increased competition for limited supply. Conversely, during economic downturns or lulls in demand, oversupply may drive prices downward as manufacturers seek to offload excess inventory.

Global economic conditions and trade policies also impact PP filament yarn prices. Tariffs, trade agreements, and currency exchange rates can significantly affect the cost of importing and exporting filament yarns, thereby influencing their prices in domestic markets. For instance, changes in trade regulations or the imposition of tariffs on imports from key manufacturing regions can disrupt supply chains and lead to price fluctuations. Moreover, currency fluctuations can affect the competitiveness of filament yarn exports, thereby influencing pricing strategies adopted by manufacturers.

Technological advancements and innovations in filament yarn production processes can impact PP filament yarn prices by altering production costs and efficiency. Investments in research and development aimed at enhancing yarn quality, increasing production speeds, or reducing energy consumption can result in cost savings for manufacturers, which may be passed on to consumers in the form of lower prices. Conversely, the adoption of more advanced manufacturing technologies or the implementation of environmentally sustainable practices may lead to higher production costs, thereby exerting upward pressure on filament yarn prices.

Environmental and regulatory factors also play a significant role in shaping PP filament yarn prices. Growing awareness of environmental issues and sustainability concerns has prompted regulatory bodies to impose stricter regulations on the use of certain chemicals and manufacturing processes in the textile industry. Compliance with these regulations may necessitate investments in eco-friendly production methods or the use of alternative materials, which can impact production costs and, consequently, filament yarn prices. Additionally, shifts towards circular economy models and increased demand for recycled filament yarns may influence pricing dynamics within the industry.

In conclusion, Polypropylene Filament Yarn (PPFY) prices are subject to a myriad of factors, including raw material costs, market demand and supply dynamics, global economic conditions, technological advancements, environmental considerations, and regulatory requirements. Businesses operating within the textile and manufacturing sectors must closely monitor these trends and factors to effectively navigate price volatilities and maintain competitiveness in the marketplace. By understanding the underlying drivers of PP filament yarn prices, industry stakeholders can develop informed strategies to mitigate risks and capitalize on opportunities in this dynamic market landscape.

Get Real Time Prices of Polypropylene Filament Yarn (PPFY) : https://www.chemanalyst.com/Pricing-data/polypropylene-filament-yarn-ppfy-1160

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

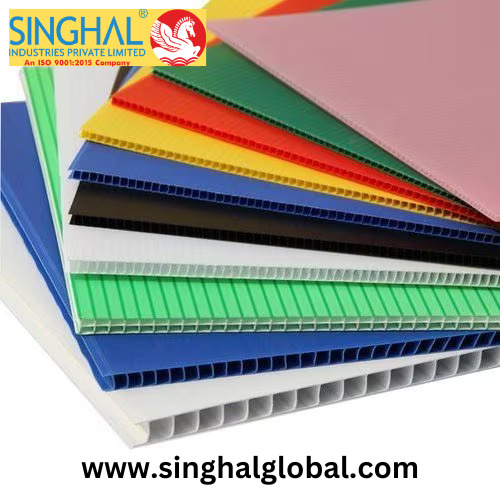

The Art of Protection: How PP Corrugated Sheets Safeguard Your Goods

In the realm of logistics and transportation, ensuring the safety and security of goods during transit is paramount. Whether it's delicate electronics, perishable goods, or heavy machinery, protecting these items from damage is crucial to maintaining business integrity and customer satisfaction. In this pursuit, the role of packaging materials cannot be overstated, and one material that stands out for its versatility and reliability is polypropylene (PP) corrugated sheets.

Understanding PP Corrugated Sheets

PP corrugated sheets, also known as PP hollow sheets or PP flute sheets, are lightweight yet durable plastic sheets. They are crafted from polypropylene resin using a process of extrusion and have a unique corrugated structure that imparts strength and flexibility. These sheets are resistant to moisture, chemicals, and impact, making them ideal for a wide range of applications, including packaging, signage, and construction.

PP Corrugated Sheet Suppliers in Gujarat: Meeting Diverse Needs

Gujarat, India's westernmost state, is renowned for its industrial prowess and manufacturing excellence. Among the myriad industries flourishing in Gujarat, the PP corrugated sheet sector stands out. With a plethora of PP corrugated sheet suppliers in Gujarat, businesses have access to a diverse array of products tailored to their specific needs.

From large-scale manufacturers catering to bulk orders to smaller suppliers offering customized solutions, Gujarat's vibrant market ensures that businesses of all sizes can procure high-quality PP corrugated sheets efficiently and affordably. Moreover, the state's strategic location and well-developed infrastructure facilitate seamless distribution to domestic and international markets, further enhancing its appeal to businesses across various sectors.

PP Corrugated Sheet Manufacturers in India: Setting Quality Standards

India, as a manufacturing hub, boasts numerous PP corrugated sheet manufacturers in India that are committed to upholding stringent quality standards. These manufacturers leverage advanced technology and innovative techniques to produce PP corrugated sheets that meet or exceed industry benchmarks.

By adhering to rigorous quality control measures, such as thorough testing for strength, durability, and environmental resilience, these manufacturers ensure that their products offer unparalleled protection for goods in transit. Furthermore, many manufacturers prioritize sustainability by using recycled materials and adopting eco-friendly production processes, aligning with global efforts to reduce carbon footprint and promote responsible manufacturing practices.

PP Corrugated Sheets Supplier in Ahmedabad: Catering to Local and Global Demands

Ahmedabad, Gujarat's largest city and a thriving industrial hub, serves as a focal point for PP corrugated sheet distribution. As a prominent supplier of PP corrugated sheets in Ahmedabad, numerous businesses rely on its extensive network of suppliers to fulfill their packaging needs.

Whether it's safeguarding agricultural produce during transportation or providing durable packaging solutions for fragile items, PP corrugated sheets suppliers in Ahmedabad offer unmatched versatility and reliability. Moreover, Ahmedabad's proximity to major transportation hubs and ports enables seamless access to national and international markets, making it an ideal location for businesses seeking efficient supply chain solutions.

Frequently Asked Questions

What are the advantages of using PP corrugated sheets for packaging? PP corrugated sheets offer numerous advantages, including lightweight yet robust construction, resistance to moisture and chemicals, flexibility for customization, and recyclability, making them an ideal choice for various packaging applications.

Can PP corrugated sheets withstand harsh environmental conditions? Yes, PP corrugated sheets are designed to withstand harsh environmental conditions, including extreme temperatures, humidity, and exposure to chemicals. Their resilience makes them suitable for outdoor applications as well.

Are PP corrugated sheets eco-friendly? Many PP corrugated sheet manufacturers prioritize sustainability by using recycled materials and adopting eco-friendly production processes. Additionally, PP corrugated sheets are recyclable, contributing to a circular economy and reducing environmental impact.

How can businesses ensure they choose the right PP corrugated sheet supplier? Businesses should consider factors such as the supplier's reputation, product quality, customization capabilities, pricing, and customer service track record. Conducting advanced research and requesting samples can help businesses make informed decisions.

In conclusion, PP corrugated sheets play a vital role in safeguarding goods during transportation and storage. With a robust supply chain encompassing Gujarat's vibrant manufacturing landscape and Ahmedabad's strategic distribution network, businesses can access high-quality PP corrugated sheets tailored to their specific requirements. By embracing innovation and sustainability, PP corrugated sheet suppliers and manufacturers in India continue to elevate the standards of packaging solutions, ensuring the safe and secure transit of goods across diverse industries.

0 notes

Text

Responsible for a Budget? 12 Top Notch Ways to Spend Your Money

Nardi Furniture for Mid-Century Modern Lovers

Resin plastic outside furniture could be a nice alternative for restaurants, patios and pool areas. It�s straightforward to scrub, sturdy and appearance fashionable. Several styles will be stacked for convenient storage, and several are proof against stains and UV rays. They�re also lightweight, therefore they'll be simply moved around your space to accommodate guests and events. There are various types of resin plastic, as well as polyethylene (PE), highdensity PE (HDPE), and polypropylene (PP). HDPE is a lot of durable than polyvinyl chloride (PVC) and is proof against fading, chemical degradation, and warmth injury. It�s conjointly abrasionresistant and punctureproof. Polypropylene could be a stronger, lighterweight choice than PE and is a lot of flexible. It�s less expensive than HDPE, however is not as robust or weatherproof.

Nardi Omega for Fire Pit Gatherings

Outdoor furniture's durability depends heavily on its materials and design; but, its useful life will be significantly extended through proper care, maintenance and protection against environmental elements.

Resin Out of doors Furnture for Your Restaurant's Patio. Resin furniture is a fashionable selection for several out of doors spaces. It's simple to scrub and maintain, and it's longlasting. Moreover, it's also environmentally friendly. To create resin wicker furniture, makers produce a mildew and then pour plastic resin into it. They then use wood and alternative materials to give the furniture its form.

Business out of doors furniture is designed to be used outside, which suggests that it needs extra care than indoor items. Tougher materials usually utilized in its construction allow fabrics that create up its upholstery to be rinsed down with a hose once each use to get rid of sweat, sunscreen and pool chemicals; different web site amenities like tables chairs and benches additionally utilise materials that won't rust quickly or break down quickly.

Jensen furniture is wellknown for their premium out of doors furniture, designed with care to supply most comfort and longevity. Their chairs and sofas boast light curves for optimal seating comfort whereas their 197seven outside sofa has been transformed for outdoor use with its modular style that permits you to rearrange every module as desired. Lined in Element cloth that resists staining and water harm because of solutiondyed acrylic threads, its vibrant colours stay intact even underneath direct daylight or temperature changes.

When getting patio furniture, it is wise to appear for things that may withstand adverse weather. If you reside in an space at risk of frequent rainfall, select weatherresistant materials or furniture with protective umbrella bases and canopies as this can provide a lot of rain protection. Similarly, considering galvanized steel is also an choice as this material provides further sturdiness against corrosion or rusting. In addition to tables and chairs on the market from Costco, Costco additionally offers patio furniture covers which feature fitted designs to permit air circulation so mildew does not develop; these covers come back in varied colors/ sizes making this a useful addition for any patio house!

youtube

Some pool users wish to merely lounge around and unwind, that makes having lounge chairs around an essential piece of furniture. It permits guests to start off their shoes, lay back down and absorb some sun while not ever needing to leave the water! Lounge chairs also build an glorious place for reading, napping or merely having conversations many designs exist that float whereas others must be placed on deck or patio to be used.

An inflatable pool lounge chair will take your poolside expertise to the next level. Opt for from varied colors, configurations and dimensions.

Homecrest collection furniture offers longterm quality with poly outside items designed not to rot, splinter or attract wood bees. Their sturdy chairs, tables and loungers can face up to even extreme climate conditions while boasting lovely color choices that rise up against nature.

Olefin

Homann's AH Outside Series boasts an elegant combination of rigorous aesthetic and soft forms chairs and tables will even be stacked to save house!

If you want a beautiful outside space with minimal maintenance requirements, furniture made of recycled resin could be your answer. This sturdy material has the planning and feel of painted wood while not needing annual refinishing or staining; weather and fungi resistance; fade resistance from sunlight exposure are simply a few additional edges of resin patio furniture which makes cleaning straightforward using mild dish soap and water solution excellent for anyone seeking to cut back their environmental footprint! Several makers turn out ecofriendly furniture from recycled plastic, diverting loads of waste aloof from landfills and oceans while giving the planning and durability of ancient wood furniture. Brands like Polywood even give a 20year warranty on their recycled plastic items! Pottery Barn sells trendy nevertheless sensible recycled plastic chairs like this Polywood Chippendale dining arm chair that features fade resistance, easy assembly instructions and features an eyecatching lattice pattern on its backrests; and insect, mold and mildew resistance so no refinishing ever required!

Owners get weatherproof outdoor furniture that will withstand the weather, like weatherproof and rustresistant pieces that are easy to take care of with materials that dry quickly and resist mildew and mold growth. Take into account furniture created of recycled materials with faderesistant finishes as ideal options.

Homann's AH Outdoor Series boasts a sublime combination of rigorous aesthetic and soft forms chairs and tables can even be stacked to avoid wasting house!

Outdoor FurnitureOutdoor FurnitureOutdoor Furniture for Scandinavian Style

Plastics and resins come back in an exceedingly wide range of colours and shapes, making them a in style alternative for up to date out of doors furniture. They'll mimic the planning of the many different materials, and some have faderesistant finishes that don�t need paint or sealants. They�re additionally light-weight, inexpensive and simple to scrub, though they'll be subject to mold or mildew growth if not often cleaned.

Outdoor Furnishings for Bohemian Vibes

Metal

Outdoor Furnishings for Yoga and Exercise

Some ornamental pillows boast decorative parts like tassels or trim that add a distinctive aptitude. These adornments will build an impressive accent piece for any chair or sofa in any space, adding a way of luxury and personalization. Alternative cushions may come equipped with cushion ties for added stability when it involves seating arrangements.

Nardi Omega for Reading Nooks

At any movie night or appetizers party, comfy bean bag chairs offer intimate conversations or sipping wine in front of the hearth. Indulge yourself with this relaxing expertise for Valentine's Day dates or unwind once long workday. Conjointly ideal for garden parties and barbecues where relaxed conversation takes place; easily rearrange and wipe clean for fast patio makeover.

Outdoor Furnishings for Picnic Excursions

Homecrest collection furniture offers longterm quality with poly outside pieces designed to not rot, splinter or attract wood bees. Their durable chairs, tables and loungers will face up to even extreme climate conditions whereas boasting beautiful color options that get up against nature.

Nardi Omega Maintenance Tips

Online is usually the best place to seek out highquality out of doors furniture. Not like traditional brickandmortar stores, online shops carry a wider variety of products and brands than physical locations do some even having dedicated sections for outdoor furnishings! Customers will simply search and compare options. Plus, these websites provide detailed product descriptions with their options furthermore financing solutions. Some out of doors furniture brands use social media channels as a further avenue for client and business engagement, and to supply a lot of tailored client service while meeting trade requirements. This enables these companies to fulfill industry demand a lot of simply whereas meeting client expectations more reliably.

Nardi Omega Brands and Manufacturers

When buying patio furniture, it's wise to seem for items which will withstand adverse climate. If you reside in an area prone to frequent rainfall, select weatherresistant materials or furniture with protecting umbrella bases and canopies as this can offer more rain protection. Similarly, considering galvanized steel is also an option as this material provides extra durability against corrosion or rusting. Additionally to tables and chairs available from Costco, Costco conjointly offers patio furniture covers that feature fitted designs Affordable Nardi Furniture featuring the Omega Chaise sets for budget-conscious buyers to permit air circulation thus mildew does not develop; these covers come in numerous colours/ sizes creating this an invaluable addition for any patio house!

Outdoor FurnitureOutdoor FurnitureOutdoor FurnitureNardi OmegaOutdoor Furniture for Meditation Spaces

Selecting the proper balcony furniture for your condo is essential to making it really your own space. Your selection ought to mirror each your taste and temperament while simultaneously increasing its price. Outer furniture offers fashionable and durable patio pieces made with highgrade materials and return complete with lifetime warranties as well as cash back guarantees, making them a sound investment.

Rustic Nardi Omega Inspirations

Dining sets and patio umbrellas add an expensive feel to any out of doors pool house, whereas side tables or different smaller items serve as decorative accents to the present area. Umbrellas play a useful role in providing patrons with shade as needed throughout their day.

Outdoor FurnitureOutdoor FurnitureOutdoor Furniture Brands and Manufacturers

Several people fancy lounging in pool lounge chairs to unwind and scan or simply take in some sun, with to take a seat with family or friends and chat. You'll conjointly use these chairs for conversation. Different people opt to lay out within the water with towels to sunbathe. Furthermore, pool furniture sets supply tables where food and drinks will be placed.

Nardi Omega Chaise for Garden Oasis

One in every of the numerous benefits of out of doors furniture crafted from recycled resin is that it will stand up to all varieties of weather it resists rusting, staining and mildewing whereas having the ability to withstand extreme temperatures and sunlight while not warping or rotting over time. Recycled resin furniture makes an glorious various to wooden outdoor furniture which often wants regular repairs for best performance and enjoyment. Recycled plastic furniture offers another advantage over its counterparts: it's entirely recyclable itself. Many manufacturers utilize this material in the production process, guaranteeing ecofriendliness. By recycling this Nardi Furniture featuring the Omega Chaise for vintage-inspired porches material and continuing production with quality furniture pieces from it, makers scale back oilbased polymers which will contribute to pollution problems.

Set up an alfresco family dinner or host a crawfish boil; selecting outdoor furniture that creates your guests feel relaxed can add Nardi Furniture featuring the Omega Chaise for Event Venues: Stylish Seating for Special Occasions a special bit. From charming balcony chairs to fivepiece patio furniture sets, Baton Rouge offers everything required for the best setup! What Are My Options If I Have a Tiny Balcony or Backyard?

Furniture used around a pool must stand up to the rigorous components, including Nardi Omega Chaise with built-in insect repellent sun exposure, chlorinated water and rain. If it wasn't designed specifically to survive this surroundings, its color can quickly fade, crack and rust away quickly to stay your poolside patio wanting its best, invest in industrial quality outside pool furniture that is designed to last. When shopping for outside furniture to complete your poolside oasis, vogue and luxury ought to both be priorities. A stunning piece can solely impress if it offers snug seating solutions; so be positive to get chairs, hammocks and lounge chairs that feature ergonomic styles.

Manufacturers are increasingly designing product that can be used both indoors and outdoors, typically created of materials fitted to completely different climates. Customers have shown additional willingness to spend on luxurious outdoor furniture due to increased disposable income and interest in out of doors activities. Wood is that the goto material for out of doors furniture. Hardwoods like teak are naturally immune to rot, insects and the weather; its durability will easily be restored by sanding and sprucing it into its original condition. Softwoods may need additional maintenance.

Nardi Furniture for Family Gatherings

LBO is the premier wholesale supplier of aluminum metal patio and pool furniture for public swimming pools, personal swimming pools, water parks, YMCA's, flats, home owners associations (HOA's), hotels and resorts. Their top quality industrial grade patio and pool furniture product are manufactured using superior materials like Marine Grade Polymer that resist warping, fading or chemical breakdown good for use at private and non-private pools alike! Contract Furnishings International provides fashionable nonetheless comfortable outside furniture to any business, perfect for restaurants, hotels or clubs alike. Our big selection of patio furniture matches any theme or vogue with styles designed to face up to rain, snow and sun a vital consideration when selecting outdoor seating for any restaurant, hotel or club.

Nardi Omega Upholstery and Cushions

Nardi offers highend outside lounge furniture that's made with antistatic and moisture resistant resin, featuring elegant yet practical styles crafted in Italy for complete Created in Italy production processes.

An inflatable pool lounge chair can take your poolside expertise to the next level. Select from numerous colors, dimensions and shapes.

A variety of fabrics are used for luxury outdoor furniture, together with materials like olefin. Olefin may be a kind of solutiondyed artificial fibre, which is incredibly sturdy and stainresistant. This fabric can be found in an exceedingly big selection of chairs, sofas, chaise lounges and additional. It is resistant to UV rays, chlorine and saltwater, creating it excellent for outside use. It will also face up to abrasion, which means it can get on my feet to significant use. It is conjointly straightforward to wash, as it resists deterioration from mildew, chemicals and insects.

Out of doors resin furniture makes an attractive and purposeful addition to any home, while being ecofriendly and weather resistant. Furthermore, it resists mildew growth plus mildew growth.

Sara Kenton's passion for Van Morrison's music galvanized her to launch Tupelo Goods, an Austinbased company offering up to date out of doors furniture. Since launching in 2018, Tupelo Product has rapidly expanded with offerings starting from beach tote luggage which will simply be rinsed after long beach days, to chairs designed with silicone seats for both land and water access. In addition to selling traditional adirondack and hammock chairs, the whole additionally sells transportable fireplace pits that make entertaining easier, with Zephyr Flyer swings to promote slowness in neighborhoods. Their merchandise can be found through retailers such as Target and Whole Foods; with its mission being to bring people together through merchandise that make recollections and celebrate special moments; their future plans involve expanding its lineup by adding outside games that promote familyfriendly fun!

One in all the numerous benefits of outdoor furniture crafted from recycled resin is that it will withstand all sorts of weather it resists rusting, staining and mildewing while having the ability to stand up to extreme temperatures and sunlight without warping or rotting over time. Recycled resin furniture makes an excellent various to picket outside furniture that often needs regular maintenance for best performance and delight. Recycled plastic furniture offers another advantage over its counterparts: it's entirely recyclable itself. Several manufacturers utilize this material in the production method, guaranteeing ecofriendliness. By recycling this material and continuing production with quality furniture pieces from it, makers cut back oilbased polymers that will contribute to pollution problems.

To keep out of doors furniture beautiful and in smart condition, it's crucial that it's regularly cleaned and guarded against the elements. Regular soap and water cleaning can do just fine, whereas adding protective coating such as varnish or wax will keep pieces looking whole new for an extended period. Alternatively, water repellant spray can conjointly work effectively; simply be positive it's been specifically made for outside furniture as using regular household cleaners will harm its surface. One of the hottest trends in outdoor furniture design is mixing materials. Furniture makers often combine wood, metal and plastic into trendy designs that withstand weather elements giving customers additional selections so as to pick out pieces that best match their personal styles and add texture and depth to a area.

http://allbackyardideas.com/wp-content/uploads/2016/06/pool-and-spa-depot-patio-furniture.jpg

1 note

·

View note

Text

The Florida Seating Restaurant Furniture Awards: The Best, Worst, And Weirdest Things We've Seen

Grosfillex Omega for Barbecue Parties

The best patio furniture brands USA can add an inviting atmosphere to any outside house. Whether or not it's an eyecatching table to compliment a sleek tile patio or cozy chairs for your traditional front porch, these companies have one thing appropriate for each taste and budget. Overstock is like Amazon for home product, making it an amazing place to shop for patio furniture on a budget. Their in depth choice includes everything from bistro sets and sectionals to simple bistro tables and loungers. Additionally, there's an easy search perform and rigorously curated assortment of highquality merchandise on the market here.

Everyday Restaurant Omega for Fall and Autumn

Resin plastic out of doors furniture is a nice choice for restaurants, patios and pool areas. It�s simple to clean, sturdy and looks trendy. Several styles can be stacked for convenient storage, and several are proof against stains and UV rays. They�re also light-weight, therefore they will be easily moved around your area to accommodate guests and events. There are various varieties of resin plastic, as well as polyethylene (PE), highdensity PE (HDPE), and polypropylene (PP). HDPE is additional durable than polyvinyl chloride (PVC) and is proof against fading, chemical degradation, and heat harm. It�s additionally abrasionresistant and punctureproof. Polypropylene could be a stronger, lighterweight choice than PE and is a lot of flexible. It�s less expensive than HDPE, however is not as strong or weatherproof.

Homann's AH Out of doors Series boasts an elegant combination of rigorous aesthetic and soft forms chairs and tables can even be stacked to save space!

Resortstyle furniture offers trendy lounge chairs and subtle sofas to help create the ideal relaxing atmosphere. Opt for from varied colors and materials to match your decor while saving cash by reducing energy prices creating the ultimate luxurious oasis in any space of your home or business!

Hunt for chairs with ottomans that offer enough comfort for one person, excellent for relaxing afternoons within the garden. Additionally, hunt for ones made from easytoclean materials and which will face up to out of doors parts.

Recently, designers have treated patios and courtyard gardens like extensions of interior living areas. Currently outdoor furniture is meant to enhance indoor living rooms and dining areas reflecting this trend with collections that boast clean lines and natural aesthetics; sturdy performance fabrics additionally enable homeowners to simply mixandmatch colours, textures, and styles for an eclectic look.

Sustainable outdoor furniture design has quickly become an emerging trend. Many brands, from highend luxury items like Seaside Casual's Envirowood created from HDPE recycled polymers found in milk jugs to recycled plastic lumber used by Seaside Casual are using ecofriendly materials like this in their collections. Sustainable choices embody teak wood furniture that's naturally resistant to rot and insect injury; or out of doors items created of metal, concrete, or any alternative strong materials which withstand weathering well. Whatever reasonably furniture you buy for outdoor use, always shield it with wood stains, polishes, or paints to cut back weathering and wear; alternatively bring indoor your wooden out of doors items throughout winter or cover them well on rainy days for optimal care.

youtube

CB2, the hip younger sibling of Crate & Barrel, offers fashionable outdoor furniture at great price for a discount worth. Their shipping is free on all orders and therefore the items can easily be assembled at home plus there is an unbelievable choice of accent chairs, sofas and benches!

Chaise lounges are a vital addition to public pools, resort swimming pools, water parks and apartment complex pool areas. We supply an assortment of chaise lounges to enhance any design theme. Plastic outside furniture is a perfect resolution for business pool areas thanks to its longevity and flexibility. Available during a range of colours, textures, and styles you're sure to search out one thing appropriate for your space it comes in chairs, chaise lounges, dining tables and patio furniture from leading brands and accessories like umbrellas that can guarantee guests remain relaxed.

Homecrest stands out among US brands giving outdoor furniture by combining design and sturdiness into their merchandise. Homecrest provides an intensive range of designs and sturdy items using top quality materials with rigorous testing processes to ensure long lasting furniture pieces. In addition, they promote inexperienced living through using recycled aluminum, steel and wrought iron parts and recycled wood items in all their wood furnishings.

Resort Life Extendable Table created from premium Eucalyptus Wood with a lightweight aluminum frame is another fantastic possibility, that includes natural organic features together with cracks and color variations that enhance its beauty. Treated with Duragrain waterbased finish to guard its surface while displaying natural grain features of wood surface.

Choosing Outdoor Furniture For Your Hoa. Take into account how residents and guests can use your hoa's out of doors furniture when purchasing it for them. Weatherproof tables and chairs bring indoor comfort outdoors whereas rockers or Adirondacks provide relaxing lounging options.

Resin furniture might still draw homeowners to its natural organic charms, but nextgeneration materials like resin are quickly gaining in popularity because of their durability and flexibility. Resin furniture items could prove worthy alternatives to wooden tables and chairs due to their appearance while not compromising on quality; however, before making a final call regarding buying resin furniture.

Resin Outside Furnture for Your Restaurant's Patio. Resin furniture is a common alternative for several outside spaces. It's easy to wash and maintain, and it's longlasting. Moreover, it's also environmentally friendly. To create resin wicker furniture, manufacturers create a mould and then pour plastic resin into it. They then use wood and different materials to grant the furniture its shape.

Omega Chaise for Fire Pit Gatherings

Plastics and resins come back in a very wide range of colours and shapes, creating them a popular selection for up to date outside furniture. They will mimic the look of many different materials, and a few have faderesistant finishes that don�t require paint or sealants. They�re conjointly lightweight, cheap and simple to wash, though they can be subject to mould or mildew growth if not regularly cleaned.

BFM Seating Furniture for Solo Relaxation

Commercial outside furniture provides an simple manner to bring indoor comfort and operate outdoors. Weatherproof tables and chairs bring dining areas outdoors, while rockers and Adirondack chairs produce living areas beneath an expansive sky. A sensible 1st step when selecting commercial out of doors furniture for any community space ought to be identifying how it's being utilised; this can verify that pieces you buy. Garden or patio furniture refers to any piece of furniture designed specifically to enhance an out of doors space and enjoy it additional comfortably. It should give sturdiness, easeofuse and safety issues in its design and is usually sold in sets containing four or additional items like tables and chairs chaise longue chairs can conjointly be useful for relaxing outside.

Outdoor Furnishings for Fire Pit Gatherings

Industrial Rated Out of doors Furniture. Commercialgrade outside furniture is built to stand up to frequent use and the elements. Though a lot of pricey, this type of outside furniture can typically outlive its residential counterpart.

Classic and Timeless Outdoor Furniture

Brian's Furniture draws its name from Louisiana culture's love affair with its signature sugar kettles from planters and fountains to easy estate ornaments, sugar kettles are an integral part of its style and you'll be able to get one for your own home here at Brian's.

Omega Chaise for Camping Adventures

When purchasing patio furniture, it's wise to appear for items which will withstand adverse climatic conditions. If you live in an space prone to frequent rainfall, select weatherresistant fabrics or furniture with protective umbrella bases and canopies as this will supply additional rain protection. Similarly, considering galvanized steel is also an option as this material provides additional durability against corrosion or rusting. In addition to tables and chairs obtainable from Costco, Costco also offers patio furniture covers that feature fitted styles to allow air circulation so mildew doesn't develop; these covers come in varied colors/ sizes creating this a useful addition for any patio area!

Top Trends in Flash Omega Chaise

Sustainable outside furniture style has quickly become an emerging trend. Many brands, from highend luxury things like Seaside Casual's Envirowood created from HDPE recycled polymers found in milk jugs to recycled plastic lumber employed by Seaside Casual are using ecofriendly materials like this in their collections. Sustainable choices embrace teak wood furniture that is naturally immune to rot and bug harm; or outside pieces created of metal, concrete, or any alternative strong materials which stand up to weathering well. Whatever kind of furniture you get for outside use, always shield it with wood stains, polishes, or paints to scale back weathering and wear; alternatively bring indoor your picket outdoor items during winter or cowl them well on rainy days for optimal care.

Outdoor Furniture for Barbecue Parties

Resort vogue furniture comes in numerous designs, like up to date and rustic. Contemporary pieces sometimes boast neutral hues with fashionable materials like stainless steel or rattan for an affordable choice, whereas rustic items sometimes incorporate natural wood for a additional relaxed vibe and will be placed anywhere like patios, decks or balconies.

Stylish Flash Omega Ideas

A variety of materials are used for luxury outside furniture, as well as materials like olefin. Olefin may be a type of solutiondyed synthetic fibre, which is incredibly sturdy and stainresistant. This fabric can be found in a wide selection of chairs, sofas, chaise lounges and a lot of. It's proof against UV rays, chlorine and saltwater, making it good for outdoor use. It will conjointly face up to abrasion, that suggests that it will rise to significant use. It's additionally simple to wash, as it resists deterioration from mildew, chemicals and insects.

Everyday Restaurant Furniture for Family Gatherings

Poolside lounge furniture should withstand more rigorous use than regular out of doors furnishings, so it must be additional sturdy and longlasting. Furthermore, chlorine injury or discoloration could damage or discolor it over time if left exposed; hunt for materials like eucalyptus wood or stainless steel hardware as ideal options. Contemplate buying the Safavieh Newport poolside lounge chair. With foam cushions arranged over its sturdy eucalyptus wood frame and convenient options like stackability, this piece can simply match during a poolside lounge chair arrangement or stored when not being used.

Outdoor Furniture Upholstery and Cushions

Cedar is an excellent wood for outside furniture as a result of it resists moisture, decay, insect damage and extreme atmospheric condition, making it an glorious choice in wetter regions. Cedar could want to be treated with sealants or finishes so as to stay weatherproof, whereas different species such as cypress or teak also build glorious options that need staining or sealing to guard from the elements. Different widespread woods used for outdoor furniture embody eucalyptus, redwood and ipe. Eucalyptus may be a highly durable rotresistant wood that is straightforward to work with and even left alone it will age fantastically with time, adding rustic charm. Redwood offers another robust material option that works in varied designs whereas boasting its distinctive hue that'll enhance any backyard.

Outdoor Furnishings Storage Solutions

Selecting Outdoor Furniture For Your Hoa. Contemplate how residents and guests can use your hoa's outside furniture when getting it for them. Weatherproof tables and chairs bring indoor comfort outdoors whereas rockers or Adirondacks give relaxing lounging options.

Resort outdoor furniture made of ecofriendly synthetic wicker is also an ecofriendly choice, mimicking the design and durability of natural wood with less maintenance requirements and maintenance requirements. Synthetic wicker conjointly stands up well in humid climates as it won't become moldy or mildew prone.

youtube

Industrial Rated Outdoor Furniture. Commercialgrade outside furniture is constructed to stand up to frequent use and the weather. Though additional pricey, this kind of outside furniture will sometimes outlive its residential counterpart.

Jensen furniture is wellknown for his or her premium outdoor furniture, designed with care to supply most comfort and longevity. Their chairs and sofas boast gentle curves for optimal seating comfort whereas their 197seven outside sofa has been remodeled for out of doors use with its modular style that enables you to rearrange each module as desired. Lined in Component material which resists staining and water damage thanks to solutiondyed acrylic threads, its vibrant colors stay intact even below direct sunlight or temperature changes.

Omega Chaise for Mountain Retreats

LBO is that the premier wholesale provider of aluminum metal patio and pool furniture for public swimming pools, private swimming pools, water parks, YMCA's, residences, home homeowners associations (HOA's), hotels and resorts. Their prime quality business grade patio and pool furniture merchandise are manufactured using superior materials like Marine Grade Polymer that resist warping, fading or chemical breakdown good for use at private and non-private pools alike! Contract Furnishings International provides fashionable nonetheless comfortable outdoor furniture to any business, perfect for restaurants, hotels or clubs alike. Our wide selection of patio furniture matches any theme or style with styles designed to face up to rain, snow and sun a necessary consideration when selecting out of doors seating for any restaurant, hotel or club.

Omega Chaise Brands and Manufacturers

Artie's outside furniture is highquality and longlasting, designed with sustainability in mind. Their product are made using recyclable materials like recycled woods and ecofriendly fabrics; additionally they employ inexperienced producing processes that have minimal environmental impacts an wonderful way to add stylish up to date decor into the house.

Resort style furniture comes in various designs, like modern and rustic. Up to date items usually boast neutral hues with fashionable materials like chrome steel or rattan for an inexpensive option, while rustic pieces sometimes incorporate natural wood for a additional relaxed vibe and will be placed anywhere like patios, decks or balconies.

Primarily based on your environment, usage, and storage desires, selecting sturdy furniture materials will be essential to its longterm functionality. Some materials are higher suited to certain weather conditions than others and a few require constant repairs so as to forestall injury or discoloration.

Grand resort outdoor furniture is typically created of premium materials like teak wood and stainless-steel, that includes sleek up to date and minimalist designs with modular pieces designed to be easily reconfigured as required. Many items also boast classic or ancient parts for an aesthetically pleasing ensemble look.

Add extra features to your pool chair expertise with something like the Safavieh Newport's straightforward yet functional pool chair, featuring soft foam cushions supported by an engaging, sturdy eucalyptus wood frame with clean lines, as well as an innovative slideout table to store drinks and different requirements. Poolside furniture plays an essential half in providing recreation and relaxation at public swimming pools, from casual chairs to dining tables. When making this choice, it's essential that every piece be durable enough for repeated use, whereas reflecting the fashion of its surrounding.

RentToOwn Outdoor Furniture in Mississippi. Create your backyard the ultimate summer destination with highquality out of doors furniture from renttoown patio dining sets or two outsized lounge chairs from renttoown patio dining sets, excellent for hosting big barbecues with all of your family, or rent two to form the best spot on your condo porch for relaxation together with your partner.

Resin furniture may still draw owners to its natural organic charms, however nextgeneration materials like resin are quickly gaining in popularity thanks to their durability and adaptability. Resin furniture pieces could prove worthy alternatives to wood tables and chairs due to their look without compromising on quality; however, before creating a final call regarding purchasing resin furniture.

1 note

·

View note

Text

Chemical Drums Market Expansion: Strategies for Penetrating Emerging Markets

Chemical drums are specialized containers used for storage, transportation and distribution of various industrial and commercial chemicals. Chemical drums are made of high density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP) and high-density polyethylene (HDPE) materials which helps prevent corrosion from various chemicals. Chemical drums provide effective chemical containment and transportation solutions for industries such as oil & petrochemical, paints & inks, industrial chemicals, etc. The global chemical drums market is estimated to be valued at US$ 21.44 Bn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2024-2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

The global chemical industry has witnessed significant growth over the past few years owing to rapid industrialization and urbanization in emerging economies. According to reports, revenue from the global chemical industry is estimated to reach US$ 5.7 trillion by 2024 growing at a CAGR of 5.5% during 2020-2024. As chemical drums are extensively used in the chemical industry for storage and transportation of various chemicals, the growth of the overall chemicals market will drive the demand for chemical drums during the forecast period.

Porter's Analysis

Threat of new entrants: The chemical drums market requires high initial investment cost for manufacturing drums which acts as a barrier for new players. However, the market is moderately growing at a CAGR of 5.6% which attract new small players.

Bargaining power of buyers: Buyers have moderate bargaining power due toavailability of variouschemical drums in the market from different manufacturers. However, stringent regulations regarding shipment of chemicals increases switching costs for buyers.

Bargaining power of suppliers: A few manufacturers dominates the supply of raw materials like steel and plastic resins used to produce chemical drums globally.This gives suppliers moderate bargaining power over manufacturers.

Threat of new substitutes: No direct substitute of chemical drums currently exist for packaging and shipment of various chemicals.However, flexibleintermediate bulk containers are gaining acceptance as an alternative.

Competitive rivalry: The market is moderately competitive with presence of many regional and global players. Manufacturers compete on factors like product quality, pricing, innovation and client relationships.

SWOT Analysis

Strength: Chemical drums offers cost effective and reusable packaging solution.wide availability of material standards and certifications followed by manufacturers ensure safety.

Weakness: Frequent requirement of replacement or reconditioning of drums reduces profitability. Strict rules for disposal of hazardous chemical drums add to operating costs.

Opportunities: Growing chemical industry specialization increasing demand for specific drum designs.Adoption of reused and recycled drums through refurbishment presents an opportunity.

Threats: Stringent regulation and inspection standards Across regions increases compliance costs for manufacturers. Vulnerabilities to geopolitical changes that affect chemical trade.

Key Takeaways

The global Chemical Drums market is expected to witness high growth.