#Fasteners Suppliers in India

Text

Fasten Your Success: Leading Fastener Suppliers in India

Explore a comprehensive directory of fastener suppliers in India, offering a vast array of products to meet diverse industry needs. From standard nuts and bolts to specialized components, discover reliable suppliers delivering quality and efficiency. Streamline your procurement process and access top-notch fastening solutions for your projects with ease.

#fastener suppliers#fasteners suppliers in india#best fasteners company in india#industrial fasteners suppliers india#industrial fasteners suppliers

0 notes

Text

India's Leading Manufacturer of SS Fasteners - Ananka Group

Ananka Group is a well-known Stainless Steel Fasteners Manufacturer in India, producing a wide variety of stainless steel fasteners in various weights, grades, and dimensions. Our extensive expertise in the sector spanning production, sourcing, and exporting allows us to provide a wide range of stainless steel fasteners used in instruments, heat exchangers, and other applications.

As a trustworthy SS Fasteners Supplier, We are experts in producing a broad variety of premium fasteners, including washers, threaded rods, bolts, nuts, screws, and studs. They guarantee goods that withstand corrosion and provide optimal performance by adhering to strict quality standards and striving for excellence.

We are a reliable Fasteners Manufacturer in India. Our products stand out for their superior quality, dependability, and durability. Additionally, we produce bespoke fastener items in accordance with client specifications.

For more details:

Product Source: Stainless Steel Fasteners Supplier in India

#Fasteners Manufacturer in India#Fasteners Manufacturers#Fasteners Suppliers in India#Fasteners Suppliers#SS Fasteners manufacturer#SS Fasteners manufacturer in India#Stainless Steel Fasteners Manufacturer in India

0 notes

Text

fasteners manufacturer | Roll Fast

Roll-Fast is a Fasteners Manufacturer bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4" to 4". We have 25 years of World Class Manufacturing experience in nuts and bolts we manufactures and exports ss fasteners manufacturers, automotive fastener, Industrial Fasteners and Fasteners for Oil & Gas from our plant in India.

0 notes

Text

Types of Flanges

A flange is a projecting flat rim, collar, or rib on a pipe, pump, or any other mechanical component used to connect and secure two parts together. Flanges are used in piping systems to allow for easy assembly and disassembly of the pipe components. There are various types of flanges available, each with a unique design and function.

Flanges play a critical role in piping systems, serving as the connectors and fasteners for pipes, valves, pumps, and other mechanical components. By providing a flat surface, flanges create a seal that prevents leaks and make it easier to assemble and disassemble the system. In this overview, we will examine the benefits of using flanges, their properties, and the materials used to manufacture them.

Here are some of the most common types of flanges:

Weld Neck Flange: This type of flange has a neck that extends from the flange base and is used to connect to a pipe. They are used for high-pressure applications and are popular in process piping, oil and gas, and chemical industries.

Slip-On Flange: This type of flange has a smooth bore and slips over the end of the pipe to which it is connected. They are used in low-pressure applications and are easy to install.

Blind Flange: This type of flange is used to close off the end of a piping system. It has no bore and is bolted to the end of a pipe to prevent the flow of fluid.

Lap Joint Flange: This type of flange has a small ridge that fits into a corresponding groove on the pipe. They are used in low-pressure applications and are easy to install and disassemble.

Threaded Flange: This type of flange has threads on the inside of the flange, allowing it to be screwed onto the end of a pipe. They are used in low-pressure applications and are commonly used in small-diameter piping systems.

Socket Weld Flange: This type of flange has a socket that fits over the end of a pipe and is then fillet welded to the pipe. They are used in high-pressure applications and are commonly used in process piping and power generation.

Spectacle Blind Flange: This type of flange consists of two pieces, one that is a solid disc and the other a ring. They are used to isolate a section of the pipe for maintenance or to redirect the flow of fluid.

These are some of the most common types of flanges used in the piping industry. The type of flange used in a piping system will depend on the pressure, temperature, and fluid being transported, as well as the application requirements.

Advantages of Flanges:

Ease of assembly and disassembly: Flanges make it easier to assemble and disassemble the piping components. This is especially important in maintenance and repair work.

Improved Leak Tightness: Flanges provide a leak-tight seal between two components, making them suitable for high-pressure and high-temperature applications.

Cost-effective: Flanges are a cost-effective solution for connecting pipes and other mechanical components as they are easy to install and do not require any special tools.

Versatility: Flanges are available in a variety of materials and types to suit different applications and pressure ratings.

Properties of Flanges:

Pressure Rating: The pressure rating of a flange refers to the maximum pressure it can safely withstand without leaking. Flanges are available in various pressure ratings, from 150 PSI to 4500 PSI.

Temperature Rating: The temperature rating of a flange refers to the maximum temperature it can safely withstand without degrading. Flanges are available in temperature ratings from -450°F to +1000°F.

Corrosion Resistance: The material used to make a flange must be corrosion-resistant, as the flange will be exposed to the fluid being transported in the piping system.

Dimensional Accuracy: The dimensional accuracy of a flange is important for a leak-tight seal. Flanges must meet specific dimensional standards, such as ANSI B16.5, to ensure proper fit and seal.

Materials used for Flanges:

Carbon Steel: Carbon steel is a popular material for flanges, as it is strong, durable, and corrosion-resistant.

Stainless Steel: Stainless steel is another popular material for flanges, as it is corrosion-resistant and has a high resistance to temperature and pressure.

Alloy Steel: Alloy steel is a combination of carbon steel and other alloys, such as chromium or nickel. It is used for high-temperature and high-pressure applications.

Brass: Brass is a soft metal that is commonly used for low-pressure applications, as it is easy to machine and has good corrosion resistance.

Bronze: Bronze is a copper-based alloy that is commonly used for marine applications, as it is resistant to corrosion from salt water.

These are the main advantages, properties, and materials used for flanges. The type of flange used in a piping system will depend on the pressure, temperature, fluid being transported, and the application requirements.

SPP Alloys is a leading manufacturer and supplier of flanges in India. They offer a wide range of flanges that are manufactured to meet the highest standards of quality and performance. These flanges are supplied all over India and are used in a variety of applications, including piping systems, valves, pumps, and other mechanical components.

Flanges are an essential component in piping systems, as they provide a flat surface to make a leak-proof joint and simplify the assembly and disassembly of components. SPP Alloys offers flanges with various advantages, properties, and materials, including:

Ease of assembly and disassembly

Improved leak tightness

Cost-effectiveness

Versatility

High pressure and temperature ratings

Corrosion resistance

Dimensional accuracy

SPP Alloys is committed to providing high-quality flanges that meet the specific needs of their customers. Their flanges are manufactured to meet the dimensional standards of ANSI B16.5, ensuring proper fit and seal for a leak-tight connection.

In conclusion, SPP Alloys is a reliable and trustworthy supplier of flanges in India, offering a wide range of flanges for various applications and pressure ratings. Their flanges are manufactured to meet the highest standards of quality and performance and are supplied all over India.

#Fasteners Manufacturer And Suppliers in India#Fasteners Manufacturer And Suppliers#Fasteners Manufacturer And Suppliers in UAE#Fasteners Manufacturer in India#Fasteners Suppliers in India

0 notes

Text

Inconel 625 Fasteners Exporters In India

INTRODUCTION:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2008. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

DESCRIPTION:-

Among manufacturers, suppliers, and exporters of inconel 625 fasteners, Shasan Piping Solution is the most reputable. Among the conventional-grade fasteners, these are the workhorse of the Inconel family. We keep all of the cutting-edge quality fasteners in stock in a variety of standards and non-standard materials. We establish ourselves as a reliable, conscientious Manufacturer of clear explanation fasteners for a vast array of organizing and current work applications. Our unit has an endless supply of current fasteners in various subtleties, tasks, and unique viewpoints. We perform creation with the aid of sophisticated machinery and other items. Everyone completes the process of gathering by big standards. Our workforce executes creation according to the most recent plan codes.

It contains chromium, molybdenum, and nickel. It is incredibly strong at temperatures as high as 1500 °F. Its development is generally less than that of other strong strategy-reinforced composites at higher temperatures. The remarkable oxidation resistance of these fasteners extends to 980 °C. Although these fasteners provide excellent protection against wet usage, stream-grade fasteners cannot be used. These fasteners have incredible welding and shaping capabilities. These are shipped or heated worked, and the temperature is kept between 1800 °F and 2150 °F. Hot working development is carried out in the lower temperature range in order to regulate both improvement and grain size. It can adapt more readily; It is quickly framed by interesting work duties in this way. Because of how quickly these fasteners set up, variable supporting medications are ridiculous for intricate component framing. Parts that have been hot or cold worked should be built up and quickly chilled in order to restore the optimal property equilibrium. Both manual and modified welding techniques are used to weld these fasteners. The plant is provided with these fasteners in its Stainless state. For optimal qualities, this composite is frequently water-smothered or rapidly cooled to district thickness. Heat medicine techniques are carried out based on the final application's basic course of action. Certain plant solidifying medications work by causing part of the second-stage mixture to precipitate.

SPECIFICATION:-

Standard : DIN, ASTM, BS and all International Standards

Size : 3 mm to 200 mm

Bolt / Screw Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Nuts Size : M3 - M56 | 3/6" to 2" | Custom Sizes

Washers Size : M1 - M64 | #4 to 3" | Custom Sizes

Length : M02 to M33

Types : Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-Bolts, J Bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, Structural Bolts.

BENEFITS:-

High Temperature Resistance: Inconel 625 demonstrates exceptional resistance to high temperatures, maintaining its mechanical properties at temperatures up to 2000°F (1093°C). This property makes it suitable for use in applications such as aerospace, marine engineering, and chemical processing where elevated temperatures are encountered.

Corrosion Resistance: Inconel 625 provides outstanding resistance to corrosion in harsh environments, including seawater, acidic solutions, and chloride-containing media. This corrosion resistance makes it ideal for marine applications, chemical processing equipment, and oil and gas industry components.

Excellent Strength and Toughness: Inconel 625 offers high tensile strength and toughness, providing reliability and durability in demanding conditions. It can withstand high mechanical loads and impacts without compromising its integrity.

Fatigue Resistance: Inconel 625 exhibits excellent fatigue resistance, making it suitable for applications subjected to cyclic loading and high-stress conditions, such as turbine blades, springs, and fasteners.

Weldability: Inconel 625 can be readily welded using various welding techniques, allowing for easy fabrication and repair of components without sacrificing performance.

Creep Resistance: Inconel 625 maintains its structural integrity even under prolonged exposure to high temperatures, providing resistance to creep deformation in applications such as high-temperature bolting and turbine components.

CONCLUSION:-

Inconel 625 is a highly versatile and reliable alloy known for its exceptional combination of high temperature resistance, corrosion resistance, and mechanical properties. Its ability to withstand extreme environments makes it indispensable in industries such as aerospace, marine engineering, chemical processing, and oil and gas exploration.

CONTACT US:-

PHONE: +91-88797-09191/ +91-22-6651 8642

E-MAIL:- [email protected]

#Inconel 625 Fasteners Manufacturers In India#Inconel 625 Fasteners Suppliers In India#Inconel 625 Fasteners Stockists In India#Inconel 625 Fasteners Exporters In India

0 notes

Text

Choosing the Right Stainless Steel Fastener for Extreme Temperature Conditions

Ananka Group is one of the Top SS Fasteners Manufacturers in India, In industrial areas where high temperatures are common, choosing the right fastener materials becomes crucial. Stainless steel, which is recognized for its corrosion resistance and durability, is often the preferred material. However, not all stainless steel alloys are created equally, particularly in high-temperature applications. In this post, we'll go over the most significant factors and techniques for selecting the finest stainless steel fastener for high-temperature applications.

Understand the Operating Conditions:

Before selecting stainless steel fasteners High-temperature applications require a thorough grasp of the operating conditions. The maximum and variable temperatures, exposure to corrosive chemicals, and probable thermal cycling should all be carefully considered. This data will serve as the basis for selecting a stainless steel alloy that can handle the unique difficulties of the climate. Additionally, we are the Bolt Supplier in India

Select the Right Stainless Steel Alloy:

Different stainless steel alloys have varied degrees of resistance to high temperatures and corrosion. Some of the most often utilised alloys for high-temperature applications are:

Austenitic Stainless Steels (e.g., 304, 316):

These alloys are noted for their strong corrosion resistance and are appropriate for moderately high-temperature situations.

Ferritic Stainless Steels (e.g., 430, 446):

Ferritic alloys have strong oxidation resistance and are ideal for applications that need lower temperatures.

Martensitic Stainless Steels:

These alloys are heat-treatable and have good strength at high temperatures, making them ideal for specialised applications.

Nickel-Based Alloys (e.g., Inconel, Hastelloy):

These alloys are highly resistant to high-temperature corrosion and are often chosen for extreme conditions.

Consider Mechanical Properties:

Aside from corrosion resistance, the mechanical qualities of the selected stainless steel alloy are critical. Tensile strength, yield strength, and elongation at high temperatures are all important factors to consider. A comprehensive grasp of the mechanical qualities assures that the chosen Fastener will perform consistently under stress at high temperatures.

Evaluate Oxidation Resistance:

High temperatures frequently cause oxidation, which can affect the integrity of stainless steel fasteners. Choosing an alloy with high oxidation resistance is critical to avoiding the production of harmful oxide layers. Alloys combining chromium, aluminium, and silicon have superior oxidation resistance and can endure extended exposure to high temperatures. Also, We manufacture eye bolts, U-bolts, and Hex nuts

Thermal Expansion and Contraction:

Consider the coefficient of thermal expansion of the selected stainless steel alloy. In applications with frequent temperature changes, thermal expansion and contraction can impact the fastener's performance. Matching the thermal expansion characteristics of the fastener material to the surrounding components helps prevent issues such as loosening or stress fractures over time.

Selecting the right SS Fasteners for high-temperature applications involves a comprehensive analysis of operating conditions, material properties, and environmental factors. Engineers and industry experts may make educated judgments to enhance the lifetime and dependability of fasteners in harsh temperature settings by first knowing the application's particular needs. Always speak with a materials expert or supplier to select the best stainless steel alloy for your specific high-temperature application.

For more details:

Also Visit: Fasteners Supplier in India

#SS Fasteners#Hex nuts#U-bolts#eye bolts#Bolt Supplier in India#Stainless Steel Fasteners#SS Fasteners Manufacturers in India

0 notes

Text

Incoloy® Alloy 800H Fully Threaded Stud Bolts, Incoloy 800H Hex Head Screws, Alloy 800H Heavy Hex Bolts, 800H Incoloy Industrial Fasteners Distributors, 800H Incoloy Half Threaded Stud Bolts, Incoloy 800H Square Nuts, Alloy 800H Fasteners at Best Price, Incoloy DIN 1.4958 / 1.4876 Spring Washers Manufacturer in India.

#Incoloy 800H Fasteners Manufacturers#Incoloy 800H Fasteners Suppliers#Incoloy 800H Fasteners Stockists#Incoloy 800H Fasteners Exporters#Incoloy 800H Fasteners Manufacturers in India

0 notes

Text

Buy high quality Incoloy Inconel 600 Fasteners, Inconel UNS N0660Fastener, DIN 2.4816 Fasteners, Inconel 600 Hex Cap Screws, 600 Inconel Hex Bolts, ASTM B166 Inconel 600 Stud Bolt Suppliers in India

#Inconel 600 Fasteners Supplier India#ASTM B166 Inconel 600 Fasteners Manufacturer#ASTM F467 Inconel 600 Nut Exporter#UNS N05500 Bolt stockist

0 notes

Text

High Quality Industrial Fastener Suppliers in India

Discover premier industrial fastener suppliers in India with Fastener World India. Our platform showcases trusted manufacturers offering a wide range of high-quality fastener products. Connect with reliable suppliers to meet your industrial fastening needs efficiently. Explore our directory today for top-notch solutions.

0 notes

Text

#Inconel 718 Fasteners Manufacturers In India#Inconel 718 Fasteners Suppliers In India#Inconel 718 Fasteners Stockists In India#Inconel 718 Fasteners Exporters In India

0 notes

Text

fasteners suppliers in india | Roll Fast

Roll-Fast is a fasteners suppliers in india bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4" to 4". We have 25 years of World Class Manufacturing experience in nuts and bolts we manufactures and exports ss fasteners manufacturers, automotive fastener, Industrial Fasteners and Fasteners for Oil & Gas from our plant in India.

0 notes

Text

https://sppalloys.com/fasteners/

Fasteners Manufacturer And Suppliers in India

SPP Metals and Alloys is a well-known company for fastener manufacturers in India. We hold a large market for fastener exporters in India and other countries. Our nuts, bolts, and fasteners are exported to several countries and India. We provide the highest quality fasteners for significant long-lasting, and strongly uphold.

#Fasteners Manufacturer And Suppliers in India#Fasteners Manufacturer And Suppliers#Fasteners Manufacturer And Suppliers in UAE#Fasteners Manufacturer in India#Fasteners Suppliers in India

0 notes

Text

How to Find the Best Fastener Suppliers in India

In addition to choosing the right manufacturer, finding a reliable fastener supplier is equally important. Here are some tips to help you find the best fastener suppliers in India

Research supplier networks - Look for the best fastener suppliers who have a wide network of manufacturers. Suppliers with a diverse supplier base will be able to provide you with a variety of fasteners to meet your specific requirements.

Consider reputation and reliability - Reputation and reliability are key factors to consider when choosing a fastener supplier. Look for suppliers who have a positive reputation in the industry and a track record of delivering products on time.

Evaluate inventory management capabilities - Assess the supplier's inventory management capabilities. Suppliers who have efficient inventory management systems will be able to ensure a steady supply of fasteners, preventing any delays in your production processes.

Check delivery timelines and logistics - Timely delivery is crucial in the manufacturing industry. Ensure that the supplier has a reliable logistics network and can deliver the fasteners within the agreed timelines. Prompt delivery will help you maintain your production schedules without any interruptions.

Assess customer support - Consider the level of customer support provided by the supplier. Look for suppliers who have a dedicated customer support team that can address any queries or concerns you may have regarding their products or services.

Compare pricing - While pricing should not be the sole determining factor, it's important to compare the prices offered by different suppliers. Look for suppliers who offer competitive pricing without compromising on the quality of the fasteners.

Best Way to Find Suppliers

Once you have identified potential fastener manufacturers, the next step is to find reliable suppliers. Suppliers play a crucial role in ensuring timely delivery and maintaining a steady supply chain. Here are some tips to help you find the best suppliers for your fastener requirements:

Supplier Directories

Supplier directories are a useful resource for finding reliable suppliers. These directories provide information about suppliers' products, capabilities, and contact details. Some popular supplier directories in India include IndiaMART, TradeIndia, and ExportersIndia. Use relevant keywords to search for fastener suppliers and explore the listings to find suppliers that meet your specific requirements.

Supplier Reviews and Ratings

Customer reviews and ratings can provide valuable insights into the reliability and performance of suppliers. Look for reviews on online platforms, forums, and industry-specific websites. Pay attention to feedback regarding the quality of products, delivery times, and customer service. This information will help you assess the credibility and reputation of potential suppliers.

Supplier References and Recommendations

Seeking references and recommendations from industry contacts can be an effective way to find reliable suppliers. Reach out to manufacturers, industry associations, or colleagues who have experience in the fastener industry. They may be able to recommend trusted suppliers or provide insights into their experiences with different suppliers. Personal recommendations can often provide a higher level of confidence in the reliability of suppliers.

Finding the right suppliers is crucial for maintaining a smooth supply chain and ensuring timely delivery of fasteners. By conducting thorough research, considering customer reviews, and seeking recommendations, you can find reliable suppliers that meet your specific requirements.

By following these tips, you can find the best fastener suppliers in India who can ensure a steady supply of high-quality fasteners for your manufacturing needs.

In conclusion, fasteners are an integral part of the manufacturing process, and choosing the right manufacturers and suppliers is crucial for ensuring product integrity and safety. India has several top-notch fastener manufacturers and suppliers who are known for their commitment to quality, innovation, and customer satisfaction. By conducting thorough research and evaluating various factors, you can find the best fastener manufacturers and suppliers in India to meet your specific requirements.

0 notes

Text

Premium-Quality Screw Manufacturer in India - Ananka Group

Ananka Group is the best leading high-quality Screw Manufacturer in India. We offer a huge range of screws in stock and ready for delivery and export. As the largest manufacturer of bigger diameter screws and bolts in high tensile and stainless steel grades, as well as fasteners, we provide key contractors and consultants in India working on infrastructure, wind, electricity, and renewable energy projects.

We take pride in being more than just a screw manufacturer. By providing our clients with solid fastening solutions that encourage efficiency and innovation, we become partners in their success. We are well-positioned to continue setting the standard in India's fastener industry for many years to come due to our exceptional heritage, devotion to quality, and excitement for innovation.

Since we are an Indian screw manufacturers, We also take orders depending on our clients' specifications. Also, we are the best Fasteners Manufacturer in India. We provide fastener grades that meet all international and national requirements. Our clients may select from the best stainless steel fasteners in India.

For more details:

Product Source: Screw Supplier in India

#Screw Manufacturer in India#Screw Manufacturer#Screw Supplier in India#Screw#Fastener Manufacturer India#Fastener Supplier#Fastener

0 notes

Text

What Is the Manufacturing Method Of The Washer?

Washers are flat and small metal discs that have holes in their center. These accessories are essential for distributing load from the fasteners like bolts, screws, or threaded fasteners.

These fastening accessories find applications in manufacturing, construction, and more. These accessories provide better fastening. Washers available at reputed fastener manufacturers in India like Fasteners & Fixtures LLP utilize advanced manufacturing

processes, guaranteeing high quality. The following article explains washer manufacturing and the processes involved.

Washer: Definition

A washer is a perforated disc or plate made of metals of different types. These accessories are placed between the fastener surfaces like nuts and bolts. The washers are subject to rotary

force. One more example can be screw and bolt fitting. A washer is perfect to close the gap between the threaded fasteners.

Metal washer: Manufacturing processes

Washers undergo multiple manufacturing processes like stamping, cutting, machining, and more. They utilize metal sheets for manufacturing and have a hole punched in the middle. Washers are available in flat, spring, or lock washers. Each fastener provides features like lock ability, spring tension, or load distribution.

Washers utilize manufacturing techniques like stamping, waterjet cutting, machining, laser cutting, etc. Stamping is one of the common manufacturing processes of washers. It involves

passing a flat metal sheet in a stamping press, which can cut and shape the washers per their design requirements. Another process in washer manufacturing is machining, which requires a lathe machine or milling machine for material removal. The raw material in the form of a metal rod or bar is fitted in the lathe and undergoes material removal, offering it the desired shape and dimension. Washers can also be made using laser or waterjet cutting. These are advanced

manufacturing techniques utilizing laser beams or water pressure for cutting the metal in the desired shape of the washers.

Steps in washer manufacturing

Washers are available in multiple material options, like copper, aluminum, stainless steel, and carbon steel. The choice of the washer is dependent on its application. For instance, stamping is the top choice in washer manufacturing. This process utilizes a die made for designing washers and their thickness can be determined with gauge. Following are the steps involved in washer manufacturing using mental stamping:

Washer manufacturing using stamping requires a power press. It also involves using a

die that gives the washer its shape during stamping.

A metal disc is placed in the press, which undergoes punching in the die. The bolster

plate undergoes punching, giving the desirable shape using the downward motion from the ram, producing washers in desirable shapes, also called blanks.

The die used on these metals is a custom washer die for manufacturing a washer from a metal sheet. One sheet of metal can produce many washers as they are really small.

After punching the washers from the metal sheet, a gauge is utilized to determine the washer thickness, ultimately deciding its spacing.

Metals for manufacturing washers Washers can be manufactured from stainless steel, copper, brass, aluminum, and carbon steel.

Stainless steel is the top choice for manufacturing stainless steel 304 fasteners like washers as the material has high durability and strength. S.S. washers offer properties like corrosion resistance, making them perfect for corrosive environments. Copper and brass washers are another washer type suitable for applications like electrical and plumbing as they have high conductivity. Aluminum washers on the other hand have low weight and find applications requiring low system weight. The washer material choice is dependent on the desirable properties and application.

Final thoughts

Washers offer an extensive range of benefits. They are strong and durable and help distribute the load on fasteners. These fasteners also allow reuse, making them sustainable. If you are looking for a reputed fastener manufacturer for sourcing washers for your project, consult experts at the leading fastener manufacturer Fasteners and Fixtures LLP.

0 notes

Text

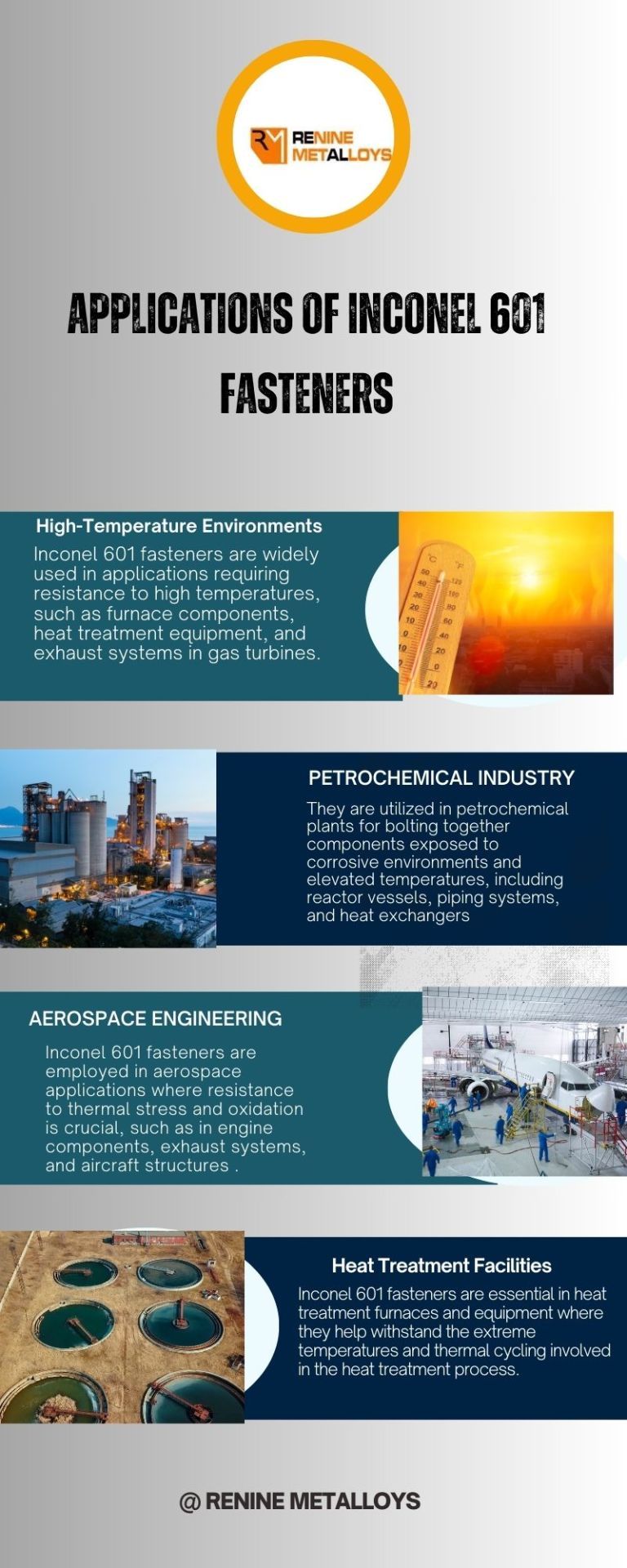

Buy Inconel 601 Fasteners Suppliers, Alloy 601, Werkstoff Nr 2.4851 Bolt, ASTM B166 Inconel 601 Nut, UNS N06601 Bolts, Nickel Alloy 601 Hex Bolt, DIN 2.4851 Stud Bolts, Check inconel 601 price.

#Inconel 600 Fasteners Supplier India#ASTM B166 Inconel 600 Fasteners Manufacturer#ASTM F467 Inconel 600 Nut Exporter#UNS N05500 Bolt stockist

0 notes