#Expanded Polystyrene market Trends

Text

Expanded Polystyrene Market to Flourish with an Impressive CAGR during 2022-2032 | Alpek, Evonik Industries AG, LG Corp

Expanded Polystyrene Market to Flourish with an Impressive CAGR during 2022-2032 | Alpek, Evonik Industries AG, LG Corp

A recent market research report added to repository of insightSLICE is an in-depth analysis of Global Expanded Polystyrene Industry. On the basis of historic growth analysis and current scenario of Expanded Polystyrene industry place, the report commits to offer actionable insights for the industry participants. Authenticated data presented in report is based on exhaustive primary and secondary…

View On WordPress

#Expanded Polystyrene#Expanded Polystyrene manufacturing companies#Expanded Polystyrene market Trends

0 notes

Text

2032, Expanded Polystyrene (EPS) Recycling Market Growth and Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Expanded Polystyrene (EPS) Recycling Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Expanded Polystyrene (EPS) Recycling Market Size share, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Expanded Polystyrene (EPS) Recycling Market?

The expanded polystyrene (EPS) recycling market size reached US$ 19.7 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 36.5 Billion by 2032, exhibiting a growth rate (CAGR) of 6.7% during 2024-2032.

What are Expanded Polystyrene (EPS) Recycling?

EPS recycling is the practice of collecting, sorting, and processing EPS foam products to reclaim the material for reuse. EPS, also known as Styrofoam, is a lightweight and rigid plastic material utilized in packaging and insulation. The recycling process involves compressing the foam to reduce its size and then melting it down to create dense blocks or pellets suitable for manufacturing new products. EPS recycling contributes to environmental sustainability by diverting EPS waste from landfills and reducing the demand for new plastic production.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1775

What are the growth prospects and trends in the Expanded Polystyrene (EPS) Recycling industry?

The expanded polystyrene (EPS) recycling market growth is driven by various factors. The market for recycling expanded polystyrene (EPS) is expanding, fueled by growing environmental consciousness and regulatory measures promoting recycling practices. EPS, widely utilized in packaging and construction, significantly contributes to plastic waste. Recycling EPS involves collecting, cleaning, and processing it into reusable material for diverse applications. Market growth is propelled by increasing demand for recycled EPS in the construction and packaging sectors, driven by sustainability objectives and economic advantages. Moreover, technological advancements in EPS recycling and government support for recycling initiatives are further driving market growth. Hence, all these factors contribute to expanded polystyrene (EPS) recycling market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By EPS Waste Type:

Post-consumer EPS waste

Pre-consumer EPS waste

By EPS Recycling Process:

Mechanical recycling

Chemical recycling

Other recycling processes

By End-Use Industry:

Packaging

Construction

Electrical and Electronics

Automotive

Others

By Recycled EPS Product:

Packaging materials

Insulation boards

Molded products

Composite materials

Others

By Source of Collection:

Municipal recycling programs

Industrial and commercial collection

Retail collection

Other

By Recycling Equipment:

Shredders

Granulators

Densifiers

Extruders

Others

By Application:

Packaging

Building and construction

Insulation

Consumer goods

Others

By Distribution Channel:

Direct sales

Distributor sales

E-commerce

By Market Type:

Business to Business (B2B)

Business to Consumer (B2C)

Segmentation By Region:

North America:

United States

Canad

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Dart Container Corporation

NOVA Chemicals Corporation

ACH Foam Technologies, LLC

Ravago Recycling Group

Styro Recycle LLC

Total, Petrochemicals & Refining USA, Inc.

Alpek Polyester

Repsol S.A.

Vanden Recycling

Plasti-Fab Ltd.

NexKemia Petrochemicals Inc.

EPS Industry Alliance

Vita Group

FPC Foam Plastics Corporation

Winco Foam Industries Limited

View Full Report: https://www.reportsandinsights.com/report/Expanded Polystyrene (EPS) Recycling-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Expanded Polystyrene (EPS) Recycling Market share#Expanded Polystyrene (EPS) Recycling Market size#Expanded Polystyrene (EPS) Recycling Market trends

0 notes

Text

#Expanded Polystyrene (EPS) Market#Expanded Polystyrene (EPS) Market size#Expanded Polystyrene (EPS) Market share#Expanded Polystyrene (EPS) Market trends#Expanded Polystyrene (EPS) Market analysis#Expanded Polystyrene (EPS) Market forecast

0 notes

Text

Biofoam Packaging Market Research Report | Growth, Trends and Advancements | 2024 - 2031

The "Biofoam Packaging Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Biofoam Packaging Market?

Market Analysis and Size

Biofoams comprises starches and biopolyesters because these are adequate replacements to expanded polystyrene. Polylactic acids (PLAs) compounds are a common type of the basis of these biofoams since they provide an alternative for polyolefin-based foams which are normally used in pharmaceutical products, white goods products, furniture, food & beverage boxes, crockery, automotive parts and short life-time disposable packaging industries because of their biodegradable and bio-based properties.

Data Bridge Market Research analyses that the biofoam packaging market was valued at USD XX billion in 2021 and is expected to reach USD XX billion by 2029, registering a CAGR of XX% during the forecast period of 2022 to 2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, patent analysis and technological advancements.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Biofoam Packaging market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Biofoam Packaging Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-biofoam-packaging-market

Which are the driving factors of the Biofoam Packaging market?

The driving factors of the Biofoam Packaging market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Biofoam Packaging across various industries further propel market expansion.

Biofoam Packaging Market - Competitive and Segmentation Analysis:

Global Biofoam packaging Market, By Product (Rigid Packaging, Flexible Packaging), Material (Vegetable Oil and Fat, Corn Starch, Sugarcane, Others), Application (Electronic Product, Crockery, White Good Products, Delicate Items, Food and Beverage Boxes, Medical Equipment, Furniture, Other) – Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Biofoam Packaging market?

Some of the major players operating in the biofoam packaging market are:

BEWi (Norway)

Recticel Insulation (U.K.)

Chevron Phillips Chemical Company LLC. (U.S.)

Eco-Global Manufacturing (U.S.)

Sealed Air (U.S.)

HWA CHING INDUSTRY (China)

BASF SE (Germany)

Bayer Material Science (U.S.)

Dow (U.S.)

Huntsman International L.L.C (U.S.)

Rogers Corporation (U.S.)

Ube corporation (Japan)

Recticel (Belgium)

Zotefoams Plc (U.K.)

The Woodbridge (Canada)

Sekisui Alveo (Switzerland)

Indoac corporation (Japan)

covestro AG (Germany)

Short Description About Biofoam Packaging Market:

The Global Biofoam Packaging market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Biofoam Packaging. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Biofoam Packaging Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Biofoam Packaging in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Biofoam Packaging Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Biofoam Packaging market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Biofoam Packaging Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Biofoam Packaging market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Biofoam Packaging?

What are the upcoming industry applications and trends for Biofoam Packaging market?

What Are Projections of Global Biofoam Packaging Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Biofoam Packaging?

What are the raw materials used for Biofoam Packaging manufacturing?

How big is the opportunity for the Biofoam Packaging market?

How will the increasing adoption of Biofoam Packaging for mining impact the growth rate of the overall market?

How much is the global Biofoam Packaging market worth? What was the value of the market In 2020?

Who are the major players operating in the Biofoam Packaging market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Biofoam Packaging Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-biofoam-packaging-market

Detailed TOC of Global Biofoam Packaging Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Biofoam Packaging Market By Type

Biofoam Packaging Market By Function

Biofoam Packaging Market By Material

Biofoam Packaging Market By End User

Biofoam Packaging Market By Region

Biofoam Packaging Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-biofoam-packaging-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

#Biofoam Packaging Market#Biofoam Packaging Market Size#Biofoam Packaging Market Share#Biofoam Packaging Market Trends#Biofoam Packaging Market Growth#Biofoam Packaging Market Analysis#Biofoam Packaging Market Scope & Opportunity#Biofoam Packaging Market Challenges#Biofoam Packaging Market Dynamics & Opportunities

0 notes

Text

Plastic Compounding Market looks to expand its size in Overseas Market

A Latest intelligence report published by Market Research Forecast with title "Global Plastic Compounding Market Outlook to 2032. A detailed study accumulated to offer Latest insights about acute features of the Plastic Compounding market. This report provides a detailed overview of key factors in the Global Plastic Compounding Market and factors such as driver, restraint, past and current trends, regulatory scenarios and technology development.

Definition:

The Plastic Compounding Marketsize was valued at USD 52.74 USD million in 2023 and is projected to reach USD 74.71 USD million by 2032, exhibiting a CAGR of 5.1 % during the forecast period.

Major Players in This Report Include:

Asahi Kasei Corporation, BASF SE",LyondellBasell,SABIC,"Solvay S.A., Celanese Corporation, Covestro AG",DuPont,"LANXESS A.G., Kingfa SCI. & TECH. CO., LTD., Adell Plastics",PolyVisions,"Foster Corporation, RTP Company, KURARAY CO., LTD., MRC Polymers, Kraton Corporation, Aurora Plastics LLC, Other Key Players

Free Sample Report + All Related Graphs & Charts @ : https://marketresearchforecast.com/report/plastic-compounding-market-1636/sample-report

Global Plastic Compounding the manufacturing cost structure analysis of the market is based on the core chain structure, engineering process, raw materials and suppliers. The manufacturing plant has been developed for market needs and new technology development. In addition, Global Plastic Compounding Market attractiveness according to country, end-user, and other measures is also provided, permitting the reader to gauge the most useful or commercial areas for investments. The study also provides special chapter designed (qualitative) to highlights issues faced by industry players in their production cycle and supply chain.

The Global Plastic Compounding Market segments and Market Data Break Down are

illuminated below:

Type: Polyethylene, Polypropylene, Poly Vinyl Chloride, Polystyrene, Polyethylene, Polybutylene Terephthalate, Polyamide, Polycarbonate, Acrylonitrile Butadiene Styrene, and Others

Market Drivers:

Increasing Demand for Plastic Compounding from Construction Industry to Drive the Market

Market Trend:

Adoption of Compounded Plastics to Enhance the Properties of Virgin Plastics Will be a Key Market Trend

Restrains:

Fluctuations in Prices of Raw Material to Restrict Plastic Compounding Market Growth

Enquire for customization in Report @: https://marketresearchforecast.com/report/plastic-compounding-market-1636/enquiry-before-buy

Geographically World Global Plastic Compounding markets can be classified as North America, Europe, Asia Pacific (APAC), Middle East and Africa and Latin America. North America has gained a leading position in the global market and is expected to remain in place for years to come. The growing demand for Global Plastic Compounding markets will drive growth in the North American market over the next few years.

In the last section of the report, the companies responsible for increasing the sales in the Global Plastic Compounding Market have been presented. These companies have been analyzed in terms of their manufacturing base, basic information, and competitors. In addition, the application and product type introduced by each of these companies also form a key part of this section of the report. The recent enhancements that took place in the global market and their influence on the future growth of the market have also been presented through this study.

Report Highlights:

Comprehensive overview of parent market & substitute market

In-depth market segmentation (Trends, Growth with Historical & Forecast Analysis)

Recent industry trends and development activity

Competitive landscape (Heat Map Analysis for Emerging Players & Market Share Analysis for Major Players along with detailed Profiles)

Strategic Points Covered in Table of Content of Global Plastic Compounding Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Plastic Compounding market

Chapter 2: Exclusive Summary – the basic information of the Plastic Compounding Market.

Chapter 3: Changing Impact on Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Plastic Compounding;

Chapter 4: Presenting the Plastic Compounding Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2019-2024

Chapter 6: Evaluating the leading manufacturers of the Plastic Compounding market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2024-2032)

…………….

Buy this research @ https://marketresearchforecast.com/report/plastic-compounding-market-1636/checkout?type=corporate

Key questions answered

Who are the Leading key players and what are their Key Business plans in the Global Plastic Compounding market?

What are the key concerns of the five forces analysis of the Global Plastic Compounding market?

What are different prospects and threats faced by the dealers in the Global Plastic Compounding market?

What possible measures players are taking to overcome and stabilize the situation?

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Asia.

Contact US:

Craig Francis (PR & Marketing Manager)

Market Research Forecast

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: (+1 201 565 3262, +44 161 818 8166)

[email protected]

#Global Plastic Compounding Market#Plastic Compounding Market Demand#Plastic Compounding Market Trends#Plastic Compounding Market Analysis#Plastic Compounding Market Growth#Plastic Compounding Market Share#Plastic Compounding Market Forecast#Plastic Compounding Market Challenges

0 notes

Text

0 notes

Text

Foam Glass Market Trends: Revolutionizing Insulation Technology

The foam glass market comprises materials that are lightweight, insulating and fire resistant. Foam glass is produced by heating an indefinite mixture of glass batch materials, stabilizing agents and blowing agents in a furnace. This results in a structure with a closed-cell porous network comprising small bubbles in a matrix of glass. The strong bonds formed between glass form stable structures with high mechanical strength and thermal insulation. Foam glass finds wide applications as an insulating material in construction, industrial and other sectors due to its excellent properties.

The Global Foam Glass Market is estimated to be valued at US$ 2.17 Bn in 2024 and is expected to exhibit a CAGR of 8.6% over the forecast period 2023 to 2030. Key players like Pittsburgh Corning, Glapor, Owens Corning, Polydros S.A., Misapor AG, Earthstone International, Refaglass, Zhejiang Zhenshen Insulation Technology Corp. are enhancing innovations to expand the market reach.

Key Takeaways

Key players: Key players operating in the foam glass market are Pittsburgh Corning, Glapor, Owens Corning, Polydros S.A., Misapor AG, Earthstone International, Refaglass, Zhejiang Zhenshen Insulation Technology Corp. These companies are investing in R&D for developing enhanced foam glass formulations with improved properties to cater to the growing demand.

Growing demand: The rising need for thermal insulation in various end use industries like construction, industrial and others is driving the demand for foam glass globally. Its characteristics like low thermal conductivity and resistance to heat transfer make it suitable for high temperature applications.

Global expansion: Leading players are expanding their global footprint through supply contracts and partnership agreements with domestic players in emerging markets of Asia Pacific and Middle East & Africa. This is helping gain higher shares in the lucrative developing regions.

Market key trends

One of the key trends gaining traction in the foam glass market is the development of ultra-lightweight foam glass aggregates. Manufacturers are focusing on reducing the density of foam glass to 1/10th of conventional glass through innovations in production processes. This leads to enhanced insulation, durability and cost benefits which is increasing its preference across various applications. The trend is expected to continue and boost the market demand over the forecast period.

Porter’s Analysis

Threat of new entrants: High capital requirements and established players make the entry difficult for new players. Bargaining power of buyers: Buyers have low bargaining power due to lack of substitutes and differentiated products. Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of raw materials. Threat of new substitutes: Substitutes like extruded polystyrene (XPS) foam pose threat but differ in properties. Competitive rivalry: Intense competition exists among established players to gain higher market share.

The foam glass market in North America accounts for the largest share in terms of value. Countries like United States and Canada dominate the market due to high usage in industries like construction and industrial insulation where properties of foam glass are highly valued.

Asia Pacific region is expected to witness the highest growth during the forecast period. Rapid industrialization and infrastructure development in countries like China, India, Indonesia, Vietnam etc. will drive the demand for foam glass as insulating material during the coming years. Increasing per capita income and growing population is also favoring the market growth in Asia Pacific.

0 notes

Text

Building Insulation Materials Market - Forecast(2024 - 2030)

Building Insulation Materials market size is forecast to reach US$31.6 billion by 2030, after growing at a CAGR of 5% during 2024-2030. The market is growing because of the extended demand for, rising infrastructure, and industrialization globally. Building Insulation is an important economic and environmental investment, as installing thermal insulation, buildings use less energy for heating and cooling thus occupants experience less thermal variability. Insulating concrete forms (ICFs), used to hold fresh concrete that remain in place permanently to provide insulation, and energy efficiency. Developing countries are heavily investing in infrastructure and industrialization, as developed countries broke the poverty cycle by industrializing rather than focusing on agriculture and other industries. This aids in the growth of the Building Insulation Market.

There's a growing emphasis on using insulation materials that are environmentally friendly and sustainable. This trend involves moving away from traditional insulation materials like fiberglass and polystyrene, which can have negative environmental impacts during production and disposal. Asbestos is one of the traditional building insulating materials. It poses high risks of lung diseases like mesothelioma. Thus, there's a focus on utilizing renewable and recycled materials such as recycled denim, cellulose insulation made from recycled paper, sheep's wool, hemp, and cork. These materials offer excellent thermal performance while minimizing the carbon footprint of buildings.

Advanced insulation materials have emerged as a game-changer in the quest for energy-efficient homes. These cutting-edge solutions offer better thermal resistance, reduced heat transfer, and enhanced moisture control, resulting in optimal comfort and energy savings. Advanced insulation materials, such as spray foam and aerogel insulation, provide superior thermal resistance compared to traditional options. This results in better heat retention during colder months and effective heat reflection during hot summers. Homeowners can expect reduced reliance on heating and cooling systems, ultimately saving energy and money. Advanced insulation not only benefits homeowners but also contributes to a greener future. By reducing energy consumption, these solutions help decrease greenhouse gas emissions.

COVID-19 Impact

Due to the COVID-19, many Building insulation materials manufacturing companies shut down due to lockdown restriction, cross border import export restrictions, till receipt of further directions from the government authorities. There has been a significant undersupply of housing globally to match demand. This created a major opportunity for investors and developers to adopt innovative construction technologies and partnerships in order to accelerate development. However, production at certain manufacturing companies' plants later resumed, which is a positive sign. Residential Constructions are increasing due to increased population globally; thus, the market is expanding rather than experiencing minor economic disruptions.

Downlaod report sample

Key Takeaways

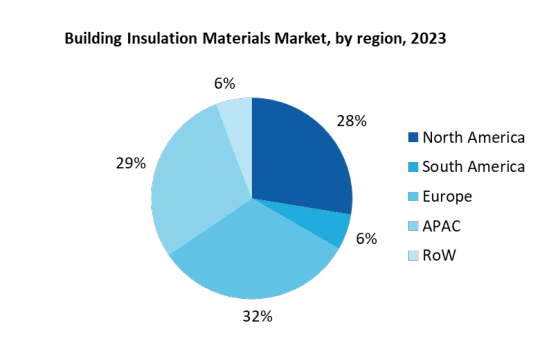

• North American region dominated the building insulation materials market and is also forecasted to be the fastest-growing market during the forecast period owing to the increasing demand for thermal Insulation in the region.

• Because of massive construction sector and broad industrial base, the intensity of insulation use in the United States exceeds global averages in terms of GDP, population, and fixed investment spending. Construction companies use an extensive amount of insulation materials, which is partly owing to building rules requiring insulation.

• In China, rapidly growing construction and industrial markets contribute to the high levels of insulation demand. However, intensity of insulation use relative to fixed investment spending and population is lower than more developed countries in the region, including Japan and Australia.

• The competitiveness of the European industry of thermal insulation materials in relation to other international competitors is moderate to strong. In the EU the demand for thermal insulation materials is on the rise due to strong economy and housing market. Advanced insulating materials are rising in popularity due to EU Health and Environmental Concerns. Wool minerals (glass and stone wool) and plastic foams (EPS, XPS, PUR) are the most required materials for building insulation.

For More Details on This Report - Request for Sample

Building Insulation Market Segment Analysis – By Type

The Polystyrene segment held the largest share of 81.1% in the Building Insulation Materials Market in 2023. Among the many types of plastics, Polystyrene (PS) foam is a lightweight, rigid plastic insulation material, and is widely recognized as the most immediate and affordable means to fight climate change. Polystyrene is made into a foam material, called expanded polystyrene (EPS), which accounts for 49.6% of the building insulation market has no global warming potential as the material does not decompose at the end of its life and it does not release any ozone-depleting substances. Polystyrene is also made into a rigid foam material, called extruded polystyrene (XPS), accounting for 30.5% of the market share. The plastic insulation materials were compared to mineral wool and glass foam, with the result that on average plastic insulation materials consume 16 % less energy and produce 9% less GHG emissions than the alternative mix of mineral wool and glass foam. Polystyrene Insulation enable significant energy savings during their entire lifecycle. For example, the energy needed to produce the panels is offset by the energy savings recovered during their first four months use. In fact, across their total life cycle, Polystyrene Insulation boards save 150 times more energy than is needed for their production.

Rigid insulation panels made from polyurethanes are light but strong, moisture-resistant and easy to install. Insulation panels and other types of foam insulation can retain their energy-efficient properties for as long as the building exists. Compared to other forms of insulation polyurethane foams are much more space-efficient, allowing architects and designers to maximise use of internal spaces. Sustainable insulation aid to sustainable buildings thus boosting the infrastructure sector and aiding to the growth of Building Insulation Materials Market.

Building Insulation Materials Market Segment Analysis – By Application

Residential segment held the largest share in the Building Insulation Materials market in 2023 and is growing at a CAGR of 5% during 2024-2030. In US, Spending for energy efficient buildings has shown an increase in 2023, with investment in building energy efficiency across global markets increasing to USD $358 billion in 2023, an increase of 22% from 2022. However, this remains a small proportion of the USD $11.9 trillion spent in the building and construction sector. According to the U.S. Census Bureau the Total Construction spending during November 2023 was estimated at a seasonally adjusted annual rate of US$2050.1 billion. According to the U.S. Census Bureau the Non-residential construction was at a seasonally adjusted annual rate of US$698.2 billion in November 2023.

Building Insulation Materials Market Segment Analysis – By Geography

North American region held the largest share in the Building Insulation Material market in 2023 up to USD $12.29 billion, owing to the need of thermal Insulation due to cold climatic condition and the rapid urbanization in the region. Another factor contributing to the growth of the Building Insulation Market in this area is growing population and the need to create a new eco-friendly urbanization that can help achieve high-quality growth in the coming decade and create an economy based on high value-added manufacturing and services while avoiding enormous environmental costs. Globally, over 50% of the population lives in urban areas today. By 2045, the world's urban population will increase by 1.5 times to 6 billion. 55% of the world’s population – 4.2 billion inhabitants live in cities. This trend is expected to continue. By 2050, with the urban population more than doubling its current size, nearly 7 of 10 people in the world will live in cities.

With more than 80% of global GDP generated in cities, urbanization can contribute to sustainable growth of construction and housing sector and thus aid to expansion of Building Insulation Material Market globally.

Purchase report

Building Insulation Materials Market – Drivers

Rise in Population and Urbanization globally:

The two causes of urbanization are natural population increase and rural to urban migration. Urbanization affects all sizes of settlements from small villages to towns to cities, leading up to the growth of mega-cities which have more than ten million people. According to the National Mission for Urban Housing, The Indian government’s ‘Housing for All by 2022’ was also a major game changer for the Building Insulation Materials market. The Mission also prescribed certain mandatory reforms for easing up the urban land market for housing, to make adequate urban land available for affordable housing. Central assistance at the rate of US$2300 (Rs.1.5 lakh) per house for EWS (Economically Weaker Section) category was provided under the Affordable Housing in Partnership and Beneficiary-led individual house construction or enhancement. Insulation will help Buildings keep the desired temperature all the year-round, protecting it against cold in winter and excess heat in summer. Insulation is also useful to reduce noise pollution. A well-insulated house is very energy efficient and will need very little additional heating and cooling.

Conservation Of Energy:

Insulation is one of the most efficient ways to save energy, since it keeps it warm in the winter and cool in the summer. In fact, the Energy Saving Trust estimates that in one year a typical three-bedroom semi-detached house can save up to US$354 Billion (£310) on energy bills by installing loft and cavity wall insulation. Building Insulation leads to energy savings, which reduce the demand for fossil fuels and associated GHG emissions and other environmental impacts. It is estimated that improvements in the level of insulation of the existing building stock can reduce heating requirements by a factor of two to four.

For countries with milder winters, where heating is still required, as is the case in many developing countries, modest levels of insulation at a reasonable cost may already reduce the heating requirements by more than half of current levels, and in addition may contribute to reducing indoor temperatures in summer. If there is no air conditioning, lower temperatures in summer improve indoor comfort, or, if air conditioning is used, lead to additional energy savings. As 10% of the energy for heating than houses built according to the local national building codes.

Building Insulation Materials Market – Challenges

High Initial Investment Cost:

Common barriers for Building Insulation materials are high investment costs, lack of financing options for the up-front investments, the time and effort required to undertake renovation measures in existing buildings, lacking knowledge and awareness, and split incentives. Governments in different regions of the world have introduced measures to reduce these barriers, including mandatory energy efficiency standards, building certification, voluntary labeling, and financial incentives to stimulate investments into increased insulation and other energy saving measures in buildings. Moreover governments, civil society and industry organizations use information campaigns to increase awareness and knowledge of energy saving options in buildings. In the EU the Energy Performance of Buildings Directive (EPBD) is the main regulatory framework to prescribe the use of energy labels for European buildings. In other regions such as the United States and some Asian countries, there is a stronger focus on a combination of mandatory regulation

Building Insulation Materials Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Building Insulation Materials market. Building Insulation Materials Market top companies

Berkshire Hathaway (Johns Manville Corporation)

Saint-Gobain S.A.

BASF SE

Kingspan Group plc

Knauf Insulation, Inc.

Owens Corning

Huntsman Corporation

Rockwool International A/S

Holcim Group (Firestone Building Products Company)

Cabot Corporation

Inquiry before buying

Acquisitions/Technology Launches/Product Launches

• In March 2022, BASF expanded its graphitic expandable polystyrene (EPS) granulate portfolio. BASF had launched Neopor F 5 McycledTM, which contains 10 percent recycled material and is suitable for numerous building applications, particularly exterior insulation.

• On 28th November 2023, Kingspan Group, announced the launch of HemKor range of products which is a bio-based insulation product largely made up of hemp. It was launched as an effort to reduce the carbon footprint of buildings.

For more Information and Communications Technology Market reports, please Click Here

#Building Insulation Materials Market#Building Insulation Materials Market share#Building Insulation Materials Marketsize

0 notes

Text

Styrene Market Report: Trends, Analysis, and Projections

Styrene, a key monomer in the production of various polymers and plastics, holds a significant position in the global petrochemical industry. This blog explores the dynamics of the global styrene market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the Styrene Market:

Styrene (C8H8) is an aromatic hydrocarbon obtained from the dehydrogenation of ethylbenzene, primarily used in the production of polystyrene, acrylonitrile-butadiene-styrene (ABS), styrene-butadiene rubber (SBR), and various thermoplastic elastomers.

Market Dynamics:

Polystyrene Production: Styrene is a crucial raw material for manufacturing polystyrene (PS), a versatile thermoplastic used in packaging, disposable containers, insulation, and consumer goods due to its lightweight and insulating properties.

ABS and SBR Production: Styrene contributes to the production of ABS, a high-impact engineering thermoplastic used in automotive parts, appliances, and electronics, as well as SBR, a synthetic rubber widely used in tires, footwear, and industrial applications.

Expanded Polystyrene (EPS): Styrene is essential for producing EPS foam, used in insulation boards, packaging materials, and construction applications due to its lightweight, thermal insulation, and cushioning properties.

Resins and Coatings: Styrene-based resins and coatings find applications in fiberglass-reinforced composites, boat hulls, automotive parts, and protective coatings for metal and concrete surfaces.

Applications Across Industries:

Packaging: Polystyrene foam, containers, packaging materials.

Automotive and Transportation: ABS plastics, SBR rubber for tires.

Construction: EPS insulation, foam boards, building materials.

Consumer Goods: Appliances, electronics, household products.

Market Trends:

Circular Economy Initiatives: Growing emphasis on recycling, sustainability, and circular economy models drive innovations in styrene recycling technologies and the development of bio-based styrene from renewable feedstocks.

Demand from Emerging Economies: Increasing urbanization, infrastructure development, and rising consumer demand in emerging economies fuel the demand for styrene-based products across multiple industries.

Technological Advancements: Innovations in polymerization processes, catalyst technologies, and material science lead to the development of high-performance styrene-based polymers with enhanced properties and applications.

Future Prospects:

The global styrene market is poised for continued growth, driven by the expanding plastics, packaging, automotive, and construction sectors. Sustainable practices, technological innovations, and strategic collaborations will shape the market's evolution towards greener and more efficient production processes.

Conclusion:

Styrene remains a vital component in the production of polymers, plastics, and rubber materials essential for diverse industries. Understanding market trends, regulatory shifts towards sustainability, and technological advancements is crucial for stakeholders in the styrene market. With a focus on innovation, recycling, and market diversification, the styrene market presents promising opportunities for growth and advancements in global industrial applications and sustainable solutions.

0 notes

Text

Eco-friendly Innovations Propel Industrial Foam Market Toward Sustainable Growth on Global Scale by 2033

Overview and Scope

Industrial foam is an expanded plastic and rubber created by forcing gas bubbles into a polymer material. Industrial foam is highly-efficient for insulation against water, air, chemical substances, and adhesives. Industrial foam is used as padding for several consumer and business products, such as mattresses, furniture, car interiors, carpet underlay, and packaging.

Sizing and Forecast

The industrial foam market size has grown strongly in recent years. It will grow from $63.14 billion in 2023 to $68.05 billion in 2024 at a compound annual growth rate (CAGR) of 7.8%.

The industrial foam market size is expected to see strong growth in the next few years. It will grow to $91.5 billion in 2028 at a compound annual growth rate (CAGR) of 7.7%.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/industrial-foam-global-market-report

Segmentation & Regional Insights

The industrial foam market covered in this report is segmented –

1) By Foam Type: Flexible, Rigid

2) By Resin Type: Polyurethane, Polystyrene, Polyolefin, Phenolic, PET, Other Resin Types

3) By End-Use: Building And Construction, HVAC, Industrial Pipe Insulation, Marine, Aerospace, Industrial Cold Storage, Others End-Uses

Asia-Pacific was the largest region in the industrial foam market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the industrial foam market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8209&type=smp

Major Driver Impacting Market Growth

Growing demand for energy-efficient and lightweight materials is expected to propel the industrial foam market. Lightweight materials are manufactured using lightweight raw materials that directly reduce the weight of the material while maintaining its performance. Industrial foam is a type of lightweight material made up of tiny cells filled with gas or air and used in applications such as insulation, packaging, and construction.

Key Industry Players

Major companies operating in the industrial foam market report are Covestro AG, BASF SE, Dow Inc., Huntsman Corporation, Sekisui Chemical Co. Ltd., Saint-Gobain S.A., Chemtura Corporation, Recticel N.V, Rogers Corporation

The industrial foam market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Expanded Polystyrene Market Growth Insights, Future Trends, Regional Outlook to 2032 | Alpek, Evonik Industries AG, LG Corp

Expanded Polystyrene Market Growth Insights, Future Trends, Regional Outlook to 2032 | Alpek, Evonik Industries AG, LG Corp

Complete study of the Global Expanded Polystyrene Market 2023-2032 is authored by the analysts, taking into consideration key factors like drivers, challenges, recent trends, opportunities, advancements, and competitive landscape. This report offers a clear understanding of the present as well as future scenario of the global Expanded Polystyrene industry. Research tolls such as PESTLE and…

View On WordPress

#Expanded Polystyrene#Expanded Polystyrene market share#Expanded Polystyrene market size#Expanded Polystyrene market Trends

0 notes

Text

Global Rigid Plastic Packaging Market Growth and Challenges Analysis Forecast by 2031

Global Rigid Plastic Packaging Market Scope & Overview

The report's purpose is to provide decision-makers with the market intelligence and strategic insights they require to make sound investment decisions and identify market gaps and expansion opportunities. The Global Rigid Plastic Packaging Market study includes information on industry trends, growth patterns, and corporate strategies to help participants make decisions that will help them maintain a favorable profit trajectory in the next years. The purpose of this research report is to provide readers with a thorough grasp of the industry as well as market segmentation.

Global Rigid Plastic Packaging market research is an in-depth examination of the industry with an emphasis on global market trends. The most recent market study analyses the industry's potential for future growth and provides detailed and useful data on the market's composition and size. The most recent market report analyses the industry's potential for future growth and provides detailed and useful data on the market's composition and size.

Get a Sample Report https://www.snsinsider.com/checkout/2848

Market Key Players:

Silgan Holdings, Berry Plastics Corporation, Amcor Limited, Consolidated Container Company, Pactiv Evergreen Inc, Al Jabri Plastic Factory, Sonoco Products Company, SABIC, Mauser Packaging Solutions, Ball Corporation, and other players.

Market Segmentation Analysis

In today's global economy, the dynamic corporate environment is increasing the demand for business specialists who can keep up with evolving market dynamics. The global Global Rigid Plastic Packaging market is divided into four areas in the report: vertical, service, end use, and geography to gain better understanding of the market.

By Raw Material

Bioplastics

Polyethylene Terephthalate

Polypropylene

Polyethylene

Polystyrene

Polyvinyl Chloride

Expanded Polystyrene

Others

By Product type:

Bottle & Jars

Trays

Rigid Bulk Products

Others

By Production Process:

Thermoforming

Injection Molding

Extrusion

Blow Molding

Others

By Application:

Food & Beverages

Household

Healthcare

Personal Care

Others

COVID-19 Impact Analysis

The emergence of COVID-19 had a tremendous influence on the Global Rigid Plastic Packaging market. Furthermore, future developments have been postponed globally, thus terminating the sector. The COVID-19 lockout compelled the development of new tactics for dealing with oncoming crises while maintaining steady rates of growth.

Regional Outlook

The global Global Rigid Plastic Packaging market study includes geographic analysis for regions such as North America, Latin America, Asia-Pacific, Europe, and the Rest of the World. The market research report includes a regional market analysis, company market shares, and profiles of important revenue sources.

Competitive Analysis

Businesses use a variety of growth and expansion strategies to gain a competitive advantage. Participants in the industry pay close attention to how the various stages of the value chain are connected with business operations. Industry leaders are improving supply chain logistics, increasing their worldwide footprints, and strengthening their company portfolios to get a competitive advantage in the global market, all of which are included in the Global Rigid Plastic Packaging market research report.

Key Reasons to Purchase Global Rigid Plastic PackagingMarket Report

To investigate and investigate micro markets in terms of their market contributions, potential, and distinctive growth tendencies.

The research report goes over the important steps that successful firms take to limit the negative consequences of a pandemic on their operations.

The research includes important industry statistics, major market trends and prospects, and market position data for the leading players in the field.

Conclusion

The latest market research report assesses the current condition of the Global Rigid Plastic Packaging market as well as predicted future changes that may foretell market growth over the projected period.

Buy the Research Report Now https://www.snsinsider.com/checkout/2848

About Us:

SNS Insider is one of the leading Market Size research and consulting agencies that dominates the Market Size research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate Market Size data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

0 notes

Text

Top 10 Plastics Market Size and Share Analysis

Top 10 Plastics Market report provides the broader perspective of the market place with its comprehensive market insights and analysis which eases surviving and succeeding in the market. This market report brings into focus plentiful of factors such as the general market conditions, trends, inclinations, key players, opportunities, and geographical analysis which all aids to take the business towards the growth and success. Moreover, Top 10 Plastics Market report explains better market perspective in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. Hence, the Top 10 Plastics Market report brings into the focus, the more important aspects of the market or Chemicals & Materials industry.

Top 10 Plastics Market, by Type (Polyethylene, Polypropylene, Polystyrene, Polyethylene Terephthalate, Polyvinyl Chloride, Polycarbonate, Acrylonitrile Butadiene Styrene, Polyoxymethylene, Polyamide, Polyurethane), End-Use Industry (Building & Construction, Electronics & Consumer, Automotive, Textile, Packaging), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America).

Download Free Sample Report: https://www.delvens.com/get-free-sample/top-10-plastics-market

Top players covered in the Top 10 Plastics Market report:

Arkema

BASF SE

Braskem

Celanese Corporation

Chevron Phillips Chemical Co., LLC

Covestro AG

Dow Inc

Ducor Petrochemicals

DuPont de Nemours, Inc

Eastman Chemical Company

Evonik Industries

Exxon Mobil Corporation

Formosa Plastic Corporation

INEOS

Lotte Chemical Corporation

Mitsui & Co. Plastic Ltd.

Reliance Industries Limited

Repsol

SABIC

Sumitomo Chemical Co., Ltd.

Toray Industries, Inc.

Top 10 Plastics Market Recent Developments:

In August 2023, A joint venture agreement was formed by the biopolymer manufacturer Braskem and SCG Chemicals to create bio-ethylene from bio-ethanol dehydration and to market Braskem's "I'm green" bio-based Polyethylene.

In June 2023, BASF set up a new polyethylene plant in Zhanjiang Verbund site in China. The brand-new facility, with a yearly capacity of 500,000 metric tons of PE, will meet China's rapidly expanding demand. In 2025, the facility is expected to begin operations.

The Top 10 Plastics Market size was estimated at USD 503.11 billion in 2023 and is projected to reach USD 777.21 billion in 2030 at a CAGR of 6.41% during the forecast period 2023-2030.

Although they generally incorporate additional materials, plastics are high molecular mass organic polymers. The majority of the time, they are synthetic and made from petrochemicals. However, the current emphasis on the environment has led to an increase in the number of plastics made from renewable resources, such as cellulosic from cotton linters and polylactic acid made from corn. Due to their comparatively low cost, simplicity of production, adaptability, and water resistance, plastics are now used in a wide variety of items. Plastic is used in everything, from basic items like paperclips to large ones like airplanes. Based on their availability and application, the top 10 most abundantly used plastics are polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide and polyurethane.

Plastic consumption is being driven by the food and beverage sectors' expanding requirement for packaging materials. product manufacturers seek packaging that guards against contamination and deterioration of product quality. Demand is being fuelled by plastic's ability to act as a shield between food products and the outside world. Moreover, their increased demand in textile, electrical and electronic, automotive, and consumer goods sectors is driving the growth of the market further.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/top-10-plastics-market

Top 10 Plastics Market Key Findings:

Based on type, the market is segmented into polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polyvinyl chloride, polycarbonate, acrylonitrile butadiene styrene, polyoxymethylene, polyamide, polyurethane. Polyethylene dominated the market in this segment owing to its extensive usage packaging, construction, electrical & electronics and construction. Moreover, the substitution of metal-based products with plastic based products is expected to drive the growth of polyethylene market further during the forecast period.

Based on end use industry, the market is segmented into building & construction, electronics & consumer, automotive, textile, packaging. Packaging dominated the market in this segment owing to the increased packaging demand from the rapidly growing food and beverages industry.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector, increased R&D activity, presence of major key players and easily available raw materials.

Top 10 Plastics Market Regional Analysis:

Asia Pacific to Dominate the Market

Asia Pacific is estimated to account for the largest market share during the forecast period owing to the rapidly growing construction sector and increased R&D activity within the region.

Moreover, the presence of major key players and availability of raw materials are expected to drive the growth of the market further during the forecast period.

Top 10 Plastics Market report involves use of latest tools and techniques for researching, analyzing and gathering of data and information. The market analysis here includes competitive study, product information analysis, applications, and region-wise analysis, competitor landscape, consumption and revenue study, cost structure analysis, price evaluation and revenue analysis up to 2030. This Top 10 Plastics Market report performs systematic gathering, recording and analysis of data about the issues related to the marketing of goods and services and serves the businesses with an excellent market research report. The global Top 10 Plastics Market report provides smart solutions to the complex business challenges and commences an effortless decision-making process.

Direct Purchase of the Top 10 Plastics Market Research Report at: https://www.delvens.com/checkout/top-10-plastics-market

Explore Related Reports:

Fire Protection Materials Market

Battery Recycling Market

Metal Foam Market

3D Printing Metals Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

#consulting company#strategic advisory firm#best market reports#market analysis reports#trending reports#syndicated reports#Top 10 Plastics Market#Top 10 Plastics#Top 10 Plastics Industry#Chemicals & Materials#Chemicals

0 notes

Text

Exploring Polystyrene: Manufacturing and Market Trends (2023-2034)

Polystyrene stands as a versatile plastic polymer deeply embedded in various aspects of our daily lives. Its utility extends from packaging and food containers to insulation materials, showcasing a wide range of benefits. Despite its adaptability, polystyrene raises environmental concerns due to its non-biodegradable nature. In this comprehensive examination of polystyrene, we will delve into its unique characteristics, manufacturing processes, diverse applications, and the environmental challenges it presents. We'll explore its lightweight composition, durability, and moldable properties that make it a preferred material for many industries. Furthermore, we'll examine its significant role in sectors such as packaging, food service, and construction. With the global polystyrene market valued at around 11.2 million tons in 2023, it is projected to grow at a Compound Annual Growth Rate (CAGR) of 3.39% until 2034.

Introduction

Polystyrene is a synthetic resin characterized by its robust, rigid, and translucent properties. It is derived from styrene, a liquid hydrocarbon, which acts as the monomer in the polymerization process. Polystyrene's unique attributes, such as its lightweight nature and insulation properties, drive its utilization across various industries. The benefits of polystyrene plastic injection molding encompass its minimal shrinkage, versatility in being utilized in blended and foam states, and its moldability. Polystyrene, like all thermoplastics and can be easily molded, exhibiting minimal shrinkage throughout the injection molding process.

Various forms of polystyrene exist, each tailored for specific applications:

1. Solid Plastic: This category includes General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS), designed for different levels of impact resistance. High-impact grades of polystyrene typically contain 6–12% elastomers, while medium-impact grades have about 2–5%. High impact polystyrene (HIPS) resins are valued for their ease of processing, good dimensional stability, impact strength, and rigidity. These qualities make HIPS suitable for a variety of applications where toughness and durability are required, such as packaging, appliances, and consumer goods.

2. Foam: Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are foam variants suitable for insulation, packaging, and construction purposes.

3. Films: Oriented Polystyrene (OPS) finds applications in packaging films, offering clarity and stiffness. Oriented Polystyrene (OPS) is processed through orientation techniques to enhance its strength and clarity. Commonly used in clear containers, trays, and lids for food packaging, OPS offers excellent transparency, making it ideal for showcasing food items like salads, desserts, and deli products. OPS stands as a versatile material in the food packaging industry, meeting the demands for both aesthetic appeal and functional performance.

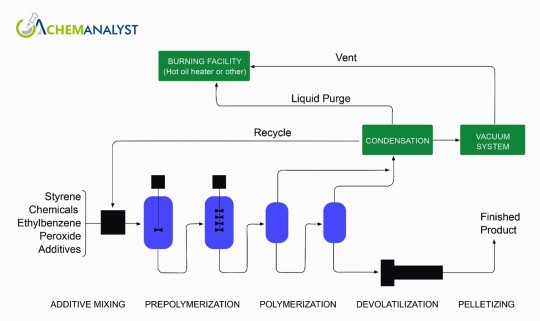

Manufacturing Process

Polystyrene is produced through batch processes that ensure high conversion efficiency, minimizing emissions of unreacted styrene. In the batch bulk polymerization process, styrene monomer, and optionally comonomer, are dissolved in a feed dissolver. The continuous mass peroxide-initiated polymerization of styrene is a multi-stage process designed for efficiency and control. Beginning with the monomer and chemicals into a mixing section, the mass reaction occurs in the presence of a solvent. This mixture then progresses to the polymerization section, typically comprising two continuously stirred tank reactors (CSTRs), where heat generated during the reaction is dissipated by evaporating volatile components. Following the reaction, the polymer solution undergoes devolatilization in two consecutive stages under vacuum conditions, eliminating monomers and low-boiling compounds. The resulting polymer is then transferred to the pelletizing unit, supplied with heat via a thermal oil system.

Polymerization Stage

CSTR reactors facilitate precise control over molecular weight, Alternative configurations, like CSTR combined with plug flow reactors (PFR), offer flexibility to meet diverse process needs.

Devolatilization Stage

The devolatilization section ensures efficient removal of monomers and organic substances, minimizing polymer degradation without additional agents through high rates of heat and mass transfer. This stage consists of a two-step process with low residence periods and high heat and mass transfer rates. Even at very low operating temperatures, the effective removal of monomers and organic compounds is ensured by this special combination.

Expanded polystyrene (EPS), synthesized through suspension polymerization and impregnation with a blowing agent like pentane, and exhibits rigidity, lightweight nature, and low thermal conductivity. Expanded Polystyrene (EPS) foam is derived from expandable polystyrene beads, a rigid cellular plastic containing an expansion agent, typically sourced from oil. The EPS manufacturing process intricately links back to the initial chemical transformation from oil to expandable polystyrene. Now, we delve into the subsequent stages leading to the formation of EPS foam parts. In the first stage of pre-expansion, the raw beads undergo heating in specialized pre-expanders using steam. This process reduces the material density significantly, transforming hard beads into cellular plastic beads with small, closed cells containing air. Following pre-expansion, the beads undergo intermediate maturing and stabilization. As the recently expanded particles cool, they form a vacuum inside, which is compensated for by air diffusion. This enhances mechanical elasticity and expansion capacity, achieved during the material's intermediate maturing in aerated silos or mesh bags, where simultaneous drying occurs. In the final stage of expansion and molding, the stabilized pre-expanded beads are transferred to molds, where they are exposed to steam again to bind together. This results in the formation of large blocks through block molding or products in their final finished shape through shape molding, catering to various applications like boards, panels, and cylinders.

Market Dynamics

The global Polystyrene market is propelled by its distinctive attributes, including its water-resistant nature, making it a preferred choice in the packaging industry. Additionally, its ability to blend seamlessly with other polymers further enhances its versatility and widens its range of applications. Polystyrene's utilization in the manufacturing of automotive components and electronic goods is poised to drive market growth in the coming years, owing to its properties such as insulation and high strength.

Applications of Polystyrene:

1. Construction

Polystyrene is extensively utilized in the construction industry for various purposes. It is a key component in the production of lightweight concrete blocks, which are prized for their ease of handling and installation on construction sites.

2. Appliances

Polystyrene, both in solid and foam forms, is a prevalent material choice for a wide array of appliances, including refrigerators, air conditioners, ovens, microwaves, vacuum cleaners, and blenders.

3. Automotive

Polystyrene serves as a fundamental material in the manufacturing of numerous automotive components.

4. Electronics

Polystyrene is essential for crafting housing and components in televisions, computers, and IT equipment. Its lightweight and moldable nature allow for intricate designs that balance functionality and aesthetics.

5. Food Packaging

Polystyrene foodservice packaging is renowned for its superior insulation properties, which effectively maintain food freshness for extended periods. Compared to alternative packaging materials, polystyrene offers better insulation for hot & cold foods.

Market Outlook:

The global Polystyrene market is anticipated to reach approximately 17.8 million tonnes by 2034. Its affordability, combined with its excellent insulation capabilities, makes polystyrene a preferred choice in various industries, meeting both practical and economic needs effectively. Asia Pacific region is the leading consumer of Polystyrene and with rapid urbanization & construction paired with increasing dispensable income anticipated to remain so in the coming years.

Polystyrene Key Market players

Significant companies in the Global Polystyrene market are Total Petrochemicals, INEOS Styrolution, PS Japan, Jiangsu Laidun Baofu Plastifying, Zhenjiang Chi Mei Chemical, Shanghai Secco Petrochemical, Formosa Plastics, Versalis, Trinseo, Supreme Petrochem Limited, LG Chem, DIC Corporation, and Jiangsu Lyan Qingfeng Newmaterial.

Challenges and Opportunities

While the polystyrene market offers numerous opportunities, it also faces several challenges that impact its growth.

· Environmental Concerns: One of the significant challenges facing the polystyrene market is its environmental impact. Polystyrene is non-biodegradable and can persist in the environment for hundreds of years, contributing to pollution and posing risks to wildlife.

· Shift Towards Alternatives: Growing awareness of environmental and health issues associated with polystyrene has led to a shift towards alternative materials in various industries. Biodegradable and compostable alternatives, as well as recyclable plastics, are gaining popularity as consumers and businesses seek more sustainable options, posing a competitive challenge for the polystyrene market.

Conclusion:

The polystyrene market is diverse and driven by its versatile properties and cost-effectiveness. It finds applications in packaging, construction, automotive, electronics, and more. Polystyrene's advantages include its lightweight nature, thermal insulation properties, and moldability. In packaging, it is known for its resistance to moisture and impact, making it suitable for food packaging and protective materials. High Impact Polystyrene has remarkable dimensional stability alongside easy thermoforming capabilities. Its high impact resistance renders it ideal for various applications such as refrigerator liners, toilet seats, and disposable items, offering both functionality and aesthetic appeal, especially when painted. Additionally, its suitability for food packaging, exemplified by yogurt cups, underscores its versatility. Polystyrene foams leverage their excellent thermal insulation properties for diverse applications in construction and packaging.

0 notes

Text

From Insulation to Preservation: Exploring Foam Cooler Box Market Trends

The foam cooler box market has witnessed steady growth in recent years, driven by the increasing demand for convenient and portable cooling solutions across various industries and consumer segments. Foam cooler boxes, also known as coolers or ice chests, are insulated containers designed to keep contents cool or cold for extended periods, making them popular for picnics, outdoor activities, transportation of perishable goods, and medical applications such as vaccine storage. This market has seen a surge in demand, particularly in regions with warm climates and during summer seasons, as people seek efficient ways to keep beverages, food, and other items chilled.

One of the key drivers of market growth is the rising trend of outdoor recreational activities such as camping, hiking, and beach outings. Consumers are increasingly investing in high-performance foam cooler boxes that offer superior insulation, durability, and portability. Additionally, the food and beverage industry relies on foam cooler boxes for safe and efficient transportation of perishable goods, contributing to market expansion.

The foam cooler box market can be segmented based on product type, material, size, end-user, and distribution channel. Product types include hard-sided coolers, soft-sided coolers, and disposable foam coolers, each catering to different preferences and use cases. Materials used in foam cooler boxes range from traditional expanded polystyrene (EPS) foam to advanced materials like polyurethane foam, offering varying levels of insulation and environmental sustainability.

Despite the market's growth potential, there are challenges and restraints to consider. These include increasing competition from alternative cooling solutions such as electric coolers and refrigeration units, concerns about environmental impact due to disposable foam coolers, and price sensitivity among certain consumer segments. Manufacturers are responding to these challenges by focusing on product innovation, eco-friendly materials, and strategic partnerships to expand their market presence and meet evolving consumer demands.

Looking ahead, the foam cooler box market is poised for continued growth, driven by factors such as technological advancements in insulation materials, growing emphasis on sustainability, and expanding applications in healthcare and pharmaceutical logistics. Emerging trends like the integration of smart features such as temperature monitoring and IoT connectivity are also expected to shape the future landscape of foam cooler boxes, providing further opportunities for market expansion and differentiation.

0 notes

Text

0 notes