#High Barrier Packaging Films Market

Text

Global High Barrier Packaging Films Market Surges with Sustainable Solutions in 2030

The packaging industry has experienced a significant breakthrough with the emergence of high barrier packaging films, incorporating a variety of materials such as polyethylene, polypropylene, polyethylene terephthalate (PET), and polyvinyl chloride. These advanced films provide enhanced barrier properties against moisture, gas, and temperature when compared to traditional packaging materials. Moreover, high barrier packaging films are renowned for preserving the quality characteristics of packaged products, including taste, texture, color, and consistency. In addition to surpassing conventional plastic or paper packaging, high barrier packaging also improves the absorption and bioavailability of nutrients in food products. Beyond the food and beverage sector, the pharmaceutical and agriculture industries are increasingly embracing high barrier packaging films for their respective products.

To Know More Request Sample of this Report@ https://www.infiniumglobalresearch.com/market-reports/sample-request/10

The high-barrier packaging films market is experiencing growth due to the rising demand for packaged food and beverages. The surge in demand for convenient food and ready-to-eat meals has led to a substantial uptick in the need for high-barrier packaging films. These films prove highly effective in maintaining the freshness and quality of food and beverages while extending their shelf life. The expansion of the pharmaceutical industry further fuels market growth, as high-barrier packaging films are extensively employed to protect drugs from moisture, oxygen, and other environmental factors. Nevertheless, fluctuating raw material prices pose a challenge to the market's expansion, introducing cost uncertainties and diminishing profit margins for manufacturers. These challenges may impede investment and innovation, limiting the industry's growth potential. However, the escalating demand for user-friendly packaging creates a lucrative avenue for the high barrier packaging films market. Consumers are increasingly seeking convenience and sustainability, propelling the adoption of innovative packaging solutions. This trend presents significant growth opportunities as companies develop barrier films that align with both consumer preferences and environmental considerations.

The Asia Pacific region holds the global high barrier packaging films market owing to its substantial consumer base. The region is expected to provide immense growth opportunities, given the easy availability of raw materials. The food and pharmaceutical industries in the region are expanding rapidly, and the healthcare sector is receiving increasing government budget allocations, which will further propel market growth. Moreover, North America is the fastest growing region in global high barrier packaging films market. The region's robust packaged food and pharmaceutical industries, coupled with the booming e-commerce industry, are driving the demand for high barrier packaging films in North America.

Enquire Here Get Customization & Check Discount for Report @ https://www.infiniumglobalresearch.com/market-reports/customization/10

Key Market Players:

Cosmo Films

Amcor plc

Sealed Air

Mondi

Glenroy, Inc.

Ampac Packaging

Cosmo Films

Berry Global Inc.

TCL Packaging

Eagle Flexible Packaging

More Insights on this report, Speak to Our Analyst @ https://www.infiniumglobalresearch.com/market-reports/enquiry/10

The report provides deep insights into demand forecasts, market trends, and micro and macro indicators. In addition, this report provides insights into the factors that are driving and restraining the growth in this market. Moreover, The IGR-Growth Matrix analysis given in the report brings an insight into the investment areas that existing or new market players can consider. The report provides insights into the market using analytical tools such as Porter's five forces analysis and DRO analysis of the high barrier packaging films market. Moreover, the study highlights current market trends and provides forecasts from 2023-2030. We also have highlighted future trends in the market that will affect the demand during the forecast period. Moreover, the competitive analysis given in each regional market brings an insight into the market share of the leading players.

About Us:

Today, the business organizations are going through transformation with competition getting fiercer and business practices becoming more aggressive. Companies that have abilities to fine tune their internal environment and amend themselves to be more competitive only survive, img/abouts have a risk of failure or being acquired. Some business organizations are vigorously working on their business strategies to make the most of the competition, while img/abouts are striving to survive in the competition and get along.

Infinium Global Research LLP is started with a single motto of being business partner of first choice. We at Infinium work on the strengths of our clients to ensure we help them consolidate their market position. We firmly believe in the fact that ‘if you are able to develop newer opportunities then you find there is no dearth of opportunities for you. With our strategic research approaches and deep dive in the market segments, we try to find out new opportunities that our clients can encash with their existing resources. Our experts with over 100 years of cumulative experience in research offer the best in the industry services to our clients to ensure that they achieve their business goals.

Contact Us:

2nd Floor, Ganadish Empire,

Rahatani Chowk, Pimple Saudagar,

Pimpri-Chinchwad, Maharashtra 411027

+91 99239 50043

0 notes

Text

0 notes

Link

https://www.databridgemarketresearch.com/reports/global-high-barrier-packaging-films-market

0 notes

Text

#Vietnam High Barrier Packaging Films Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

Designing Custom Potato Chip Bags: The Ultimate Guide

In the snack aisle, your packaging isn't just a bag; it's your brand's ambassador. Potato chip bags need to stand out, tell your brand's story, and keep those chips fresh and crunchy.

Designing custom potato chip bags is a mix of art and strategy, combining eye-catching aesthetics with practical functionality.

Dive into this comprehensive guide to create potato chip bags that not only look amazing but also protect your product and boost your brand.

The Basics of Potato Chip Bags

Potato chip bags are usually made from a blend of materials designed to keep the chips crispy and delicious. Common materials include:

Polyethylene (PE): Adds flexibility and moisture resistance.

Polypropylene (PP): Offers a high barrier against moisture and gases.

Metalized Films: Used inside for light and oxygen protection.

Why Custom Design Matters

Custom potato chip bags are more than just containers; they're powerful marketing tools. A well-designed bag can set your product apart, convey your brand’s personality, and create a memorable experience for consumers.

Steps to Designing Custom Potato Chip Bags

Designing the perfect potato chip bag involves several crucial steps. Here's a detailed guide to help you create standout chip bags for your brand:

Step 1: Define Your Brand and Audience

Before diving into design, understand your brand’s identity and target audience. Ask yourself:

What’s our brand’s story and mission?

What values and emotions do we want to convey?

Who’s our target audience, and what are their preferences?

Answering these questions helps you craft a design that resonates with your audience and aligns with your brand’s image.

Step 2: Choose the Right Materials

Selecting the right materials is crucial for keeping your chips fresh and the bag durable. Consider:

Barrier Properties: Ensure materials protect against moisture, light, and air.

Durability: Choose materials that withstand handling and transport.

Sustainability: Opt for recyclable or biodegradable materials to appeal to eco-conscious consumers.

Step 3: Determine the Size and Shape

Tailor the size and shape of your chip bags to your product and target market. Consider:

Portion Size: Are you offering single-serving bags, family-sized packs, or something in between?

Shelf Presence: Ensure your bag stands out on the shelves and fits well in retail displays.

Ease of Use: Make sure the bags are easy to open and reseal if needed.

Step 4: Design the Artwork

Artwork is crucial for attracting attention and conveying your brand’s message. Here are some tips:

Bold Colors: Use vibrant colors to grab attention and differentiate your product.

High-Quality Images: Include high-res images of the product and ingredients to entice consumers.

Clear Branding: Make sure your logo, brand name, and tagline are prominent and easily recognizable.

Legible Text: Use readable fonts and sizes for product info, nutritional facts, and other details.

Step 5: Add Functional Features

Enhance user experience with functional features. Consider:

Resealable Zippers: Allow consumers to reseal the bag to keep chips fresh.

Tear Notches: Make it easy for consumers to open the bag without scissors.

Clear Windows: Provide a view of the product inside, building trust.

Step 6: Compliance and Information

Ensure your packaging complies with all regulations and includes necessary information:

Nutritional Facts: Detailed breakdown of nutritional content.

Ingredients List: Clear listing of all ingredients, including allergens.

Regulatory Statements: Include “best before” dates and manufacturer info.

Step 7: Printing and Finishing Techniques

Choose the right printing and finishing techniques to enhance visual appeal and durability. Options include:

Flexographic Printing: Ideal for large runs, offering high-quality prints.

Digital Printing: Best for small runs and detailed designs, with quick turnaround.

Rotogravure Printing: Known for high-quality, detailed prints, suitable for large-scale production.

Special Finishes: Matte or gloss finishes, embossing, and foil stamping for a premium feel.

Step 8: Prototype and Test

Before mass production, create a prototype to test functionality and appearance. This allows for adjustments to ensure the final product meets your expectations.

Functionality: Test durability, ease of use, and protection capabilities.

Design Accuracy: Ensure artwork and printing are accurate and align with your brand’s vision.

Consumer Feedback: Gather feedback to identify any potential improvements.

Step 9: Production and Quality Control

Once the prototype is approved, move to mass production with strict quality control:

Material Quality: Verify consistency and meet specified requirements.

Printing Quality: Check for defects or inconsistencies.

Functional Features: Ensure zippers, tear notches, and other features work as intended.

Step 10: Packaging and Distribution

Package the potato chip bags for distribution, considering:

Packaging: Use appropriate methods to protect the bags during transit.

Logistics: Plan distribution to ensure timely delivery to retailers or consumers.

Storage: Store bags in suitable environments to maintain quality.

Trends in Potato Chip Bag Design

Stay ahead with the latest design trends. Here are some hot trends in chip bag design:

1. Sustainability

Eco-friendly packaging is a significant trend. Brands are using recyclable, biodegradable, and compostable materials to appeal to eco-conscious consumers.

2. Minimalist Design

Less is more. Clean lines, simple typography, and white space create a modern, sophisticated look.

3. Bold and Vibrant Colors

Bright, unexpected color combinations grab attention and make your product stand out.

4. Personalization

Personalized packaging, allowing consumers to add names or messages, is popular, especially for limited editions and gifts.

5. Interactive Elements

QR codes and augmented reality features enhance customer engagement and add value to the product.

6. Luxury Finishes

Premium finishes like foil stamping, embossing, and UV coating add a luxurious touch and elevate the perceived value.

Case Studies: Winning Potato Chip Bag Designs

To illustrate successful designs, let’s look at some case studies:

Case Study 1: Organic Snack Brand

Using recyclable materials and earthy tones, this brand emphasized sustainability. The minimalist design and clear windows showcased chip quality, boosting consumer trust and sales.

Case Study 2: Gourmet Potato Chips

Bold colors and high-quality images created a premium look. Resealable zippers and a matte finish added luxury, making the product popular in upscale markets.

Case Study 3: Interactive Packaging

A well-known brand used QR codes linking to recipes and games, increasing engagement and loyalty through innovative packaging.

Conclusion

Designing custom potato chip bags that captivate and protect your product involves careful planning and creativity. By understanding your brand and audience, choosing the right materials, incorporating functional features, and staying current with design trends, you can create packaging that stands out and enhances your brand’s image.

Ready to elevate your potato chip packaging? Use this guide to design custom bags that not only protect but also captivate and convert customers.

0 notes

Text

2,5-Furandicarboxylic Acid (FDCA) Market to Cross USD 980.3 million, at a CAGR of 8.2% by 2031

The global 2,5-Furandicarboxylic Acid (FDCA) market is estimated to flourish at a CAGR of 8.2% from 2023 to 2031. According to Transparency Market Research, sales of 2, 5-Furandicarboxylic Acid (FDCA) are slated to US$ 980.3 million by the end of the aforementioned period of assessment.

Innovations in FDCA applications beyond packaging and polyester production are vital drivers reshaping its market landscape. The development of FDCA-based polymers for the electronics and automotive industries marks a transformative stride. Due to its exceptional thermal and mechanical properties, research is unveiling FDCA's potential as a high-performance material in electronic components and lightweight automotive parts.

Download Sample Report@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2014

FDCA's integration into the pharmaceutical sector as a building block for novel drugs and drug delivery systems is gaining attention. Its biocompatibility and ability to modify drug-release kinetics present promising opportunities in pharmaceutical formulations, potentially revolutionizing drug manufacturing.

Market Segmentation

By Service Type:

Production Services: Custom manufacturing, bulk production

Consulting Services: Technical support, market analysis

By Sourcing Type:

Bio-based: Derived from renewable resources like plant biomass

Synthetic: Derived from petrochemical processes

By Application:

Polyesters: Such as polyethylene furanoate (PEF)

Polyamides: Used in fibers and engineering plastics

Polyurethanes: For foams, elastomers, and coatings

By Industry Vertical:

Packaging: Bottles, films, and containers

Textiles: Fibers and fabrics

Automotive: Parts and components

Construction: Insulation materials and coatings

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominates the FDCA market due to significant investments in R&D and a robust regulatory framework promoting sustainable materials.

Europe: A strong advocate for green initiatives, Europe is a key market for FDCA, driven by stringent environmental regulations and high consumer demand for eco-friendly products.

Asia-Pacific: Expected to witness the fastest growth due to rapid industrialization, urbanization, and increasing government support for bio-based products in countries like China and India.

Latin America and Middle East & Africa: Emerging markets with growing awareness of sustainable practices and potential for significant future growth.

Market Drivers and Challenges

Market Drivers:

Environmental Concerns: Growing awareness of environmental pollution and the carbon footprint of petrochemical products.

Government Regulations: Supportive policies and regulations promoting the use of bio-based materials.

Technological Advancements: Innovations in FDCA production processes making it more cost-effective and efficient.

Consumer Preferences: Increasing consumer preference for sustainable and biodegradable products.

Market Challenges:

High Production Costs: Bio-based FDCA production is still more expensive compared to petrochemical counterparts.

Limited Infrastructure: Insufficient infrastructure for large-scale production and distribution of FDCA.

Technical Barriers: Challenges related to the scalability and stability of FDCA-based products.

Market Trends

Sustainable Packaging: Growing use of FDCA in the packaging industry as an alternative to PET (polyethylene terephthalate).

R&D Investments: Increased investment in research and development to improve production efficiency and expand FDCA applications.

Partnerships and Collaborations: Strategic collaborations between companies to enhance market reach and technological capabilities.

Future Outlook

The future of the FDCA market looks promising with ongoing advancements in production technologies and increasing adoption across various industries. By 2031, FDCA is expected to play a crucial role in the global shift towards sustainable and biodegradable materials, driven by regulatory pressures and consumer demand.

Key Market Study Points

Market dynamics and growth opportunities

Detailed segmentation analysis

Regional market performance and growth prospects

Analysis of market drivers, challenges, and trends

Future outlook and potential market developments

Competitive Landscape

The FDCA market is characterized by the presence of several key players focusing on innovation and strategic collaborations. Major companies are investing in R&D to enhance product quality and reduce production costs. The competitive landscape is expected to intensify with the entry of new players and increasing demand for sustainable materials.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=2014<ype=S

Recent Developments

Partnerships: Recent collaborations between major chemical companies to develop and commercialize FDCA-based products.

Technological Innovations: Advances in bio-based production methods reducing costs and improving yield.

Regulatory Approvals: New government regulations supporting the use of bio-based chemicals in various applications.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Nanotechnology Packaging Market Dynamics: Global Growth and Trends (2023-2032)

The global nanotechnology packaging market has witnessed steady growth in recent years and is expected to continue growing at a CAGR of 18.20% between 2023 and 2030. The market was valued at USD 15.1 billion in 2022 and is expected to reach USD 48.67 billion in 2030.

Nanotechnology Packaging Market is an emerging sector that leverages the unique properties of nanomaterials to enhance the performance and functionality of packaging solutions across various industries, including food and beverages, pharmaceuticals, electronics, and personal care products. Nanotechnology in packaging involves incorporating nanoparticles and nanostructures into traditional packaging materials to achieve superior barrier properties, improved strength and durability, and enhanced antimicrobial protection.

This innovative approach helps in extending the shelf life of perishable products, ensuring the safety and quality of packaged goods, and reducing food waste by preventing spoilage and contamination. The market is driven by increasing consumer demand for longer-lasting and safer products, stringent regulatory standards for food safety, and the need for sustainable and efficient packaging solutions. Additionally, the rise in e-commerce and global trade amplifies the necessity for robust and reliable packaging that can withstand long shipping times and varying environmental conditions.

Key advancements include nanocoatings that provide moisture and oxygen barriers, nanosensors that monitor freshness and detect contamination, and biodegradable nanocomposites that offer eco-friendly alternatives to traditional plastic packaging. Companies operating in this market are investing in research and development to explore new applications and improve the scalability of nanotechnology-based packaging. However, challenges such as high production costs, potential health risks associated with nanoparticles, and regulatory hurdles need to be addressed to fully realize the potential of nanotechnology in packaging. Overall, the Nanotechnology Packaging Market represents a transformative shift towards smarter, safer, and more sustainable packaging solutions, promising significant benefits for manufacturers, consumers, and the environment.

Nanotechnology packaging encompasses a variety of types, each designed to address specific challenges and enhance the functionality of packaging solutions. Here are the primary types of nanotechnology packaging:

1. Active Packaging:

Incorporates nanoparticles with antimicrobial properties (e.g., silver, zinc oxide) to inhibit the growth of bacteria, fungi, and other microorganisms, extending the shelf life of food products.

Uses nanoparticles to absorb oxygen from within the packaging, preventing oxidation and spoilage of oxygen-sensitive products like fresh meats and certain beverages.

Contains nanoparticles that absorb excess moisture, maintaining an optimal environment to prevent mold and degradation in food products.

2. Intelligent Packaging:

Embeds sensors that can detect and monitor the freshness, temperature, and integrity of the packaged contents, providing real-time information to consumers and retailers.

Utilizes nanomaterials to create indicators that change color based on the cumulative exposure to temperature, ensuring that temperature-sensitive products have been stored and transported correctly.

3. Barrier Packaging:

Incorporates nanoclays and other nanocomposites to create films with superior barrier properties against gases, moisture, and UV light, preserving the quality and extending the shelf life of packaged products.

Applies ultra-thin nanocoatings to packaging materials to improve their resistance to external elements such as oxygen, water vapor, and chemical contaminants.

4. Biodegradable Packaging:

Develops biodegradable packaging materials by incorporating natural nanofibers (e.g., cellulose nanocrystals) into biopolymers, providing an eco-friendly alternative to traditional plastics while maintaining strength and durability.

5. Structural Packaging:

Enhances the mechanical properties of packaging materials by embedding nanoparticles like carbon nanotubes or nanofibers, making them stronger and more resistant to damage during handling and transportation.

6. Smart Packaging:

Integrates nanotechnology to create packaging that can interact with external devices (e.g., smartphones) to provide additional information about the product, such as its origin, ingredients, and nutritional value.

Key Players:

Avery Dennison

PPG Industries

Klöckner Pentaplast

Sealed Air

Tetra Pak International

Asahi Kasei

Dow

Plasmatreat

Sciessent

Toyo Seikan Kaisha

Valentis Nanotech

Amcor Limited

Honeywell International

BASF SE

Chevron Phillips Chemical

Sonoco Products Company

Danaflex Nano LLC

More About Report- https://www.credenceresearch.com/report/nanotechnology-packaging-market

Nanotechnology Packaging Market is experiencing a surge of innovative trends that are transforming the packaging industry. One significant trend is the development of smart packaging solutions that incorporate nanosensors to monitor the freshness, temperature, and integrity of packaged goods in real-time, providing valuable data to consumers and supply chain managers. Another innovative trend is the use of antimicrobial nanoparticles, such as silver and zinc oxide, in packaging materials to extend the shelf life of perishable goods by preventing microbial growth. Sustainability is also at the forefront, with biodegradable nanocomposites gaining traction as eco-friendly alternatives to traditional plastics, reducing environmental impact while maintaining strength and durability.

Enhanced barrier properties are achieved through nanocoatings and nanocomposites, which offer superior protection against moisture, oxygen, and UV light, preserving the quality and safety of products. Additionally, the integration of nanotechnology in active packaging, including oxygen scavengers and moisture absorbers, helps maintain optimal conditions inside the package, further extending product shelf life. These innovative trends reflect the growing demand for smarter, safer, and more sustainable packaging solutions, driven by advancements in nanotechnology and changing consumer expectations. As the market continues to evolve, these innovations are expected to play a pivotal role in enhancing the functionality and efficiency of packaging across various industries.

Nanotechnology Packaging Market Challenges-

The Nanotechnology Packaging Market faces several challenges that need to be addressed to fully leverage its potential. One major challenge is the high cost of production. The development and incorporation of nanomaterials into packaging solutions can be expensive, making it difficult for small and medium-sized enterprises to adopt these technologies. This cost factor can also impact the final product price, potentially limiting market acceptance among cost-conscious consumers.

Another significant challenge is regulatory hurdles. The use of nanotechnology in packaging is subject to stringent regulatory scrutiny to ensure safety for consumers and the environment. Navigating these regulations can be complex and time-consuming, with different regions having varying standards and requirements. This regulatory landscape can slow down the commercialization and widespread adoption of nanotechnology-based packaging solutions.

Health and safety concerns associated with nanomaterials also pose a challenge. There is ongoing debate and research about the potential health risks of nanoparticles, particularly regarding their migration from packaging materials into food and beverages. Ensuring that nanotechnology applications are safe for consumers requires rigorous testing and validation, which can be resource-intensive.

The lack of awareness and understanding among consumers and manufacturers about the benefits and safety of nanotechnology packaging can hinder market growth. Educating stakeholders about the advantages and addressing misconceptions is crucial for wider acceptance.

Environmental impact is another challenge, as the disposal and degradation of nanomaterials may pose ecological risks. While there is a push for biodegradable nanocomposites, the overall environmental footprint of nanotechnology packaging solutions needs careful consideration and management.

Segmentation:

By Type

Active Packaging

Controlled Release Packaging

Intelligent Packaging

By Application

Food & Beverages

Pharmaceutical

Personal Care & Cosmetics

Others

Browse the full report – https://www.credenceresearch.com/report/nanotechnology-packaging-market

Browse Our Blog: https://www.linkedin.com/pulse/nanotechnology-packaging-market-insights-comprehensive-pydqf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Metalized Holographic Films: The Future of Packaging in Rajkot

Rajkot, an industrially vibrant city in Gujarat, is renowned for its manufacturing prowess, particularly in sectors such as textiles, electronics, and engineering. As the global market continues to evolve, so does the need for innovative and eye-catching packaging solutions. Enter Top metalized holographic film in Rajkot and Surat—an advanced technology that is revolutionizing the packaging industry in Rajkot. These films offer a perfect blend of functionality and aesthetic appeal, making them the future of packaging in the region.

What are Metalized Holographic Films?

Top metalized holographic film in Rajkot and Surat are thin, flexible sheets composed of a base film coated with a metallic layer and embossed with holographic patterns. This combination results in a dazzling visual effect that captures light and creates a three-dimensional appearance. Beyond their aesthetic appeal, these films possess numerous practical benefits that are transforming packaging across various industries.

Key Benefits of Metalized Holographic Films

1. Enhanced Visual Appeal

In a crowded marketplace, standing out is crucial. Top metalized holographic film in Rajkot and Surat provide an unparalleled visual appeal, making products more attractive to consumers. The shimmering, reflective surfaces of these films draw attention and create a premium look, which can significantly boost product visibility and sales.

2. Improved Brand Recognition

Packaging plays a pivotal role in brand recognition. By incorporating metalized holographic films, brands can create distinctive packaging that is memorable and easily recognizable. This helps in building a strong brand identity and fosters customer loyalty.

3. Anti-Counterfeiting Measures

Counterfeiting is a persistent issue that affects many industries, from pharmaceuticals to consumer electronics. Top metalized holographic film in Rajkot and Surat can incorporate complex holographic patterns and security features that are difficult to replicate, thus providing an effective deterrent against counterfeiting. This enhances product security and ensures that consumers receive genuine products.

4. Durability and Protection

These films are not just visually appealing but also provide excellent protection. The metallic layer adds strength and durability to the packaging, protecting products from environmental factors such as moisture, light, and oxygen. This extends the shelf life of products and maintains their quality.

5. Sustainability

Sustainability is a growing concern in the packaging industry. Metalized holographic films can be designed to be recyclable and environmentally friendly. By using sustainable materials and production processes, manufacturers in Rajkot can reduce their ecological footprint and meet consumer demands for green packaging solutions.

Applications of Metalized Holographic Films in Rajkot

1. Textile Industry

Rajkot's textile industry is well-known for its quality and innovation. Top metalized holographic film in Rajkot and Surat can be used in packaging high-end textile products, adding a touch of luxury and enhancing the overall presentation. This not only protects the products but also adds value to them.

2. Electronics and Engineering

The electronics and engineering sectors in Rajkot are rapidly growing. Packaging for electronic components and engineering products can benefit greatly from the protective and anti-counterfeiting properties of metalized holographic films. These films ensure that products are securely packaged and reach customers in pristine condition.

3. Food and Beverage

In the food and beverage industry, packaging is crucial for maintaining freshness and attracting consumers. Top metalized holographic film in Rajkot and Surat offer excellent barrier properties that keep food products fresh while their eye-catching designs can make products stand out on supermarket shelves.

Everest Holovisions: Pioneering Packaging Innovation in Rajkot

Everest Holovisions is a leader in the holography industry, providing cutting-edge solutions that are shaping the future of packaging in Rajkot. Their expertise in creating customized metalized holographic films helps businesses in various sectors enhance their packaging and product appeal.

Everest Holovisions works closely with clients to understand their specific needs and develop tailored holographic solutions. Whether it's adding security features to prevent counterfeiting or creating visually stunning packaging that attracts consumers, Everest Holovisions ensures that their clients stay ahead of the competition.

Conclusion

Top metalized holographic film in Rajkot and Surat represent the future of packaging in Rajkot. Their unique combination of visual appeal, protection, and security features make them an ideal choice for various industries. As Rajkot continues to grow as an industrial hub, the adoption of innovative packaging solutions like metalized holographic films will play a crucial role in maintaining the city’s competitive edge. With pioneers like Everest Holovisions leading the way, the future of packaging in Rajkot looks both bright and brilliantly holographic.

0 notes

Text

BOPP Bags: What They Are and Why Your Business Needs Them

Introduction

Welcome to our guide on BOPP bags, an essential packaging solution for businesses worldwide. In this comprehensive resource, we’ll delve into the benefits of BOPP bags, explore their manufacturing process, and highlight why your business needs them for optimal packaging. Join us as we uncover the key features and advantages of BOPP bags in today’s dynamic market landscape.

What are BOPP Bags?

BOPP, short for Biaxially Oriented Polypropylene, is a specialized packaging material renowned for its stability and versatility. BOPP bags are among the most prevalent packaging solutions due to their durability and reliability. These bags are manufactured by weaving and coating organic fabric during the production process, resulting in a robust packaging option.

In summary, BOPP bags offer a combination of stability, durability, and customization options, making them indispensable for packaging requirements across industries.

Manufacturing Process

Manufacturers employ a reverse printing technique to create these bags, wherein multi-colored films are inserted into cylinders. Subsequently, the bag is layered with woven materials, precisely cut, and sewn according to the customer’s specifications. For a more in-depth understanding of the manufacturing process, we encourage readers to refer to our detailed article [“The Intricacies of BOPP Bag Manufacturing: A Comprehensive Guide”] where we delve into each step with thorough explanations and visuals.

As a BOPP printed bag manufacturer, we prioritize providing diverse options to meet your packaging needs. Customers have the flexibility to choose from a wide range of colors to craft distinctive designs for their bags. The printing process occurs within a specialized machine known as an etched cylinder, ensuring precise application of brand logos and graphics onto the bags.

How Are They Diverse From Woven Bags?

BOPP bags and woven bags differ significantly in material composition, construction method, visual appeal, barrier properties, and cost considerations.

Material Composition: BOPP bags are made from Biaxially Oriented Polypropylene, while woven bags typically consist of woven polypropylene or other materials.

Construction Method: BOPP bags are produced through an extrusion process, whereas woven bags are created by weaving polypropylene tapes together.

Visual Appeal: BOPP bags offer superior printability and clarity, ideal for vibrant graphics and logos.

Barrier Properties: BOPP bags provide excellent moisture resistance compared to woven bags.

Cost Considerations: While BOPP bags may seem more expensive initially, their durability and printing capabilities often justify the investment.

BOPP bags and woven bags serve as viable packaging solutions, each with distinct advantages. Depending on specific needs, businesses can choose the option that best aligns with their objectives and budget constraints.

Choosing the Right BOPP Bags for Your Business

When it comes to selecting the perfect packaging solution for your business, Formosa Synthetics Pvt. Ltd. understands the importance of making informed choices. BOPP bags, known for their durability, versatility, and visual appeal, offer a range of benefits for various industries. However, choosing the right BOPP bags requires careful consideration of several factors to meet your specific packaging needs.

Product Specifications

Packaging Requirements

Branding Needs

Environmental Considerations

Budget Constraints

In conclusion, choosing the right BOPP bags for your business involves considering various factors such as product specifications, packaging requirements, branding needs, environmental considerations, and budget constraints. At Formosa Synthetics Pvt. Ltd., we offer a wide selection of high-quality BOPP bags tailored to meet your unique packaging needs. Contact us today to discover how our BOPP bags can enhance your packaging strategy and elevate your brand presence.

Conclusion

In conclusion, BOPP bags represent the epitome of modern packaging solutions, offering unmatched durability, versatility, and customization options essential for businesses across diverse sectors. At Formosa Synthetics Pvt. Ltd., we recognize the pivotal role packaging plays in shaping consumer perceptions and enhancing brand identity. With a meticulous focus on quality and innovation, our BOPP bags are meticulously crafted to meet the evolving needs of today’s dynamic market. Whether it’s safeguarding products during transportation or amplifying brand visibility through vibrant custom designs, our BOPP bags offer a winning combination of reliability and aesthetic appeal. Trust Formosa Synthetics Pvt. Ltd. to elevate your packaging strategy, ensuring your products stand out in the competitive marketplace while delivering exceptional value to your business.

Read More

#BOPPbags#packaging#manufacturing#business#branding#environment#FormosaSynthetics#productprotection#customization#marketpresence

0 notes

Text

Your Trusted Plastic Film Products Manufacturer and Customized Plastic Packaging Supplier

In today's competitive market, the role of effective and innovative packaging solutions cannot be overstated. Industries ranging from food and beverage to pharmaceuticals rely heavily on the quality and functionality of their packaging. This article delves into the services of a Plastic Film Products Manufacturer, and a Customized Plastic Packaging Supplier, highlighting how these entities play a crucial role in catering to diverse industry needs with precision and creativity.

The Critical Role of a Plastic Film Products Manufacturer:

A Plastic Film Products Manufacturer specializes in producing high-quality plastic films used in various packaging applications. These products are essential for ensuring product safety, enhancing shelf life, and providing cost-effective solutions for bulk packaging needs. Plastic films, such as polyethylene, polypropylene, and PVC, are chosen based on their strength, clarity, and barrier properties, which are critical in protecting and preserving products from environmental factors.

Manufacturers of plastic film products invest heavily in technology and research to develop films that are not only durable and lightweight but also environmentally friendly. By improving the recyclability and reducing the thickness of the plastic films without compromising quality, manufacturers can meet both consumer demand and environmental standards.

The Versatility of a Customized Plastic Packaging Supplier:

On the other hand, a Customized Plastic Packaging Supplier provides tailored packaging solutions that meet specific client requirements. This customization is vital for businesses looking to differentiate their products on the shelves or require unique packaging shapes and functionalities for special applications.

Customized suppliers work closely with clients to design packaging that aligns with branding efforts and product protection needs. They offer a range of services from graphic design and prototype development to final production, ensuring that the packaging not only looks appealing but performs exceptionally well under various conditions.

Choosing the Right Partner for Plastic Packaging Needs:

Selecting the right Plastic Film Products Manufacturer and Customized Plastic Packaging Supplier involves several considerations. Key factors include the supplier’s ability to innovate, their commitment to sustainability, the quality of materials used, and their capacity to provide scalable solutions. Additionally, the provider's reputation for reliability and customer service is paramount, as consistent product quality and timely delivery are crucial for maintaining supply chain efficiency.

Prospective clients should also evaluate the technological capabilities of the manufacturer or supplier, ensuring that they employ advanced processes that can adapt to the evolving demands of the packaging industry.

Whether you are a startup requiring distinctive product packaging or a large corporation looking for efficient and sustainable plastic film solutions, partnering with the right Plastic Film Products Manufacturer and Customized Plastic Packaging Supplier is critical.

Our website is the best source for additional information.

Polyethylene Encasement Polywrap

Poly Pipe Manufacturer in Colorado

0 notes

Text

BOPP Bags: Exploring Versatile Packaging Solutions by Singhal Industries

Singhal Industries, a trusted manufacturer of flexible packaging products, offers a comprehensive range of Bopp rice bag manufacturer designed to meet the diverse packaging needs of various industries. In this guide, we explore the applications, benefits, manufacturing processes, and environmental considerations associated with BOPP bags.

Applications of BOPP Bags

BOPP bags, also known as Biaxially Oriented Polypropylene bags, find extensive applications across industries due to their versatility, durability, and excellent barrier properties. These bags are commonly used for packaging a wide range of products, including snacks, confectionery, grains, pet food, pharmaceuticals, and textiles. The transparent and glossy appearance of BOPP bags enhances product visibility, making them ideal for retail packaging of consumer goods.

In addition to retail packaging, BOPP bags are also used for industrial packaging of bulk commodities such as fertilizers, chemicals, seeds, and animal feed. Their moisture resistance, tear resistance, and ability to withstand rough handling make them suitable for transporting and storing various products in challenging environments.

Benefits of BOPP Bags

Bopp woven bag offer numerous benefits that make them a preferred choice for packaging applications. One of the key advantages is their excellent barrier properties, which provide protection against moisture, oxygen, and light, preserving the freshness and quality of packaged goods. Additionally, BOPP bags are lightweight, strong, and puncture-resistant, ensuring the safe handling and transportation of products.

Another significant benefit of BOPP bags is their versatility in printing and customization. These bags can be printed with vibrant colors, high-resolution graphics, and product information to create eye-catching packaging that enhances brand visibility and consumer appeal. The ability to customize BOPP bags according to specific requirements allows businesses to differentiate their products and stand out in the market.

Manufacturing Processes of BOPP Bags

The manufacturing of Bopp rice bags involves several key processes, starting with the extrusion of BOPP film from polypropylene resin. The BOPP film is then treated with special coatings to improve its barrier properties and printability. The coated film is then laminated, cut, and heat-sealed to form bags of various sizes and configurations.

Singhal Industries utilizes advanced manufacturing technologies and quality control processes to produce high-quality BOPP bags that meet the stringent requirements of customers. Our BOPP bags are manufactured in a clean and controlled environment to ensure hygiene and safety standards are maintained throughout the production process.

Environmental Considerations

In recent years, there has been increasing emphasis on sustainability and environmental responsibility in packaging. BOPP bags offer several eco-friendly features that make them a sustainable packaging choice. These bags are recyclable, reusable, and lightweight, reducing the environmental impact of packaging waste. Additionally, BOPP bags can be manufactured using bio-based or recycled materials, further reducing their carbon footprint.

Conclusion

BOPP bags are versatile packaging solutions that offer numerous benefits for a wide range of industries. With their excellent barrier properties, strength, customization options, and sustainability features, BOPP bags manufactured by Singhal Industries are an ideal choice for businesses looking to optimize their packaging strategies and enhance their brand image.

FAQS

What are BOPP bags, and what are they commonly used for?

BOPP bags, or Biaxially Oriented Polypropylene bags, are packaging solutions made from polypropylene film that has been stretched in both the machine and transverse directions. They are commonly used for packaging a wide range of products, including snacks, confectionery, grains, pet food, pharmaceuticals, textiles, fertilizers, chemicals, seeds, and animal feed.

What are the key advantages of using BOPP bags compared to other packaging materials?

BOPP bags offer several advantages, including excellent barrier properties against moisture, oxygen, and light, ensuring the freshness and quality of packaged goods. They are lightweight, strong, and puncture-resistant, providing safe handling and transportation of products. Additionally, BOPP bags can be customized with vibrant colors and high-resolution graphics to enhance brand visibility and consumer appeal.

How are BOPP bags manufactured?

The manufacturing process of BOPP bags involves extruding polypropylene resin to form BOPP film, which is then treated with special coatings to improve barrier properties and printability. The coated film is laminated, cut, and heat-sealed to create bags of various sizes and configurations. Singhal Industries utilizes advanced manufacturing technologies and quality control processes to produce high-quality BOPP bags.

Are BOPP bags recyclable and environmentally friendly?

Yes, BOPP bags are recyclable and environmentally friendly. They can be recycled and reused, reducing the environmental impact of packaging waste. Additionally, BOPP bags can be manufactured using bio-based or recycled materials, further reducing their carbon footprint and contributing to sustainability efforts.

What factors should be considered when selecting BOPP bags for packaging needs?

When selecting BOPP bags for packaging needs, factors to consider include the type of product being packaged, desired barrier properties (moisture, oxygen, light), required strength and puncture resistance, printing and customization options, environmental considerations, and regulatory compliance. Singhal Industries offers a wide range of BOPP bags designed to meet the diverse packaging needs of various industries

0 notes

Text

#Japan High Barrier Packaging Films Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

1 note

·

View note

Text

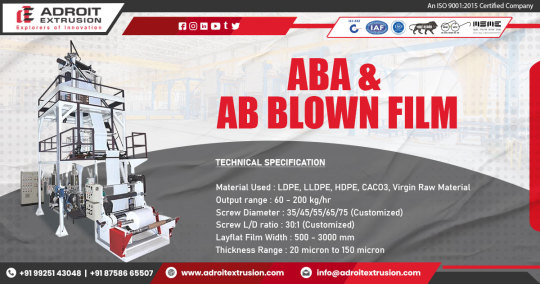

Exporter of Multilayer ABA Blown Film Machine in Egypt

Adroit Extrusion is a Manufacturer, Supplier, and Exporter of Multilayer ABA Blown Film Machine in Egypt.

Adroit Extrusion specializes in manufacturing Monolayer Blown Film, ABA, and AB Blown Film, as well as Multilayer Blown Film.

A-B-A type films, the outer and inner layers originate from the same polymer, supplied by one extruder, while the middle layer is of a different polymer, fed by a second extruder.

With the annual increase in the cost of virgin (raw) materials like HDPE/LDPE, many packaging film producers are turning to 3-layer (A-B-A) films to reduce costs and maintain competitiveness in the market.

Our machines ensure efficient and consistent production, resulting in films of exceptional clarity, strength, and barrier properties.

Our Multilayer ABA Blown Film Machine, equipped with state-of-the-art features, streamlines production and maximizes efficiency.

Each component, meticulously engineered from precision control systems to advanced cooling mechanisms, delivers consistent, high-quality films with minimal waste.

These films find applications in packaging perishable goods, protecting crops, extending shelf life, and even in construction for moisture barriers and insulation.

Adroit Extrusion is an Exporter of Multilayer ABA Blown Film Machine in Egypt, and various locations like Alexandria, Aswan, Assiut, Beheira, Beni Suef, Cairo, Dakahlia, Damietta, Fayoum, Gharbia, Giza, Ismailia, Kafr el-Sheikh, Matrouh, Minya, Menofia, New Valley, North Sinai, Port Said, Qualyubia, Qena, Red Sea, Al-Sharqia, Soha, South Sinai, Suez, Luxor.

For further details and inquiries, please feel free to contact us.

Read the full article

0 notes

Text

MDO-PE Film Market Forecast Growth by 2032

The Reports and Insights, a leading market research company, has recently releases report titled “MDO-PE Film Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global MDO-PE Film Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the MDO-PE Film Market?

The MDO-PE film market size reached US$ 764.2 million in 2023. Looking forward, Reports, Insights expects the market to reach US$ 1,165.4 million by 2032, exhibiting a growth rate (CAGR) of 4.8% during 2024-2032.

What are MDO-PE Film?

MDO-PE (Machine Direction Oriented Polyethylene) film is a polyethylene film that undergoes stretching in one direction through a machine direction orientation process. This stretching aligns the polymer chains within the film, enhancing its mechanical characteristics like strength, stiffness, and barrier properties. These films find widespread use in packaging, particularly in industries like food and beverages, where durability and high performance are essential. The orientation process enables the film to maintain or improve its performance while using less material, making it both cost-effective and environmentally friendly.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2217

What are the growth prospects and trends in the MDO-PE Film industry?

The MDO-PE (Machine Direction Oriented Polyethylene) film market growth is driven by various factors. The MDO-PE (machine direction-oriented polyethylene) film market is experiencing steady growth, thanks to its versatile applications in various industries like packaging, agriculture, and construction. Its superior strength, puncture resistance, and barrier properties make it an ideal choice for flexible packaging, particularly in food packaging, where durability and protection are critical. Furthermore, its printability enhances its appeal in packaging. In agriculture, MDO-PE films are used for greenhouse covers, mulching, and silage wrapping, offering protection against harsh environmental conditions and improving crop yields. In construction, these films serve as vapor barriers and for concrete curing, thanks to their excellent tensile strength and moisture resistance. As the demand for sustainable packaging solutions rises, MDO-PE films are gaining traction due to their recyclability and potential for reduced material usage, further propelling market growth. Hence, all these factors contribute to MDO-PE (Machine Direction Oriented Polyethylene) film market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Coveris Holdings Inc.

Klockner Pentaplast Group

Polythene UK Ltd.

Saes Coated Films S.P.A.

Lenzing Plastics Gmbh Co Kg

RKW Group

Nowofol

Camvac Limited

Others

View Full Report: https://www.reportsandinsights.com/report/MDO-PE Film-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes