#Environmental Silica Market

Text

Environmental Silica Market Is Estimated To Witness High Growth Owing To Increasing Demand For High-quality Silica In Various Industrial Applications

The global Environmental Silica Market is estimated to be valued at US$ 2.45 Billion In 2023 and is expected to exhibit a CAGR Of 9.8% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Environmental silica refers to high-purity silica used in various industrial applications such as oil and gas, rubber and plastics, and paints and coatings. The market for environmental silica is driven by the increasing demand for high-quality silica for use in activities such as hydraulic fracturing, refineries, and foundries. The high purity and exceptional physical properties of environmental silica make it suitable for use in diverse applications where stringent quality requirements exist.

Market Key Trends:

One of the key trends in the Environmental Silica Market is the growing demand from the oil and gas industry. With the increasing exploration and production activities in the oil and gas sector, the demand for environmental silica for use in hydraulic fracturing operations is expected to rise significantly. Environmental silica is used as a proppant in hydraulic fracturing to keep the fractures open and improve the flow of oil and gas. The rising demand for oil and gas globally is driving the need for high-quality proppants, thereby fueling the growth of the environmental silica market.

Furthermore, the growing awareness regarding the benefits of environmental silica in various industrial applications is also contributing to market growth. Environmental silica offers advantages such as improved strength and durability in rubber and plastic products, enhanced gloss and resistance to abrasion in paints and coatings, and excellent thermal stability in foundries. These benefits are driving the adoption of environmental silica across different industries, leading to market expansion.

Overall, the environmental silica market is poised for high growth due to the increasing demand for high-quality silica in various industrial applications, particularly in the oil and gas sector. The market is expected.

Key Takeaways:

The global environmental silica market is projected to witness high growth, exhibiting a CAGR of 9.8% over the forecast period from 2023 to 2030. This growth can be attributed to several drivers, including the increasing demand for environmentally-friendly materials, the growth of the construction industry, and the rising adoption of silica in various end-use industries.

In terms of regional analysis, Asia-Pacific is expected to be the fastest growing and dominating region in the environmental silica market. The region is witnessing rapid industrialization, urbanization, and infrastructural development, which drives the demand for environmental silica in construction, automotive, and electronics sectors.

Key players operating in the environmental silica market include U.S. Silica Holdings Inc., Sibelco Group, Fairmount Santrol Holdings Inc., Emerge Energy Services LP, Badger Mining Corporation, Covia Holdings Corporation, Preferred Sands LLC, Hi-Crush Partners LP, SCR-Sibelco N.V., and Pattison Sand Company. These key players contribute to the market growth through their extensive product portfolios, global presence, and strategic initiatives such as mergers, acquisitions, and partnerships.

Overall, the environmental silica market is expected to witness significant growth in the coming years, driven by factors such as increasing environmental concerns, infrastructure development, and technological advancements. The key players in the market are well-positioned to capitalize on these opportunities and maintain their market dominance

0 notes

Text

Exploring how Arrowsmith North Silica Sand Project by VRX Silica advances?

Discover the notable progress made by VRX Silica Limited (ASX: VRX) in the approval process for the Arrowsmith North Silica Sand Project. Learn about the commencement of the Public Environmental Review (PER) period and the company's dedication to addressing stakeholder feedback. Get insights into VRX Silica's investor outlook and explore the projects within their expansive silica sand portfolio in Western Australia.

When it comes to sustainable silica sand projects, VRX Silica Limited is making significant strides. With the initiation of the four-week Public Environmental Review (PER) period, following the publication of the Environmental Review Document (ERD), VRX Silica's Arrowsmith North Silica Sand Project is advancing closer to reality.

The acceptance of the Arrowsmith North Environmental Review Document by the Department of Water and Environmental Regulation (DWER) further demonstrates the company's commitment to transparency and environmental responsibility.

During the PER process, VRX Silica understands the importance of addressing all comments received regarding the Arrowsmith North Silica Sand Project proposal. This comprehensive review and response stage serves as the final step before the Environmental Protection Authority (EPA) of Western Australia prepares an assessment report. The recommendations made in the report will play a crucial role in the approval decision by the Western Australian Environment Minister.

Investor Outlook:

VRX Silica's commitment to sustainability and responsible resource extraction has captured the attention of investors. With a share price of AUD 0.125 per share and a 52-week range of AUD 0.093 to AUD 0.190 per share, the company's performance in the market has been notable. As of June 19th, 2023, VRX Silica has a market capitalization of AUD 70 million, with 560.40 million shares issued.

About VRX Silica:

VRX Silica Limited is an ASX-listed pure-play silica sand company with a dedicated focus on driving innovation and sustainable practices. The company's portfolio comprises four silica sand projects in Western Australia. In addition to the Arrowsmith North Silica Sand Project, they also have the Arrowsmith Central Silica Sand Project, located near Eneabba, south of Geraldton. Furthermore, VRX Silica has the Muchea Silica Sand Project, situated north of Perth, and the Boyatup Silica Sand Project, positioned 100 km east of Esperance.

Conclusion:

The Arrowsmith North Silica Sand Project by VRX Silica is making significant progress in its approval process, evident through the commencement of the PER period and the publication of the ERD. By addressing stakeholder feedback and adhering to sustainable practices, VRX Silica is laying a strong foundation for the project's success. With their robust investor outlook and dedication to responsible resource extraction, VRX Silica continues to shape the future of the silica sand industry in Western Australia.

#VRX Silica#Arrowsmith North Silica Sand Project#Public Environmental Review#Environmental Review Document#Department of Water and Environmental Regulation#DWER#Environmental Protection Authority#EPA#Western Australia#assessment report#investor outlook#share price#market capitalization#sustainability#silica sand projects#Arrowsmith Central Silica Sand Project#Muchea Silica Sand Project#Boyatup Silica Sand Project#silica sand industry#resource extraction#ASX-listed#sustainability practices#stakeholder feedback#responsible resource extraction#transparent processes#environmental responsibility#market performance#Western Australian Environment Minister#silica sand portfolio#resource development

0 notes

Text

Understanding Different Types of Cat Litter: Pros and Cons

Making the right choice of cat litter is a crucial decision for every cat owner. With an array of options available, selecting the most suitable one for your feline friend can feel overwhelming. This guide will explore the various options of cat litter on the market, including traditional clay litter, clumping litter, natural and biodegradable litter, silica gel litter, scented and unscented litter, and even alternative options. We'll discuss the pros and cons of each type, so you can make an informed decision and select the best litter for your furry friend.

Clay Cat Litter

Traditional clay cat litter is one of the most popular options on the market. It's made from natural clay minerals that are dried and processed into small granules. Clay cat litter is available in both unscented and scented varieties, and is often the most affordable litter option.

One of the benefits of clay cat litter is its ability to absorb moisture, which helps control odors. However, it's important to note that traditional clay litter is non-clumping, which means it can be more difficult to clean and may require more frequent replacement.

In addition, some cat owners may have concerns about the environmental impact of using clay cat litter. The production and disposal of clay litter can contribute to environmental issues such as mining and landfill waste.

Overall, clay cat litter is a reliable and cost-effective option for cat owners who prioritize odor control. However, if you're looking for litter that's more environmentally friendly or easier to clean, other options may be worth considering.

Clumping Cat Litter

One of the most popular cat litter options on the market today is clumping cat litter. Known for its easy clean-up and convenience, this type of litter has become a go-to for many cat owners.

Clumping litter is made of small granules of clay or other absorbent materials that form tight clumps when wet, making it easy to scoop out urine and feces. This type of litter is also known as scoopable litter, due to its easy removal.

One key benefit of clumping cat litter is its ability to trap and eliminate odors quickly. The clumps form around any waste, sealing in smells and making it easier to keep litter boxes smelling fresh.

This type of litter is also highly absorbent, meaning it requires less frequent changes compared to non-clumping litter. With clumping litter, cat owners can simply scoop out the clumps and add more litter as needed, extending the life of the litter box fill.

However, there are some potential downsides to consider. Clumping litter can be more expensive than traditional non-clumping litter and may not be suitable for all cats. Some cats may be sensitive to the dust that is often created by this type of litter, leading to respiratory problems. To avoid these issues, it's important to select a high-quality clumping litter that is free of harsh chemicals and additives.

Natural and Biodegradable Cat Litter

For cat owners who are environmentally conscious, natural and biodegradable cat litter options are becoming increasingly popular. These litters are typically made from materials such as pine, corn, wheat, and recycled paper and are marketed as eco-friendly alternatives to traditional clay litter. However, they also have some potential drawbacks to consider.

Pros:

Environmentally friendly: These litters are often biodegradable, compostable, or recyclable, making them a more sustainable option than clay litter.

Dust-free: Many natural litters are less dusty than clay litter, which can be beneficial for cats and their owners who have respiratory issues.

Easy to dispose of: Some natural litters can be safely flushed down the toilet or composted in your backyard.

Cons:

Expensive: Natural and biodegradable litters are generally more costly than traditional clay litter.

Less effective odor control: Some natural litters may not control odor as well as clay litter, which can be a concern for cat owners.

Variability in quality: With so many options available, it can be difficult to find a natural litter that works well for you and your cat.

Tracking: Some natural litters can be lightweight and prone to tracking, meaning that your cat may carry litter outside the box.

Ultimately, the decision to use natural and biodegradable cat litter will depend on your individual preferences and values. If you are looking for a more sustainable option and are willing to pay a higher price, these litters may be a good fit for you and your feline friend. However, it's important to keep the potential drawbacks in mind and test out a few different options before committing to one particular brand.

Silica Gel Cat Litter

If you're looking for highly efficient and low-maintenance cat litter, silica gel cat litter might be the right option for you and your feline friend. This type of litter is made of small beads of silica gel, which are highly absorbent and can lock in moisture and odors effectively.

Silica gel cat litter also tends to last longer than other types of litter, as it doesn't need to be changed as frequently. It's also a good option for busy cat owners who want to minimize clean-up time, as the litter doesn't clump and can be easily scooped out of the litter box.

Crystal Cat Litter

One variation of silica gel cat litter is crystal cat litter, which is made of larger crystals that can absorb even more moisture. Crystal cat litter tends to be even more long-lasting than standard silica gel litter, and it can be a great option if you have multiple cats or a particularly busy litter box.

However, it's worth noting that some cat owners and cats may not enjoy the texture of crystal cat litter, as the large, hard crystals can be uncomfortable to walk on. Additionally, the litter can be quite dusty when poured or disturbed, which may be a concern for some households.

Scented and Unscented Cat Litter

When it comes to choosing cat litter, there are two main options to consider: scented and unscented. Scented cat litter is formulated with added fragrances to help control odor and create a more pleasant smell in the litter box. Unscented litter, on the other hand, does not contain any added fragrances and relies on other methods to control odor.

Many cat owners prefer the unscented litter to avoid potential fragrance sensitivity issues with their feline friends. Scented litter may also mask the odor of waste rather than neutralize it, which may be less effective for some cat owners.

Unscented litter may be a better option for cats with respiratory issues or sensitivity to certain fragrances. However, this type of litter may require more frequent cleaning and changing to keep the litter box fresh and odor-free.

Both scented and unscented litter options may come with added benefits such as strong clumping abilities for easy clean-up, low-dust formulas for those with allergies, or eco-friendly materials for those who prioritize sustainability.

Scented cat litter pros:

Added fragrance helps control odor

May create a more pleasant smell in the litter box

Some options may have strong clumping abilities and low-dust formulas

Scented cat litter cons:

May mask odor rather than neutralize it

Some formulas may contain harmful ingredients

May cause sensitivity issues for some cats and humans

Unscented cat litter pros:

No additional fragrances that may cause sensitivity issues

Maybe more natural and eco-friendly options are available

Some options may have strong clumping abilities and low-dust formulas

Unscented cat litter cons:

May require more frequent cleaning and changing to control odor

Does not have added fragrance to mask the odor

Cat Litter Alternatives

If you're looking for alternatives to traditional cat litter, there are a few options available.

Natural Litter Substitutes

Natural substitutes for cat litter can be a great option for environmentally conscious pet owners. Shredded newspaper, wood pellets, and even dried leaves can all be used as alternatives to traditional cat litter.

One benefit of these alternatives is that they are often cheaper than store-bought cat litter. They can also be composted or disposed of more easily than clay or crystal litter.

DIY Cat Litter

Another alternative to traditional cat litter is making your litter at home. This can be done by shredding old newspapers or using recycled materials like sawdust or wood chips.

While homemade litter may be cheaper than store-bought options, it can be time-consuming to make and may not provide the same level of odor control or moisture absorption as commercial litter.

Conclusion:

Choosing the right cat litter for your furry friend is essential for their health and well-being as well as your convenience and budget. After reviewing all the types of cat litter available, let's summarize the key points to keep in mind when selecting the best option for you and your pet. Pets Lounge UAE is your best destination for shopping for high-quality cat litter.

Feline Preference

Cats can be very picky when it comes to their litter box, and some may prefer a specific type of litter. Pay attention to your cat's behavior and preferences. Natural litters may be a good choice for cats who love to scratch and dig in their litter, while others may prefer the texture and scent of clumping clay litter.

Odor Control

If odor control is a top concern, consider scented or clumping litters, as they tend to be more effective at trapping odors. Unscented litter may be a better option for cats with fragrance sensitivities.

Budget

When it comes to cat litter, there's a range of prices available. While clay litter may be more affordable, it may also need to be replaced more frequently. Natural litter and silica gel litter may be more expensive, but they have longer-lasting properties. Consider your budget and how much you're willing to spend on cat litter before making a final decision.

Environmental Concerns

If reducing your environmental footprint is a top priority, opt for biodegradable and natural cat litter that is made from sustainable materials. These eco-friendly options are better for the planet and can be disposed of safely.

Ultimately, the right cat litter for you and your feline friend will depend on your preferences and needs. Consider the pros and cons of each option and be willing to experiment until you find the right one. Just remember, a happy cat means a happy pet owner, and choosing the right cat litter is an important part of creating a comfortable and healthy home for your beloved feline.

2 notes

·

View notes

Text

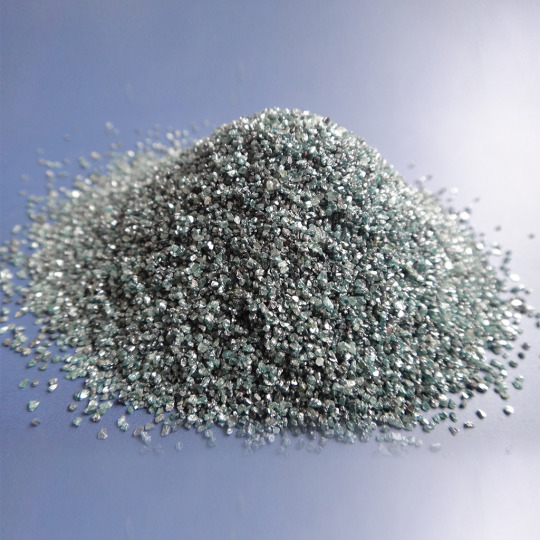

Introducing Nice Abrasive: Leaders in White Silicon Carbide

Nice Abrasive, a forefront name in the abrasive industry, is revolutionizing the market with its premium quality white silicon carbide products. Known for its superior hardness and high thermal conductivity, white silicon carbide is an essential material in various industrial applications. Nice Abrasive has honed its expertise to deliver unparalleled performance and reliability, setting new standards in the field.

What is White Silicon Carbide?

White silicon carbide, also known as carborundum, is a crystalline material produced by the high-temperature electrochemical reaction of silica and carbon. Its exceptional hardness makes it ideal for a variety of applications, including grinding, cutting, and polishing. The white variety is particularly noted for its purity and uniformity, which contribute to its effectiveness in precision applications.

Applications of White Silicon Carbide

Abrasive Tools: White silicon carbide is widely used in grinding wheels, sandpapers, and cutting tools due to its ability to cut hard materials efficiently.

Refractory Materials: Its high thermal conductivity and low thermal expansion make it an excellent choice for kiln furniture, furnace linings, and other high-temperature applications.

Electronics: In the electronics industry, white silicon carbide is used for semiconductors and LEDs, benefiting from its stability and thermal properties.

Surface Treatment: From blasting media to coatings, white silicon carbide is employed in various surface treatment processes to enhance durability and finish.

Nice Abrasive’s Commitment to Quality

At Nice Abrasive, quality is paramount. The company employs state-of-the-art production techniques and rigorous quality control measures to ensure that every batch of white silicon carbide meets the highest industry standards. Their commitment to excellence is reflected in the consistent performance and reliability of their products.

Why Choose Nice Abrasive?

Expertise and Innovation: With years of experience and a dedicated R&D team, Nice Abrasive continues to innovate, bringing advanced solutions to the market.

Customized Solutions: Understanding that each industry has unique needs, Nice Abrasive offers tailored solutions to meet specific requirements.

Global Reach: Serving clients worldwide, Nice Abrasive has built a reputation for dependability and superior customer service.

Environmental Responsibility

Nice Abrasive is also committed to sustainable practices. The company invests in eco-friendly production processes and ensures that their operations minimize environmental impact. By choosing Nice Abrasive, customers not only get top-notch products but also support a company that values sustainability.

Contact Nice Abrasive

To learn more about Nice Abrasive and their range of white silicon carbide products, visit their website or contact their customer service team. Discover how their expertise can help optimize your industrial processes and achieve superior results.

0 notes

Text

Nucleic Acid Sample Preparation Market Future Trends to Look Out | Bis Research

Nucleic acid sample preparation refers to the set of processes and techniques employed to isolate, purify, and prepare nucleic acids (DNA or RNA) from various biological samples for downstream applications and analysis.

The global Nucleic Acid Sample Preparation Market is projected to reach $5,615.9 million by 2033 from $2,922.8 million in 2023, growing at a CAGR of 6.75% during the forecast period 2023-2033.

Nucleic Acid Sample Preparation Overview

This process is critical for ensuring the integrity and quality of nucleic acids, which are essential for reliable and accurate downstream applications such as polymerase chain reaction (PCR), sequencing, and gene expression analysis.

Key Steps in Nucleic Acid Sample Preparation

Sample Collection

Cell Lysis

Nucleic Acid Isolation

Purification

Quantification and Quality Assessment

Grab a look at the free sample page for more understanding click here !

Nucleic Acid Sample Preparation Important Considerations

Contamination - Avoiding contamination with nucleases, other nucleic acids, and environmental contaminants is critical. Use nuclease-free reagents and consumables.

Sample Handling - Gentle handling minimizes mechanical shearing of nucleic acids.

Control Samples - Always include control samples to monitor for contamination and process consistency.

Sample Collection and Preparation

Biological Source - Samples can be obtained from various sources such as blood, tissue, saliva, buccal swabs, or cultured cells.

Preservation - Immediate and appropriate preservation is crucial. For RNA, samples should be stabilized quickly using RNA stabilizing agents (e.g., RNAlater) to prevent degradation by RNases. For DNA, samples should be kept at low temperatures or preserved in ethanol.

Cell Lysis

Lysis Buffers: The choice of lysis buffer depends on the sample type and the nucleic acid to be extracted.

Mechanical Disruption: Methods like bead beating, sonication, or homogenization are often used to physically disrupt tough tissue samples.

Nucleic Acid Extraction

Phenol-Chloroform Extraction: This traditional method uses phenol and chloroform to separate proteins from nucleic acids, followed by ethanol precipitation to concentrate the nucleic acids.

Silica Column-Based Extraction: Common in commercial kits, this method involves binding nucleic acids to a silica membrane in the presence of chaotropic salts, followed by washing and elution.

Magnetic Beads: Nucleic acids bind to magnetic beads under specific conditions, allowing for easy washing and elution with the help of a magnetic field.

4. Purification

RNase and DNase Treatment: To remove contaminating RNA from DNA preparations, DNase treatment is applied, and vice versa for RNA preparations.

Column Wash Steps: Additional wash steps in column-based methods help to remove impurities such as proteins, salts, and other contaminants.

5. Quantification and Quality Assessment

Spectrophotometry: Measuring absorbance at 260 nm (A260) provides a quantitative estimate of nucleic acid concentration. The A260/A280 ratio indicates protein contamination, with ideal values around 1.8 for DNA and 2.0 for RNA.

Fluorometry: More sensitive than spectrophotometry, fluorometric assays (e.g., Qubit) use fluorescent dyes that bind specifically to nucleic acids.

Electrophoresis: Agarose gel electrophoresis can be used to assess the integrity and size distribution of the nucleic acids.

6. Storage

Short-Term Storage: Nucleic acids can be stored at 4°C for short-term use.

Long-Term Storage: For long-term preservation, DNA is stored at -20°C or -80°C, while RNA is best stored at -80°C to prevent degradation.

Nucleic Acid Sample Preparation Market Drivers

Increasing demand for molecular diagnostics

Advancements in Biotechnology and Genomics

Rising Research and Development Activities

Expansion of Biopharmaceutical Manufacturing

Key Market Players

Agilent Technologies, Inc.

Autogen, Inc.

Bio-Rad Laboratories, Inc.

Roche AG

Merck KGaA

and many others

Visit our Precision Medicine Vertical Page Click Here !

Market Segmentation

Product Type

End Users

Applications

Geography

Various different applications involved are as follows

Clinical Diagnostics

Biomedical Research

Pharmaceutical and Biotechnology Development

Agricultural Biotechnology

And many others

Recent Developments in the Nucleic Acid Sample Preparation Market Market

Qiagen N.V. introduced two groundbreaking additions to its sample technologies portfolio, i.e., the TissueLyser III that facilitates high-throughput disruption of diverse biological samples and the RNeasy PowerMax Soil Pro Kit that isolates high-purity RNA from challenging soil samples using advanced Inhibitor Removal Technology.

PerkinElmer introduced the CHEF Magnetic Bead Cleanup System, providing automated nucleic acid purification through advanced magnetic bead technology. This novel system would help automate the nucleic acid purification process efficiently.

Conclusion

In conclusion, the Nucleic Acid Sample Preparation market continues to experience significant growth and expansion driven by a multitude of factors. The increasing demand for molecular diagnostics, fueled by the prevalence of infectious diseases and genetic disorders, underscores the importance of nucleic acid-based testing in clinical settings.

Overall, the Nucleic Acid Sample Preparation market is poised for continued expansion, driven by ongoing advancements in technology, increasing research and development activities, and the growing demand for molecular diagnostics and personalized medicine.

0 notes

Text

Silica Prices: During the First Quarter of 2024

Silica prices have experienced significant fluctuations in recent years, influenced by various factors ranging from supply and demand dynamics to economic conditions and technological advancements. Silica, a key raw material used in a wide array of industries including glass manufacturing, construction, electronics, and oil and gas production, plays a pivotal role in global economic activities.

The demand for silica is driven primarily by the construction industry, where it is used in the production of concrete, mortar, and other construction materials. As urbanization and infrastructure development continue to expand globally, the demand for silica has remained robust. Additionally, the electronics industry, particularly the semiconductor sector, relies heavily on high-purity silica for the production of integrated circuits and electronic components. With the increasing proliferation of smartphones, tablets, and other electronic devices, the demand for silica in this sector has also surged.

On the supply side, silica is abundantly available in nature, with quartz being the most common form. However, not all silica deposits are suitable for commercial exploitation due to variations in purity and accessibility. This has led to disparities in supply across different regions, contributing to price differentials in the global silica market. Moreover, the extraction and processing of silica involve significant energy and resource inputs, further impacting production costs and pricing dynamics.

Get Real Time Prices of Silica: https://www.chemanalyst.com/Pricing-data/silica-1304Geopolitical factors and trade policies also play a significant role in shaping silica prices. Trade tensions between major silica-producing countries can disrupt supply chains and lead to price volatility. Additionally, regulatory changes related to environmental protection and occupational health and safety standards can impact production costs, thereby influencing silica prices.

Technological advancements have also had a profound impact on silica prices. Innovations in extraction and processing techniques have helped improve efficiency and reduce production costs, contributing to price stabilization or even declines in some cases. Furthermore, the development of alternative materials and substitutes for silica in certain applications has exerted downward pressure on prices by expanding the range of options available to consumers.

In recent years, the COVID-19 pandemic has emerged as a significant driver of silica prices. The pandemic-induced disruptions to global supply chains and construction activities have led to fluctuations in demand and supply, resulting in price volatility. However, as economies recover and infrastructure projects resume, the demand for silica is expected to rebound, potentially driving prices higher in the medium to long term.

Environmental and sustainability concerns are increasingly influencing silica prices and market dynamics. With growing awareness of the environmental impacts associated with silica extraction and processing, as well as the carbon footprint of silica-based products, there is a growing demand for sustainably sourced and eco-friendly alternatives. This has prompted silica producers to invest in cleaner technologies and sustainable practices, which can affect production costs and ultimately influence prices.

Looking ahead, silica prices are likely to remain influenced by a complex interplay of factors, including economic trends, technological developments, geopolitical dynamics, and environmental considerations. As industries continue to evolve and adapt to changing market conditions, the silica market is expected to undergo further transformation, with implications for pricing strategies and supply chain management. In this dynamic landscape, stakeholders must stay informed and agile to navigate the challenges and opportunities that lie ahead in the global silica market.

Get Real Time Prices of Silica: https://www.chemanalyst.com/Pricing-data/silica-1304

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

A Comprehensive Guide to a Multifunctional Natural Product

Seema Minerals & Metals is a renowned supplier of high-quality Diatomaceous Earth, catering to various industries globally. Offers a wide array of DE products tailored to specific applications, ensuring optimal performance and customer satisfaction. Committed to maintaining stringent quality control standards to deliver pure and effective DE. Invests in research and development to innovate new applications and improve existing products. Supplies DE to numerous countries, establishing a robust international presence. Provides excellent customer service, offering technical support and product guidance.

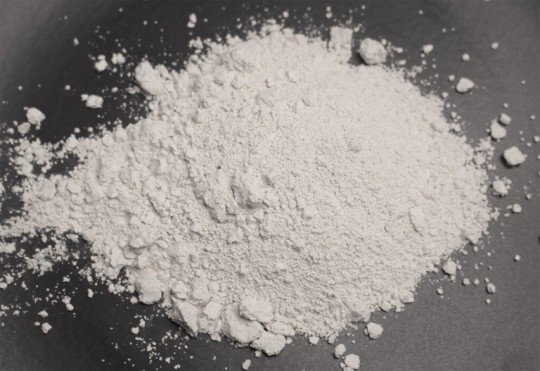

Introduction

DE is a naturally occurring, soft, siliceous sedimentary rock that can be crumbled into a fine white to off-white powder. Composed mainly of the fossilized remains of diatoms, a type of hard-shelled algae. Typically looks like a fine, white powder, with a mildly abrasive texture.

Origins and Formation

Formed from the accumulation of diatom remains over millennia, primarily in freshwater and marine environments. Significant DE deposits are found worldwide, including in the USA, Germany, and China.

Properties of DE

Lightweight, porous, and slightly abrasive. High in silica content (80-90%), with small amounts of other minerals. Can withstand high temperatures, making it suitable for various industrial applications.

Applications of DE

Widely used in water filtration, including swimming pool filters and potable water systems, due to its ability to trap fine particles. Acts as a natural insecticide by damaging the exoskeletons of insects, leading to dehydration. Used as a soil conditioner and a natural pesticide, promoting healthy plant growth. Utilized as an anti-caking agent, a clarifying agent in beer and wine production, and a component in animal feed. Incorporated into products like toothpaste, facial scrubs, and dietary supplements for its abrasive and detoxifying properties. Employed in the production of paint, plastics, rubber, and as a stabilizing component in dynamite.

Health Benefits and Safety

Claimed to support detoxification, improve digestive health, and provide trace minerals. However, these claims should be approached cautiously and preferably under medical advice. Safe for use in personal care products due to its gentle abrasive nature. While food-grade DE is considered safe for consumption and use, inhaling DE dust can cause respiratory issues. Proper handling and protective measures are essential.

Environmental Impact

Biodegradable and non-toxic, making it an environmentally friendly alternative to chemical pesticides and industrial additives. Abundant and naturally replenishing, ensuring a sustainable supply.

Market Demand and Trends

Increased awareness of natural and eco-friendly products is driving the demand for DE. Emerging applications in health supplements, cosmetics, and green pest control are expanding the market. Seema Minerals & Metals stands out due to its commitment to quality and customer satisfaction.

Potential Risks and Mitigation

Wear protective masks to avoid respiratory issues when handling DE powder. Use gloves to prevent potential skin irritation from prolonged exposure. Ensure proper disposal and avoid contaminating water sources.

Conclusion

DE is a versatile, eco-friendly material with a wide range of applications across multiple industries. Seema Minerals & Metals: A trusted supplier committed to quality, innovation, and customer satisfaction. With ongoing research and development, the potential uses of DE continue to expand, promising a sustainable and beneficial resource for various applications.

By understanding the multifaceted benefits and applications of DE, businesses and consumers can make informed decisions about incorporating this remarkable natural resource into their practices. Seema Minerals & Metals remains at the forefront, providing top-tier DE products and supporting its customers every step of the way.

Contact Us today to learn more about our products and how they can benefit you. Reach out to our expert team for personalized advice and exceptional customer support. Let's start a conversation and explore how we can help you harness the power of this amazing natural resource.

0 notes

Text

Australia Supplementary Cementing Materials Market Is Likely to Experience a Tremendous Growth in Near Future

Latest added Australia Supplementary Cementing Materials Market research study by Market Research Forecast offers detailed outlook and elaborates market review till 2030. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario; some of the key players in the study are Cement Australia (Australia),Boral (Australia),Wagners (Australia),Fly ash Australia (Australia),Adelaide Brighton Cement (Australia),Millmerran Flyash (Australia),Hallett Group (Australia)} etc.

Free Sample Report + All Related Graphs & Charts @: https://marketresearchforecast.com/report/australia-supplementary-cementing-materials-market-1359/sample-report

The Australia Supplementary Cementing Materials Marketsize was valued at USD 141.8 USD million in 2023 and is projected to reach USD 214.63 USD million by 2032, exhibiting a CAGR of 6.1 % during the forecast period.

The latest edition of this report you will be entitled to receive additional chapter / commentary on latest scenario, economic slowdown and COVID-19 impact on overall industry. Further it will also provide qualitative information about when industry could come back on track and what possible measures industry players are taking to deal with current situation. Each of the segment analysis table for forecast period also high % impact on growth.

This research is categorized differently considering the various aspects of this market. It also evaluates the upcoming situation by considering project pipelines of company, long term agreements to derive growth estimates. The forecast is analyzed based on the volume and revenue of this market. The tools used for analyzing the Global Australia Supplementary Cementing Materials Market research report include SWOT analysis.

Influencing Trend:

Rising Emphasis on Environmentally Sustainable Iron Production to Create New Growth Opportunities

Market Growth Drivers:

Expanding Packaging Industry to Propel the Market Growth

The Global Australia Supplementary Cementing Materials segments and Market Data Break Down are illuminated below:

Type: Fly Ash, Slag Cement, Silica Fumes, and Others,End-Use Industry: Construction, Agriculture, and Others}

Have Any Questions Regarding Global Australia Supplementary Cementing Materials Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/australia-supplementary-cementing-materials-market-1359/enquiry-before-buy The regional analysis of Global Australia Supplementary Cementing Materials Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2021-2030.

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article, we can also provide customized report as per company’s specific needs. You can also get separate chapter wise or region wise report versions including North America, Europe or Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

Market Research Forecast

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

0 notes

Text

The Rise of AAC Block Factories in India: Paving the Way for Sustainable Construction

In the realm of construction, the push towards sustainable and eco-friendly building materials has led to the adoption of Autoclaved Aerated Concrete (AAC) blocks. In India, a country experiencing massive growth in infrastructure and housing development, AAC blocks have emerged as a popular choice. This is due to their lightweight, thermal insulation, fire resistance, and energy efficiency. The rise of AAC block factories in India not only aligns with the global trend of environmentally conscious construction but also presents unique opportunities and challenges in the Indian context.

Overview of AAC Blocks

AAC blocks are manufactured from natural ingredients including sand, lime, cement, water, and an aerating agent, typically aluminum powder. These components undergo a high-temperature autoclave process which results in the creation of air pockets within the blocks, giving them their lightweight and insulative properties. The final product is a building material that is about one-fifth the weight of traditional concrete, making it easier to handle and transport, while still providing significant structural integrity.

Growth of AAC Block Factories in India

The proliferation of AAC block factories in India can be attributed to several factors. Firstly, the Indian government’s initiatives to promote sustainable development have encouraged the construction industry to adopt greener practices. AAC blocks contribute significantly to this by reducing the overall carbon footprint of buildings. They require less energy to manufacture compared to traditional bricks and their lightweight nature reduces emissions related to transportation.

Secondly, the increasing cost of traditional building materials like clay bricks, coupled with environmental regulations restricting clay mining, has made AAC blocks an attractive alternative. Moreover, AAC blocks offer better earthquake resistance, which is crucial in a seismically active country like India.

Manufacturing Process in Indian Context

The manufacturing process in an Indian AAC block factory typically involves several key stages:

Raw Material Preparation: Silica-rich materials and lime are finely ground to produce a homogeneous mixture. Cement acts as a binder while gypsum helps in adjusting the setting time of the concrete.

Batching and Mixing: Ingredients are then batched and mixed with water and an aluminum powder paste which acts as the aerating agent. This mixture forms a slurry that is poured into molds.

Cutting and Curing: Once the slurry sets slightly, it is cut into blocks or panels using wire cuts or saws. These are then cured under heat and pressure in autoclaves for up to 12 hours, which significantly enhances their mechanical properties.

Packaging and Distribution: The finished blocks are packaged and stored in moisture-free conditions before being distributed.

Challenges Facing AAC Block Factories in India

Despite their benefits, AAC block factories in India face several challenges:

Initial Investment: Setting up an AAC block factory requires substantial initial investment, particularly in machinery and technology. This can be a barrier for small to medium enterprises.

Awareness and Adoption: There is still a significant portion of the construction industry in India that relies on traditional materials due to lack of awareness about the benefits of AAC blocks.

Distribution and Logistics: Given their bulk, even though lighter than traditional blocks, AAC blocks require efficient logistics solutions to minimize damage during transport and to reach remote construction sites effectively.

Market Potential and Future Outlook

The market for AAC blocks in India is projected to grow significantly. Urbanization is a key driver of this growth, with cities expanding and new urban centers emerging. The demand for residential and commercial spaces that adhere to newer, stricter building codes favoring energy efficiency and environmental sustainability is expected to rise.

In addition, the Indian government’s focus on affordable housing projects under schemes like the Pradhan Mantri Awas Yojana (PMAY) provides a significant opportunity for the expansion of AAC usage. The factory-made quality of AAC blocks ensures consistent performance, which is essential for such large-scale housing projects.

Technological Innovations and Skilled Workforce Development

As AAC block factories grow in number across India, technological advancements play a crucial role in optimizing production efficiency and product quality. Modern AAC factories are increasingly incorporating automation and robotics to streamline various stages of the manufacturing process, from raw material handling to final packaging. This not only increases production capacity but also enhances the consistency of the blocks produced, a critical factor in large-scale construction projects.

Furthermore, the growth of this industry has spurred the need for a skilled workforce capable of operating sophisticated machinery and managing the technical aspects of AAC production. Training programs and partnerships with educational institutions are vital for developing the necessary human resources. Initiatives to train workers not only support the AAC industry but also contribute to job creation, uplifting the socio-economic status of communities around manufacturing sites, thereby fostering a more skilled and economically active population.

Conclusion

AAC block factories in India represent a pivotal shift in the construction landscape, embodying the move towards more sustainable, efficient, and innovative building practices. While challenges remain, the potential for growth and the benefits of adopting AAC blocks are clear. As more stakeholders in the construction industry recognize these benefits, AAC block factories are set to play a crucial role in India’s construction boom, aligning economic growth with environmental sustainability. The future of construction in India, with AAC blocks at the forefront, looks not only promising but also greener and more sustainable.

0 notes

Text

"Silica Sensation: Unveiling Specialty Silica Market Trends (2024-2033)"

The specialty silica market is poised for significant growth from 2024 to 2033, driven by its diverse applications across industries such as rubber, coatings, and personal care.

Market research indicates a rising demand for specialty silica due to its unique properties including reinforcement, abrasion resistance, and rheology modification, which enhance product performance and durability. With increasing applications in high-performance tires, silicone rubber, and advanced coatings, specialty silica is becoming an indispensable component in various manufacturing processes. Moreover, the growing emphasis on sustainability and environmental regulations is prompting manufacturers to develop eco-friendly and renewable specialty silica formulations, aligning with the broader trend towards green manufacturing practices. As industries strive for innovation and efficiency, specialty silica is expected to play a pivotal role in shaping the future of materials science and industrial development. This decade will witness continued advancements in specialty silica technologies, driving market expansion and fostering sustainability in various sectors. #SpecialtySilica #MarketTrends #RubberIndustry #CoatingsIndustry #PersonalCare #Sustainability #GreenManufacturing #MaterialsScience #Innovation #HighPerformance #EcoFriendly #RenewableMaterials #IndustrialDevelopment #MarketExpansion #SilicaSensation #FutureofMaterials

0 notes

Text

Ilmenite Market: Sustainable Solutions with Titanium Dioxide Photocatalysts

Decoding Ilmenite Industry: Exploring the economic and Environmental Impact

Formation and Properties

Ilmenite is a widespread titanium-iron oxide mineral with the chemical formula FeTiO3. It forms as a natural material from magmatic or hydrothermal processes. When lava or magma cools slowly, it will crystallizes and solidifies. Contact metamorphism of suitable rocks under mountain building processes can also result in new formation.

It has a hexagonal crystal structure and usually forms black to steel-gray crystals. However, it can also appear in massive forms without distinct crystal shapes. It has a Mohs hardness of 5.5-6.5 and specific gravity in the range of 4.7-5. Its luster is typically submetallic. It is quite common in igneous and metamorphic rocks worldwide. Some of the notable ilmenite deposits are found in Australia, South Africa, Canada, Ukraine and India.

Uses and Demand

It is one of the most industrially useful ores as it is the chief ore of titanium. Around 60% of the global ilmenite production is utilized to manufacture titanium dioxide pigment. Titanium dioxide pigment has premium qualities like brightness, opacity and durability. It finds extensive applications in paints, plastics, paper, textiles, rubber and other industries.

A major portion of the remaining ilmenite is processed to obtain titanium metal and titanium alloys. Titanium and its alloys have outstanding corrosion resistance and high strength to weight ratio. They are extensively used in aerospace, military, medical and other specialized applications. It is also a rich source of iron units that can be recovered as by-products during titanium processing.

With rising global consumption of titanium dioxide pigment and increasing demand from high-tech industries, the market for ilmenite is steadily growing. Ilmenite production in most years over the last decade has been pegged at 6-7 million tonnes annually. Australia with its mineral sands deposits is the leading producer followed by South Africa and Canada. Countries like India, Ukraine, and Vietnam are also emerging as important players.

Beneficiation and Processing

Raw ilmenite as mined contains other associated mineral impurities like silica, rutile, zircon, monazite apart from iron. Hence, it needs to be upgraded through various beneficiation methods before utilization. Commonly used beneficiation techniques include washing, magnetic separation, electrostatic separation, gravity separation etc.

This upstream processing liberates the valuable residue from gangue minerals and improves its iron and titanium content. Washing deslimes and removes most of the silica impurities. Electrostatic separation exploits the difference in electrical conductivity between ilmenite and other minerals. Magnetic separation works on its magnetic properties to concentrate it.

The next stage involves metallurgical processing to recover titanium, iron units and produce value added products. Rotary kiln processes roasted concentrates at 1000-1200 °C to form synthetic rutile or titanium slag as intermediate products. These are then subject to chlorination or sulphate processes to yield pure titanium tetrachloride which upon hydrolysis produces titanium dioxide. Additional processing produces titanium metal, sponge and alloys.

Environmental Concerns and Regulations

Major environmental issues relate to land disturbance, dust generation, sedimentation of rivers during beneficiation plant operations. Toxic tailings and slag from processing plants require scientific disposal and management.

Stringent regulations are in place worldwide to control emissions, effluents, dumping/storage of wastes from titanium industries. Environmental Impact Assessments and Cleaner Production plans are mandatory. Mining leases specify strict compliance on pollution control, site reclamation and biodiversity conservation measures. In many countries, public consultation is part of approval process for new projects.

With growing environmental consciousness, the titanium sector emphasises on judicious resource utilisation, recycling, greener technologies and sustainability. Adoption of international standards on safety, health and environment protection will enable responsible mining and value addition of this important mineral resource for the long term.

So in summary, ilmenite is a key industrial mineral with major applications in pigment and metal industries. Its deposits are widely distributed but selective countries dominate production. Beneficiation and metallurgical processing upgrades it into various economically valuable titanium compounds and alloys. Like all mining activities, this industry too needs to factor in environmental management for sustainable development.

0 notes

Text

Technical Insulation Market: Trends, Growth, and Forecast

Introduction

The Technical Insulation Market plays a vital role in various industries by providing thermal, acoustic, and fire protection solutions. From residential buildings to industrial facilities, technical insulation is essential for optimizing energy efficiency, enhancing occupant comfort, and ensuring the safety and longevity of infrastructure. In this comprehensive analysis, we delve into the key trends, growth drivers, and future forecasts shaping the Technical Insulation Market.

According to the study by Next Move Strategy Consulting, the global Technical Insulation Market size is predicted to reach USD 11.82 billion with a CAGR of 4.0% by 2030.

Request for a sample, here: https://www.nextmsc.com/technical-insulation-market/request-sample

Trends Shaping the Technical Insulation Market

Rising Demand for Energy Efficiency

The increasing emphasis on energy efficiency across industries is a primary driver fueling the demand for technical insulation solutions. As organizations strive to reduce energy consumption and minimize environmental impact, there is a growing preference for insulation materials that offer superior thermal performance. Technical insulation plays a crucial role in minimizing heat loss or gain in buildings, industrial equipment, and pipelines, thereby contributing to energy conservation efforts.

Advancements in insulation materials, such as aerogels, vacuum insulation panels, and eco-friendly foams, are enabling improved thermal insulation properties while ensuring sustainability. These innovative materials offer high thermal resistance and durability, making them ideal for applications where energy efficiency is paramount.

Advancements in Insulation Materials

Technological innovations have revolutionized the technical insulation industry, leading to the development of advanced materials with superior performance characteristics. Traditional insulation materials such as fiberglass and mineral wool are being augmented with newer options that offer enhanced thermal conductivity, moisture resistance, and fire retardancy.

Aerogels, for instance, are lightweight, highly porous materials with exceptional thermal insulating properties. These silica-based materials possess low thermal conductivity, making them effective insulators for a wide range of applications, including building envelopes, cryogenic systems, and aerospace components.

Vacuum insulation panels (VIPs) represent another breakthrough in insulation technology. Consisting of a rigid core encased in a gas-tight envelope, VIPs achieve extremely low thermal conductivity by minimizing convective and conductive heat transfer. These panels are increasingly being used in refrigeration, cold chain logistics, and building insulation applications.

Furthermore, eco-friendly insulation materials derived from renewable sources, such as soybean oil-based foams and cellulose insulation made from recycled paper, are gaining traction due to their sustainability credentials. These bio-based materials offer comparable thermal performance to traditional insulation options while reducing environmental impact.

Focus on Green Building Standards

The construction industry is undergoing a paradigm shift towards sustainable building practices, driven by increasing awareness of environmental conservation and energy efficiency. Green building standards and certifications, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), are becoming increasingly prevalent, influencing design and construction decisions worldwide.

Technical insulation plays a pivotal role in achieving green building certifications by enhancing energy efficiency and thermal comfort within buildings. By minimizing heat transfer through walls, roofs, and floors, insulation helps reduce heating and cooling loads, thereby lowering energy consumption and operational costs. Additionally, insulation materials with high recycled content and low embodied energy contribute to the overall sustainability of building projects.

Expansion in Industrial Infrastructure

The rapid expansion of industrial infrastructure, particularly in emerging economies, is driving significant demand for technical insulation solutions. Industries such as power generation, oil and gas, petrochemicals, and manufacturing rely heavily on insulation to maintain optimal operating temperatures, protect personnel and equipment, and ensure process efficiency.

In power generation facilities, for example, thermal insulation is critical for steam turbines, boilers, and piping systems to minimize heat losses and maximize energy conversion efficiency. Similarly, in the oil and gas sector, insulation is utilized in pipelines, storage tanks, and processing equipment to prevent heat transfer, reduce energy consumption, and mitigate the risk of corrosion under insulation (CUI).

The petrochemical industry also relies on technical insulation for maintaining process temperatures and ensuring product quality and safety. Insulation materials with excellent chemical resistance and thermal stability are essential for withstanding harsh operating conditions in chemical processing plants and refineries.

Growth Drivers of the Technical Insulation Market

Regulatory Mandates

Stringent regulations and building codes mandating the use of energy-efficient insulation materials are driving market growth across regions. Governments worldwide are implementing measures to reduce greenhouse gas emissions, combat climate change, and promote sustainable development. As a result, building energy codes are being updated to include requirements for enhanced thermal performance and insulation levels.

In Europe, for instance, the Energy Performance of Buildings Directive (EPBD) sets minimum energy performance standards for new and existing buildings, including requirements for thermal insulation. Similarly, in the United States, the International Energy Conservation Code (IECC) establishes criteria for building envelope insulation, HVAC systems, and lighting efficiency to improve overall energy efficiency.

Compliance with these regulatory mandates necessitates the adoption of advanced insulation materials and construction techniques to achieve the prescribed energy performance targets. As a result, manufacturers and suppliers of technical insulation products are witnessing increased demand for their solutions, particularly those that offer high thermal resistance, durability, and environmental sustainability.

Urbanization and Industrialization

The ongoing trends of urbanization and industrialization are driving the demand for technical insulation solutions globally. As populations migrate to urban centers in search of employment opportunities and better living standards, there is a corresponding need for infrastructure development to accommodate growing urban populations.

Residential and commercial construction projects in urban areas require effective insulation solutions to ensure thermal comfort, indoor air quality, and energy efficiency. Proper insulation of buildings helps reduce heating and cooling loads, thereby lowering energy consumption and utility bills for occupants.

In addition to urban construction, industrial infrastructure projects are also driving demand for technical insulation products. The expansion of manufacturing facilities, power plants, refineries, and chemical processing plants necessitates the installation of insulation systems to maintain process temperatures, protect equipment, and ensure operational reliability.

Focus on Renewable Energy

The global transition towards renewable energy sources, such as solar, wind, and geothermal power, is creating new opportunities for the technical insulation market. Renewable energy technologies rely on efficient insulation systems to maximize energy capture, storage, and distribution while minimizing heat losses and environmental impact.

Solar photovoltaic (PV) systems, for example, require insulation materials to protect electrical components, minimize thermal losses, and optimize performance under varying weather conditions. Insulated piping and storage tanks are essential for solar thermal systems used for heating water or generating steam for industrial processes.

Similarly, wind turbines utilize insulation to protect critical components such as gearboxes, generators, and control systems from temperature extremes, moisture ingress, and mechanical wear. Insulated enclosures and thermal barriers help maintain stable operating conditions within turbine nacelles, ensuring reliable performance and longevity.

Geothermal heating and cooling systems also rely on effective insulation to enhance energy efficiency and thermal stability. Underground piping networks, heat exchangers, and thermal storage tanks are insulated to minimize heat loss during heat transfer processes, thereby improving system efficiency and reducing operating costs.

Forecast for the Technical Insulation Market

The outlook for the technical insulation market remains promising, with sustained growth expected in the coming years. Factors such as increasing investments in infrastructure development, regulatory support for energy efficiency initiatives, and the expansion of end-use industries will drive market expansion across regions.

Furthermore, advancements in insulation materials, manufacturing processes, and installation techniques will continue to drive innovation and product development in the technical insulation sector. Manufacturers are investing in research and development to enhance the performance, sustainability, and cost-effectiveness of their insulation products, thereby addressing evolving customer needs and market demands.

Regional Insights and Market Dynamics

North America

North America is a significant market for technical insulation products, driven by robust construction activity, industrial expansion, and regulatory mandates for energy efficiency. The United States and Canada are witnessing increased adoption of insulation solutions in residential, commercial, and industrial applications to meet stringent building codes and sustainability goals.

In the United States, initiatives such as the Department of Energy's Better Buildings Challenge and the Environmental Protection Agency's ENERGY STAR program are driving demand for energy-efficient building solutions, including insulation upgrades and retrofits. Building owners and facility managers are investing in insulation improvements to reduce energy consumption, lower operating costs, and enhance occupant comfort.

Inquire before buying, here: https://www.nextmsc.com/technical-insulation-market/inquire-before-buying

Europe

Europe leads the global technical insulation market, supported by stringent energy efficiency regulations, green building standards, and sustainability initiatives. Countries such as Germany, the United Kingdom, France, and Scandinavia are at the forefront of sustainable construction practices, driving demand for high-performance insulation materials and systems.

The European Union's Energy Efficiency Directive (EED) sets ambitious targets for reducing energy consumption and greenhouse gas emissions, spurring investments in energy-efficient building envelopes and HVAC systems. The nearly-zero energy building (NZEB) concept, which aims to minimize energy demand and maximize renewable energy use in new construction, is driving the adoption of advanced insulation solutions across Europe.

Asia Pacific

Asia Pacific is emerging as a lucrative market for technical insulation products, fueled by rapid urbanization, industrialization, and infrastructure development. Countries such as China, India, Japan, South Korea, and Australia are witnessing significant investments in residential, commercial, and industrial construction projects, driving demand for insulation materials and systems.

In China, the government's focus on sustainable development and green building initiatives is driving the adoption of energy-efficient building materials, including insulation products. The implementation of building energy codes and certification programs, such as Three-Star and Green Building Label, incentivizes developers and building owners to invest in insulation upgrades and energy-saving measures.

In India, the construction of smart cities, industrial corridors, and infrastructure projects is driving demand for technical insulation solutions to enhance energy efficiency, occupant comfort, and environmental sustainability. Insulation manufacturers are partnering with developers, architects, and contractors to promote the use of advanced insulation materials and construction techniques in building projects.

Latin America

Latin America is experiencing steady growth in the technical insulation market, driven by infrastructure investments, urban development, and regulatory measures to promote energy efficiency. Countries such as Brazil, Mexico, Argentina, and Chile are witnessing increased demand for insulation products in residential, commercial, and industrial applications.

In Brazil, the construction of new residential complexes, commercial buildings, and industrial facilities is driving demand for thermal insulation materials to improve energy efficiency and indoor comfort. The government's My House My Life program, aimed at providing affordable housing to low-income families, includes provisions for energy-efficient building design and insulation installation.

In Mexico, the implementation of building energy codes and standards is driving the adoption of insulation solutions in new construction and retrofit projects. The National Housing Commission (CONAVI) promotes sustainable building practices and energy-efficient technologies, encouraging developers to incorporate insulation upgrades and energy-saving measures in housing projects.

Middle East and Africa

The Middle East and Africa region is witnessing increasing demand for technical insulation products, driven by infrastructure development, urbanization, and industrial expansion. Countries such as Saudi Arabia, the United Arab Emirates, South Africa, and Nigeria are investing in construction projects and energy infrastructure, driving demand for insulation materials and systems.

In the Gulf Cooperation Council (GCC) countries, the construction of residential, commercial, and industrial buildings is driving demand for insulation solutions to mitigate heat transfer and enhance energy efficiency. Insulation manufacturers are leveraging innovative materials and technologies to address the region's unique climate challenges and regulatory requirements.

In South Africa, the government's focus on sustainable development and energy efficiency is driving investments in green building initiatives and renewable energy projects. The Green Building Council of South Africa (GBCSA) promotes green building practices and certification programs, incentivizing developers to incorporate insulation upgrades and energy-saving measures in building projects.

Conclusion

In conclusion, the Technical Insulation Market is poised for significant growth driven by evolving trends, regulatory mandates, and the need for sustainable solutions. Advancements in insulation materials, technological innovations, and market dynamics will continue to shape the industry landscape, presenting opportunities for stakeholders across the value chain.

As industries strive to enhance energy efficiency, reduce environmental impact, and comply with regulatory requirements, the demand for technical insulation solutions will continue to rise. Manufacturers, suppliers, contractors, and end-users must collaborate to develop and implement cost-effective, high-performance insulation solutions that meet the evolving needs of the market.

By embracing innovation, sustainability, and collaboration, the Technical Insulation Market can play a pivotal role in advancing energy conservation, environmental stewardship, and sustainable development worldwide.

#technical insulation#materials#chemicals#metals#minerals#business insights#market research#market trends

0 notes

Text

Arrow Smith and VRX Silica: Pioneering Sustainable Silica Sand Mining

Arrow Smith and VRX Silica have emerged as industry leaders in the field of sustainable silica sand mining. With a strong commitment to environmental responsibility and innovative practices, they are revolutionizing the way mining operations impact the ecosystem. In this article, we explore the accomplishments and milestones of Arrow Smith and VRX Silica's Arrowsmith North Silica Sand Project, shedding light on their sustainable initiatives and the path they are paving for the future.

Environmental Review Document Approval: A Turning Point for Arrowsmith North Project

DWER's approval of the Environmental Review Document (ERD) marks a significant milestone for Arrow Smith and VRX Silica.

The commencement of the Public Environmental Review (PER) period reflects their commitment to transparency and environmental responsibilities.

VRX Silica's proposed unique rehabilitation method for the mined area showcases their dedication to native vegetation regeneration.

Milestones in the Approvals Process: Demonstrating Dedication and Compliance

VRX Silica's previous confirmation from the Commonwealth Department of Climate Change, Energy, the Environment, and Water highlights their commitment to meeting regulatory standards.

The Environmental Protection Authority's assessment and approval of the Environmental Scoping Document (ESD) indicate the project's progress.

The introduction of the Vegetation Direct Transfer (VDT) rehabilitation methodology underscores VRX Silica's innovative approach to site restoration.

Moving Forward: Public Environmental Review and Response

The completion of the four-week PER period initiates the collection and review of public submissions by the Department of Water and Environmental Regulation.

VRX Silica's diligent response to the submissions demonstrates their commitment to engaging with stakeholders and addressing concerns.

The compilation of an assessment report by the Environmental Protection Authority, containing recommendations for the Western Australian Environment Minister's decision, represents a crucial milestone.

Investor Outlook: Transparent and Responsible Development

VRX Silica's achievements in the approvals process for the Arrowsmith North Silica Sand Project reinforce their dedication to responsible development.

The significant increase in VRX Silica's share price and its market capitalization exemplify investor confidence in the company's sustainable practices.

VRX Silica's focus on four Western Australian silica sand projects, including the Arrowsmith North and Arrowsmith Central projects, highlights their commitment to long-term growth and positive environmental impact.

Conclusion:

Arrow Smith and VRX Silica are leading the charge in sustainable silica sand mining, setting new industry standards through their commitment to environmental responsibility. With their innovative practices, engagement with regulators, and dedication to stakeholder satisfaction, they are reshaping the future of mining. As the Arrowsmith North Silica Sand Project progresses, their achievements serve as a testament to the transformative power of sustainability in the resource extraction sector.

#Arrow Smith#VRX Silica#Arrowsmith North Silica Sand Project#Environmental Review Document#Public Environmental Review#Sustainable Mining#Silica Sand Mining#Rehabilitation Methodology#Environmental Responsibility#Environmental Protection Authority#Department of Water and Environmental Regulation#Mining Approvals Process#Native Vegetation Regeneration#Environmental Scoping Document#Vegetation Direct Transfer#Stakeholder Engagement#Investor Outlook#Resource Extraction#Sustainability#Market Capitalization#Share Price#Western Australia#Ecosystem Impact#Innovative Practices

0 notes

Text

Start Solar Panel Manufacturing Business

In the realm of renewable energy, solar power stands out as a beacon of hope for a sustainable future. With its abundant availability and low environmental impact, solar energy has emerged as a key player in the global energy transition. Central to the harnessing of solar power are solar panels, the backbone of solar energy systems. In this comprehensive guide, we delve into the intricate world of solar panel manufacturing and explore the thriving solar business landscape.

Understanding Solar Panel Manufacturing

Solar panels, also known as photovoltaic (PV) modules, are devices that convert sunlight into electricity through the photovoltaic effect. They consist of interconnected solar cells, typically made of silicon, which absorb sunlight and generate direct current (DC) electricity. This electricity is then converted into usable alternating current (AC) power through inverters for residential, commercial, and industrial applications.

1. Silicon Ingot Production:

The manufacturing process begins with the production of silicon ingots, the primary material used in solar cells. Silicon, extracted from silica sand, undergoes purification processes to achieve high purity levels required for efficient solar cell production.

2. Wafer Production:

Silicon ingots are sliced into thin wafers using diamond wire saws or multi-wire saws. These wafers undergo surface etching and doping processes to enhance their electrical conductivity and efficiency in converting sunlight into electricity.

3. Solar Cell Fabrication:

Wafers are then processed into solar cells through techniques such as diffusion, deposition, and metallization. This involves creating p-n junctions, applying anti-reflective coatings, and attaching metal contacts to facilitate the flow of electricity.

4. Module Assembly:

Solar cells are assembled into modules through encapsulation between tempered glass, EVA (ethylene-vinyl acetate) encapsulant, and back sheet materials. Frame assembly, junction box installation, and quality testing complete the manufacturing process.

Solar Business Landscape

The solar industry encompasses a diverse range of businesses involved in solar panel manufacturing, installation, financing, and maintenance. With increasing awareness of climate change and the need for clean energy solutions, the solar business landscape is witnessing exponential growth and innovation. Let’s explore key aspects of the solar business ecosystem:

1. Solar Panel Manufacturing Business:

Solar panel manufacturing companies play a crucial role in meeting the growing demand for solar energy systems worldwide. These companies invest in research and development to enhance solar panel efficiency, reduce manufacturing costs, and expand production capacity to meet market demand.

2. Solar Energy Business:

Beyond manufacturing, the solar energy business encompasses project development, installation, and operation of solar power plants. Solar developers identify suitable locations, secure permits, and finance solar projects, leveraging incentives and subsidies to make solar energy competitive with conventional sources.

3. Solar Farm Business Plan:

Solar farms, also known as solar parks or solar power plants, are large-scale installations that generate electricity from sunlight. Developing a solar farm business plan involves site selection, feasibility studies, financing arrangements, grid connection agreements, and regulatory compliance to ensure the project's success and profitability.

4. Solar Energy Business in India:

India has emerged as a global leader in solar energy deployment, driven by ambitious renewable energy targets, government incentives, and favorable solar irradiance conditions. The Indian solar business landscape presents lucrative opportunities for solar panel manufacturers, project developers, and investors seeking to capitalize on the country's renewable energy potential.

5. Solar Panel Business Plan:

A well-defined solar panel business plan outlines market analysis, competitive positioning, manufacturing strategy, distribution channels, sales projections, and financial forecasts. It serves as a roadmap for entrepreneurs and investors looking to enter or expand their presence in the solar panel market.

Future Outlook

The future of solar panel manufacturing and the solar business landscape looks promising, fueled by technological advancements, policy support, and growing environmental awareness. Key trends shaping the industry include:

1. Technological Innovation:

Ongoing research and development efforts aim to enhance solar panel efficiency, durability, and affordability through innovations in materials, manufacturing processes, and cell technologies such as thin-film, PERC (Passivated Emitter Rear Cell), and bifacial cells.

2. Market Expansion:

The global shift towards renewable energy, coupled with declining solar panel costs, is driving market expansion across residential, commercial, and utility-scale segments. Emerging markets in Asia, Africa, and Latin America present untapped opportunities for solar business growth.

3. Energy Storage Integration:

The integration of energy storage solutions such as lithium-ion batteries with solar power systems enables better grid stability, energy management, and increased self-consumption of solar-generated electricity, fostering the transition towards a decentralized energy paradigm.

4. Policy Support: