#Knitted Fabric Manufacturer in India

Text

Knitted Fabric Manufacturer in India

Knitted Fabric Manufacturer in India

Response Fabrics is one of the largest Manufacturer, and Exporter of Knitted Fabric in India. The offered extent is unequivocally outlined, and created utilizing premium quality fundamental material, and advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Designer Knitted Fabric Manufacturer

For the best Manufacturer & Exporter of Designer Knitted Fabric Manufacturer check the Response Fabrics that is the professional supplier of high quality Designer knitted Fabrics in Delhi. We specialized in supplying quality Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we. The primary advantage of artificial leather is that it doesn’t get faded, doesn’t get easily cracked or wrinkled.

cotton knitted fabric manufacturers

This manufacturer of fabrics offers the excellent quality of cotton furnishing knitted fabrics. These cotton knitted fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Knitted Fabrics Supplier

If you’re looking for the knitted fabrics suppliers in India. Then choose Responsive Fabric brands that are highly liked by the customers due to their strength, skin friendliness, and durability. We make sure that we use only superior quality raw material for manufacturing the fabric.

READ MORE...Best Fabric Manufacturers In India, Upholstery Fabrics

0 notes

Text

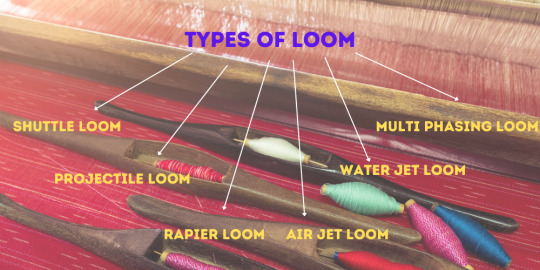

“Discover: Types of Loom in Textile Manufacturing”

Loom? What are They? What Do They Manufacture?

Looms is the weaving machine which converts the yarn into a fabric. There is no history of when looms were discovered but one thing is clear that it was before the birth of Jesus christ. There are 2 types of looms: Shuttle Looms and Shuttleless Looms. Below we are going to learn about various types of looms. The end result of this machine is fabric and wholesalers and retailers buy t-shirts in bulk made out of those fabric.

Learn About Shuttle Looms

This is the most primitive loom in the history of loom. In this machine there is a shuttle which contains bobbins and around bobbins there are yarn wounded. In this weaving machine the shuttle travels from one corner to the other and hence the fabric is made. The speed of this machine is 110-225 ppm [Picks Per Minute]. It is quite noisy and inefficient.

Fabric Weaving Without a Shuttle in the Loom Is It Possible?

Projectile Loom

Projectile loom is a shuttleless loom, in this looms instead of a shuttle projectile are there. Projectiles are made out of stainless steel and hence it was light weight. As the projectile lightweight this saves lots of energy and increases the efficiency of the machine. This loom speed was 300 ppm. The weaving takes place when the projectile goes across the width of the loom with the yarn.

Rapier Loom

This loom is also shuttleless. In this loom the weft is carried by a rapier which is a long rod like structure. Many kinds of fabric could be made using this loom and it is highly efficient. The range of GSM things loom could weave is 20-850 GSM. From home fabric to industrial fabric can be made using this loom. There are 4 types of rapier loom in the market.

Single Rigid Rapier Loom

Double Rigid Rapier Loom

Double Flexible Rapier Loom

Telescopic Rapier Loom

Air-Jet Loom

In this loom the yarn is transferred from the force of air, it does not have any shuttle. This loom is highly efficient and versatile. This loom does not make noise because it does not have many moving parts. As the moving parts are less then the floor space requirement and maintenance is low. The weft travels with the help of air pressure and once it reaches the shedding area interlacement takes place. This machine can be used in manufacturing Denim fabric, polyester dress material and cotton shirting fabric.

Water Jet Loom

Water pressure is used in this loom to transfer weft from one end to the other. It is a shuttleless loom machine. The speed of this machine is 600 ppm. This machine is highly efficient but we can use yarn which is hydrophobic, like polyester, polyamides etc. Hydrophilic yarn can not be used.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

8 notes

·

View notes

Text

If you are looking to Buy best knitted fabric, find find the largest knitted fabric manufacturer in India. The knitted fabric manufacturer leveraging advanced technologies and state-of-the-art machinery, they produce fabrics that strike the perfect balance between performance and durability.

For more details, go through official RSWM website to know more.

0 notes

Text

One Of The Trusted Knitted Fabric Manufacturers in Ludhiana

Our fabrics are woven by skilled specialists with high-quality yarn, thread, and advanced machinery. Aside from that, we provide our customers with affordable products within the timeframe specified.

We have a large and well-functioning infrastructural unit in Ludhiana (Punjab, India), which allows us to weave a stunning range of fabrics that meet global standards. Pi Cottex is one of the trusted knitted fabric manufacturers in Ludhiana. Get in touch with us now!

1 note

·

View note

Text

Revolutionizing Sustainability: Gupta Fibres as the Premier Regenerated Cotton Yarn Manufacturers in India

In the ever-evolving landscape of textile innovation, Gupta Fibres emerges as a pioneer in sustainability, leading the way as Regenerated Cotton Yarn Manufacturers in India. This article explores the significance, processes, and impact of choosing regenerated cotton yarn, setting Gupta Fibres apart as a trusted name in eco-conscious textile manufacturing.

1. The Essence of Regenerated Cotton: Dive into the core principles of regenerated cotton and how it contributes to a circular economy. Gupta Fibres excels as manufacturers by transforming discarded cotton into regenerated yarn, reducing waste and environmental impact.

2. Innovative Manufacturing Processes: Explore the cutting-edge techniques employed by Gupta Fibres in the production of regenerated cotton yarn. From advanced recycling methods to upcycling discarded textiles, discover the innovation that defines the manufacturing process.

3. Environmental Responsibility at Its Core: Gupta Fibres aligns with a commitment to environmental responsibility, reflecting in every strand of regenerated cotton yarn. The article delves into the sustainable practices and initiatives undertaken by the company, showcasing its dedication to a greener future.

4. Versatility in Applications: Highlight the versatility of regenerated cotton yarn manufactured by Gupta Fibres. From apparel to home textiles, delve into the diverse applications and creative possibilities that this sustainable yarn offers to designers and manufacturers.

5. The Role of Gupta Fibres in India's Textile Landscape: Gupta Fibres not only leads as Regenerated Cotton Yarn Manufacturers but also plays a pivotal role in shaping India's textile landscape. Explore how the company contributes to the nation's reputation as a hub for sustainable and high-quality textile manufacturing.

6. Collaborations and Sustainable Partnerships: Discuss any noteworthy collaborations or partnerships Gupta Fibres has forged in the realm of sustainable textile manufacturing. Highlight how these collaborations enhance the scope and impact of regenerated cotton yarn in the market.

7. Meeting Global Standards: Emphasize Gupta Fibres' commitment to meeting and exceeding global standards in the production of regenerated cotton yarn. Compliance with eco-certifications and industry benchmarks solidifies the company's position as a leader in sustainable textile manufacturing.

8. Consumer Awareness and Education: Gupta Fibres takes an active role in consumer awareness and education regarding the benefits of regenerated cotton yarn. The article explores initiatives, educational campaigns, or resources provided by Gupta Fibres to inform and empower consumers to make sustainable choices.

Conclusion: Conclude the article by underlining Gupta Fibres' role as a trailblazer among Regenerated Cotton Yarn Manufacturers in India. Celebrate the company's dedication to sustainability, innovation, and its impact on reshaping the textile industry with regenerated cotton yarn.

#Order Yarn Online#Wholesale Yarn Online#Cotton Knit Ribbing Fabric#Wool Knitting Yarn#Recycled Polyester Yarn Manufacturers in India#Fiber Weaving Products#Top Polyester Yarn Manufacturers in India#Cotton Wool Yarn#Organic Yarn Manufacturers India#cotton weaving yarn#best polyester yarn companies in india#cotton fiber yarn#cheapest place to buy yarn#best quality dyed yarns#Open End Yarn Manufacturers in Panipat

0 notes

Text

Explore the comprehensive guide to denim fabric. From its history and types to fashion trends and care tips, discover everything you need to know about denim. Elevate your denim knowledge now!

#organic clothing manufacturers in india#private label clothing manufacturer in india#organic cotton knit fabric#sustainable fabric suppliers india#digital fabric printing india

0 notes

Text

Discover our extensive regenerated yarn range - a testament to our commitment as leading recycled yarn manufacturers in India. Embrace eco-consciousness with recycled cotton yarn and dyed knitting yarn for sustainable fabric and garment creations. Join us in promoting a greener future!

#Regenerated Yarn Range#Recycled Yarn manufacturers in India#Recycled Cotton yarn manufacturers in India#Recycle Yarn Manufacturers#Regenerated Cotton Yarn#Dyed Knitting Yarn for Recycled Fabric and Garment

0 notes

Text

Why is Spun Polyester Yarn the Preferred Choice for Textile Industry in India?

In the intricate tapestry of the textile industry in India, one thread stands out as the preferred choice for manufacturers seeking durability, versatility, and quality: Spun polyester yarn. As we unravel the reasons behind its dominance, we discover why producers, such as SD Polytech, a leading yarn manufacturer Delhi, continue to play a pivotal role in this fabric of success.

Exceptional Strength and Durability

Spun polyester yarn is renowned for its remarkable strength and durability. In the demanding landscape of the textile industry, where fabrics endure constant stress and strain, this yarn emerges as a reliable choice. Garments and textiles crafted with it exhibit superior resistance to wear and tear, ensuring longevity and customer satisfaction.

Versatility in Applications

Spun polyester yarn producers in India cater to the diverse needs of the textile industry. From fashion apparel to industrial fabrics, this yarn seamlessly integrates into various applications. Its versatility makes it an ideal choice for a wide range of products, allowing manufacturers to explore creative avenues without compromising on performance.

Color Retention and Vibrancy

The vibrancy of colors is a hallmark of quality textiles. Spun polyester yarn excels in color retention, ensuring that fabrics maintain their original brilliance even after multiple washes. This characteristic is crucial for the fashion industry in India, where vibrant and long-lasting colors are synonymous with the cultural richness embedded in textiles.

Resistance to Wrinkles and Shrinkage

In a country with diverse climates like India, resistance to wrinkles and shrinkage is paramount. Spun polyester yarn provides textiles with excellent shape retention, making it well-suited for garments that need to withstand varying environmental conditions. This resistance enhances the overall appearance and wearability of the final product.

Cost-Effective Manufacturing

Efficiency and cost-effectiveness are key considerations for textile manufacturers. Spun polyester yarn producers in India like SD Polytech, align with these priorities. Its availability in bulk quantities and the ability to integrate seamlessly into modern manufacturing processes contribute to streamlined production, minimizing costs without compromising on quality.

Environmental Sustainability

As environmental consciousness grows, Spun Polyester Yarn's eco-friendly attributes become increasingly significant. Its production process consumes less water compared to natural fibers, and its durability reduces the frequency of replacements, contributing to a more sustainable and eco-conscious textile industry.

Conclusion

In essence, the prevalence of Spun Polyester Yarn in the textile industry in India can be attributed to its exceptional strength, versatility, color retention, resistance to wrinkles, and cost-effective manufacturing. SD Polytech and other spun polyester yarn producers in India play a crucial role in weaving success for textile manufacturers, providing them with a thread of excellence that strengthens the fabric of India's rich textile heritage.

Also, Read:

The Advantages of Using Polycotton Knitted Yarns in Textile Manufacturing

The Rise of Yarn Manufacturing in India: A Historical Perspective

Originally Published by: https://sdpolytech.blogspot.com/

2 notes

·

View notes

Text

Plr Clothing Manufacturer

Private brand clothing companies are basically your one-stop destination to generate a brand with out your own manufacturing unit. These companies handle end-to-end production from outsourcing fabrics to finishing typically the desired products with the brand? s label. Private label apparel manufacturers also handle customization of the products to match your brand name? s needs.

16th july exports is known around the globe for its vast desire for textile production. Because of this, private content label clothing manufacturers inside India are already discovering quite the need coming from independent brands simply because well as global ones.

16TH THIS SUMMER EXPORTS specialize inside private label clothes manufacturing for various international brands for their collections. We will be pleased with our staff of experienced -- specialists and sophisticated infrastructure and equipment that helps all of us deliver only the particular most of the products. This gives virtually any brand an extensive range of options to choose from in terms regarding product range and customization that will be produce in the greatest possible quality. Were also one associated with the few white label clothing manufacturers that offer a wide selection of carefully made sustainable products that will undergo intensive quality checking methods to be able to make sure that only typically the best of the particular lot is distributed through your brand? s i9000 name.

Today, typically the number of plr manufacturers has elevated a lot, confusing personal label brands in order to choose one amongst many and work a successful dress business in numerous places. Still, a few good-quality private label clothing manufacturers can serve you with utmost top quality and competitive rates. At 16TH SEPTEMBER EXPORTS we supply that you simply world-class apparel manufacturing unit that is usually equipped with top-level machinery. We offer you clothing/apparel intended for kids, women, plus men.

youtube

The private label clothing producers today have made it simpler with regard to clothing brands to have swift access to all kinds regarding manufacturing methods with out costing them the fortune. If an individual have your vision and have typically the basic knowledge regarding running a clothes business then that wouldn? t become a challenging task for you in order to get touching the particular private label services that can present you whatever you possess in mind. A person no longer need to rely on costly white label clothing manufacturers that supply no power over the particular manufacturing process plus have a constrained approach towards clothes products.

Some regarding the services 16TH JULY EXPORTS offer you are the following:

Knitting, cutting and even sewing, dyeing associated with garments, screen making, sticker printing, exclusive packaging, and embelleshment.

Make your clothing brand stand out from the group. 16TH JULY EXPORT PRODUCTS have a lot of experience in Plr garments and a rapid response time, Additionally , they have a huge fabric assortment, and, most importantly, skilled sample makers will certainly ensure that your own brand is just how you need it.

2 notes

·

View notes

Text

Propeller Pumps manufacturers, exports, and distributes numerous industrial pump types. It includes Polypropylene process pumps, self-priming centrifugal pumps, and polypropylene pumps. These are just a few. All of the diverse needs of a large range of industries. It includes waste water treatment, engineering, transportation, pumping equipment, sugar manufacturing, and many more.

Several Requests

● Managing agricultural land with irrigation and drainage

● The primary purpose of Propeller pump and pump stations is to regulate the water level.

● Sewage treatment systems require water circulation as a fundamental component.

● Increasing the oxygen content of water sources used for fish farming

● Tankers, ferries, and ships all need to be rigged.

● Docks built near bodies of water may flood or drain.

● The process of filling or emptying tanks

Water might have anything from zero to fifty milligrams of solids per liter. It happens depending on where it comes from. Freshwater, saltwater, and brackish water are a few types of clean water.

Mid-range temps that pump up to fifty degrees Celsius

Our team of skilled engineers designs and fabricates industrial pumps to rigorous standards in a range of capacities and technical features in response to specific customer requirements. They are able to achieve this because of their extensive industry knowledge and proficiency. Flowmore Limited has established a close-knit community of Propeller Pumps Manufacturer India in order to improve the lives of the clients and the efficiency of the pumps.

The decapitations

● Centrifugal force pumps with a single stage, an open semi-axial impeller, and

● Water-resistant motors having an IP 68 rating that can be filled, rewound, and submerged

● Moreover, a very efficient and reasonably priced permanent magnet synchronous submersible motor is already available on the market.

#propeller pump manufacturers india#propeller pumps#Propeller pump#Propeller Pumps Manufacturer India

0 notes

Text

Unveiling the World of Ready-Made Garment Manufacturers: Crafting Style and Comfort

In the fast-paced world of fashion, where trends change in an instant, readymade garment manufacturers serve as the industry's backbone, seamlessly combining innovation and efficiency. These manufacturers have a significant impact on how we dress, providing a wide range of products to suit every style, occasion, and desire. Ready-made clothing makers bring our sartorial aspirations to life, one stitch at a time.

Crafting Quality with Precision:

Every ready-made garment producer is committed to high-quality craftsmanship. These manufacturers use talented craftspeople and cutting-edge technology to ensure that each garment reaches the highest standards of quality. From the selection of premium fabrics to the intricate stitching and finishing, every step of the production process is executed with precision and attention to detail.

A Diverse Range of Products:

One of the most impressive features of ready-made clothing manufacturers is their capacity to provide a vast selection of products to suit a wide range of tastes and preferences. Whether you're looking for casual clothes, formal attire, sporting, or ethnic ensembles, there are plenty of alternatives to pick from. Ready-made garment manufacturers have something for everyone, from timeless classics to cutting-edge innovations that push the frontiers of fashion.

Adapting To Trends:

To remain relevant in an industry where trends change so quickly, ready-made garment producers must stay ahead of the curve. These firms pay close attention to emerging trends, using market information and consumer preferences to guide their design decisions. By continuously innovating and experimenting with new styles, colors, and silhouettes, ready-made garment manufacturers ensure that their products resonate with contemporary tastes while staying true to their brand identity.

Sustainability and Ethical Practice:

In recent years, there has been an increased emphasis on sustainability and ethical practices in the fashion business, and ready-made clothing producers are no exception. Many manufacturers are embracing eco-friendly products, eliminating waste, and establishing ethical labour practices to reduce their environmental effects and promote social responsibility. By putting sustainability and ethics first, these manufacturers are not only helping to create a cleaner future but also setting a good example for the industry as a whole.

Global Reach:

Readymade garment exporters in India now have a global reach because of technological and logistical developments, with their products supplied and sold in marketplaces all over the world. This global presence enables manufacturers to tap into varied consumer demographics and cultural influences, expanding their design offers and expanding their customer base. Whether you're in New York, Paris, Tokyo, or Mumbai, you're likely to encounter the products of ready-made garment manufacturers, each reflecting the unique flavor of its origin.

Conclusion:

In the ever-changing world of fashion, ready-made garment makers play an important role in creating trends, catering to varied tastes, and fostering innovation. With their dedication to exceptional craftsmanship, broad product lines, trend adaptation, sustainability initiatives, and global reach, these manufacturers remain at the forefront of the industry, enhancing our lives with style, comfort, and expression. As we look to the future of fashion, let us acknowledge and appreciate the vital contributions of ready-made garment producers in defining how we dress and express ourselves.

Looking for a dependable and inventive garment manufacturer with a strong infrastructure to make your clothes ideas a reality? Choose Mectech Knitfabs. It is one of India's major readymade garment manufacturers and exporters, producing the finest knitted clothes for men, women, and children. Our vast assortment of clothing, which is widely praised for its skin-friendliness, colorfastness, lifespan, and tear resistance, is meticulously developed, and made for comfort and style by market demands and fashion trends. The company is the most popular knitwear manufacturers for women in India.

For latest fashion trends and designs, visit Mectech Knitgab website.

SOURCE

0 notes

Link

Knitted Fabric Manufacturer in India - Response Fabrics

Knitted Fabric Manufacturer in India

Response Fabrics is one of the largest Manufacturer, and Exporter of Knitted Fabric in India. The offered extent is unequivocally outlined, and created utilizing premium quality fundamental material, and advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Designer Knitted Fabric Manufacturer

For the best Manufacturer & Exporter of Designer Knitted Fabric Manufacturer check the Response Fabrics that is the professional supplier of high quality Designer knitted Fabrics in Delhi. We specialized in supplying quality Fabrics, Leather, Synthetic Suede leather, which is widely used for automotive furniture sofa, footwear, fashion, gloves, sports, equipment, consumer electronics, etc. Response fabrics offer you all types of qualities in Leatherette, manufacturers offer you a wide range of artificial leather that can be used in offices, sofas, chairs, cinema halls, auditoriums, automobiles, jackets and so do we. The primary advantage of artificial leather is that it doesn’t get faded, doesn’t get easily cracked or wrinkled.

cotton knitted fabric manufacturers

This manufacturer of fabrics offers the excellent quality of cotton furnishing knitted fabrics. These cotton knitted fabrics are mainly used for designed home furnishing items, carry bags, and many other things. These products are high on every feature like color, look, design, and finishing. We are having excellent task work, and world class production machinery that aids to manage the urgent order on time. These fabrics are ideal for designing handicrafts items, and home furnishing items. Thisoffers the best suited for making apparel, and accessories.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

Knitted Fabrics Supplier

If you’re looking for the knitted fabrics suppliers in India. Then choose Responsive Fabric brands that are highly liked by the customers due to their strength, skin friendliness, and durability. We make sure that we use only superior quality raw material for manufacturing the fabric.

READ MORE...Fabric Manufacturers In India - Response Fabrics

Artificial Leather For Bean Bags Manufacturers India

Printed Fabric Manufacturers for Upholstery

Digital Printed Fabric Manufacturers India

Knitted Fabric Manufacturer in India

#Designer Knitted Fabric Manufacturer#Knitted Fabric Manufacturer in India#cotton knitted fabric manufacturers

0 notes

Text

Learn About 2 Types of Circular Knitting Machine and Their Advantages

Comprehensive Guide of Single Jersey Circular Knitting Machine and Its Advantages

Single jersey knitting machine has one cylinder of around 30 inches. This machine can knit fabric with less GSM [gsm in fabric how to calculate] compared to a double jersey knitting machine. Knitting is done in one direction in this machine. The knitting in this machine takes place by the coordination of needle and sinker, where needle makes the loop and sinker push it toward the fabric. Sinker plays an important part in this machine. Using this fabric we can manufacture plain fabric which is used in the production of t-shirts, blouses, tops and casual dress. Since the invention of knitting plain fabric is being made. Plain fabric can be made using hand and machine both. Wool production is limited to 20 gauge using this fabric. The fabric made out of this machine has curling ends.

Advantages of Single Jersey Circular Knitting Machine

A- This machine is a good choice for mass production

B- This machine can manufacture a variety of products from lightweight to heavy-weight fabric.

C- Single jersey machine is easy to maintain and repair

D- Less expensive compared to double jersey knitting machine ]

E- It can switch between colors easily

Introducing Double Jersey Circular Knitting Machine and Its Advantages

A double jersey circular knitting machine is nothing but a single jersey knitting machine; the only difference in this type of knitting machine is that it has an extra set of needles which moves horizontally. In this machine there are 2 sets of needles adjacent to each other. This machine knit in 2 directions perpendicular to each other. Sinker is not required in this machine. The final product that is made out of this machine are sweaters, sweatshirt, hoodies, etc. The final product of this machine does not curl unlike a single jersey circular knitting machine.

Advantages of Double Jersey Circular Knitting Machine

A- Can produce fabric with different textures such as terry and pique

B- It can produce multiple patterns, such as stripes and jacquards

C- It can produce thicker fabric with higher insulated properties

Fabric is an important part of t-shirts or any garment manufacturing. We as a t-shirt manufacturer see that when a wholesaler buy t-shirts in bulk from us they check the quality of the fabric.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#fabric#fiber#cotton#linen#wool#tshirt#weaving#small business#entrepreneur#india#made in india#trade#wholesale t shirts#wholesalers

5 notes

·

View notes

Text

Cut Resistant Fabrics Market to Reach US$ 8.4 Bn by 2031

Cut resistant fabrics find massive utilization in a vast range of applications notably including sportswear, auto upholstery, packing materials, and safety apparel in several end-use industries, which has propelled streams of revenue of cut resistant fabrics market. Apparel manufacturers seek cut resistant fabrics that are also comfortable and lightweight in order to meet the demands from various end-use industries, which will enrich the future market outlook for cut resistant fabrics. The size of cut resistant fabrics market was pegged at US$ 5.1 Bn in 2021.

The authors of the TMR study observed that high performance polyethylene (HPPE) and aramid are the key market segments in cut resistant fabrics market in terms of materials. Massive utilization of cut resistant fabric in personal protective equipment (PPE) currently presents the largest opportunity for cut resistant fabrics market, where these are pervasively used in apparel and gloves. Rise in adoption of PPE among workers in multiple industries in developed nations has invigorated generation of revenue of cut resistant fabrics market.

Request Sample Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77312

Market Segmentation

By Service Type

Woven Fabrics

Knitted Fabrics

Non-Woven Fabrics

By Sourcing Type

Natural

Synthetic

By Application

Industrial Gloves

Protective Clothing

Sports & Leisure Equipment

By Industry Vertical

Manufacturing

Construction

Healthcare

Food Processing

Oil & Gas

By Region

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis

North America and Europe: These regions are expected to dominate the market due to stringent safety standards in industries and a high awareness of workplace safety measures.

Asia Pacific: Rapid industrialization in countries like China and India, coupled with a focus on worker safety, is driving market growth in this region.

Latin America, Middle East & Africa: Increasing adoption of safety standards in industries is fueling demand for cut resistant fabrics in these regions.

Market Drivers and Challenges

Drivers:

Regulatory Compliance: Stringent safety regulations mandating the use of protective clothing and equipment.

Industry Demand: Growing awareness among industries about the importance of worker safety.

Technological Advancements: Continuous innovation leading to the development of lighter, more durable fabrics.

Challenges:

Cost Factors: High initial costs of advanced cut resistant fabrics may hinder widespread adoption.

Compatibility Issues: Ensuring compatibility with other protective equipment and comfort for users.

Market Competition: Increasing competition among manufacturers driving the need for differentiation and innovation.

Market Trends

Advanced Materials: Integration of nanotechnology and advanced fibers to enhance protective properties.

Customization: Tailoring fabrics to specific industry needs and application requirements.

Sustainability: Focus on eco-friendly materials and production processes.

Future Outlook

The future of the cut resistant fabrics market looks promising with sustained innovation, increased adoption across industries, and a growing focus on sustainable practices. Market players are expected to invest in R&D to develop novel materials and cater to evolving industry needs.

Key Market Study Points

Market Dynamics: Understanding key drivers, challenges, and trends shaping the market.

Competitive Landscape: Analyzing major players, their strategies, and market share.

Regional Opportunities: Identifying growth opportunities in emerging markets and key regions.

Product Innovation: Tracking advancements in materials, manufacturing processes, and application areas.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=77312<ype=S

Competitive Landscape and Recent Developments

Major players in the cut resistant fabrics market include DuPont, Honeywell International Inc., Teijin Limited, Ansell Ltd., and Kimberly-Clark Corporation, among others. Recent developments in the market include the introduction of lightweight yet highly protective fabrics, strategic partnerships for distribution and market expansion, and investments in sustainable manufacturing practices.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Woven Elastic Manufacturers & Suppliers in India

Viken Tape is one of the leading manufacturers & exporter of Nose Wire, Face Mask Elastic premium quality

narrow fabrics, woven elastics, knitted elastics & covered rubber thread in Surat, Gujarat, India.

Elastic Tapes Wholesalers & Wholesale Dealers in Surat - Your ultimate source for elastic excellence.

Explore a premium range of products, including mask elastic, woven elastic, BOPP tape, knitted elastic,

and Jacquard elastic. Elevate your projects with our diverse selection of high-quality elastic tapes.

Trust us as your dedicated partners in delivering top-notch solutions for all your elastic needs.

Face mask elastic manufacturer & exporter, Bouffant Cap Elastic Manufacturer, Bouffant Cap Elastic supplier,

face mask Elastic manufacturer,mask elastic manufacturer,Elastic Tapes Wholesalers & Wholesale Dealers in Surat,

Elastic Tapes Wholesalers,Woven Elastic Manufacturers & Suppliers in India,

Face mask elastic manufacturer & exporter in surat contact number, mask elastic manufacturer in surat,

Rubber thread manufacturers in india, Rubber thread manufacturers, woven elastic manufacturers in surat,

woven elastic tape manufacturers in india, woven elastic tape manufacturers, mask elastic manufacturer,

woven elastic tape manufacturers, knitted elastic manufacturers in surat, knitted elastic manufacturers,

Elastic Tapes in Surat, इलास्टिक टेप, सूरत, Gujarat.

#top elastic tape manufacturers in surat#elastic tape manufacturers in india#Woven Elastic Manufacturers & Suppliers in India

0 notes

Text

Elevate Your Creations with Gupta Fibres: Your Destination for Premium Yarn

Discover a world of creativity and sustainability with Gupta Fibres, the trusted name in the industry. We bring you an exquisite range of yarns, including fancy knitting yarn, recycled yarn for knitting, and more.

Fancy Knitting Yarn for Stylish Creations: Unleash your creativity with our fancy knitting yarn. Gupta Fibres offers a spectrum of colors and textures, providing you the perfect palette to craft stylish and unique pieces.

Recycled Yarn for Sustainable Crafting: Embrace eco-conscious creativity with our recycled yarn for knitting. Gupta Fibres is committed to sustainability, offering recycled cotton yarn at competitive prices. Craft beautiful projects while contributing to a greener planet.

Affordable and High-Quality Recycled Cotton Yarn: Explore our recycled cotton yarn range, where affordability meets quality. Gupta Fibres ensures that your knitting endeavors are not only cost-effective but also contribute to the circular economy.

Cotton Soft Yarn for Comfortable Creations: Indulge in the luxurious feel of cotton soft yarn. Gupta Fibres brings you soft and comfortable yarns, perfect for creating garments, accessories, and home decor items that prioritize comfort.

Regenerated Cotton Yarn: Crafting with a Purpose: Our regenerated cotton yarn reflects our dedication to responsible manufacturing. Gupta Fibres takes pride in being among the top manufacturers in India, offering regenerated cotton yarn for those who value sustainability in their creations.

Why Choose Gupta Fibres?

Quality Assurance: Gupta Fibres is synonymous with quality. Our yarns undergo rigorous testing to ensure they meet the highest standards, providing you with materials you can trust.

Diverse Selection: From fancy knitting yarn to recycled options, we boast a diverse range to cater to various creative pursuits. Gupta Fibres is your one-stop destination for all your yarn needs.

Customer-Centric Approach: Your satisfaction is our priority. Gupta Fibres is committed to providing excellent customer service, ensuring a seamless experience from selection to delivery.

Elevate your knitting experience with Gupta Fibres. Dive into a world where creativity meets sustainability, and every stitch tells a story of craftsmanship and responsibility.

#Order Yarn Online#Wholesale Yarn Online#Cotton Knit Ribbing Fabric#Wool Knitting Yarn#Recycled Polyester Yarn Manufacturers in India#Regenerated Cotton Yarn Manufacturers in India#Cotton Soft Yarn#Recycled Cotton Yarn Suppliers#Recycled Yarn for Knitting#Fancy Knitting Yarn

0 notes