#Internal Pipe Cutters

Text

Advancing Pipeline Maintenance: Internal Pipe Technologies' Drain Lining Equipment

Internal Pipe Technologies specializes in advanced drain lining equipment, essential for pipeline repair and maintenance. Their range includes CCTV cameras for inspection, robotic cutters for debris removal, and resin impregnation systems for durable lining. These tools offer non-invasive solutions, minimizing disruption and costs associated with traditional excavation methods. With a focus on sustainable infrastructure management, Internal Pipe Technologies provides precise and efficient equipment, ensuring the preservation of underground networks while reducing environmental impact and downtime.

1 note

·

View note

Text

The Comprehensive Guide to Seamless Swimming Pool Heater Installation

Introduction: Transforming Your Pool Experience

Embarking on the journey to install a swimming pool heater is an exciting decision that promises extended swim seasons and added comfort. As seasoned experts in the field, we're here to walk you through a step-by-step guide, ensuring a smooth installation process that guarantees optimal performance.

Selecting the Right Swimming Pool Heater

Choosing the right swimming pool heater is pivotal for achieving peak performance. Consider factors such as pool size, climate, and budget. Gas, electric, and solar heaters each offer unique advantages. Gas heaters provide quick heating, electric heaters are energy-efficient, and solar heaters harness the power of the sun. Assess your needs thoroughly to make an informed decision.

Assessing Your Pool Area

Before diving into the installation process, conduct a thorough assessment of your pool area. Ensure ample space for the heater and prioritize proper ventilation. Efficient operation and safety hinge on strategic placement. Additionally, inspect the pool's plumbing and electrical systems to guarantee compatibility with the chosen heater.

Preparing for Installation

Clearing the Area Commence the installation by clearing the area of any debris or obstacles. A clean, clutter-free space facilitates a smoother installation process and reduces the risk of complications.

Gathering Tools and Materials Ensure you have all the necessary tools and materials for installation, including a screwdriver, pliers, pipe cutter, and Teflon tape. Having everything on hand minimizes interruptions during the installation.

Installing the Swimming Pool Heater

Step 1: Connecting the Heater Initiate the installation by connecting the swimming pool heater to the existing plumbing system. Use Teflon tape to secure tight connections, preventing leaks. Adhere to the manufacturer's guidelines specific to your heater model.

Step 2: Electrical Connections If your chosen heater requires electrical connections, carefully follow the provided instructions. Ensure proper grounding of electrical components for safety.

Step 3: Ventilation Proper ventilation is critical for gas heaters. Install the heater in an open area to facilitate adequate airflow, ensuring efficient combustion and safe operation.

Step 4: Testing the System Before finalizing the installation, conduct a thorough system test. Check for leaks, verify proper water circulation, and ensure the heater produces the desired heat level.

Maintaining Your Swimming Pool Heater

With the installation complete, regular maintenance is essential for the longevity and efficiency of your swimming pool heater.

Regular Inspections Schedule regular inspections to promptly identify and address potential issues. Look for signs of wear, corrosion, or malfunctioning components.

Cleaning Keep the heater and its surroundings free from debris, leaves, and obstructions. Regular cleaning prevents clogs and ensures optimal performance.

Professional Servicing Consider professional servicing at least once a year to ensure all internal components are in top condition, extending the lifespan of your heater.

Conclusion: Dive into Extended Swim Seasons

Congratulations on successfully installing a swimming pool heater that will elevate your pool experience for years to come. Adhere to the manufacturer's maintenance guidelines and reach out to professionals if issues arise. Now, dive into the joy of extended swim seasons and cozy poolside gatherings.

0 notes

Text

Essential Guide to Installing Your Farm's Irrigation System

In the realm of modern agriculture, irrigation systems play a pivotal role in driving efficiency and sustainability. These systems are not just about water distribution; they are essential tools for conserving water, reducing operational costs, and boosting crop yields. The installation of a proper irrigation system, while complex, can yield significant benefits for farmers and the environment alike. In this comprehensive guide, we'll explore the critical steps for setting up an effective agricultural irrigation system, with insights from industry experts and reputable suppliers like International Pipe & Supply.

Getting the Right Equipment

The foundation of a successful irrigation system lies in having the right equipment. Essential tools for this task include shovels, rakes, tape measures, and pliers. Crucially, the choice of pipes is vital. Quality pipes, available from trusted suppliers, are central to a durable and efficient system. When selecting pipes, factors like size, material, and durability are key considerations. PVC pipes are often preferred for their lightweight, ease of installation, and resistance to corrosion and UV damage.

Preparing Clean Pipes for Irrigation

Before laying out the pipes, it's imperative to ensure they are clean and free of debris. Dirty pipes can compromise water flow and quality, potentially harming crops. Flushing pipes with water to remove dirt and using a pipe-cleaning solution for any residual residue is recommended. Additionally, a pipe inspection camera can be invaluable in checking for blockages or internal damage.

Utilizing Vibratory Plow in Installation

In areas with hard or rocky soil, a vibratory plow can be a game-changer. This tool, with its vibrating blade, efficiently cuts a trench for pipe installation, minimizing soil disruption. While faster than manual digging, vibratory plows do require technical know-how, and hiring a professional might be the best approach for those less familiar with the equipment.

Protecting the Sod during Installation

Maintaining the health of your sod – the layer of grass and soil – is crucial during installation. Sod plays a significant role in preventing soil erosion and retaining moisture. To avoid damage, using a sod cutter to remove sections of grass for pipe installation is advisable, followed by careful replacement post-installation.

Avoiding and Addressing Pipe Kinks

Kinks in irrigation pipes can disrupt water flow, leading to uneven irrigation. To prevent this, opt for flexible pipes and plan layouts that avoid sharp bends. Employing pipe clamps or fittings can also help maintain the integrity of the pipe structure.

Correct Pipe Cutting Techniques

Precision in cutting pipes ensures a well-functioning irrigation system. Using a pipe cutter or saw, it's important to make clean, straight cuts and smooth out any rough edges to prevent leaks and ensure a snug fit of pipe sections.

Wire Protection in Irrigation Systems

Protecting the electrical wiring of your irrigation system is as important as the pipes themselves. Wires, which control water flow and power pumps and valves, should be covered with wire mesh or conduit to shield them from external damage. Burying wires at least six inches deep is also recommended to prevent accidental damage.

Maintenance and Troubleshooting Tips for Your Irrigation System

Maintaining your irrigation system is crucial for its longevity and efficiency. Here are some key maintenance tips:

Regular Inspections: Periodically inspect your system for any signs of damage or wear. Check for leaks, clogged nozzles, and broken parts.

Cleaning Filters: Clean the filters in your irrigation system regularly. A clogged filter can reduce water flow and affect the efficiency of the system.

Seasonal Adjustments: Adjust your irrigation schedule seasonally. In cooler months, plants typically need less water. Overwatering can lead to root rot and other issues.

Winterizing Your System: In regions where it freezes, winterizing your irrigation system is essential to prevent pipe bursts. This involves draining all water from the pipes and shutting down the system.

Troubleshooting Common Problems

Even with regular maintenance, issues can arise. Here are some common problems and their solutions:

Uneven Water Distribution: If some areas are getting too much water while others aren’t getting enough, check for clogged nozzles or incorrect spray patterns. Adjust or clean the nozzles as needed.

Leakages in the System: Leaks can be a major issue, leading to water waste and increased costs. Regularly check the system for any signs of leaks, especially at joint connections, and repair them promptly.

Low Water Pressure: Low pressure can be caused by leaks, clogged filters, or issues with the water supply. Inspect the system to identify the cause and rectify it.

System Won’t Turn On: If your irrigation system won’t turn on, it could be due to electrical problems, a faulty timer, or controller issues. Check the power supply, examine the timer settings, and ensure the controller is functioning correctly.

The Value of Water Access in Farming

Access to reliable water sources is crucial in farming. As noted by a representative from Mossy Oak Properties, a leader in rural land transactions, "Having direct access to water on your farm is not just a convenience; it's a strategic advantage. Farms with established water resources tend to be more productive and sustainable." This insight underscores the importance of considering water access in both land acquisition and agricultural planning.

Beyond the immediate benefits, having direct access to water resources on your farm plays a critical role in long-term sustainability and resilience. Reliable water access allows for more consistent crop growth and can significantly reduce vulnerability to weather fluctuations and droughts. It enables farmers to implement more diverse and intensive farming practices, increasing both the quantity and quality of their produce.

Furthermore, self-sufficient water resources contribute to a more controlled agricultural environment. It allows for precision in water usage, aligning with sustainable farming practices that not only preserve vital water supplies but also protect the surrounding ecosystem. This stewardship of natural resources is not just an ethical practice; it's increasingly becoming a key factor in the agricultural market, where consumers and businesses are leaning towards products that are produced sustainably.

In essence, owning land with access to water resources is not just a practical asset; it's an investment in the farm's future. It fosters a robust and adaptable farming operation, ensuring that the farm can thrive under varying environmental conditions and market demands.

Sowing the Seeds for a Flourishing Farm

Installing an efficient irrigation system requires careful planning and attention to detail. By following the guidelines outlined, you can ensure your system is set up correctly for optimal performance. For high-quality irrigation supplies, International Pipe & Supply is an excellent resource, offering a wide range of products and expert advice. And for those looking into land acquisition, especially with favorable water resources, Mossy Oak Properties offers valuable insights and expertise. Don't hesitate to reach out to these experts for your irrigation and land acquisition needs to maximize the potential of your agricultural ventures.

#This Summer#Guest Author#Guest Blogger#Guest Contributor#Guest Post#Guest Writer#Best Ways To Prevent The Most Common Plumbing Problems#Plumbing Problems#broken pipes#leaking pipes#clogged toilets#garbage disposals#prevent drains from clogging#plumber in tinley park#tinley park plumbers#plumber in orland park#orland park plumbers#plumber in homer glen#homer glen plumbers#plumber in frankfort#frankfort plumbers#plumber in mokena#mokena plumbers#plumber in lemont#lemont plumbers#plumber in new lenox#new lenox plumbers#plumber in oak forest#oak forest plumbers#plumber in homewood

0 notes

Text

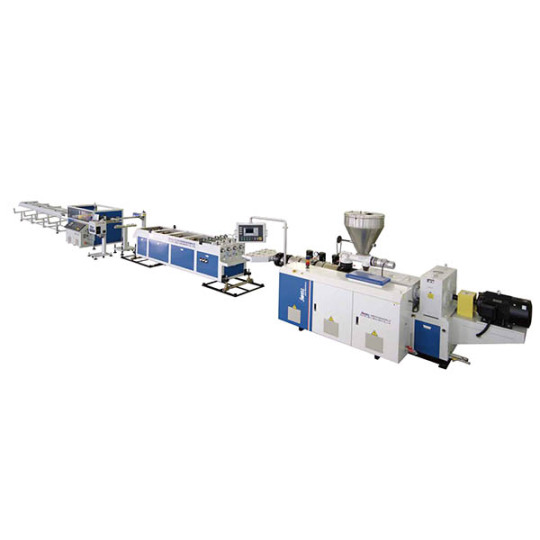

PVC Four-pipe Extrusion Machine

Performance&Advantages

Performance characteristics: The latest type of four PVC electrical bushing production line adopts a twin-screw extruder with high output and good plasticization performance, and is equipped with a mold optimized for flow path design. Four pipes discharge evenly and the extrusion speed is fast;

Four vacuum cooling tanks can be individually controlled and adjusted without affecting each other in the production process;

Four out of the traction cutting integrated design, save space. Universal rotary clamping, no change clip block. Chipless cutting speed, high precision, accurate cutting length. Optional automatic laser printing system.

Planetary Saw Cutting Machine Performance & Advantages

The equipment running stably and reliably, adopt high-speed rotating saw, Circular Saw blade cut the pipe. Suitable for extra thick large - diameter pipe; Cemented carbide cutting blades, high wear resistance and long service life; Powerful suction chips Dust removal used ionic wind, equipped with dust filters collection device.

In view of the large diameter PVC pipe is equipped with a dedicated chamfering cutter, tungsten carbide blade, sharp and durable; The internal structure of advanced design, make the PVC pipe cutter surface smooth and tidy, chamfer Angle and uniformity nice.

For small diameter PVC pipe, we had a special high-speed cutting machine dust - free. Ribbon cuttings avoid the pollution of dust on the work shop.

Main technical specification

Model

Pipe diameter

Extruder

Main Power

Capacity

JWG-PVC32

Φ16-32mm

SJZ65/132

37kw

250~300kg/h

JWG-PVC32-H

Φ16-32mm

SJZ80/156

55kw

300~400kg/h

Product image display

Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

How to install shower pipes

A shower faucet and all associated pipes are installed behind the shower wall. The best time for installation is during a renovation, when the walls are exposed. The valve itself is attached to the frame, and the part that protrudes into the bathroom is covered with the handle trim. The valve has two inlet ports and a single outlet for the shower head, and these ports are usually internally threaded. Most plumbers screw copper or brass welding adapters into these ports before installing copper pipes.

Locate suitable hot and cold water lines from which to draw water for the shower. These should be 2 cm thick main supply lines - not 1.8 cm thick secondary lines. Turn off the water, cut the pipes with a pipe cutter, and solder a 2 x 1.8 cm tee into each pipe.

Assemble the pipes and connections needed to carry the water to the wall behind the shower. You may need to drill 2 cm holes in the floor slab to feed the pipes through. When you are finished with the rough-in, you should have two branches in the wall behind the shower that extend at least one meter above the floor.

Install cladding in the wall to support the shower valve. The type of trim and the distance behind the wall will depend on the type of valve you have, although a crossbar of 5 x 10 cm wood is typical.

Prepare the valve so that you can solder pipes to it. If the valve has female threaded connections, prepare three 1.8 cm welding adapters by soldering a 7.5 cm pipe to each. Then wrap tape around the threads of the adapters, screw one into each port, and tighten with a wrench.

Extend the pipes to the valve by fitting 1.8 cm pipes with the correct fittings. You'll need 1.8-cm couplings on both ends of these pipes, and probably 90-degree elbows to run them into the sides of the valve.

Assemble an elbow for the shower head by bolting it at the proper height to a crossbar or blocking attached to the frame. Connect this shower pipe to the top connection of the valve with a 1.8 cm copper pipe and solder the pipe to the pipe and adapter attached to the valve.

Tip

When you are done installing the shower valve, turn on the water and check for leaks. If there are none, you can cover the wall and install the valve handle and shower head.

It is advisable to leave an access panel somewhere in the wall so that you can access the valve in case of repair. If there is no space for this plate in the wall of the bathroom, install it in a cabinet in an adjacent room.

Call the Emergency Plumber in Worcester. The plumbers that we send, are licenced and professionals. Contact us now, 01905959004.

0 notes

Text

भारत में एक सफल प्लंबिंग बिजनेस (plumbing business) चलाने के लिए 7 स्मार्ट टिप्स

प्लंबिंग बिजनेस (plumbing business) उन सभी बिजनेस में से एक है जिसकी आम आदमी को हर जगह ज़रूरत रहती है । बिना प्लंबिंग के कोई घर या ऑफिस चल ही नहीं सकता क्योंकि ये बिजनेस सीधे पानी से जुड़ा है और ऐसा कोई नहीं जिसको इसकी ज़रूरत न हो । चाहे वो फीटिंग हो, लीकेज, ब्लॉकेज, टंकी या कुछ और, एक बेहतर प्लंबिंग सर्विस की ज़रूरत सबको रहती है क्योंकि इस बिज़नेस में क्वालिटी वर्क की सबसे ज़्यादा डिमांड है और अगर आपकी सर्विस को पसंद किया जाता है तो आप भारत में एक सफल बिजनेस बना सकते हैं ।

नोएडा में प्लंबिग सर्विस Plumbing service in noida

नोएडा क्षेत्र जितनी तेजी से बस रहा है, वहां उतनी ही तेजी से plumbing service की ज़रूरत पड़ रही है । फ्लेट हो, ऑफिस हो या फिर घर, नोएडा में plumbing business एक सफल बिजनेस का रूप ले चुका है । यहाँ पहले से काफी ज़्यादा plumber service मौजूद है, उसके बावजूद यहां plumbing service demand लगातार बढ़ रही है । आप भी अगर plumbing business को एक सफल बिजनेस बनाना चाहते हैं तो हम नीचे प्लंबिंग बिजनेस (plumbing business) को सफल बनाने वाले 7 स्मार्ट टिप्स आपको बता रहे हैं, आप इन्हें फॉलो कीजिए -

इनवेस्टमेंट यानी निवेश करना

किसी भी बिजनेस को बढ़ाने के लिए इनवेस्टमेंट एक ज़रूरी पहलू है । Plumbing service को सफल बनाने के लिए आपके पास एक बेहतर पूंजी निवेश करने के लिए होनी ज़रूरी है । आपको ये निवेश सोच-समझकर करना है और हां, ये उम्मीद न करें कि पहले ही महीने से आपको नतीजे दिखाई देने लगेंगे । आप सबसे पहले नए प्लंबिंग औज़ार (plumbing equipment) और लगने वाली बाकी लागत के लिे लोन भी ले सकते हैं ।

बिजनेस प्लान

Plumbing business एक ऐसा बिजनेस है जिसमें नल, टैंक, पाइपलाइन, ट्यूब या फिर किसी दूसरे टूल की मदद से पानी के लिए फीटिंग, लीकेज, ब्लॉकेज फिक्स किया जाता है, इसके लिए एक बिजनेस प्लान बनाने की ज़रूरत पड़ती है । अगर आंकड़ों की मानें तो noida plumbing services में 16% की बढ़त देखी गई है । एक बिजनेस प्लान आपको बिजनेस में लगने वाले खर्चे, समय और निकलने वाले नतीजों की जानकारी दने के लिए ज़रूरी है ।

अपनी स्किल चुनें

Plumbing service business तभी सफल हो सकता है जब आप इस काम के माहिर हों क्योंकि इस क्षेत्र में आप जितना बेहतर करेंगे आपके पास उतने कस्टमर आएंगे और जिसके पास जितना बड़ा कस्टमर होता है, वो बिजनेस उतना ही सफल होता है । अगर आप plumbing repair expert हैं, तो numberdekho app आपको प्रमोट करने का काम करता है ।

ऑफिस सेट-अप

एक सफल Plumbing business में ऑफिस की जगह बहुत बड़ी भूमिका निभाती है । आपके अपना ऑफिस एक ऐसी जगह पर जमाना होगा जहाँ से आप आसानी से ज़्यादा से ज़्यादा लोगों तक पहुंच सकें । ऑफिस का साइज़ इतना हो कि वहाँ plumbing tools रखने के लिए ठीक-ठाक जगह हो ताकि आपको कस्टमर की समस्या को दूर करने के लिए किसी दूसरे उपकरण की ज़रूरत न हो, मतलब ये कि आपके पास plumbing service के लिए एक्स्ट्रा उपकरण होने चाहिए । हालांकि अब numberdekho App ने आपको ऑनलाइन प्लेटफॉर्म देकर सेट-अप कर दिया है ।

ज़रूरी औज़ार

अगर आप plumbing business में एक्टिव हैं तो आपके पास ये plumbing tools होने ज़रूरी हैं -

Tubing Cutter (ट्यूब कटर)

Hacksaw ( हॉकशॉ)

Hole saw kit ( होल शॉ किट )

Pipe and tube benders ( पाइप और ट्यूब बैंडर )

Mole grips ( मोल ग्रिप्स )

Plumber’s torch ( प्लंबर टॉर्च )

Thread sealing tape ( थ्रैड सीलिंग टेप )

Pliers ( पाइलर्स )

Press fitting systems ( प्रैस फीटिंग सिस्टम )

Flashlight ( फ्लैश लाइट )

A bucket ( एक थैला )

Ratcheting pipe threader set ( रैचइटिंग पाइप थ्रैडर सेट )

Plumber Wrenches ( प्लंबर व्रैंच )

Pipe wrench ( पाइप व्रैंच )

Adjustable wrench ( एडजस्टेबल व्रैंच )

Basin wrench ( बेसिन व्रैंच )

Faucet key ( फुकैट कि )

Torque wrench ( टॉर्क व्रैंच )

Internal pipe wrench ( इंटरनल पाइप व्रैंच )

Plumber Drain Cleaning Tools ( प्लंबर ड्रैन क्लिीनिंग टूल्स )

Plungers Hand auger ( प्लंगर हैंड ऑगर )

Snake machine ( स्नैक मशीन )

Drain inspection camera ( ड्रेन इन्पेकशन कैमरा )

Hydro jetting machines ( हाइड्रो जेटिंग मशीन )

Plumbing Safety Tools ( प्लंबिंग सेफ्टी टूल )

Gloves ( ग्लोव्स )

Goggles ( चश्मे )

Heat shields or pads ( हीट शील्ड या पैड )

मार्केटिंग

Plumbing business में दूसरे बिजनेस की तरह ही मार्केटिंग फैक्टर बहुत अहमियत रखता है । क्योंकि प्लंबिंग बिजनेस में दी जाने वाली सेवाएं भी कस्टमर तक तभी पहुंचेंगी जब मार्कटिंग मज़बूत होगी, Numberdekho App आपके लिए एक मार्केटिंग रणनीति की तरह काम करता है । इस ऐप में अपना बिजनेस रजिस्टर करते ही आप plumbing business में ऑटोमेटिक एक्टिव हो जाते हैं और आ जाते हैं भारत के सबसे बड़े सर्विस/रिपेयर कस्टमर नेटवर्क के साथ ।

खर्चों को कंट्रोल करें

क्यूंकि आपने अभी-अभी एक स्टार्ट-अप के तौर पर अपना plumbing business शुरू किया है तो इस बात का ध्यान रखें कि आपके बिजनेस में लगने वाली लागत आपके जेब खर्चों पर हावी न हो जाए । आपको शुरूआत से अंत तक इस बात का ध्यान रखना होगा ताकि आप किसी भी नुकसान से बच सकें । जब आप numberdekho App पर अपने बिजनेस की रजिस्टर कर देते हैं तो आप अपने चार्ज अपने बजट के हिसाब से दर्ज कर सकते हैं ।

अगर आप प्लंबिंग बिजनेस को कुछ ही समय में सफल बनाकर एक बड़ा बिजनेस बनाना चाहते हैं तो आज ही भारत के सबसे उत्तम सर्विस प्रोवाइडर ऐप numberdekho पर अपने बिसनेस और खुद को लिस्ट करें ।

0 notes

Text

A Guide to Pipe Cleaning and Cutting Machines in Singapore

Pipe cleaning and cutting machines are essential tools for any plumbing, construction, or industrial project that involves working with pipes.

Whether you need to remove dirt, scale, rust, or other deposits from the inside of pipes or cut pipes to the desired length and shape, you need reliable and efficient machines that can handle the job.

But how do you choose the right pipe cleaning and cutting machines for your project? There are many factors to consider, such as the type, size, and material of the pipes, the level of cleanliness and accuracy required, the budget and availability of the machines, and the safety and environmental standards of the project.

In this article, we will introduce some of the most common types of pipe cleaning and cutting machines available in Singapore, and how they can help you achieve your project goals. We will also mention some of the leading suppliers of these machines in Singapore, such as AARON Accessories Pte Ltd.

Pipe Cleaning Machines

Pipe cleaning machines are devices that use various methods to remove unwanted substances from the inside of pipes. Depending on the method, they can be classified into:

• Internal pipe cleaners: These are machines that use pressurized air, water, or chemicals to blast away dirt and debris from the inside of pipes. They usually have a nozzle that can be inserted into the pipe opening and rotated to cover the entire surface. Some examples of internal pipe cleaners are:

• Internal pipe blasting equipment: This is a machine that uses pressurized air and abrasive media (such as sand or steel shot) to clean metal pipes from rust, scale, paint, or other coatings. It is suitable for pipes with a diameter of 60mm to 280mm.

• Internal pipe water jetting equipment: This is a machine that uses pressurized water (up to 3000 bar) to clean pipes from grease, oil, sludge, or other organic matter. It is suitable for pipes with 20mm to 1500mm diameter.

• Internal pipe chemical cleaning equipment: This is a machine that uses chemical solutions (such as acids or alkalis) to dissolve mineral deposits (such as calcium or iron) from pipes. It is suitable for pipes with a diameter of 25mm to 300mm

• External pipe cleaners: These are machines that use brushes, scrapers, or other tools to clean the outside of pipes. They usually have a clamp that can hold the pipe in place and a motor that can rotate the tool around the pipe. Some examples of external pipe cleaners are:

• External pipe brushing equipment: This is a machine that uses wire brushes to remove dirt and rust from the outside of metal pipes. It is suitable for pipes with a diameter of 50mm to 300mm

• External pipe scraping equipment: This is a machine that uses metal scrapers to remove paint or other coatings from the outside of pipes. It is suitable for pipes with a diameter of 50mm to 300mm.

Pipe Cutting Machines

Pipe-cutting machines are devices that use various methods to cut pipes to the desired length and shape. Depending on the method, they can be classified into:

• Manual pipe cutters: These are hand-held tools that use blades, wheels, or chains to cut pipes by applying manual force. They are usually cheap and easy to use, but they may not be very accurate or fast. Some examples of manual pipe cutters are:

• Pipe cutter: This is a tool that has a sharp wheel that can cut through metal pipes by rotating around them. It is suitable for pipes with a diameter of up to 100mm.

• Pipe saw: This is a tool that has a blade that can cut through plastic or PVC pipes by moving back and forth along them. It is suitable for pipes with a diameter of up to 160mm.

• Pipe chain cutter: This is a tool that has a chain that can cut through cast iron or clay pipes by tightening around them. It is suitable for pipes with a diameter of up to 600mm.

• Electric pipe cutters: These are machines that use electric motors to power blades, wheels, or chains to cut pipes by applying mechanical force. They are usually more accurate and fast than manual pipe cutters, but they may be more expensive and require electricity. Some examples of electric pipe cutters are:

• Electric pipe cutter: This is a machine that has a sharp wheel that can cut through metal pipes by rotating around them. It is suitable for pipes with a diameter of up to 300mm.

• Electric pipe saw: This is a machine that has a blade that can cut through plastic or PVC pipes by moving back and forth along them. It is suitable for pipes with a diameter of up to 400mm.

• Electric pipe chain cutter: This is a machine that has a chain that can cut through cast iron or clay pipes by tightening around them. It is suitable for pipes with a diameter of up to 900mm.

• Hydraulic pipe cutters: These are machines that use hydraulic pressure to power blades, wheels, or chains to cut pipes by applying fluid force. They are usually more powerful and versatile than electric pipe cutters, but they may be bulky and noisy. Some examples of hydraulic pipe cutters are:

• Hydraulic pipe cutter: This is a machine that has a sharp wheel that can cut through metal pipes by rotating around them. It is suitable for pipes with a diameter of up to 600mm.

• Hydraulic pipe saw: This is a machine that has a blade that can cut through plastic or PVC pipes by moving back and forth along them. It is suitable for pipes with a diameter of up to 600mm.

• Hydraulic pipe chain cutter: This is a machine that has a chain that can cut through cast iron or clay pipes by tightening around them. It is suitable for pipes with a diameter of up to 1200mm.

Pipe Grooving Machines

Pipe grooving machines are devices that use various methods to create grooves on the ends of pipes. These grooves are used to connect pipes with couplings or fittings without welding or threading. Pipe grooving machines can improve pipe installation and maintenance efficiency and safety.

Depending on the method, pipe grooving machines can be classified into:

• Roll grooving machines: These are machines that use rollers to press grooves into metal pipes by rotating around them. They are suitable for pipes with 25mm to 600mm diameter.

• Cut grooving machines: These are machines that use blades to cut grooves into metal pipes by moving along them. They are suitable for pipes with 50mm to 900mm diameter.

Pipe Threading Machines

Pipe threading machines are devices that use various methods to create threads on the ends of pipes. These threads are used to connect pipes with couplings or fittings by screwing them together. Pipe threading machines can provide a strong and leak-proof connection for pipe systems.

Depending on the method, pipe threading machines can be classified into:

• Manual pipe threading machines: These are hand-held tools that use dies to create threads on metal pipes by applying manual force. They are usually cheap and easy to use, but they may not be very accurate or fast. They are suitable for pipes with a diameter of up to 50mm.

Electric pipe threading machines: These are machines that use electric motors to power dies to create threads on metal pipes by applying mechanical force.

They are usually more accurate and fast than manual pipe threading machines, but they may be more expensive and require electricity. They are suitable for pipes with a diameter of up to 150mm.

Hydraulic pipe threading machines: These are machines that use hydraulic pressure to power dies to create threads on metal pipes by applying fluid force.

They are usually more powerful and versatile than electric pipe threading machines, but they may be more bulky and noisy. They are suitable for pipes with a diameter of up to 300mm.

How to Choose the Right Pipe Cleaning and Cutting Machines for Your Project

As you can see, there are many types of pipe cleaning and cutting machines available in Singapore, each with its own advantages and disadvantages. To choose the right ones for your project, you need to consider the following factors:

The type size and material of the pipes: Different types of pipes may require different methods of cleaning and cutting.

For example, metal pipes may need blasting or brushing, while plastic or PVC pipes may need water jetting or sawing.

Similarly, different sizes and materials of pipes may have different limitations and specifications for cleaning and cutting. For example, larger or thicker pipes may need more powerful or specialized machines, while softer or brittle pipes may need more gentle or precise machines.

• The level of cleanliness and accuracy required: Different levels of cleanliness and accuracy may require different methods of cleaning and cutting. For example, if you need to remove all traces of dirt, rust, paint, or coatings from the inside or outside of pipes, you may need blasting or scraping equipment. If you need to cut pipes to exact lengths and shapes, you may need

1 note

·

View note

Text

A Homeowner's Guide To Electrical And Plumbing Tools

A Homeowner's Guide To Electrical And Plumbing Tools

Do you own a home and wish you knew how to do basic electrical and plumbing fixes? If that's the case, you'll need electrical tools that are also safe for use in plumber brunswick Here are some suggestions for what to get the handyman or handywoman in your life for the upcoming holidays of Hanukkah, Christmas, and Kwanzaa.

The licensed professionals will reveal their favorite plumbing and electrical supplies for the home.

ELECTRICAL HARDWARE

Professional electricians rely heavily on a wide variety of specialized equipment.

The professionals recommend the following for the ordinary homeowner who undertakes occasional electrical work:

PORTABLE POWER TOOL

The strength and maneuverability of cordless drills make them ideal for a wide variety of electric and DIY tasks around the home. An electrician's drill makes rapid work of driving screws, for example, during the installation of switches and outlets. A good model should have a voltage of at least 20 volts and be able to drill through both wood and metal.

IMPACT DRIVEN WITHOUT CORDS

When working with strong materials like hardwood or sheetrock, an impact driver designed for electricians can be a huge time saver. This device is roughly the size and shape of a standard drill, but it contains an additional mechanism that allows it to drive huge screws at high speeds by harnessing the motion of the motor. Unlike conventional drill/driver bits, which are stored internally and connected to the chuck key, the chucks on an electrician's impact driver are external.

licensed electricians advise going for a three-pound unit that has at least eighteen volts of electricity.

LONG-SHANKED SCREWDRIVER

A multi-bit screwdriver is a screwdriver with many interchangeable bits (or tips) that fit onto a standard screwdriver handle. Many home appliances require Phillips head screws to secure panels and trim, so having them on hand is really helpful. Our electricians recommend multi-bit screwdrivers with interchangeable tips that fit into your drill and separate handles for those times you will need more torque or strength from the tip itself to remove screws.

PLUMBING EQUIPMENT

Doing plumbing repairs around the house is a lot less of a hassle if you have the proper equipment.

For those quick fixes around the house, the plumbing experts suggest keeping the following on hand.

ADJUSTABLE WRENCH

Like electricians, plumbers highly recommend owning an adjustable wrench for being able to tighten or loosen any type of nut or bolt inside a plumbing system.

TUBE SLICER

When it's time to cut PVC pipe down to correct lengths before putting together new plumbing systems, plumbing tube cutters make short work of the task. This electrical tool makes quick work of slicing through copper or PVC pipe.

PETFE TAPE

Teflon tape is used by professional plumbers because it creates an airtight seal between two pieces of metal piping while preventing leaks to corrosion or abrasion. This electrician tool is often used for connecting threaded fittings and joints, such as the faucet to a sink or toilet bowl to its discharge pipe.

INTERCHANGEABLE PLUNGER

By simply screwing on different sized rubber cups, plumbers with an adjustable plunger may do a wide variety of tasks, both inside and outside of residences.

0 notes

Text

Thread Milling Machine Market Outlook, Trends & Demand Analysis during Forecast 2023 to 2033

According to a recent FMI report, the global thread milling machine market is expected to grow at a CAGR of 5.1% in the forecast period from 2023 to 2033. The market is anticipated to be valued at US$ 17,437.7 Million in 2023 and reach US$ 28,675.9 Million by the end of 2033.

The thread milling machine has been around for over a hundred years and is used in a wide range of industries. There are several types of thread milling machines, each with its own unique set of features and capabilities.

Milling machines are used to create various types of threads, including external threads on pipes and screws, as well as internal threads on tapped holes. A thread milling machine consists of a cutter with multiple flutes that rotates about an axis. The cutter progressively removes material from the work piece to create the desired thread form.

Thread milling machines were first developed in the early 1900s. These early machines were rudimentary compared to today's standards. However, they were still able to perform the basic function of cutting threads into metal.

Throughout the years, thread milling machines have undergone numerous improvements and refinements. The most common type of thread milling machine is the computer numeric controlled (CNC) model.

Request a Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-16164

Key Takeaways from the Thread Milling Machine Market Study:

The demand for thread milling machines in Australia is expected to grow at 2.7% CAGR in 2023.

The demand for thread milling machines in Japan is expected to grow at 8.0% CAGR in 2023.

Sales of thread milling machines in the U.S. are expected to grow at a rate of 32.7% in 2023.

The demand for thread milling machines is projected to grow at a CAGR of 6.3% in India during the assessment period.

The U.K. thread milling machine market is projected to grow at a CAGR of 5.3% in the evaluation period.

“Increasing popularity of eco-friendly fibers in designer apparel and garments is anticipated to boost sales of thread milling machines. Apart from that, expansion of the online fashion market, development of high-quality innovative fabrics, and rising disposable income are anticipated to drive growth,” says a lead analyst at Future Market Insights.

Competition Landscape: Thread Milling Machine Market

Major players in the global thread milling machine market are DMG Mori Seiki Co., Ltd., Junker Group, Sandvik Coromant AB, Kennametal Inc., Walter AG, Yamazaki Mazak Corporation, EMAG GmbH & Co.

North America currently holds the largest market share, and this region is expected to continue to expand during the projection period. This can mainly be due to the region's growing population and rising disposable income levels. Furthermore, the North America thread milling machine market is expected to expand in the next ten years due to the presence of a favorable legal and regulatory environment.

Get Valuable Insights into Thread Milling Machine Market

FMI, in its new offering, provides an unbiased analysis of the thread milling machine market presenting historical demand data (2018-2022) and forecast statistics for the period from (2023-2033). The study divulges compelling insights on the demand for Thread milling machine based on material (stainless steel, mild steel), by application (food equipment, automotive, aerospace, power generation, medical), by distribution channel (online and offline), and by region.

Get Full Information on this Report @

https://www.futuremarketinsights.com/reports/thread-milling-machine-market

Thread Milling Machine Market Outlook by Category

By Application:

Food Equipment

Automotive

Aerospace

Power Generation

Medical

By Material:

Stainless Steel

Mild Steel

By Distribution Channel:

Online

Offline

By Region:

North America

Latin America

Europe

East Asia

South Asia

Oceania

MEA

0 notes

Text

Ensuring Proper Installation and Long-Term Performance of Your Water Heater

when installing a new water heater in your house, ensure that everything is accomplished perfectly and that the appliance keeps operating reliably for a very prolonged period. So, Hiring a professional Plumbing Service Fishers Indiana is essential and also offers you benefits. While you might entice to try a Do-It-Yourself task to hold cash, there are a few explanations why hiring a professional Water Heater Installation service.

Some of the reasons why hiring a professional plumbing service in Fishers is essential for your requirements regarding water radiator installation are as follows:

Skills and Background

Water Heater Installation Indianapolis Indiana possesses the knowledge and skills to install a water heater correctly. They can evaluate your home's plumbing system and determine the best location for your new equipment, ensuring it is installed safely and following local building codes. When attempting a Do-It-Yourself project, mistakes can result in breaks, water damage, or gas leaks if you have an internal combustion water radiator.

Appropriate Gear and Instruments

Introducing a water radiator requires specialised equipment and gadgets, which most mortgage borrowers do not keep handy. Competent handypersons have the tools to install your water radiator safely and successfully, such as pipe cutters, binding devices, and pressure gauges. Installing your water heater alone may damage your plumbing system or equipment.

puts money and time away

Although it may appear that hiring a professional Water Softener Installation Anderson Indiana, is an extra expense, it can save you money in the long run. Competent handypersons can complete your water warmer installation quickly and efficiently, lowering the risk of costly mistakes or fixes soon. Additionally, skilled handypersons have access to high-quality components and can recommend the best water warmer for your needs and budget.

Correct Maintenance and Repairs

Maintaining your water heater properly after installation is crucial to ensure long-term performance. Competent handypersons can provide ongoing maintenance services like flushing your tank to remove residue build-up and replace damaged components. If your water radiator develops a problem, they can also provide expert repairs, ensuring that your machine continues to function reliably for a very long time.

1 note

·

View note

Text

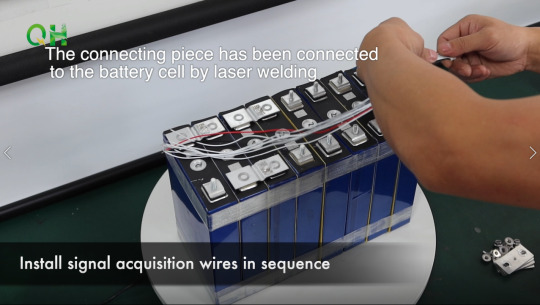

Full DIY Process Of 25.6V 50Ah LiFePO4 Floor Machine Battery For Battery Assemblers

LiFePO4 floor cleaning machine is convenient for our daily lives. Floor machines require reliable and long-lasting backup power to ensure the job is complete without interruption. Lithium iron phosphate LiFePO4 batteries have longer life spans and higher energy densities. Compared with lead-acid batteries, LiFePO4 batteries are lightweight and maintenance-free. They are excellent partners for our housework and cleaning projects.

Do you want a durable LiFePO4 battery instead of a lead-acid one? Would you like to DIY your own battery? Here is the full tutorial in the following post.

*Note: It is recommended that you learn some basic knowledge about LiFePO4 batteries before assembling the battery pack. Keep safe when you are assembling the battery pack.

youtube

Material Used:

3.2V 50Ah LiFePO4 battery cells (8 pieces)

There are currently three common shapes of LiFePO4 batteries: cylindrical, prismatic, and pouch. Different shapes of batteries will have a certain impact on performance. At present, the most suitable battery DIY enthusiasts are the prismatic LiFePO4 batteries, which are very suitable for both performance and operational difficulty.

We recommend you purchase the Grade A battery with a high quality and reliable warranty.

BMS (Battery Manage System, 1 piece)

Connectors (About 8 pieces)

Others: EVA cotton, screws, ribbon cables, plastic pipes, etc.

Tool Used:

Spot Welder

Spot Welding Pen

Soldering Iron

Wire Cutter

Wire Stripper

Multimeter

Assembly Methods: 8 Series And 1 Parallel

Series(S): The way of connecting the positive and negative electrodes of two different cells is called a series connection. As a result, the voltage of the battery pack will increase while the capacity remains the same.

Parallel(P): where the positive and positive electrodes of two different cells are connected in parallel. The result is that the capacity of the battery pack increases while the voltage remains the same.

Assembly Process

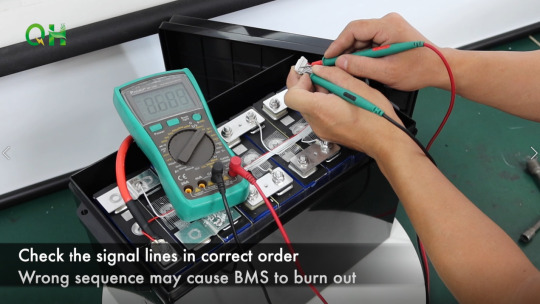

1. Install Signal Acquisition Wires In Sequence

The connecting piece has been connected to the battery cell by laser welding. Laser welding is a process used to join together metals or thermoplastics using a laser beam to form a weld.

Before we connect this group of battery cells, we should use the multimeter to check their voltage of them to ensure consistency. It is better if you have a testing device to check the internal resistance. Without testing the consistency, the battery pack may cause an accident.

Then we place them in order and fix them with fiber tape. (Made of hot melt adhesive and forms a stronger tape that is resistant to tears and has better temperature tolerance than regular tape.)

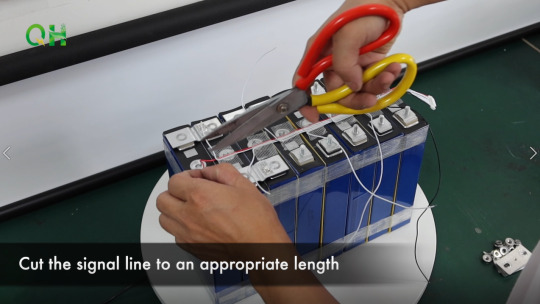

2. Cut The Signal Line To An Appropriate Length

Tidy up the messy lines, then cut them into an appropriate length.

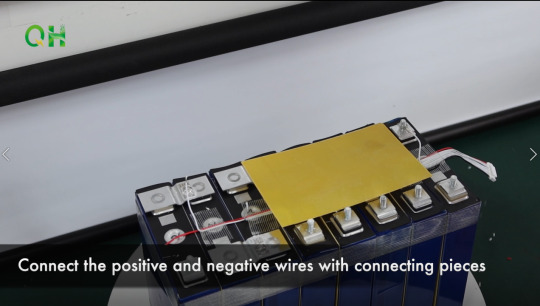

3. Connect The Positive And Negative Wires With Connecting Pieces

4. Soldering Signal Lines With Lead-Free Solder

Generally, leaded solder is composed of tin and lead. The advantages of using leaded solder include: being easier to bring to working temperature, being shock resistant, and having fewer internal flaws in the structure after cooling. However, lead material is harmful to the body as it’s readily absorbed. We’d better choose lead-free solder to protect our health and environment.

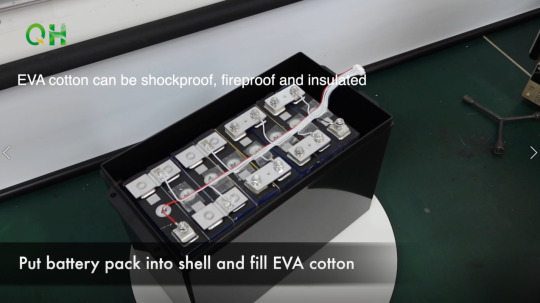

5. Put Battery Pack Into Shell And Fill EVA Cotton

EVA cotton can be shockproof, fireproof, and insulated, which can protect the LiFePO4 battery cells well.

6. Secure BMS With Thermally Conductive Tape

Thermally conductive tapes are designed to provide preferential heat transfer between heat-generating electronic components and cooling devices such as fans, heat sinks, or heat spreaders. They are also used for the thermal management of high-powered LED’s which can run at high temperatures, thus increasing the efficiency and reliability of the system.

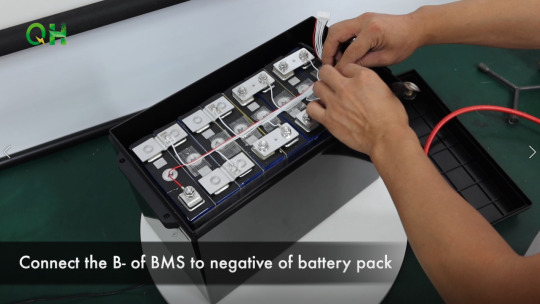

7. Connect B- Of BMS To Negative Of Battery Pack

A BMS is one of the most important elements in a LiFePO4 battery, like the brain of the battery pack. It calculates the State of Charge (the amount of energy remaining in the battery) by tracking how much energy goes in and out of the battery pack and by monitoring cell voltages, which can prevent the battery pack from overcharging, over-discharging, and balancing all the cells voltage equally.

There are two main sets of wires we need to install, the thick wires and the thin wires. The thick wires are your charging/discharging wires and the thin wires are your balance wires. Not every BMS is the same, but most are similar. Your BMS will likely have 3 thick wires or 3 pads to solder on your own heavy gauge wires. These are the B-, P-, and C- wires (or pads for adding wires). We usually start with the B- wire. We can connect the B- of BMS to the negative pole of the battery pack.

8. Connect Positive Power Line

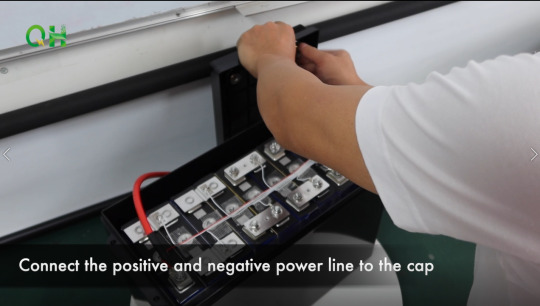

9. Connect The Positive And Negative Power Line To The Cap

10. Check The Signal Lines In The Correct Order

The wrong sequence may cause BMS to burn out.

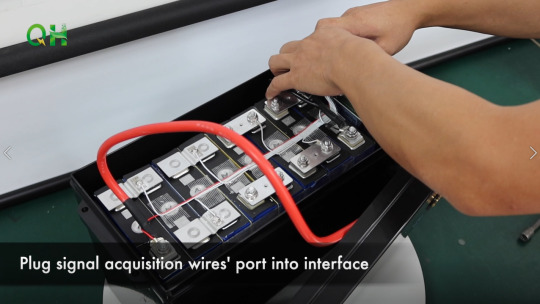

11. Plug Signal Acquisition Wires’ Port Into Interface

Battery Tests

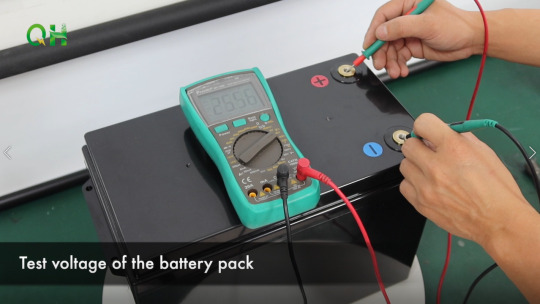

1. Test Voltage Of The Battery Pack

In these steps, we can use a multimeter to check the voltage of the whole battery pack. Attach the multimeter probes to the positive and negative battery terminals. Then we can check the voltage on the screen. The multimeter’s red probe must be connected to the positive terminal, while the black probe must be connected to the negative one.

A fully-charged battery must indicate a slightly higher voltage than the voltage listed on the battery. For instance, a 24 volts battery will indicate about 25.6 volts when it is fully charged.

2. Charging Test

The battery capacity, or the amount of energy a battery can hold, can be measured with a battery analyzer. If you’re doing a capacity test, be sure to charge the battery until the battery reaches 100%. Then discharge the device until the battery is fully depleted. The charge and discharge rates of a battery are governed by C rates. The capacity of a battery is commonly rated at 1C, meaning that a fully charged battery rated at 50Ah should provide 50A for one hour.

3. Discharging Test

The discharging test of the battery is very helpful to the battery cycle life and discharge performance evaluation. We can use a professional device(Such as a Programmable DC Electronic Load) to check whether the battery works well or not during the discharging process, which can protect our battery and devices for further daily use.

When testing, there are three factors we need to pay attention to the port voltage of the battery, the resistance of the wire between the battery and the electronic load, and the temperature of the battery.

Summary

Thanks for reading the full tutorial on 25.6V 50Ah lifepo4 battery assembly! It is not hard for us to build a LiFePO4 battery. Which voltage and capacity of the LiFePO4 battery do you need? Welcome to share your comments below!

0 notes

Text

A Practical Guide to Drain Lining Equipment

Drainage issues can be a headache for any homeowner or property manager. When pipes become damaged, traditional methods of repair can be costly, time-consuming, and disruptive. However, thanks to advancements in technology, drain lining offers a more efficient and cost-effective solution. In this blog, we'll take a closer look at drain lining equipment, with a focus on the offerings from Internal Pipe Technologies.

Understanding Drain Lining: Drain lining is a trenchless method used to repair damaged or deteriorating pipes from the inside. Instead of digging up the pipes for replacement, a liner is inserted into the existing pipe and then inflated, creating a new, seamless pipe within the old one. This process not only saves time and money but also minimizes disruption to the surrounding area.

The Importance of Quality Equipment: When it comes to drain lining, having the right equipment is crucial for achieving successful results. Poor-quality equipment can lead to subpar repairs and even further damage to the pipes. That's where Internal Pipe Technologies comes in.

Key Features of Internal Pipe Technologies Equipment: Internal Pipe Technologies offers a range of high-quality equipment designed specifically for drain lining applications. Here are some key features:

Robust Construction: Internal Pipe Technologies' equipment is built to withstand the rigors of drain lining operations, ensuring durability and longevity.

User-Friendly Design: Their equipment is designed with ease of use in mind, allowing operators to perform repairs efficiently and effectively.

Precision Engineering: Every piece of equipment undergoes rigorous testing and quality control measures to ensure optimal performance.

Versatility: Whether you're working on residential or commercial projects, Internal Pipe Technologies' equipment is versatile enough to handle a variety of pipe sizes and materials.

Popular Products from Internal Pipe Technologies:

Inversion Units: Internal Pipe Technologies offers inversion units that are used to insert the liner into the pipe. These units are available in different sizes to accommodate various pipe diameters.

Curing Equipment: Once the liner is in place, curing equipment is used to harden the liner, creating a new, structurally sound pipe. Internal Pipe Technologies offers a range of curing equipment, including UV and steam curing systems.

Robotic Cutters: For trimming the liner to the correct length and removing obstructions, Internal Pipe Technologies' robotic cutters are a valuable asset.

Conclusion: When it comes to drain lining equipment, Internal Pipe Technologies stands out for its commitment to quality, reliability, and innovation. By investing in their equipment, professionals can tackle drain lining projects with confidence, knowing they have the support of a trusted partner.

In conclusion, drain lining equipment plays a vital role in the success of trenchless pipe repair projects. With Internal Pipe Technologies' reliable and user-friendly equipment, professionals can efficiently tackle drain lining jobs with ease. So, the next time you're faced with a damaged pipe, consider the benefits of drain lining and rely on Internal Pipe Technologies for all your equipment needs.

0 notes

Text

2 inch flexible pipe price -Bangalore

Flexible PVC pipe is basically a soft, flexible material pipe that actually comes in appearances from transparent to opaque. Now it comes in various varieties and actually by adjusting the type and amount of plasticizers, plastic molders can achieve a large range of flexible compositions. PVC simply means “Polyvinyl chloride” and it is manufactured with plasticizers, which apply some rubbery kind of properties on the final end product. Now lets discuss type of PVC and mainly 2 inch flexible pipe price -Bangalore, its types and it’s manufacturing process. In between you can simply Whatsapp us to a take a quote on any kind of Hose pipe.

This Flexible PVC Pipe, commonly referred to as "flex PVC", "flex tubing", "spa tubing" and "flexible PVC" is perfect for use with pools, spas, hot tubs, water gardening (ponds, waterfalls, fountains), aquariums and fish hatcheries, irrigation, farming and gardening, sprinkler lines and other applications where the utilization of rigid pipe is either not practical or not desirable. Strong and long-lasting, this hose is ultra-flexible, and can easily be routed in any direction necessary without the use of multiple fittings, thus simplifying plumbing layouts and the installation of your job. It can be used in areas where space (for fittings) is limited and/or in situations that simply will not accommodate rigid pipe. It is sunlight, ozone and mildew resistant (although we do not recommend installations in continual sunlight).

Our Flexible PVC Pipe easily conforms to almost any contour, and experiences less heat loss than comparable copper or steel pipe. A rigid internal PVC spiral resists crushing and impact issues, and this PVC pipe can be used for above-ground or under-ground installations (with proper cushioning). It can also be used as a conduit to run protected electrical, cable, phone or fiber optic lines and can also be used as a protective liner for softer hoses or tubes. Trimming or cutting is much simpler than with rigid PVC pipe (it can be cut with PVC pipe cutters, a standard hack saw, a carpenters saw, etc.) and it accepts standard Schedule 40 fittings. It can be easily glued using any good commercially available glue for flexible or rigid PVC. It eliminates back-pressure caused by sharp turns created by multiple fittings, which increases the efficiency of your system and lowers your overall operating/energy cost. Each fitting eliminated with this highly-flexible pipe is one less fitting that can fail and cause your system to leak. It also coils easily for storage and transport

Best prices and Quality guaranteed in all kind of 2 inch flexible pipe price -Bangalore

We here at Quality flexibles as our name suggests believe in quality. Being in Karnataka, Bangalore only one thing may affect the prices a little which is the shipping cost outside India. For all over India we provide the best quality at the lowest prices possible as per the market.

along with prices and quality we also variety of ranges in the Hose segment and on-time delivery is our “most positively reviewed” USP. Now when you search for the best supplier for your needs what are actually searching

Quality

Pricing

On-time consignment

Variety of product

So all these 4 main things that you need for the right deal are all that you get. Call or Whatsapp now to get a Quote from us.

About 2 inch flexible pipe price:

Our Flexible PVC Pipe is a true Schedule 40 (Sch 40) PVC Pipe that is meant to be used with Sch. 40 fittings. It contains rigid PVC spirals that provide additional flexibility and strength above and beyond other 2 inch Flexible PVC Pipes on the market. Flexible PVC pipe can be used for direct burial or above ground use. It is UV resistant and will last for many years. Only use PVC Solvent Cements and allow adequate time for the PVC glue to cure.

Take advantage of all of the benefits of Flexible PVC Pipe and plumb systems in a whole new way. Less connections and longer runs will save you countless hours of installation time and reduce the chances of leaks.

Please see the technical chart to the left for ID and OD Measurements, Bend Ratios, Working Temperatures, Wall Thickness, etc...Our Flexible PVC Pipe is available in black or white, 1/2” thru 3" in diameter. The pipe walls are smooth inside and out which allows for unrestricted flow.

Includes Free 4oz Can of Hot Blue Gorilla PVC Glue. Works Great for Pools, Spas, Water Gardens and other applications. Recommended for use in wet conditions and/or where quick pressurization is desired.

Fastest delivery of 2 inch flexible pipe price -Bangalore, within Karnataka and With in India

As we are situated in Bangalore, Karnataka state in India. So we can provide the fastest delivery as well as the best prices in this local circle. As well as we have 100+ clients even outside Karnataka. Now it’s totally up to you, just need to reach the Whatsapp button this very page to get the Qoutes. No sales call until you schedule it.

Once you ask for a Quote we provide you a quote to you. After that you give us your affirmation to book a order. In between you can also opt for Cash on delivery.

#supreme pvc pipes price list in bangalore#2 inch pvc pipe price in bangalore#pvc pipe distributors in bangalore#2.5 inch pvc pipe price in bangalore

0 notes

Text

Essential Guide to Installing Your Farm's Irrigation System

In the realm of modern agriculture, irrigation systems play a pivotal role in driving efficiency and sustainability. These systems are not just about water distribution; they are essential tools for conserving water, reducing operational costs, and boosting crop yields. The installation of a proper irrigation system, while complex, can yield significant benefits for farmers and the environment alike. In this comprehensive guide, we'll explore the critical steps for setting up an effective agricultural irrigation system, with insights from industry experts and reputable suppliers like International Pipe & Supply.

Getting the Right Equipment

The foundation of a successful irrigation system lies in having the right equipment. Essential tools for this task include shovels, rakes, tape measures, and pliers. Crucially, the choice of pipes is vital. Quality pipes, available from trusted suppliers, are central to a durable and efficient system. When selecting pipes, factors like size, material, and durability are key considerations. PVC pipes are often preferred for their lightweight, ease of installation, and resistance to corrosion and UV damage.

Preparing Clean Pipes for Irrigation

Before laying out the pipes, it's imperative to ensure they are clean and free of debris. Dirty pipes can compromise water flow and quality, potentially harming crops. Flushing pipes with water to remove dirt and using a pipe-cleaning solution for any residual residue is recommended. Additionally, a pipe inspection camera can be invaluable in checking for blockages or internal damage.

Utilizing Vibratory Plow in Installation

In areas with hard or rocky soil, a vibratory plow can be a game-changer. This tool, with its vibrating blade, efficiently cuts a trench for pipe installation, minimizing soil disruption. While faster than manual digging, vibratory plows do require technical know-how, and hiring a professional might be the best approach for those less familiar with the equipment.

Protecting the Sod during Installation

Maintaining the health of your sod – the layer of grass and soil – is crucial during installation. Sod plays a significant role in preventing soil erosion and retaining moisture. To avoid damage, using a sod cutter to remove sections of grass for pipe installation is advisable, followed by careful replacement post-installation.

Avoiding and Addressing Pipe Kinks

Kinks in irrigation pipes can disrupt water flow, leading to uneven irrigation. To prevent this, opt for flexible pipes and plan layouts that avoid sharp bends. Employing pipe clamps or fittings can also help maintain the integrity of the pipe structure.

Correct Pipe Cutting Techniques

Precision in cutting pipes ensures a well-functioning irrigation system. Using a pipe cutter or saw, it's important to make clean, straight cuts and smooth out any rough edges to prevent leaks and ensure a snug fit of pipe sections.

Wire Protection in Irrigation Systems

Protecting the electrical wiring of your irrigation system is as important as the pipes themselves. Wires, which control water flow and power pumps and valves, should be covered with wire mesh or conduit to shield them from external damage. Burying wires at least six inches deep is also recommended to prevent accidental damage.

Maintenance and Troubleshooting Tips for Your Irrigation System

Maintaining your irrigation system is crucial for its longevity and efficiency. Here are some key maintenance tips:

Regular Inspections: Periodically inspect your system for any signs of damage or wear. Check for leaks, clogged nozzles, and broken parts.

Cleaning Filters: Clean the filters in your irrigation system regularly. A clogged filter can reduce water flow and affect the efficiency of the system.

Seasonal Adjustments: Adjust your irrigation schedule seasonally. In cooler months, plants typically need less water. Overwatering can lead to root rot and other issues.

Winterizing Your System: In regions where it freezes, winterizing your irrigation system is essential to prevent pipe bursts. This involves draining all water from the pipes and shutting down the system.

Troubleshooting Common Problems

Even with regular maintenance, issues can arise. Here are some common problems and their solutions:

Uneven Water Distribution: If some areas are getting too much water while others aren’t getting enough, check for clogged nozzles or incorrect spray patterns. Adjust or clean the nozzles as needed.

Leakages in the System: Leaks can be a major issue, leading to water waste and increased costs. Regularly check the system for any signs of leaks, especially at joint connections, and repair them promptly.

Low Water Pressure: Low pressure can be caused by leaks, clogged filters, or issues with the water supply. Inspect the system to identify the cause and rectify it.

System Won’t Turn On: If your irrigation system won’t turn on, it could be due to electrical problems, a faulty timer, or controller issues. Check the power supply, examine the timer settings, and ensure the controller is functioning correctly.

The Value of Water Access in Farming

Access to reliable water sources is crucial in farming. As noted by a representative from Mossy Oak Properties, a leader in rural land transactions, "Having direct access to water on your farm is not just a convenience; it's a strategic advantage. Farms with established water resources tend to be more productive and sustainable." This insight underscores the importance of considering water access in both land acquisition and agricultural planning.

Beyond the immediate benefits, having direct access to water resources on your farm plays a critical role in long-term sustainability and resilience. Reliable water access allows for more consistent crop growth and can significantly reduce vulnerability to weather fluctuations and droughts. It enables farmers to implement more diverse and intensive farming practices, increasing both the quantity and quality of their produce.

Furthermore, self-sufficient water resources contribute to a more controlled agricultural environment. It allows for precision in water usage, aligning with sustainable farming practices that not only preserve vital water supplies but also protect the surrounding ecosystem. This stewardship of natural resources is not just an ethical practice; it's increasingly becoming a key factor in the agricultural market, where consumers and businesses are leaning towards products that are produced sustainably.

In essence, owning land with access to water resources is not just a practical asset; it's an investment in the farm's future. It fosters a robust and adaptable farming operation, ensuring that the farm can thrive under varying environmental conditions and market demands.

Sowing the Seeds for a Flourishing Farm

Installing an efficient irrigation system requires careful planning and attention to detail. By following the guidelines outlined, you can ensure your system is set up correctly for optimal performance. For high-quality irrigation supplies, International Pipe & Supply is an excellent resource, offering a wide range of products and expert advice. And for those looking into land acquisition, especially with favorable water resources, Mossy Oak Properties offers valuable insights and expertise. Don't hesitate to reach out to these experts for your irrigation and land acquisition needs to maximize the potential of your agricultural ventures.

#This Summer#Guest Author#Guest Blogger#Guest Contributor#Guest Post#Guest Writer#Best Ways To Prevent The Most Common Plumbing Problems#Plumbing Problems#broken pipes#leaking pipes#clogged toilets#garbage disposals#prevent drains from clogging#plumber in tinley park#tinley park plumbers#plumber in orland park#orland park plumbers#plumber in homer glen#homer glen plumbers#plumber in frankfort#frankfort plumbers#plumber in mokena#mokena plumbers#plumber in lemont#lemont plumbers#plumber in new lenox#new lenox plumbers#plumber in oak forest#oak forest plumbers#plumber in homewood

0 notes

Text

UPVC/CPVC Pipe Extrusion Machine

Performance&Advantages

A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses.

Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good;

The special cutter for PVC pipe adopts a rotating clamping device, which does not require replacing the fixture with different pipe diameters. With chamfering device, cutting, chamfering, one-step molding. Support optional online belling machine.

PVC Pipe Die Head

It is for PVC 20-1000mm pipe production, split-flow frame design, very much suitable for temperature sensitive material. Adapting chrome plating mold steel, special surface hardness treatment, so that die head runner will have good flow. Easily disassembly design will offer quick change and will not affect production.

Vacuum Tank/Spray Cooling Tank Performance &Advantages

According to the specifications of the pipes can be selected single room or double room

design of the vacuum tank; SUS304 stainless steel vacuum tank and pipeline with long service life; Accurate temperature control and water level control;The large capacity of water filters and spare bypass;Centralized water supply and drainage;

Optional PLC frequency conversion precision control of vacuum degree, lower equipment energy consumption and noise;

The sizing sleeve made of high-quality materials such as alloy copper and stainless steel is particularly selected to ensure good heat conduction and a good cooling sizing effect. The inner surface of the sizing sleeve is treated with a chrome-plated special coating that provides high wear resistance and high smoothness. Water film type, disc type, dry type and other structural designs are suitable for high-speed, high-volume extrusion of different raw material pipes.

Main technical specification

Model

Pipe diameter

Extruder

Main Power

Capacity

JWG-PVC160

Φ63-1600mm

SJZ65/132

37kw

250~300kg/h

JWG-PVC250

Φ75-250mm

SJZ65/132

37kw

250~300kg/h

JWG-PVC315

Φ160-315mm

SJZ80/156

55kw

300~400kg/h

JWG-PVC450

Φ200-450mm

SJZ80/156

75kw

400~500kg/h

JWG-PVC630

Φ315-630mm

SJZ92/188

110kw

650~750kg/h

JWG-PVC800

Φ400-800mm

SJZ92/188

132kw

850~1000kg/h

JWG-PVC1000

Φ500-1000mm

SJZ110/220

160kw

1100~1500kg/h

Product image display

Read the full article

#HDPEMarinePipeExtrusionMachine#HighSpeedExtrusionMachineforHDPEWaterPipe/GasPipe#LargeDiameterHDPESolidWallPipeExtrusionMachine#NewCorrugatedPipeExtrusionMachineforVentilationSystem#PEHeatInsulationPipeExtrusionMachine#PE/PPDoubleWallCorrugatedPipeExtrusionMachine#PipeExtrusionMachine#PPR/PERT/PEXCool&HotWaterPipeExtrusionMachine#PVCDualPipeExtrusionMachine#SiliconCorePipeExtrusionMachine#Three-layerPVCSolidWallPipeCo-extrusionExtrusionMachine#UPVC/CPVCPipeExtrusionMachine

0 notes

Text

How to install a pressure valve for a shower faucet

Remove the old valve

Turn off the water for the shower by either locating and turning off the valve for the bathroom or turning off the water for the entire house. Open the shower faucet and allow the water to drain.

Remove all the trim from the shower. Unscrew the shower arm by turning it counterclockwise with adjustable pliers. Remove the handle with a screwdriver and pry the trim panel off the wall with a flathead screwdriver. You do not need to remove the internal valve mechanism.

Locate the access panel for the shower piping. If it is not behind the shower or in a closet next to the shower, it may be in a closet in an adjacent bedroom. If you can't find a panel, use a drywall saw and a reciprocating saw to cut a hole in the wall behind or next to the shower valve at the height of the shower handle and between the flanking studs.

Cut all pipes connected to the old shower valve with a pipe cutter. Make the cuts a few centimetres away from the valve so you have room to install the connections for the new valve. Pull out the old valve along with the pipe connecting the valve to the shower head.

Installing the new valve

Prepare the valve by attaching all adapters required to connect it to the pipeline. For example, if the valve has female threaded inlets, screw a male threaded weld adapter into each inlet. Wrap tape around the threads of the male thread before tightening with a wrench.

These components usually contain plastic parts that can be damaged by the heat generated during soldering.

Attach the valve housing to the frame so that its front is flush with the shower wall. You may need to attach new frame blocks to do this. Screw the valve to the blocks or the framing.

Connect the water pipes to the valve using suitable pipes and fittings. Depending on the placement of the inlets on the valve, you may or may not need to install elbows. Dry-fit all connections, disassemble them one at a time, spread flux on the pipe and fitting, and solder the connection with a torch and lead-free solder.

Lay the pipe for the new shower head and finish it off with an angle piece screwed to the frame. Finally, mount the shower arm, the shower head and the valve handle.

Call the Emergency Plumber in Luton. We are 24 hours available.

0 notes