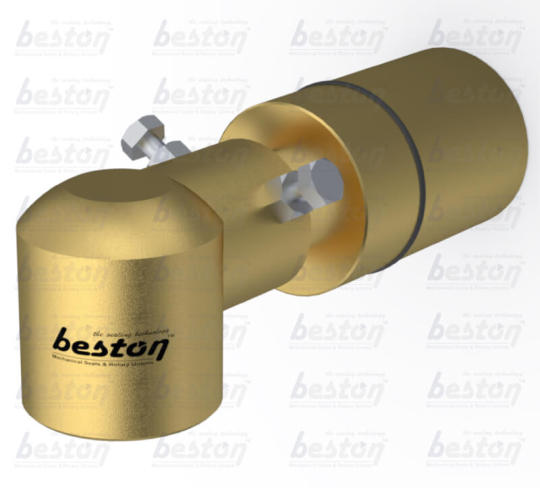

#Continuous Casting Machine Rotary Joints

Text

#Continuous Casting Machine Rotary Joints#Continuous Casting Machine Rotary Unions#Rotary Joints For Continuous Casting Machine#Rotary Unions For Continuous Casting Machine

0 notes

Text

Ningxia Ningchuang Innovation Material Technology Co., Ltd. signed an aluminum post-processing project

On March 28, the Ningxia party and government delegation held the Zhejiang-Ningxia Economic and Trade Cooperation and Entrepreneur Symposium in Hangzhou, inviting more than 180 enterprises and business associations to participate. The meeting was presided over by Chen Chunping, member of the Standing Committee of the Party Committee of Ningxia Hui Autonomous Region, executive vice chairman and deputy secretary of the party group of the People's Government of the Autonomous Region, and Wang Wenxu, vice governor of Zhejiang Province, attended and delivered a speech. Zhang Jianyang, general manager of Hangzhou Jinjiang Group, was invited to attend the conference and signed a contract.

At the meeting, Liang Yanshun, Secretary of the Party Committee of Ningxia Hui Autonomous Region and Director of the Standing Committee of the National People's Congress, praised the vast number of Zhejiang merchants and their spirit, and sincerely invited the majority of Zhejiang merchants to invest and start businesses in Ningxia, share development opportunities and unlimited business opportunities, and join hands to fight shoulder to shoulder and cooperate Win-win, constantly moving from victory to new victory. Zhang Yupu, Deputy Secretary of the Party Committee of Ningxia Hui Autonomous Region and Chairman of the Autonomous Region, introduced the development of Ningxia's economy, society and key industries.

Zhejiang Ningxia Economic and Trade Cooperation and Entrepreneur Symposium

The contracted projects include the aluminum post-processing project of Ningxia Ning Innovation Material Technology Co., Ltd., a subsidiary of Hangzhou Jinjiang Group, which was signed by Zhang Jianyang, the general manager of the group.

Ningxia Ningchuang Innovation Material Technology Co., Ltd. is a large-scale aluminum-magnesium new material and aluminum deep-processing product manufacturer invested and established by Hangzhou Jinjiang Group in Zhongning County, Ningxia Hui Autonomous Region in 2009. The company has always adhered to the concept of safe and green development, continuously strengthened enterprise management, and made important contributions to local economic development while achieving stable production and operation. As the main chain enterprise driving the development of Ningxia's aluminum-based industry and a key leading enterprise that stimulates the development of the local industrial economy, the company will accelerate the construction of deep-processing projects for the entire aluminum-based industry chain in the future and help Ningxia achieve high-quality development of the aluminum-based industry.

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter . metal foam filter. alumina foam. metal filtration.

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

degassing unit

0 notes

Text

0 notes

Text

Newbie's Information To Industrial Robots

These robots are used for handling of machine tools, spot welding, die casting, fettling machines, and fuel and arc welding. A cylindrical robot has at least one rotary joint on the base and at least one prismatic joint to connect the links. Along the joint axis, the rotary joint makes use of a rotational movement; alongside the prismatic joint, it moves in a linear movement https://columbiaokura.com/products/industrial-robots/.

They are used primarily within the food, pharmaceutical, and electronic industries. The robot itself is capable of precise motion, making it best for pick-and-place operations. The major concept past consists in using the mechanics of chosen "old" industrial robots and a very reengineering of the controller exhausting and software based on the latest requests from manufacturing automation. As the manufacturing and robotics industries proceed to develop side-by-side, a slew of new job alternatives are being created. Not solely are these kind of jobs extra fascinating, however in addition they take human workers out of probably harmful situations. Industrial robots can accomplish highly repetitive tasks with out the danger of accidents like carpal tunnel syndrome, or be employed for harmful tasks where staff can be uncovered to harmful fumes or environments.

The explanation why firms contemplate investing in a robot system differ widely. All the examples given up to now have centered on one category of producing robotics, which can be classified underneath the umbrella time period manipulation. Manipulation includes using robotic arms, the bases of which are stationary, but which have freedom to maneuver into any position and orientation within reach of the bottom, giving them precision and flexibility. Processes that require hard-to-find expert labor are frequent targets for startups constructing autonomous robotics choices as they give the impression of being to deal with probably the most acute ache points of producers. Painting, sanding, and welding fall into this class, and startups pursuing automation of those processes embody Graymatter Robotics, Omnirobotic, Path Robotics, and Scalable Robotics.

Others in addition, machine operators often use user interface units, usually touchscreen items, which function the operator control panel. The operator can switch from program to program, make adjustments inside a program and also function a host of peripheral gadgets that may be integrated inside the similar robotic system. Much of the bottleneck to reaching automation in manufacturing relates to limitations in the current programming model of commercial robotics.

If profitable, these endeavors will dramatically broaden industrial automation’s accessibility and applicability. The demand for industrial robots has accelerated significantly in current years because of continued technological developments in automation methods and synthetic intelligence. Since 2010, industrial robots have elevated by 9 per cent 12 months and on the finish of 2015 some 1.6 million robots had been deployed by industries worldwide. At their core, robots still do the mundane, monotonous and time-consuming tasks workers don't get pleasure from while providing invaluable data to enhance operations. Without sensors and different recent advancements, none of this is in a position to be potential. AI will reshape the capabilities of robotic tecnhology, but that is still at least a decade sooner or later.

Robotics start-ups are releasing solutions designed to help manufacturers address labor challenges, confront world competition and provide lasting business worth. Examples include merchandise and technologies that enhance the ease and speed of robotics software development, in addition to help sensor-driven autonomy and mobility. In the previous, robots had been asked to do very specific tasks, usually in a fixed location. But at present, the collaborative utility of industrial robots is evolving dramatically, because of environmentally conscious sensors that influence their kind issue and functionality.

The joints assist stabilize the platform over troublesome terrain, ensuring that it is in a position to climb steps with out flipping over. It can be used in uneven terrain, in addition to to transport equipment in a warehouse or workplace constructing. The robot is customizable, that means users can add sensors, robotic arms, or completely different payloads to complete a task. Try our free online training, our on-line software builder, or book your individual on-site collaborative robot demo right now. Find out how Cost-effective, protected, and flexible collaborative robots - or cobots - are making automation easier than ever for companies of each dimension. Products Overview Our household of collaborative robots presents 4 totally different payload options - 3, 5, 12.5 and sixteen kg.

Mature markets just like the US, Japan, and Europe face a manufacturing labor shortage. The scarcity is a structural one, meaning it is not resolved by cyclical occasions like the present financial downturn. As a consequence of these occasions, provide chain resiliency has turn into a entrance burner problem among manufacturing CEOs within the US and elsewhere.

While these could traditionally have been the most typical purposes and kinds of industrial robots, at present's robots are less about their mechanical construction. Earlier generations of robots had to be separated into their very own world, whereas right now they can be integrated into the workforce. Sealer robots are built with numerous robotic arm configurations that allow the robotic to apply adhesives to any type of product. The major profit on this software is elevated high quality, velocity and consistency of the final product.

In industrial robots settings, these advances are letting firms switch some of the most troublesome, harmful, and time-consuming duties from employees to robots. As this trend accelerates, each investors and robotic-component manufacturers are in sturdy positions to entry profit pools. Of course, main technologic advances may disrupt the robotic-component trade, as they've carried out in different sectors, and shift demand in surprising instructions.

Read our case studies and study our companies by visiting our Automotive Robotics and Integration part. Pouring molten metallic, transferring metallic stamps, and loading and unloading CNC machines are all best completed by a robot as they are harmful. When completed constantly with little downtime they can also be a source of main productivity. High consistency and repeatability make robots good for material elimination processes like trimming and chopping. This could probably be in the form of slicing materials, trimming plastic moldings and die castings and even polishing molds.

A report from a Swiss assume tank predicts that while robots will displace seventy five million jobs globally by 2022, they may create 133 million new ones - a web optimistic of 58 million jobs. Automation in manufacturing is extremely cost-effective for companies of all sizes. Rather than outsourcing jobs overseas, smaller firms can use robots to carry out chosen tasks at a lower cost and with greater high quality results than with outsourced employees. Industrial robots offer producers higher consistency and better quality when performing repetitive tasks. This means they're ready to produce high-quality merchandise with little variation and higher consistency than their human counterparts. As China builds its robotic installed base, it'll see a 25 % annual improve in demand for end effectors from 2018 via 2023.

Persistent identifiers are assigned to datasets by digital archives, such as institutional repositories and partners within the Data Preservation Alliance for the Social Sciences (Data-PASS). Please take a couple of moments to learn our guide to publishing permissionsto guarantee you've met all the requirements, so that we are able to process your submission at once. Non-exclusive rights to breed the material within the article or e-book chapter. If you haven’t already learn these, we urge you to take action – they'll help you keep away from the most common publishing ethics points.

We have over 25 years experience integrating robotic methods for a large variety of applications. We are an official FANUC Authorized System Integrator, Yaskawa Motoman Solution Provider, ABB Robotics Integrator, KUKA Robotics System Partner, an Integrator of Universal Robots. In the context of basic robotics, most kinds of industrial robots would fall into the class of robotic arms. The automotive manufacturing business has long been one of the quickest and largest adopters of industrial robotic technology, and that continues to this day. Robots are used in nearly every a half of automotive manufacturing in one way or another, and it stays as some of the extremely automated provide chains in the world. Mobile robots are key to enabling versatile manufacturing, during which manufacturing is break up into discrete processes and production cells working in parallel.

Now, these collaborative industrial robots, or co-bots, work alongside manufacturing facility operators, doing a fraction of all of the stuff human employees do. The proliferation of sensors has made it possible for them to function in an environment with folks and record information about their setting. As a result, we will gather knowledge on each step of the manufacturing course of for full traceability and detailed information evaluation to make better selections for the long run. Cartesian, or gantry, robots have three linear joints that use the Cartesian coordinate system.

Combines AI with the aforementioned approach of demonstration techniques, permitting humans to “show” a robot tips on how to deal with variance. leverage AI algorithms to unravel difficult problems corresponding to grasping unfamiliar objects in random orientations or adapting to different conveyor belt speeds. These companies are addressing the things that have historically precluded automation, like unstructured environments and large SKU counts. and Wandelbots, rely on enter from handheld gadgets that “teach” the robotic what to do as they're guided by a human instructor. A human demonstrates the motions concerned in, for example, picking up items and placing them in a box, and the demonstration system translates those motions into the robot’s native code. Epsilon Pi Tau is the Leading International Honor Society for Technology.

They usually feature the execution of simulations to gauge the feasibility and offline programming in combination. If the system is able to compile and upload native robot code to the robotic controller, the user no longer has to study every producer's proprietary language. Therefore, this approach may be an essential step to standardize programming methods. The setup or programming of motions and sequences for an industrial robotic is typically taught by linking the robot controller to a laptop, desktop pc or network. Reshoring (‘onshoring’ or ‘insourcing’) comes with challenges, key among them is the price of labor.

A Cartesian robotic operates in the X-, Y-, and Z-axes to reach its end place. The chart above lists the entire several varieties of robots out there at present. If nothing else, a yr of COVID-19 has taught us to anticipate the unexpected. Of course, producers have always been extremely attuned to change, however the COVID-19 pandemic hit the manufacturing trade seemingly overnight, inflicting deep and long-lasting impacts. A 12 months later, we are ready to look back and see what manufacturers have learned about how to adapt and succeed in the face of adversity. UR+ Overview UR+ offers access to peripherals and software kits designed on your success.

Many initiatives are underway to deliver manufacturing again to nations just like the United States from the place it has been closely outsourced. As their name suggests, AMRs have the power to navigate autonomously using know-how much like a self-driving automobile. Sensing applied sciences including LiDAR and vision present AMRs with details about their working surroundings. In some sense, the pursuit of autonomy is much like the brain-eye-hand coordination that allows humans to do dynamic duties. The eye and the hand are mimicked by collecting sensor information, specifically 2D and 3D imaginative and prescient knowledge and haptic knowledge . Yet most manufacturing contexts feature some component of unpredictability.

Moreover, the repeatability is different in numerous components of the working envelope and also changes with speed and payload. ISO 9283 specifies that accuracy and repeatability ought to be measured at maximum speed and at maximum payload. But this ends in pessimistic values whereas the robotic might be far more accurate and repeatable at gentle hundreds and speeds. Repeatability in an industrial process can additionally be topic to the accuracy of the end effector, for instance a gripper, and even to the design of the 'fingers' that match the gripper to the object being grasped. For example, if a robot picks a screw by its head, the screw might be at a random angle.

youtube

1 note

·

View note

Text

Cone crusher problem set

Product introduction:https://www.lvssn.com/crusher/279.html

In a long time of use, cone crusher is prone to poor lubrication, at the same time, there are many parts are easy to be worn out, directly affecting the production efficiency of enterprises.Understanding the common faults and causes of main lubricating oil is helpful to improve the ability of preventing faults and ensure the smooth production of crushing.

1. What are the differences between standard, intermediate and short-head cone crushers?

The basic structure and working principle of these three crushers are exactly the same, but the shape of the crushing cavity is slightly different.The key difference lies in the crushing parallel belt, the short head parallel belt is longer, and the medium one is second.

The parallel belt is long, the feeding port and discharging port are small, and the fine product granularity can be obtained.Generally, the short head type with long parallel band is put in the middle after crushing.The standard type is shorter due to parallel bands.Therefore, the crushing products are coarser, higher output, generally put in after the coarse crushing, that is, after the jaw type or rotary crusher as the crushing.

2. How to adjust the outlet of cone crusher?

In the process of crushing, the moving cone liner and fixed cone liner wear away continuously, which makes the ore discharge port increase gradually.In order to ensure a certain product granularity, it is necessary to adjust the size of the discharge port with the wear condition.The adjustment of the discharge port is realized by means of the serrated thread lifting and lowering cone liner between the adjustment ring and the supporting housing.In order to lubricate the tooth thread, and to adjust and disassemble easily, the thread must have enough clearance.After adjustment, the size of the ore discharge port can be measured by means of wire tying shot and crushing cavity to the ore discharge port.After the processing of the new liner can be measured at a point, the raw or worn liner should be measured at 6 ~ 8 points.After the discharge port meets the size requirement, the locking cylinder will be used to adjust the locking ring, otherwise it is not allowed to start.

3. What should be paid attention to when replacing the lining board of the cone crusher?

When the thickness of moving cone and fixed cone liner wear reaches 65% ~ 80% or local wear sag deformation and fracture, it should be replaced.After installing the linings, check that their centers are correct.If the center is not right, collision will occur during the rotation, and the product granularity is not uniform, which may cause the internal friction parts to heat up and other faults.Before casting zinc alloy, the gaps should be tightly blocked with clay or asbestos to prevent the flow of zinc alloy.Pouring on the surface of the alloy contact, do not allow moisture, otherwise it will cause explosion.Therefore, preheat, dry or, to shorten the time (no preheat), apply a layer of machine oil to the contact surface and then pour with a special tool.After pouring, tighten the fastening bolt of lining plate.

4. How to solve the main lubrication failure of cone crushing machine?

Cone crusher because of long-term operation, prone to lubrication device, it often ablative conditions in the bearing shell, and may even lead to cracks and loose bearing shell.In daily production, the main lubricating oil system faults include: high oil temperature, low flow, reduced cleanliness, overlubrication, etc.

4.1 high temperature of main lubricating oil

(1) the cooling fan does not work

The cooling fan is controlled by the sensor in the system. If the sensor fails or the fan motor burns out, the cooling fan will not work. The sensor connector should be checked or replaced.

(2) poor cooling effect of cooling fan

Due to pipe blockage, dust accumulation caused by long time of heat sink, and high ambient temperature, the heat dissipation effect is not good. Therefore, it is necessary to regularly clean the dust accumulation of cooling fan, unclog the pipe, and increase the air guide hood to improve the air conduction efficiency.

(3) internal parts of the machine are burnt out

When iron and ore storage occur in the crusher, the internal parts of the crusher will be burned to death, which will generate a lot of heat to rapidly increase the temperature of the main lubricating oil. In this case, the crusher parts should be disassembled, checked and replaced.

(4) safety valve fails

The relief valve is a pressure-reducing valve with certain pressure set in the lubrication system to protect the lubrication system.If the safety valve fails or the set value drops, the lubricating oil will not pass through the cooler. Check whether the safety valve is normal or not.

4.2 low flow of main lubricating oil

(1) the filter element is blocked

Filter block will cause flow in the system to decline, the pressure difference between the two sides of the filter element is high, so it is necessary to check the cone crusher regularly.

(2) oil pump capacity decreases

Long time running will make the gear or mechanical seal wear in the oil pump, the pump oil capacity decreases, should be timely checked and replaced.

(3) the filter is blocked

There is a pipe joint with filter net at the suction inlet of the oil pump. Large particles and sundries in the oil will stay on the filter net.If the filter is not cleaned in time, there will be blockage, decrease in oil quantity, and decrease in main oil quantity. Therefore, it is necessary to regularly clean the sundries on the filter in the pipe joint.

4.3 main lubricating oil cleanliness is reduced

(1) wear of outer dustproof sealing ring

The gap between the outer dustproof sealing ring and dustproof bucket is less than 1.9mm. If it is too large, dust will enter in large quantities. Therefore, it is necessary to check the gap between the outer dustproof sealing ring and dustproof bucket regularly.

(2) insufficient positive pressure air volume

Insufficient positive pressure air volume will reduce the positive pressure of the lubrication chamber, and dust is easily inhaled into the lubrication chamber, resulting in oil pollution and reduced cleanliness.

(3) overlubrication

Overlubrication refers to a lubrication state in which excessive lubricant is added in the working process of the equipment, which leads to the increase of bearing temperature, increase of noise and decrease of bearing life.

Note:

There is no clear standard for the evaluation of overlubrication. For example, we consider 10 minutes of oil filling every 8 hours as the normal oil filling time, so 20 minutes of oil filling every 8 hours will be overlubrication.In fact, this understanding is wrong. Overlubrication refers to the amount of grease stored in the bearing cup, which is the difference between injection and discharge. If the drainage is not smooth, overlubrication will occur even if the oil is filled every 8 hours for 1 minute.

Jiangsu LVSSN can provide high quality and efficient cement plant construction, please consult our customer service or leave a message to us, we will reply to you as soon as possible.

The page source:https://www.lvssn.com/Industry/Cone-crusher-problem-set.html

0 notes

Text

Klüber Amblygon TA 30/1

Klüber Amblygon TA 30/1 is a long-term and high-temperature grease. Klüber Amblygon TA 30/1 is a special grease for high temperature and long-term applications.

Benefits For Your Application -

- Good media water and water vapor

resistance

- Good corrosion protection - Good adhesion

- Good sealing effect

Description -

AMBLYGON TA 30/1 and TA 30/2 is a long-term and high temperature grease based on mineral oil and polyurea. This grease is used for permanent and long-term lubrication in the entire engineering industry. It has a wide temperature range. The grease adheres well and is resistant to water, hot water and dilute alkalis and acids. AMBLYGON TA 30/1 and TA 30/2 is resistant to oxidation, resistant to aging and provides reliable protection against corrosion.

Application Areas -

AMBLYGON TA 30/1 and TA 30/2 are used for high-load bearing and joint applications at high temperatures.

AMBLYGON TA 30/1 and TA 30/2 is used in:

- transportation systems

- roles in the casting sheet of slabs continuous casting

- kilns (rotary kilns)

- water pump

- heating rollers

- tar machines

- gate valves

- inlet seals (a sealing fat)

- washing machines and dishwashers

- hammer mechanisms in power tools

- Wheel, joints, hinges

- kingpin

- Sealed rolling bearing (permanent lubrication )

- Sheet metal presses

AMBLYGON TA 30/1 and TA 30/2 are also used in combination with mineral oil-resistant elastomer seals.

Application Notes -

Before the series application, we recommend that the user test the compatibility with elastomers under application-relevant influences once again, if possible in the complete component under close-to-production conditions.

Looking for any other schmierstoffe product in Kluber Lubrication or other Lubricant ? Just give us a call.

Source URL -

https://schmierstoffe-dm.de/product/kluber-amblygon-ta-301/

Email: [email protected]

Contact No: +49 8106 3978728

Tags:

Klüber Amblygon TA 30/1, Klüber schmierstoffe, Klüber lubricants, Klüber lubricant, Klüber schmierstoff, Klüber oil, Klüber motor oil, Klüber Brake Fluid, Klüber Fluid

#Lubricants #MotorOil #EngineOil #CrudeOil #Grease #HydraulicOil #SyntheticOil #CarOil #GearOill #Oil #Gas #HydraulicFluid #BrakeFluid #RapeseedOil #TractorOil #CylinderOil #Lubricant #IndustrialLubricants #Fette #MineralOil #TransmissionOil #Petronas #Kluber #Meguin #Castrol

0 notes

Text

Aluminum Circle Sheets for Cookware Punch Press

Aluminum circle sheets for cookware are obtained by punching aluminium substrates into round sheets. Punch presses are the key machine of the whole production line. Some of our clients of aluminum circle sheets for cookware ask us to look for manufacturers of punch press in China. Here we introduce a type of punch press: open tilting press, working in principle of crane presses.

As a regular machine for aluminum circle sheets for cookware, the open tilting press has a body of a tiltable cast structure that allows the aluminum circle sheet or scrap to slide off the mold when the machine is tilted. With a rigid transfer key clutch, it has a single and continuous operating specification. With the band brake, the slider is equipped with a collapsed fuse, and the fuse is collapsed when overloaded, thus ensuring that the whole machine is not damaged. This machine has the advantages of high versatility, high precision, reliable performance and easy operation. Semi-automatic stamping is possible with an automatic feeder. Emergency brakes are available for machines over 25 tons. The open tilting press is made of high-strength cast iron and uses a single-disc pneumatic block friction clutch and brake. The joint is smooth, the wear is small, and the fault-free service life is much higher than that of similar products. The slider has a collapse-type safety device. When the machine is overloaded, the fuse is first collapsed, thus ensuring that the whole machine is not damaged.

The open press for aluminum circle sheets for cookware works in principle of crane presses. A crane press works with a reciprocating linear motion of the slider that adapts the rotary motion to the reciprocating linear motion to the upper die to punch the aluminum plates, during which aluminum circles are punched off and the work is completed. The crank press transmits the motion and energy of the motor to the crankshaft through the transmission system, rotates the crankshaft, and reciprocates the slider through the connecting rod, thereby realizing the movement and power requirements of the stamping process.

Reprinted from http://www.haomei-aluminum.com/news/technologynews/aluminium-circle-sheets-for-cookware-punch-press.html

0 notes

Text

Switcheroo, and Mulling over Milling

One of the minor issues with the Zimmermann PS 1/2 sanding machine was the on/off switch, which was on the verge of having its buttons fall out. I decided to take a look-see. Fortunately, a standard hydrant key, which I happened to have in my tool set, opens the electrical box:

Inside everything looked un-molested, which was good:

The switch itself was in good shape, and there was a brochure inside the box that was for the switch. It is a Siemen's model, however not something they make these days. A little digging around and I found a NOS one in Texas, which I ordered as a back-up, for all of $22.50. Get 'em while you can.

The part which had failed was just a piece of rubber in the external push button set. I love finding stuff which is actually user-serviceable - so rare these days. The escutcheon itself is aluminum, not plastic as one might otherwise expect:

The fact that the rubber was divided into two bits, and not that cleanly cut, told me that a past repair had replaced half of the rubber, or maybe it had been repaired twice for all I know. Seems like this is a wear item.

I used a caliper to determine the thickness of the rubber sheet required and ordered some up online. When it arrived, I trimmed a piece to shape and then cut a pair of holes in the rubber using a special bit intended for that task in my milling machine:

A minute or two later, the switch was all back together and in perfect working order:

It's nice when there are straightforward tidy solutions to things that can be knocked off the tick list, at low to moderate cost, in a short time.

Not everything works this way however...

It's been a little over 2 years since my 1971 Zimmermann FZ-5V pattern milling machine arrived from Germany. That arrival was detailed in a couple of posts back in October of 2015 (here and here). While at least one reader at the time was unclear on why a woodworker might want a pattern milling machine, and another asked why I had gone the semi- 'old 'arn' route instead of a more modern portal CNC machine - perfectly legitimate and reasonable questions - I had a lot of ideas as to how I could put this machine to good use. I also knew very little about milling machines in general, so there has certainly been a learning curve, and that is a curve I continue to ascend.

In these past 2 years, I have found myself using the machine more and more and it has become an essential tool in my shop. While a lot of what it does can be replaced by any number of scratch-built jigs out of scrap wood, MDF, etc., I have come to enjoy that the machine has allowed me to reduce my consumption and use of MDF and reduce the time and energy formerly sucked up in the making of jigs and fixtures, which then tended to get stuck in a pile in the supposition of later usability (only to find that a year or three later I can barely remember what the jig was even used for - or forget that I had even made it only to discover such was the case after having made another one).

The milling machine allows me to work with higher precision - repeatable precision - and to do so with greater safety than before. For one thing, to be able to fix the material down and run a cutter over it in full view is wonderful! To be able to fasten the work down to a table which does not flex, and hold that work with assurance it will not move while being cut is simply a revelation. This, compared with what was the norm for me previously, namely, check it and check it again, and the scene of trying to tighten a fixture clamp only to watch the entire fixture bow in the process.

I'm sold on having a milling machine, and going forward it will be an important part of my shop, right up there with the planer and jointer. In fact the milling machine makes the jointing and dimensioning of small parts a breeze. To mention a couple of other plusses, I can also work aluminum and brass, which expands capabilities into making custom hardware and fixtures. I can mill steel and cast iron, which has allowed me to repair/alter some of my other woodworking machines.

There are some negatives to this machine, and I would be remiss if I did not mention them, and indeed some of these negatives have lead to certain difficulties:

- The machine is large and bulky, and weighs 2.5 tons. I was worried it might break the floor in my space, but that did not come to pass. It's not a machine though, like a jointer or planer, which you can just stuff a pallet truck under and move around conveniently.

- it's an old machine, and Zimmermann provides zero parts support. Zero technical support as well. Their business these days is making and selling large portal milling machines that weigh 20 tons or more, like this one from 2000 that forms its own room:

Even that is now old, a FZ30 model. Their new machines are FZ100 series or even later.

So 'little' old machines like the one I have from the distant past are simply unprofitable for them to pay attention to any longer I'm sure. Fortunately I have a parts manual and schematic diagrams for my machine, which helps somewhat.

- to repair certain things on a milling machine, you need a specialized machine. Care to guess what it is? Another milling machine. Toss in an engine lathe as well, and then a large granite inspection plate, and other inspection equipment. Do I have any of that? No.

- unique Zimmermann-made tool holders limit what I can do. I can make zero use of the high speed head on the machine, for example, because it has a weird tool holder that is not longer made by the company.

The age of the FZ-5V is starting to show in a bunch of ways:

1) It won't hold oil in its ways, especially the rotary table, which loses oil in a matter of minutes. I gather that the seals are worn out. Fixing them is not a simple job though. Way oil is not cheap, and I'm tired of cleaning up the puddles of oil off the floor, and it has been like this since I got it.

2) the manual spindle brake has now worn out. It's probably a simple affair similar to a drum brake on a car, however to access the brake itself requires a bunch of disassembly. Now that it is worn out, sometimes I have quite a hassle getting a tool holder out of the spindle.

3) the quill has slop which allows it to rotate a certain amount. No amount of axial rotation in the quill is in fact desirable in the least. This slop led to much frustration when using the right angle attachment on a previous job, and produced some ruined parts as a result. The quill is also sticky and does not plunge smoothly. The spindle lock works, but when clamped on it gets stuck and won't release, requiring that it be taken apart. Fixing the cluster of quill-related issues involves disassembling the machine's head. If that is going to happen, one may as well replace all the bearings and seals while one is at it. It is likely a $5000 bill to deal with the quill issues.

4) the power drive of the rotary table failed last month while working on a wheelstock for a Chinese wheelbarrow. This outcome likely connects to the problem of the non-existent oil retention. Repair may involve making a new gear, however getting access to that gear will require extensive dismantling of the machine and the parts are really heavy. Plus I have no idea what I'm doing, but why should that stop me :^). At least the manual drive system for the rotary table still functions, but it is physically and mentally tiring to use if you have to employ it for any length of time.

5) when powering the table assembly up and down in 'z' axis, there is a groaning noise during a portion of the travel. Not sure what is causing that, but it does not sound good and like other issue with the mill, extensive disassembly is required. If I am forced to take the saddle and the knee off, then I may as well replace bearings and seals while I am at it.

6) once in a blue moon, while using power feed to raise the table up, the electrical circuit sorta 'goes to sleep' and the machine table keeps raising after I have let my finger off of the button. This requires a quick sprint over to the disconnect switch on the wall. Once power is back on, the problem goes away, and it happens so infrequently that it is difficult to diagnose. I'm always apprehensive when raising the table up as a result. The machine's electrical system relies upon old ceramic fuses, and these are not so easy to source. If I were to disassemble the machine, then I would also likely be looking at going through all the electrical stuff as well.

The machine remains largely functional, but the problems described above have been coming one by one, and seemingly a little more frequent in occurrence with each passing month. It's an old machine. I worry though about what the next thing will be, and whether it will cause a part to be ruined, or further damage to the machine, or leave me stranded in the middle of a work process.

If woodworking was my hobby only, and I felt like I could take the mill's repair work on myself (which to a large extent I am confident that I can), and had some money to spend on it, then I might choose to take it all apart and repair and restore it over the course of several months. That's not my situation though. I simply can't devote the time to it, and I know that any decision to strip down the machine invites the 'tip of the iceberg' effect in terms of what one might find that you really have to deal with once things are apart. Thus it is difficult to ascertain how much money it might cost to put the FZ-5V right.

I recently had a fellow from a spindle rebuilding company in New Hampshire pay a visit to my shop. The company, SPS Spindle, offers a site visit to price out repair work, saving one from the alternative, which is to take the machine apart and bring the parts to the company for inspection and pricing. Obviously, in assessing my machine, there are any number of unknowns, so the pricing is somewhat of a guess, but it looked like a rebuild of the spindle and quill on my machine, along with attending to the various other issue, including the tool holding problem, was going to be in the zone of $10,000.00.

Well, I have so far spent about the same money just purchasing and getting the machine into my shop, so the prospect of shelling out the same amount was not exactly mouth-watering. It's not a crazy amount of money though, not in the world of large machines with spindles. The FZ-5V was selling for something like 50,000 € when it was last being made in the mid 1980's. If it were on the market today, factoring in inflation, I would be looking at a purchase price for a new machine of 123,684.43 €, according to one online calculator I tried. Would I be in the market for a machine at that price point? No. Is a $10,000 repair on a machine which would cost 123,684.43 € otherwise reasonable? Sure it is.

I don't get hung up on how much money has already gone into the machine, or let that guide any decision about what I should do now. I've spent enough time in the past dwelling on such 'sunk cost issues' to have learned that it is not the most rational approach. When faced with the prospect that $10,000 might have to go into the FZ-5V at some point, I start thinking about whether $10,000 could be better spent perhaps. Yeah, I know, 'wise use of money' and 'woodworking equipment' is not a natural or entirely sensible combination in many people's eyes. Maybe I should look at Bitcoin?

I asked myself if, at the end of the day, a $10,000 investment into that machine would result in all I ever wanted in that machine? Would it be my dream come true? No, in this case, it would not actually. The ergonomics of the FZ-5V are not the best, for one thing. I would like an even bigger work envelope, and have found turning hand wheels back and forth all day loses its charm rather quickly, as I find it hard on my rotator cuff muscles. A machine that uses a toggle switch, push button, or joystick to achieve the same motorized control of movement (like on my jointer or planer) would be preferable.

So, what are the options that loom large, besides repair?

1) Are their other machines with similar functionality and size? Well, yes.... Two similar sort of size pattern mills of which I'm aware are the Wadkin WS and the Oliver #102-103-104. Both machines are from the pre-WWII era. I'm not sure I want to step further back in time than what I have now, technology-wise, and I've been less than fully delighted with a past Oliver machine and a current Wadkin machine. The Wadkin uses a railway track on the floor for the main table, and this would not work so well with the wavy and movement-prone wooden floor in my space. The Oliver would be a challenge to get into the building, at 8' of height, so some disassembly would be required. I doubt that either machine would be as precise as the Zimmermann, and the tooling would be of some older format, likely Morse taper #3 or #4, which is less desirable to me. The Oliver #103 does have 8 speeds, max rpm of 4100 and 6" of quill travel, a bigger work envelope with loads more x-travel, so it has attractions, despite my wariness of the brand.

2) Going to a bigger machine, with a Bokö milling machine, say. These are in the 4~8 ton range. I would be interested in this direction, but a bigger machine simple wouldn't even fit through the door of the shop building, and I'm sure would be too much for the floor. At least there is parts support for Bokö however, and even a distributor in the US exists.

3) Go same again. There is a 1983 FZ-5V for sale in Germany, 12 years newer than the one I have. The machine reseller wants 6000€ for it, which is actually less than they bought it for, having had it on the market for a while now. Apparently it was not heavily used and does not leak oil, and to boot it has an additional motor fitted for powered y-travel, which would be nice. It uses a remote control panel on a swivel arm which improves the ergonomics. The electrical panel is more modern, with relays and a single circuit board. Without going to Germany to inspect in person, this is a risky purchase though, just like last time.

4) Go smaller. Zimmermann made a machine about half the size of mine, the FZ-1, which would be able to tackle 80% of what the larger machine can do, albeit at a significant reduction in work envelope:

5) Go modern with CNC. There are lots of options in this direction, ranging from machines way out of my price range to little gippers intended for pen turning and jeweler's work. There is a DIY CNC scene, people welding up their own tables and buying components with which to build their own machines. However, most of what I have seen would appear to be designed more for production in volume than the type of work I do. I am not interested in programming just for the sake of drilling a few holes, or making a series of cuts on 2~4 parts. It doesn't make sense, though the user-friendliness of these machines is improving from what I have heard. Many CNC machines are intended for sheet goods work and take up a lot of space, which I don't have. There is likely a configurable solution, however it will require a fair bit of research yet.

6) Go to a metal working mill. With that, there is a reduced work envelope - at least for the size of machine which can fit in my space - no rotary table with most machines (except as a small accessory which mounts to the main table) and much slower spindle speeds generally with machines built for cutting metal. There are high speed milling heads for some machines, and some come with really cool super versatile tables which rotate and tilt, like the Maho universal mills, and some, like Deckel mills, come with both horizontal and vertical spindle drives. A good machine though, is a chunk of change and is likely coming out of Europe, so this option is a well beyond my price range.

7) Go outside of the box with some sort of DIY fabrication to change things on the machine I have. I could, for instance, consider removing the head on my machine and fabricating a mount for an electrospindle which would solve quite a few problems. Higher speed, variable step-less speed control, built in motor braking, modern tool holding, etc.

I'm not really sure what to do at this point. There are options, including doing nothing. The machine will remain serviceable for a while longer, however I really have no idea how long I can rely upon it, so planning for what to do next is occupying my thoughts. It is tick-tocking its way toward becoming a 5500lb paperweight in my shop, and I feel I need to do something sooner rather than later.

Perhaps a reader out there has useful advice - if so, I'm all ears.

0 notes

Text

The on-site benchmarking exchange activity of the crushing and grinding process of the alumina business unit of Chinalco was held in Zhongzhou Aluminum

On March 24, the on-site benchmarking exchange event of the crushing and grinding process of the alumina business unit of Chalco was held in Zhongzhou Aluminum. Mou Xuemin, deputy general manager of Zhongzhou Aluminum, and Hou Bao, deputy manager of the alumina (mine) division of the Production Quality Management Department of Chinalco, attended the meeting. 12 companies from Chalco's alumina sector including Chalco Mining and Shanxi New Materials participated in the benchmarking exchange.

The meeting is divided into two parts: exchange discussion and on-site diagnosis. On the morning of the same day, at the exchange seminar, Mou Xuemin, on behalf of the leadership team of Zhongzhou Aluminum, expressed warm congratulations on the organization of the event, expressed his gratitude to the headquarters for their care and support, and welcomed the arrival of experts from various fraternal units. He briefly introduced the company's development history and basic situation of production and operation.

Mou Xuemin pointed out that the on-site benchmarking exchange activities are aimed at further deepening the benchmarking of alumina business units by process, improving the quality of process benchmarking, improving the ability to solve problems on site, and optimizing the benchmarking work of the crushing and grinding process. It is hoped that the expert group will conduct on-site diagnosis of the Bayer crushing and grinding system, provide precise guidance, and continuously improve the economic operation effect of the crushing and grinding system.

The person in charge of the grinding and floating area of the production control center made "Zhongzhou Aluminum Industry Reduces Power Consumption in Grinding Process and Experience Sharing in Optimizing Slurry Index", introduced relevant processes, equipment and process parameters, and proposed problem items that need to be diagnosed. Participants conducted benchmarking exchanges on related issues.

In the afternoon of the same day, the benchmarking exchange team went deep into the ore storage yard and the grinding and floating area to make on-site diagnosis. For the grinding system, each enterprise put forward its own diagnostic opinions and suggestions

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter . metal foam filter. alumina foam. metal filtration.

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes

Text

0 notes

Text

Hong Kong SAR Government welcomes WTO ruling that US steel and aluminum tariff measures violated regulations

December 12, 2022 15:24:24 Xinhuanet

On the 9th, the WTO expert group issued a report on China's lawsuit against the U.S. steel and aluminum 232 tariff measures WTO dispute, ruling that the relevant U.S. measures violated WTO rules. The Hong Kong Special Administrative Region Government welcomed this on the 10th.

A spokesman for the SAR government said that as a firm supporter of the rules-based multilateral trading system, the SAR government strongly urges the United States to fulfill its obligations as a member of the WTO as soon as possible and withdraw erroneous measures. The panel's ruling clearly shows that the United States has abused the concept of national security in an attempt to politicize economic and trade issues.

The spokesperson pointed out that since March 23, 2018, the United States has imposed a global tariff of 25% and 10% on imported steel and aluminum respectively on the grounds of "national security". The measures cover Hong Kong, and only certain economies are exempted. . In fact, Hong Kong only exports a very small amount of aluminum products to the United States, and no local steel products are exported to the United States. It is impossible to threaten or damage the national security of the United States.

The spokesperson said that the SAR government has been following up through various channels to protest the unreasonable and unfair measures of the United States.

The spokesman said that the HKSAR government will continue to closely monitor and follow up relevant developments, maintain communication with the industry through various channels, review the situation, consider and take corresponding policies and actions to safeguard Hong Kong's trade interests and rights.

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter,

ceramic foam filter .

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes

Text

Global aluminum producers offer Japanese buyers $95-105/ton premiums for the first quarter

December 15, 2022 10:31:45 Mandarin Finance

Foreign news on December 14, sources said on Wednesday that global aluminum producers provided Japanese buyers with a premium of 95-105 US dollars per ton for January-March primary aluminum, a drop of 4%-6% from the current quarter. Japan, Asia's biggest aluminum importer, agrees to pay a quarterly premium over spot aluminum prices on the London Metal Exchange (LME) that is benchmark for the region. In the current October-December quarter, Japanese buyers agreed to pay a premium of $99 per tonne, down 33% from the previous quarter. Quarterly pricing negotiations between Japanese buyers and global suppliers such as Rio Tinto and South32 began late last month and are expected to continue until the end of this month. Initial offers were made earlier this month, but one producer has lowered its offer to $95 a tonne from $105, the sources said.

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter.

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux,

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes

Text

Rising gas prices plus Ukraine-Russia geopolitical crisis threaten job security at Limerick alumina refinery

The Ukrainian-Russian geopolitical conflict and its economic fallout are threatening the future viability of Rusal-owned West Limerick, according to the company's directors and auditors.

The company has posted a net loss of more than 363 million euros since gas prices rose in the year before the Ukrainian invasion.

Now, because of the conflict, those prices have risen again, putting the group under intense pressure. Because of the document, nearly 500 employees at Europe's largest bauxite refinery, which produces 30 percent of the country's alumina, which is mainly used in aircraft, are again concerned.

Limerick Alumina Refining paid more than €46 million in wages to local workers in a report filed with the Companies Registry Office.

Aughinish's parent company has pledged continued support until December 31, 2023, and the directors said they "reasonably expected" the company would remain trading.

Niall Collins, a local TD who holds regular meetings with Aughinish management, said: "They told us, and no one refuted it, that Aughinish was the most efficient of the Rusal global groups. It was involved in the process of making a commodity that was in huge global demand. .”

Cllr Stephen Keary, former mayor and mayor of the area where the local alumina refinery is located, said: "I am very concerned about reading the reports on its viability."

Aluminum World Report

“This is a fantastic employer for West Limerick and North Kerry. If anything happens to it, it will be the death knell for the area. Many of the people who work there have a specific skill set and don’t have the opportunity to redeploy to Similar facilities," Cllr Keary said.

Dee Ryan, chief executive of Limerick Chamber, said: "If anything happens, which we hope doesn't happen, people in the area will have a hard time finding equivalent jobs nearby."

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter. deep bed filter aluminium.

ceramic foam filter . metal foam filter. alumina foam. metal filtration.

degassing aluminum,rotary degassing, inline degasser .online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes