#Aluminum Deoxidizer Market

Text

Emerging Technologies in the Aluminum Deoxidizer Market: A Detailed Analysis

The aluminum deoxidizer market comprises products that are added during aluminum production to remove dissolved oxygen from molten aluminum. Aluminum deoxidizers help improve the quality and properties of final aluminum products. They prevent oxidation, reduce gas porosity, decrease hydrogen solubility, and improve the fluidity and castability of molten aluminum. Some of the commonly used aluminum deoxidizers include titanium, boron, phosphorus, calcium and strontium.

The global Aluminum Deoxidizer Market is estimated to be valued at US$ 3.13 billion in 2023 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

The growth of aluminum deoxidizer market is driven by the opportunity for reduction in production costs. Using aluminum deoxidizers helps improve the fluidity and castability of molten aluminum. This allows aluminum producers to cast complex and thinner aluminum sections with fewer imperfections and defects. It also enhances alloy properties and resistance to corrosion. All these benefits help aluminum producers reduce costs associated with scrap generation, rework and improve productivity. The implementation of efficient aluminum deoxidization practices presents a lucrative opportunity for aluminum producers to lower costs and gain a competitive advantage in the market. This is expected to drive increased demand for specialized aluminum deoxidizers over the forecast period.

Porter's Analysis

Threat of new entrants: The aluminum deoxidizer market is moderately difficult to enter due to high production costs and the need for technical expertise. The threat is moderate.

Bargaining power of buyers: Large industrial buyers have significant bargaining power due to their bulk-buying abilities. However, the availability of substitutes balances this power.

Bargaining power of suppliers: The suppliers of raw materials and components have moderate bargaining power due to the availability of substitute raw materials.

Threat of new substitutes: The threat is low to moderate as aluminum deoxidizers have strong product differentiation and switching costs. However, alternative deoxidizing agents pose a threat.

Competitive rivalry: The competitive rivalry is intense due to many global and regional players operating across different sectors. Manufacturers compete based on product quality, technical support, and pricing.

SWOT Analysis

Strengths: Long product life, excellent deoxidizing efficiencies, compatibility with various melting furnace designs.

Weaknesses: High production costs, supply chain disruptions can impact production.

Opportunities: Growing foundry and primary aluminum industry, developments in low-carbon aluminum production present opportunities.

Threats: Stringent environmental regulations regarding metal processing emissions, substitution threat from alternative deoxidizers.

Key Takeaways

The global aluminum deoxidizer market is expected to witness high growth over the forecast period aided by growth in the end-use industries. The increasing demand for lightweight materials in the automotive and aerospace industries will drive the aluminum deoxidizer consumption.

Regional analysis: Asia Pacific dominates the global market with China being the largest producer and consumer of primary aluminum globally. The region will continue its dominance owing to increasing industrialization and infrastructure development. Europe and North America are also significant markets driven by technical advances in aluminum production.

Key players operating in the aluminum deoxidizer market are Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd.,Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., Zibo Jiuchen Industry & Trade Co., Ltd. The industry is witnessing increasing consolidation as key players focus on expanding their geographic presence and product portfolios through mergers and acquisitions.

0 notes

Text

Global Aluminum Deoxidizer Market Is Estimated To Witness High Growth Owing To Rising Demand for High-Quality Aluminum Products

The global Aluminum Deoxidizer Market is estimated to be valued at US$ 3.13 billion in 2023 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Aluminum deoxidizers are additives used in the aluminum production process to remove oxygen and other impurities from the molten aluminum. They help improve the quality and properties of aluminum products, such as strength, corrosion resistance, and heat resistance. The growing demand for high-quality aluminum products in various industries, including automotive, construction, aerospace, and electronics, is driving the market for aluminum deoxidizers. These additives play a crucial role in ensuring the production of clean and high-performance aluminum products, which are increasingly preferred in the market.

Market key trends:

One key trend in the global aluminum deoxidizer market is the increasing use of advanced deoxidizer formulations. Manufacturers are investing in research and development activities to develop innovative deoxidizer formulations that offer improved performance and cost-effectiveness. These advanced formulations provide better deoxidizing efficiency, reduced slag formation, and enhanced metal quality. For example, Almatis GmbH introduced a new generation of calcium aluminate-based deoxidizers that offer higher deoxidation rates and better control over the aluminum composition. This trend is expected to drive the growth of the aluminum deoxidizer market.

PEST Analysis:

Political: The political stability of countries with significant aluminum production and consumption impacts the global aluminum deoxidizer market. Policies related to trade, tariffs, and regulations can affect the supply and demand dynamics of aluminum products.

Economic: Economic factors, such as GDP growth, industrialization, and urbanization, influence the demand for aluminum products and, in turn, the demand for aluminum deoxidizers. Economic fluctuations can impact the overall market growth.

Social: Increasing awareness among consumers about the benefits of aluminum products, such as recyclability and lightweight, is driving the demand for aluminum deoxidizers.

Technological: Technological advancements in the aluminum production process, such as improved smelting techniques and automation, are driving the adoption of aluminum deoxidizers. Advanced deoxidizer formulations are also being developed to meet the increasing quality standards of aluminum products.

Key Takeaways:

- The global Aluminum Deoxidizer Market Demand is expected to witness high growth, exhibiting a CAGR of 5.7% over the forecast period, due to increasing demand for high-quality aluminum products in various industries.

- The Asia-Pacific region is anticipated to be the fastest-growing and dominating region in the global aluminum deoxidizer market. Rapid industrialization, infrastructure development, and automotive production in countries like China and India are driving the demand for aluminum deoxidizers.

- Key players operating in the global aluminum deoxidizer market include Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd., Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., and Zibo Jiuchen Industry & Trade Co., Ltd. These players are focusing on product innovation and expanding their market presence through strategic partnerships and acquisitions.

#Aluminum Deoxidizer#Aluminum Deoxidizer Market#Aluminum Deoxidizer Market Size#Aluminum Deoxidizer Market Share#Aluminum Deoxidizer Market Growth#Advanced Materials

0 notes

Text

Aluminum Deoxidizer Market Trends: Understanding Industry Dynamics

Aluminum Deoxidizer Market is shaping the future by innovations in 2023-2030

The aluminum deoxidizer market plays a vital role in the aluminum production process by preventing deoxidation of molten aluminum during smelting and casting. Aluminum deoxidizers such as alumina, magnesium, and silicon react chemically with dissolved oxygen to prevent it from forming oxides, allowing cleaner aluminum processing.

The Global Aluminum Deoxidizer Market is estimated to be valued at US$ 3.13 Bn in 2024 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the aluminum deoxidizer market are Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd.,Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., Zibo Jiuchen Industry & Trade Co., Ltd.

The growing demand from the automotive and construction industries is fueling market growth. These industries use aluminum extensively owing to its properties such as lightweight, corrosion resistance, and manufacturability. The aluminum deoxidizer market is also expanding globally due to the rising aluminum production across regions such as Asia Pacific, North America, and Europe.

Market key trends

Use of innovative deoxidizing agents such as rare earth metals and lanthanum is a key trend in the aluminum deoxidizer market. Rare earth metals offer better deoxidation efficiency and facilitate cleaner processing compared to conventional agents. Another major trend is the development of nanoscale deoxidizers which can achieve deoxidation more effectively at lower inclusion levels. Particle engineering is enabling finer dispersion of deoxidizers for optimized performance. Sustainable production practices by key players coupled with recyclability of deoxidizers are also influencing the market dynamics.

Porter’s Analysis

Threat of new entrants: Low as Aluminum Deoxidizer production requires significant investments and technical know-how.

Bargaining power of buyers: Moderate as buyers have alternatives but established suppliers hold pricing power.

Bargaining power of suppliers: High as raw materials are commoditized giving suppliers strong influence over prices.

Threat of new substitutes: Low as Aluminum Deoxidizers have well-established applications with no cost-effective substitutes available.

Competitive rivalry: High as the market is growing at moderate rate attracting new players intensifying competition.

Geographical Regions

The Asia Pacific region dominates the global Aluminum Deoxidizer market in terms of value owing to strong presence of aluminium production facilities and growing automotive industry in countries like China and India. Countries like China, India, Japan and South Korea account for around 60-65% share of the global market.

The Europe region is poised to be the fastest growing market during the forecast period driven by increasing automotive production in Germany, France, UK and rising aerospace sector demand in countries like UK, Italy, France. Stringent regulations regarding emissions from automotive and other industries are also pushing the adoption of Aluminum Deoxidizers.

0 notes

Text

HOW TO CLEAN FOGGY HEADLIGHTS

HOW TO CLEAN FOGGY HEADLIGHTS

Here are some tips and tricks to clean foggy headlights. Headlights play an important role in a drivers safe journey and make your car look awesome. Car manufacturers usually make the cover of headlights with polycarbonate plastic. It is tough for the road condition but vulnerable to sunlight. It causes oxidization and results in yellow and haze tint on the headlight. Here are a few tips and tricks to ensure that your headlights keep looking like new.Get more news about Acrylic Deoxidizer,you can vist our website!

CLEAN FOGGY HEADLIGHTS

The first thing to do is a simple clean Start this technique by cleaning the cover of your headlight with water and soap. Apply wax and start scrubbing a bit. You will notice an improvement. If not, it’s time for further measures.

GIVE UV PROTECTION

The direct rays from the sun are the real cause of this yellowish tint. When the cover comes in contact with sunlight, they start the process of oxidization from the air. The car manufacturer provides a clear coat of UV protective sheet on the headlight, which gets worn off over time. There are many ways to renew the protective layer Apply the new protective layer. this process can be tedious, using solutions first and then moving to abrasives. There are some household techniques as well for instance: the famous toothpaste technique.

CLEAN FOGGY HEADLIGHTS INSIDE AND OUT

If the blurriness appears from the outside of your headlights, you can try cleaning it with a glass cleaning solution. The next option would be to use many other cleaners available in the market. You can also use an acrylic lens deoxidizer for cleaning the above cover of the headlight if it is not completely yellow.

SANDING THE HEADLIGHTS

If these don’t work, there is the option of sanding the headlights. Use the method of sanding and buffering to clean foggy headlights but don’t forget to take your safety precautions. AutoWise also has a complete guide that might be beneficial for those going this route. Also consider that it might be the right time to replace them. Consider your course and stay safe on the road.

TIP: Use the WD-40 Specialist® Industrial-Strength Degreaser to clean your car and engine parts. It’s safe to use on most surfaces, including metals, plastics, rubber, glass and aluminum.

0 notes

Text

Ferro Aluminum Market Growth Factors, Opportunities, Ongoing Trends and Key Players by 2032

Ferro aluminum manufacturing process involves the production of aluminum from synthetic cryolite or bauxite. Ferro aluminum is produced by combining iron with aluminum. The manufacturing process of ferro aluminum is highly energy intensive in nature. Ferro aluminum requires a large amount of electricity during its manufacturing process.

The processed aluminum is then further transformed into aluminum oxide by using Bayer’s process through electrolysis. The resulting aluminum oxide is then mixed with iron oxide at extremely high temperatures. Ferro aluminum is further purified to make it available in several grades. Though ferroalloy contains about 65% of aluminum alloy, it exhibits the properties of about 40% alloy in terms of density.

Pure ferro aluminum usually contains aluminum in the range of 30% and 75%. Ferro aluminum is usually supplied in granular, powder, or in pieces of different sizes. Ferro aluminum is primarily used as a de-oxidation agent for the steel manufacturing process. Ferro aluminum is also used for molding applications in combination with carbon steel and carbon steel.

Ferro aluminum is stable at room temperature however; it burns at extremely intense exothermic reactions. Applications of ferro aluminum differ with the aluminum content in the alloy. Ferro aluminum is widely used as a major deoxidizing agent.

Get a Sample Copy of the Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-365

Asia Pacific is the largest consumer of ferro aluminum. The demand for ferro aluminum is expected to grow rapidly in Europe owing to the presence of large automobile industry in the region. North America is expected to experience sluggish growth in the demand for ferro aluminum market.

AMG Advanced Metallurgical Group, Tremond Metals Corp., Core Metals Group, Gulf Chemical and Metallurgical Corporation, Bear Metallurgical Company, and Hickman, Williams & Companies are some of the major participants in ferro aluminum market.

The companies are mainly focused on increasing their production capacities to achieve economies of scale and thus, in turn, achieve competitive advantage. The companies mainly strive to capture a larger market share in the market.

Key Segments Covered in the Ferro Aluminium Market Report

Type:

Pure Ferro Aluminium Alloy

Ferro Aluminium Alloy Mixture

Application:

Ferro Aluminium for the Automobile Industry

Ferro Aluminium for Machinery Manufacturing

Ferro Aluminium for the Fireworks Industry

Ferro Aluminium for Other Applications

Region:

North America

Latin America

Western Europe

Eastern Europe

APEJ

Japan

Middle East & Africa

0 notes

Text

Flocculant and Coagulant Market Size, Share, Demand, Growth & Trends by 2032

Ferro aluminum manufacturing process involves production of aluminum from synthetic cryolite or bauxite. Ferro aluminum is produced by combining iron with aluminum. The manufacturing process of ferro aluminum is highly energy intensive in nature. Ferro aluminum requires large amount of electricity during its manufacturing process. The processed aluminum is then further transformed into aluminum oxide by using Bayer’s process through electrolysis. The resulting aluminum oxide is then mixed with iron oxide at extremely high temperature.

Ferro aluminum is further purified to make it available in several grades. Though ferroalloy contains about65% of aluminum alloy, it exhibits the properties of about 40% alloy in terms of density. Pure ferro aluminum usually contains aluminum at the range of 30% and 75%. Ferro aluminum is usually supplied in granular, powder or in pieces of different sizes. Ferro aluminum is primarily used as a de-oxidation agent for steel manufacturing process. Ferro aluminum is also used for moulding applications in combination with carbon steel and carbon steel. Ferro aluminum is stable at room temperature however; it burns at extremely intense exothermic reactions.

Get a Sample Copy of the Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-365

Applications of ferro aluminum differ with the aluminum content in the alloy. Ferro aluminum is widely used as a major deoxidizing agent. Ferro aluminum is also used to manufacture welding electrodes. Ferro aluminum is also used to manufacture cutting tools. Ferro aluminum being hard and tensile strength in nature is expected to boost the demand for ferro aluminum in the near future. Ferro aluminum is widely used in manufacturing railway tracks. Ferro aluminum is also used in manufacturing several automotive components. Thus, growing demand for automobile industry is expected to boost the overall growth of the ferro aluminum market. Ferro aluminum is also used in manufacturing various pyrotechnic initiators such as fireworks. Ferro aluminum is also used in major cutting tools industry.

Ferro aluminum is widely produced and consumed in the China. Thus, the growing demand for ferro aluminum from various end-use and secondary process industry is expected to boost the demand in the in the near future. Easy availability of raw material coupled with cheap labor is expected to boost the overall demand as well as production of ferro aluminum market. Asia Pacific is the largest consumer of ferro aluminum. The demand for ferro aluminum is expected to grow rapidly in Europe owing to the presence of large automobile industry in the region. North America is expected to experience sluggish growth in the demand for ferro aluminum market.

AMG Advanced Metallurgical Group, Tremond Metals Corp., Core Metals Group, Gulf Chemical and Metallurgical Corporation, Bear Metallurgical Company and Hickman, Williams & Companies are some of the major participants of ferro aluminum market. The companies are mainly focused towards increasing their production capacities in order to achieve economies of scale and thus, in turn achieve competitive advantage. The companies mainly strive to capture larger market share in the market.

This research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data and statistically-supported and industry-validated market data and projections with a suitable set of assumptions and methodology. It provides analysis and information by categories such as market segments, regions, product types and distribution channels.

Key Segments Covered in the Ferro Aluminium Market Report

Type:

Pure Ferro Aluminium Alloy

Ferro Aluminium Alloy Mixture

Application:

Ferro Aluminium for the Automobile Industry

Ferro Aluminium for Machinery Manufacturing

Ferro Aluminium for the Fireworks Industry

Ferro Aluminium for Other Applications

Region:

North America

Latin America

Western Europe

Eastern Europe

APEJ

Japan

Middle East & Africa

Table of Content

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand-side Trends

1.3. Supply-side Trends

1.4. Technology Roadmap Analysis

1.5. Analysis and Recommendations

2. Market Overview

2.1. Market Coverage / Taxonomy

2.2. Market Definition / Scope / Limitations

3. Market Background

to be continued…!

Browse Full Report: https://www.futuremarketinsights.com/reports/flocculant-and-coagulant-market

0 notes

Text

Manganese Market Size, Share | Global Industry Trends Report Forecast Till 2030

As per the latest report by Market Research Future (MRFR), the global manganese market is estimated to reach the valuation of USD 32,586.9 Million by 2023. The report also states that the market will be expanding at a CAGR of 5.02% during the forecast period 2021-2028.

In the recent past, automotive industry has observed advancements in technology, and also in production. Manganese is an important part of the automotive sector, as it is used for the manufacturing of steel, which in turn is utilized in the manufacturing of chassis as well as body structure. Manganese helps increase the strength and the flexibility of steel. As per reports, the overall total motor vehicle production has surged by 2.36% from 2016 to 2017, manufacturing almost 97,302,534 vehicles in the time period.

Within the infrastructure sector, steel is used for constructing tunnels, bridges, ports, rail tracks, airports and railway stations. In the wake of increasing infrastructural investments by governments of developing economies like India, Brazil and China, the demand for manganese has been noted to increase at a high rate. This factor is projected to be a major driving force behind the strong growth of the manganese market in the coming years.

Moreover, the construction sector is presumed to be the strongest contender amongst all the end-users in the global manganese market, with the fastest growth rate. Almost 50% of the world’s produced steel is utilized in the construction sector for numerous applications in energy generation, buildings, and transportation. In addition, speedy urbanization across the globe has elevated the need for new residential construction, buildings, railways and roads. In the construction sector, steel has widespread use on accounts of its easy availability, affordability, and a variety of properties like versatility, durability and strength. Moreover, steel (consisting of manganese) is used in bridges, offshore oilrigs, construction machines, civil engineering, power plants, hydroelectric plants and pressure vessels. Thus, with the high growth in the construction sector, the demand for manganese is predicted to surge at a striking rate. This will most likely create ample opportunities for the market growth in the near future.

Global Manganese Market – Segmental Analysis

MRFR’s report includes a thorough segmental analysis of the market based on type, and application.

The manganese market, based on the type, is segmented into high carbon ferromanganese, medium carbon ferromanganese, low carbon ferromanganese, silico-manganese, electrolytic manganese metal, and electrolytic manganese dioxide. Out of these, in the global market, silico-manganese held the largest share in 2018, and is poised to retain its dominant position during the review period.. As silico-manganese is used in the production of steel and other alloys, its demand is set to rise in the future with the expanding construction industry and its increasing applications in it. On the other hand, the high carbon ferromanganese segment showed lucrative growth with the second-largest share of the global market in 2018, at the value of USD 5,759.5 million. The segment is projected to surge at a CAGR of 4.52% from 2018 to 2023.

The application-based segments in the global manganese market are alloying additives, depolarizer, oxidizing agent, coloring agent, and others. Among these, alloying additives ruled the global market with the largest share of more than 85% in 2018, and is set to retain its lucrative growth rate throughout the forecast period with the value share of more than 90% by 2023. In aluminum alloys, adding manganese helps in augmenting its resistance against corrosion. Also, in copper alloys, adding even a small amount of manganese aids in deoxidizing the alloy, in addition to improving its mechanical strength as well as castability. Thus, the rising demand for steel will be the driving factor for the increasing demand for alloying additives in the review period. Whereas, the oxidizing agent segment held the second position in the global market with the second-largest share in 2018 at the value of USD 1,042.7 million. Furthermore, the segment is exhibited to surge at a CAGR of 4.29% from 2018 to 2023.

Browse Complete Premium Research Report at @

Global Manganese Market – Regional Outlook

The MRFR report covers the key regions of Asia Pacific, Europe, Latin America, North America and the Middle East and Africa.

With more than 3/4th in 2018, Asia Pacific is leading the global market at the value of USD 11,947.8 million. Also, the regional market in Asia Pacific will be growing at the highest CAGR during the review period. Europe had been at the second position in the global market with the second-largest share in 2018, reaching the valuation of over USD 2,000 million.

The report, after carefully analyzing the market in Asia Pacific, acknowledges China to be the major contributor backed by its position as one of the largest automotive manufacturers in the region. There was a surge in the automotive production in the country by 3.19% in 2017 from 2016, with the total production estimated at 29,015,434 vehicles. There has been a tremendous rise in the number of railways, airports, roads, energy, water, and rural programs in the region.

In Europe, the market for manganese in Russia ruled the region with highest share in 2018 , and is expected to race ahead at the highest CAGR of 3.34% during the conjectured time frame. Following Russia is Germany with the second-largest share of over 20% in 2018, with the predictions that the market will grow at a CAGR of 2.96% in the country in the forthcoming years.

Global Manganese Market – Competitive Landscape

The top companies in the global Manganese Market profiled by MRFR in the report include Autlán (Mexico), Mizushima Ferroalloy Co., Ltd (Japan), Accura Weldrods Kovai Pvt Ltd (India), Eramet (France), MOIL Limited (India), OM Holdings Ltd (Singapore), Sakura Ferroalloys (Malaysia), Mesa Minerals Limited (Australia), Metals and Alloys Corporation (India), Nippon Denko Co., Ltd (Japan), African Rainbow Minerals Ltd (South Africa), Afarak Group Plc (Finland), Transalloys (South Africa), Translloy India Pvt Ltd (India), and Ferro Alloys Corporation Limited (FACOR) (India).

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans conducts meet with the industry experts and industrial visits for its research analyst members.

#Manganese Market#Manganese#Manganese Market Research#Manganese Market Analysis#Manganese Market Size#Manganese Market Share

0 notes

Text

The second life of aluminium packaging

We consume products wrapped in aluminum almost every day. This waste most often ends up in the incinerator because it does not fit into the traditional recycling channels. The Liège Metallurgical Research Center (CRM)[1] has found a way to give a second life to small household and industrial aluminum.

Coffee capsules, crisps’, biscuits’, chocolate or coffee wrappers, lasagna trays, medicine packaging, aerosols, hair coloring tubes, wine bottle rims, milk product jar lids ..., the list of everyday consumer products wrapped in aluminum is long.

This waste may be light but, on average, the Belgian throws almost two kilos each year in the dust bin.

And if they are found back in nature, their natural degradation is very slow: around 200 years for a can. If this packaging does not end up in the incinerator, it can end up in export circuits with industrial aluminum waste such as offcuts and shavings left over from the manufacturing process, motors and window frames and are therefore not recovered at their fair value with us (aluminum is currently worth 1800 euros per ton). It is not easy to give them a second life: they are very thin and polluted by glues, varnishes, paints, lacquers, plastic films, oils, foams or rubber.

"We need to make better use of these products and, in a conventional recycling circuit, it is very complicated. This requires special equipment to treat organic materials and, above all, the packaging aluminum burns very easily if we do not take precautions, ”explains Christian Marique, technical director at the Liège Metallurgical Research Center. "It must therefore be conditioned beforehand, mixed with other denser products, be prepared, fragmented and then compacted to be processed more easily. This is what we have put in place."

Metallurgy in reverse

Since three years, a CRM team has been working on designing a process for recycling household and industrial aluminum. This initiative is part of the "Reverse metallurgy" project, funded by the Walloon Regional Government since 2015. "Aluminum was selected as a key product by Reverse metallurgy. A secondary aluminum sector already exists , in which we recover a series of products which are melted then reformatted. When we looked in more detail at the potential of recycling, we wanted to go much further. " The technique from the Liège metallurgy industry collective research centre, doubly patented at European level, is now perfected. It also separates the aluminum from the coffee capsules from the grounds they contain and also allows domestic and industrial waste to be mixed in a single recycling process.

Outside the CRM premises, containers are filled with this little everyday waste.

"We needed raw materials. As early as 2016, the CRM asked its staff [2] to collect this household waste of small aluminum. We gave reusable bags to fetch them as well as a magnet, in order to be able to distinguish them from steel waste (such as certain capsules or boxes), which themselves are magnetic, ” says the technical director, who is also the head of the aluminum recycling project. The recycling line is on a pilot scale but the CRM, in collaboration with the Liège-based company CMI[3], has designed an economically profitable factory project in which 20,000 tons of aluminum waste can be recycled per year. The plan foresees a doubling of the volume in a second stage. The project does not only have an ecological impact (in addition to the reprocessing aspect, the recycling of aluminum consumes only 5% of the energy necessary for the primary production sector), it also aims to create a new foundry activity in Wallonia, focused on recycling.

The miniaturized line of the CRM can process between 300 and 400 kilos of waste per day. "They are crushed, fragmented; certain organic components are released and then the waste is compacted into briquettes, with a density comparable to the same volume of pure aluminum, in order to make them easily handled. We knowingly compose them with certain types of waste placed together because we are targeting a particular chemistry ", explains, with a supporting demonstration, Adrien Nélis, engineer and head of the technical part of the aluminum project.

Almost pure recycled aluminum

Then follows the stage when they are put in the oven. The oven is heated to 800 °. After 30 to 35 minutes, the recycled and molten aluminum flows, silvery and shiny, into the mold. Half a day is necessary to be able to handle a cooled ingot. After lithification, samples are presented for chemical analysis. "We can adapt the recycling recipe according to the sectors targeted as customers. We can indeed find iron or zinc in our recycled aluminum, metals that affect the properties of materials, their applications and their quality. Packaging aluminum is quite pure because it does not need other elements to provide mechanical properties, unlike that used to make frames or within the automotive and aeronautical industry. So, in the recycled version, we get very good aluminum. "

Who are the potential customers of recycled aluminum? "We have developed a cooking recipe which makes it possible to target special markets: foundries, the steel industry, a large consumer of aluminum to make calmed steels[4], the cosmetics, pharmaceutical and agrifood industries", details Christian Marique. "And we have other ideas, which are still in an exploratory state. With additive manufacturing[5] which is developing, but what still is very expensive today are the powders of the metals it uses. We could use our aluminum as a metallic powder, after an automation effort. It would be less expensive. New outlets are there. "

There remains a problem to be solved if we want to launch an industrial recycling sector: the collection of this type of waste upstream. "The public authorities will have to organize additional sorting from individuals and collection. If manufacturers are not sure of having all the necessary material, they will not invest in this project", concludes Christian Marique.

Source

Isabelle Lemaire, La seconde vie des emballages en aluminium, in: La Libre Belgique, 1-3-2021 https://stories.lalibre.be/inspire/numero98/index.html

[1] CRM Group is a collective research centre having as Core Members two major worldwide steel companies (ArcelorMittal and Tata Steel) and as Associated Members numerous companies producing non-ferrous metals, providing services to the steel industry or promoting the use of metals.

[2] 265 workers, Editor's note

[3] Cockerill Maintenance & Ingénierie (CMI), nowadays John Cockerill

[4] deoxidized, Editor's note

[5] by 3D printing, to put it simply, Editor's note

3 notes

·

View notes

Text

Know the Latest Study of the Global Aluminum Wire Rods Market 2019 in the Industry with Prominent Players

The research report mainly introduced the global aluminum wire rods market basics: a market overview, classifications, definitions, applications, and product specifications and so on. The global analytical report has been made by using significant data research methodologies such as primary and secondary research.

Download Exclusive Sample of this Premium Report at https://market.biz/report/global-aluminum-wire-rods-market-2017-mr/157261/#requestforsample

The report also targets important facets such as market drivers, challenges, latest trends, and opportunities associated with the growth of manufacturers in the global market for Aluminum Wire Rods. The report provides the readers with crucial insights on the strategies implemented by leading companies to remain in the lead of this competitive market.

Competitive landscape

Global Aluminum Wire Rods Market study covers a comprehensive competitive analysis that includes detailed company profiling of leading players, characteristics of the vendor landscape, and other important studies. Aluminum Wire Rods report explains how different players are competing in this report.

Aluminum Wire Rods Market Manufactures:

Southwire

Hongfan

UC RUSAL

Baotou Aluminium

Vedanta

Southern Cable

Hydro

Noranda Aluminum

Vimetco

Alro

Market Segmentation

The global Aluminum Wire Rods market is segmented on the basis of the type of product, application, and region. The segmentation study equips interested parties to identify high-growth portions of the global Aluminum Wire Rods market and understand how the leading segments could grow during the forecast period.

Product Segment Analysis by Types

Electrical

Alloy

Mechanical

Application of Aluminum Wire Rods Market are

Conductors and Cables

Mechanical Applications

Deoxidization

Following regions are analyzed in Aluminum Wire Rods at a provincial level

North America

Europe

China

Japan

The Middle East & Africa

India

South America

Inquire more about this report @ https://market.biz/report/global-aluminum-wire-rods-market-2017-mr/157261/#inquiry

The reports help to find the answers to the following questions:

• What is the present size of the Aluminum Wire Rods Market in the top 5 Global & American countries?

• How is the Aluminum Wire Rods market separated into various product segments & sub-segments?

• How is the market expected to grow in the future?

• What is the market potential compared to other countries?

• How are the overall Aluminum Wire Rods market and different product segments developing?

References

1. Global Aromatherapy Oils Industry Market Research Report

2. Fucoxanthin Market Is Responsible For Increasing Market Share

1 note

·

View note

Text

Cost Of Manganese Market Share, Global Industry Size, In-Depth Qualitative Insights, Explosive Growth Opportunity, Regional Analysis, Revenue, Challenges and Forecast to 2027

Market Highlights

As per the latest report by Market Research Future (MRFR), the global manganese market is estimated to reach the valuation of USD 32,586.9 Million by 2023. The report also states that the market will be expanding at a CAGR of 5.02% during the forecast period (2018-2023).

In the recent past, automotive industry has observed advancements in technology, and also in production. Manganese is an important part of the automotive sector, as it is used for the manufacturing of steel, which in turn is utilized in the manufacturing of chassis as well as body structure. Manganese helps increase the strength and the flexibility of steel. As per reports, the overall total motor vehicle production has surged by 2.36% from 2016 to 2017, manufacturing almost 97,302,534 vehicles in the time period.

Within the infrastructure sector, steel is used for constructing tunnels, bridges, ports, rail tracks, airports and railway stations. In the wake of increasing infrastructural investments by governments of developing economies like India, Brazil and China, the demand for manganese has been noted to increase at a high rate. This factor is projected to be a major driving force behind the strong growth of the manganese market in the coming years.

Moreover, the construction sector is presumed to be the strongest contender amongst all the end-users in the global manganese market, with the fastest growth rate. Almost 50% of the world’s produced steel is utilized in the construction sector for numerous applications in energy generation, buildings, and transportation. In addition, speedy urbanization across the globe has elevated the need for new residential construction, buildings, railways and roads. In the construction sector, steel has widespread use on accounts of its easy availability, affordability, and a variety of properties like versatility, durability and strength. Moreover, steel (consisting of manganese) is used in bridges, offshore oilrigs, construction machines, civil engineering, power plants, hydroelectric plants and pressure vessels. Thus, with the high growth in the construction sector, the demand for manganese is predicted to surge at a striking rate. This will most likely create ample opportunities for the market growth in the near future.

Global Manganese Market – Competitive Landscape

The top companies in the global manganese market profiled by MRFR in the report include Autlán (Mexico), Mizushima Ferroalloy Co., Ltd (Japan), Accura Weldrods Kovai Pvt Ltd (India), Eramet (France), MOIL Limited (India), OM Holdings Ltd (Singapore), Sakura Ferroalloys (Malaysia), Mesa Minerals Limited (Australia), Metals and Alloys Corporation (India), Nippon Denko Co., Ltd (Japan), African Rainbow Minerals Ltd (South Africa), Afarak Group Plc (Finland), Transalloys (South Africa), Translloy India Pvt Ltd (India), and Ferro Alloys Corporation Limited (FACOR) (India).

Global Manganese Market – Segmental Analysis

MRFR’s report includes a thorough segmental analysis of the market based on type, and application.

The cost Of Maganese Market, based on the type, is segmented into high carbon ferromanganese, medium carbon ferromanganese, low carbon ferromanganese, silico-manganese, electrolytic manganese metal, and electrolytic manganese dioxide. Out of these, in the global market, silico-manganese held the largest share in 2018, and is poised to retain its dominant position during the review period.. As silico-manganese is used in the production of steel and other alloys, its demand is set to rise in the future with the expanding construction industry and its increasing applications in it. On the other hand, the high carbon ferromanganese segment showed lucrative growth with the second-largest share of the global market in 2018, at the value of USD 5,759.5 million. The segment is projected to surge at a CAGR of 4.52% from 2018 to 2023.

The application-based segments in the global manganese market are alloying additives, depolarizer, oxidizing agent, coloring agent, and others. Among these, alloying additives ruled the global market with the largest share of more than 85% in 2018, and is set to retain its lucrative growth rate throughout the forecast period with the value share of more than 90% by 2023. In aluminum alloys, adding manganese helps in augmenting its resistance against corrosion. Also, in copper alloys, adding even a small amount of manganese aids in deoxidizing the alloy, in addition to improving its mechanical strength as well as castability. Thus, the rising demand for steel will be the driving factor for the increasing demand for alloying additives in the review period. Whereas, the oxidizing agent segment held the second position in the global market with the second-largest share in 2018 at the value of USD 1,042.7 million. Furthermore, the segment is exhibited to surge at a CAGR of 4.29% from 2018 to 2023.

Browse Complete Premium Research Report at

https://www.marketresearchfuture.com/reports/manganese-market-7724

Global Manganese Market – Regional Outlook

The MRFR report covers the key regions of Asia Pacific, Europe, Latin America, North America and the Middle East and Africa.

With more than 3/4th in 2018, Asia Pacific is leading the global market at the value of USD 11,947.8 million. Also, the regional market in Asia Pacific will be growing at the highest CAGR during the review period. Europe had been at the second position in the global market with the second-largest share in 2018, reaching the valuation of over USD 2,000 million.

The report, after carefully analyzing the market in Asia Pacific, acknowledges China to be the major contributor backed by its position as one of the largest automotive manufacturers in the region. There was a surge in the automotive production in the country by 3.19% in 2017 from 2016, with the total production estimated at 29,015,434 vehicles. There has been a tremendous rise in the number of railways, airports, roads, energy, water, and rural programs in the region. Besides, Japan has also noted a growth of 5.31% in the automotive sector in 2017 from 2016, with the manufacture of a total of 9,693,746 vehicles. Plus, the country boasts of well-established infrastructure with rise in transportation and the construction sector. Therefore, with the accelerated demand from a variety of end-user industries, the demand for manganese market in the region is bound to observe a rapid growth from 2018 to 2023.

In Europe, the market for manganese in Russia ruled the region with highest share in 2018 , and is expected to race ahead at the highest CAGR of 3.34% during the conjectured time frame. Following Russia is Germany with the second-largest share of over 20% in 2018, with the predictions that the market will grow at a CAGR of 2.96% in the country in the forthcoming years.

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/7724

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.globenewswire.com/en/news-release/2021/02/16/2176518/0/en/Carbon-Nanotubes-Market-Size-to-Reach-USD-6-03-Billion-by-2027-at-20-CAGR-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2021/02/04/2169881/0/en/Polyglycolic-Acid-Market-Size-to-Reach-USD-1989-578-Million-by-2030-at-10-45-CAGR-Market-Research-Future-MRFR.html

https://www.globenewswire.com/en/news-release/2019/07/31/1894463/0/en/Copper-Foil-Market-Share-to-Reach-USD-17-321-8-Million-at-CAGR-of-10-31-by-2023-Increasing-Demand-for-Consumer-Electronics-Expected-to-Expand-Copper-Foil-Industry.html

https://www.globenewswire.com/en/news-release/2019/07/31/1894462/0/en/Soap-Noodles-Market-To-Be-Driven-By-Surging-Household-Use-By-2023-Says-MRFR.html

0 notes

Text

Understanding the Competitive Landscape of the Aluminum Deoxidizer Market

The aluminum deoxidizer market is estimated to be valued at US$ 3.13 Bn in 2023 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Aluminum deoxidizers are chemicals added during aluminum smelting and refining to remove dissolved oxygen from molten aluminum. Common types of aluminum deoxidizers include calcium, strontium, barium and rare earths. They act as scavengers for dissolved oxygen in molten aluminum and protect the aluminum from re-oxidation. This helps improve the quality and properties of final aluminum products. Aluminum deoxidizers play a key role in enhancing heat resistance, strength and toughness in final aluminum products.

Market key trends:

One of the key drivers of the aluminum deoxidizer market is the growing aluminum production across the globe. Aluminum finds wide usage in various end-use industries like construction, transportation, packaging and consumer goods due to its light weight and corrosion resistance properties. According to International Aluminum Institute, global primary aluminum production increased from 64 million tons in 2016 to 67 million tons in 2021. This rising aluminum production is driving significant demand for aluminum deoxidizers to remove dissolved oxygen from molten aluminum during smelting and refining processes. Additionally, stringent quality and purity standards in aluminum production are also boosting adoption of specialized aluminum deoxidizers to enhance quality of final aluminum products. Leading aluminum deoxidizer manufacturers are actively engaging in new product development through advanced technology and R&D to cater to the evolving requirements of aluminum industry.

Porter's Analysis

Threat of new entrants: New entrants face high capital requirements to build production facilities.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of substitutes.

Threat of new substitutes: Substitutes like hydrazine may pose threat.

Competitive rivalry: Intense competition among existing players.

SWOT Analysis

Strengths: Large untapped market potential. Wide range of end-use industries.

Weaknesses: Fluctuations in raw material prices. Environmental concerns related to aluminum production.

Opportunities: Rising construction activities in developing nations. Increasing automobile production.

Threats: Stringent regulations regarding emissions. Growing adoption of aluminum substitutes.

Key Takeaways

The global aluminum deoxidizer market size was valued at US$ 3.13 Bn in 2023 and is expected to reach US$ 4.21 Bn by 2030, growing at a CAGR of 5.7% during the forecast period. Growth of the market can be attributed to rising consumption in the construction industry.

Regional analysis - Asia Pacific dominated the global market in 2023 and is expected to continue its dominance over the forecast period. This can be attributed to presence of developing economies like China and India with massive construction projects underway.

Key players - Key players operating in the aluminum deoxidizer market are Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd.,Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., Zibo Jiuchen Industry & Trade Co., Ltd.

0 notes

Text

The Global Market for Manganese is Projected to Reach 28 Million Metric Tons by 2024

Growing Use of Manganese in Next-Generation Lithium-Ion Batteries for Powering Eco-Friendly Electric Vehicles Drives Global Market Growth, According to a New Report by Global Industry Analysts, Inc.

GIA launches comprehensive analysis of industry segments, trends, growth drivers, market share, size and demand forecasts on the global Manganese market. The global market for Manganese is projected to reach 28 million metric tons by 2024, driven by growing use of Manganese for developing powerful, longer lasting lithium-ion batteries for electric vehicles, and positive outlook for infrastructure development projects and automobile production.

Manganese (Mn), a hard and brittle chemical element is the 4th most consumed metal in the world, behind only aluminum, iron, and copper, and is also the 5th most abundant metal in the world. Generally found in combination with iron, manganese is the 12th most abundant element found in the earth's crust and also the 2nd most abundant heavy metal in the world. The steel industry represents the largest consumer of manganese with more than 90% of global manganese used in manufacturing all kinds of steel as well as cast iron. There is no known perfect substitute for manganese, particularly with respect to its critical applications in steelmaking. Various attributes of the metal that transform steel into a highly useful engineering material and are driving its widespread adoption in steelmaking over the years include regular conditioning; deoxidizing and desulphurising effects; qualities of strength; impact resistance; wear resistance, hardness as well as hardenability, stiffness and toughness.

Future growth in the market will be driven by growing usage of NiMH and Li-ion batteries in storage battery applications, electric vehicles and consumer applications. With electric vehicles forecast to constitute more than 33% of the total new cars sold globally by 2040, the demand for electrolytic manganese dioxide (EMD) batteries from North American, Japanese and European markets is forecast to surge in the near term. Lithium- Manganese Dioxide (Li/MnO2) batteries account for a major share of the primary Lithium batteries market, given their low cost and safe operations compared to other types of batteries. Another market opportunity for Manganese emerges from non-metallurgical applications including micronutrients in animal feed, and chemicals used as colorant for bricks, textiles, car undercoat paints, glass, and tiles. Growing demand for stainless steel in aesthetic construction is also spurring opportunities for ferromanganese. Recent innovations in the green energy sector are boosting demand for electrolytic manganese metal (EMM) and electrolytic manganese dioxide (EMD).

As stated by the new market research report on Manganese, Asia-Pacific represents the largest and the fastest growing market worldwide with a CAGR of 4.6% over the analysis period. Emergence of Asia as the manufacturing hub for automobiles is the primary factor benefiting growth in the region. Steady pace of economic development, industrialization, rapid urbanization, steady rise in construction activity and robust demand for automobiles among others will help boost demand for steel in the region over the next few years. Although currently witnessing a decline, China remains the largest regional market for finished steel products, owing to the huge construction and industrial activity in the region, which generates high demand for a range of steel products.

Key players in the market include African Rainbow Minerals Limited, Anglo American plc, Assmang Proprietary Limited, Compania Minera Autlan, S.A.B. De C.V., ERACHEM Comilog Inc., Eramet SA, Eurasian Natural Resources Corporation Limited, Gulf Manganese Corporation Limited, Manganese Metal Company (Pty) Ltd., MaxTech Ventures Inc., MOIL Limited, Ningxia Tianyuan Manganese Industry Co. Ltd., Consolidated Minerals Limited, Nippon Denko Company Ltd., OM Holdings Limited, South32 Limited, Tosoh Corporation, Tronox Limited, and Vale S.A., among others.

The research report titled “Manganese: A Global Strategic Business Report” announced by Global Industry Analysts Inc., provides a comprehensive review of market trends, drivers, mergers, acquisitions and other strategic industry activities of major companies. The report provides market estimates and projections in Metric Tons for all major geographic markets including the US, Canada, Japan, Europe (France, Germany, Italy, UK, Spain, Russia and Rest of Europe), Asia-Pacific (China, India and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and Rest of World. The global and regional markets for Manganese are analyzed by the product segments, including Alloys (Ferro Manganese Alloy, Silico Manganese Alloy, Refined Ferro Manganese Alloy, and Other Alloys), and Electrolytic Manganese. The report also analyzes the global and regional markets for Manganese by the following end use segments: Steel, Batteries and Others.

For enquiries e-mail us at [email protected] or [email protected]. To connect with us, visit our LinkedIn page.

Global Industry Analysts, Inc. 6150 Hellyer Ave., San Jose CA 95138, USA, All Rights Reserved.

2 notes

·

View notes

Text

Aluminum Deoxidizer Market Trends: Understanding Industry Dynamics

Aluminum Deoxidizer Market is shaping the future by innovations in 2023-2030

The aluminum deoxidizer market plays a vital role in the aluminum production process by preventing deoxidation of molten aluminum during smelting and casting. Aluminum deoxidizers such as alumina, magnesium, and silicon react chemically with dissolved oxygen to prevent it from forming oxides, allowing cleaner aluminum processing.

The Global Aluminum Deoxidizer Market is estimated to be valued at US$ 3.13 Bn in 2024 and is expected to exhibit a CAGR of 5.7% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the aluminum deoxidizer market are Almatis GmbH, AluChem, Inc., Motim Electrocorundum Ltd., READE Advanced Materials, Zibo Honghe Chemical Co., Ltd., Henan HengXin Industrial & Mineral Products Co., Ltd., Prince Minerals LLC, HAIHUI Group Co., Ltd., Gongyi City Meiqi Industry & Trade Co., Ltd., Xinzheng Chengxin Carbon Co., Ltd.,Henan Junsheng Refractories Limited, Luoyang Zhongsen Refractory Co., Limited, Jiaozuo BeiYuan Chemical Co., Ltd., Gongyi City Xianke Water Supply Material Co., Ltd., Zibo Jiuchen Industry & Trade Co., Ltd.

The growing demand from the automotive and construction industries is fueling market growth. These industries use aluminum extensively owing to its properties such as lightweight, corrosion resistance, and manufacturability. The aluminum deoxidizer market is also expanding globally due to the rising aluminum production across regions such as Asia Pacific, North America, and Europe.

Market key trends

Use of innovative deoxidizing agents such as rare earth metals and lanthanum is a key trend in the aluminum deoxidizer market. Rare earth metals offer better deoxidation efficiency and facilitate cleaner processing compared to conventional agents. Another major trend is the development of nanoscale deoxidizers which can achieve deoxidation more effectively at lower inclusion levels. Particle engineering is enabling finer dispersion of deoxidizers for optimized performance. Sustainable production practices by key players coupled with recyclability of deoxidizers are also influencing the market dynamics.

Porter’s Analysis

Threat of new entrants: Low as Aluminum Deoxidizer production requires significant investments and technical know-how.

Bargaining power of buyers: Moderate as buyers have alternatives but established suppliers hold pricing power.

Bargaining power of suppliers: High as raw materials are commoditized giving suppliers strong influence over prices.

Threat of new substitutes: Low as Aluminum Deoxidizers have well-established applications with no cost-effective substitutes available.

Competitive rivalry: High as the market is growing at moderate rate attracting new players intensifying competition.

Geographical Regions

The Asia Pacific region dominates the global Aluminum Deoxidizer market in terms of value owing to strong presence of aluminium production facilities and growing automotive industry in countries like China and India. Countries like China, India, Japan and South Korea account for around 60-65% share of the global market.

The Europe region is poised to be the fastest growing market during the forecast period driven by increasing automotive production in Germany, France, UK and rising aerospace sector demand in countries like UK, Italy, France. Stringent regulations regarding emissions from automotive and other industries are also pushing the adoption of Aluminum Deoxidizers.

1 note

·

View note

Link

An Silicon alloy is a mixture of metals that is produced through the amalgamation of two or more metallic or non-metallic elements. The quantity of such elements is fixed so as to arrive at a desirable alloy with desirable properties and characteristics to the base metal. Silicon alloys have silicon as a major element. Ferrosilicon is an alloy which is produced from sand or silica by reducing it with iron and coke at extremely high temperatures in submerged arc electric furnaces.

Use of excess silica, above the stoichiometric requirement will prevent the formation of silicon carbide during the ferrosilicon production. Ferrosilicon is used to deoxidize steel and some of the other ferrous alloys and has other applications as reducing agents for metals. Ferrosilicon has around 2% of aluminum and calcium in it composition. Use of ferrosilicon is known to improve the corrosion resistance and thermal resistance properties of new products when used in the production of ferrous alloys.

0 notes

Text

Cushion Emina vs Pixy, Mana yang Lebih Cocok untuk Sehari-Hari?

Cushion Emina vs Pixy, Mana yang Lebih Cocok untuk Sehari-Hari?:

Pembahasan tentang cushion lokal dan kesimpulan mana yang terbaik belum juga tuntas! Kali ini giliran label Emina dengan Emina Bare With Me Mineral Cushion-nya yang akan dibandingkan dengan cushion dari Pixy yaitu Pixy Make It Glow. Cushion Emina VS Pixy, yang mana yang lebih tahan lama, sih?

Yuk, ketahui, cushion Emina VS Pixy, mana yang lebih cocok untuk sehari-hari?

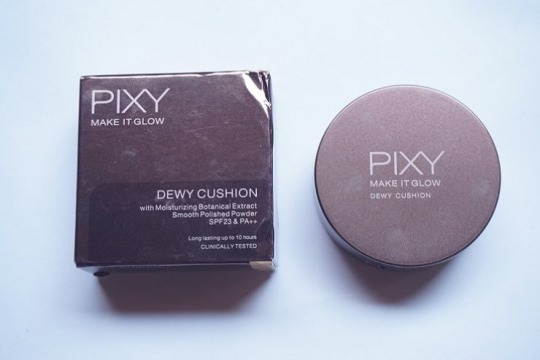

1. Keduanya memiliki packaging yang khas dan cantik

Packaging Emina Bare WIth Me Mineral Cushion dengan warna pink dan putih yang girly. (Foto: Dok. BukaReview)

Kedua produk memiliki packaging yang cantik dan travel-friendly. Keduanya pun memiliki warna yang khas, yaitu pink dan putih untuk Emina dan coklat metalik untuk Pixy.

Keduanya memiliki puff serta kaca di dalam, seperti produk cushion lainnya. Kedua kaca dan puff-nya cukup nyaman digunakan namun puff milik Emina sedikit lebih keras dibanding milik Pixy. Kedua packaging memiliki ukuran yang sama dengan berat yang sama juga, yaitu 15g.

Packaging Pixy Make It Glow elegan dan simpel. (Foto: Dok. BukaReview)

Packaging dari Pixy Make It Glow lebih elegan dan cocok untuk kamu yang sudah kerja atau menyukai packaging yang simpel namun anggun. Sedangkan packaging yang girly dari Emina Bare with Me Mineral Cushion sepertinya didesain untuk market yang lebih muda.

2. Bagaimana dengan perbandingan untuk harga, kandungan, dan klaimnya?

Perbandingan untuk harga, kandungan, dan klaim cushion Emina VS Pixy. (Foto: Dok. BukaReview)

Emina Bare With Me Mineral Cushion Pixy Make It Glow Harga dan Ukuran Rp130 ribu per 15ml Rp125 ribu per 15ml Kandungan Water, Cyclopentasiloxane, Titanium Dioxide, Ethylhexyl Methoxycinnamate, Cyclohexasiloxane, Ethylhexyl Salicylate, PEG-10 Dimethicone, Cetyl Ethylhexanoate, Silica, Pentylene Glycol, Synthetic Fluorphlogopite, Lauryl PEG-10 Tris (Trimethylsiloxy)silylethyl Dimethicone, Magnesium Sulfate, Phenoxyethanol, Aluminum Hydroxide, Stearic Acid, Triethoxycaprylylsilane, Dimethicone, Disteardimonium Hectorite, Ethylhexylglycerin, Disodium EDTA, BHT. Water, Titanium Deoxide, Cyclopentasiloxane, Diphenylsiloxy Phenyl Trimethicone, Butyelene Glycol, Ethylhexyl Methoxycinnamate, Dicapryl Yl Carbonate, Lauryl Peg-9 Polymethilsiloxethyl Dimethicone, Cyclohexasiloxane, Glycerin, Caprylic/Capric Triglyceride, Trimethylsiloxysilicate, Phenyl Trimethicone, Pentylene Glycol, Polypropylsilsesquioxane, Peg-10 Dimethicone, Phenoxyethanol, Magnesium Sulfate, Dipentaerythrity Hexa C5-9 Acid Esters, Dimethicone, Dimethicone Crosspolymer, Triethoxycarylylsilane, Alumunium Hydroxide, Polyhydroxystearic Acid, Disteardimonium Hectorite, Stearic Acid, Fragance (Parfum), Ethylhexylglycerin, Lecithin, Ethylhexyl Palmitate, Isostearic Acid, Isopropyl Myristate, Hydrogenated Castrol Oil Isostearate, Polyglyceryl-3 Polyricinoleate, Disodium Edta, Syntetic Fluorphlogopite, Bht, Tochoperol, Olea Europaea (Olive) Fruit Oil, Simmondsia Chinensis (Jojoba) Seed Oil, Citrus Junos Fruit Extract. Ci 77492, Ci 77947, Ci 77491, Ci 77499. Klaim Memberi efek brightening pada kulit juga melindungi kulit dari paparan sinar UV. Memberi tampilan dewy matte sepanjang hari karena kandungan oil absorber-nya. Tekstur ringan namun mampu memberi tampilan full coverage hingga 10 jam. Hasil di kulit cerah bercahaya/glowing tanpa minyak berlebih.

Agak disayangkan Emina tidak mencantumkan SPF dan PA pada packaging-nya. Seperti yang kita ketahui, ukuran perlindungan UV dari sebuah produk makeup atau skincare dinilai dari kedua simbol tersebut. Jadi, walau Emina telah menuliskan UVA & UVB Protection di packaging-nya dan mencantumkan titanium dioxide pada ingredient-nya, hal ini cukup mengurangi kredibilitas bagi pembeli yang membutuhkan informasi penting tersebut.

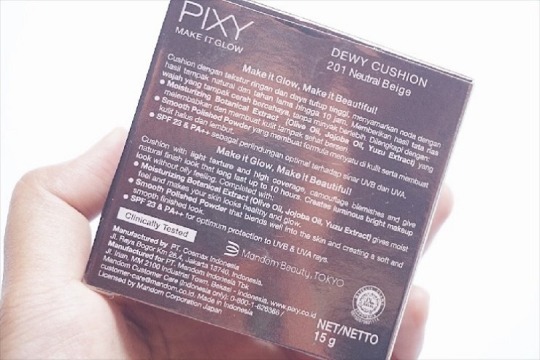

Kandungan dari Pixy Make It Glow Dewy Cushion. (Foto: Dok. BukaReview)

Kandungan dari Pixy Make It Glow Dewy Cushion. (Foto: Dok. BukaReview)

Sedangkan Pixy mencantumkan isi dari Moisturizing Botanical Extract di bungkusnya, yaitu Olive oil, Jojoba oil dan Yuzu extract. Lalu, Smooth Polished Powder serta kandungan SPF di dalamnya yaitu 23 PA++. Pixy juga menambahkan keterangan clinically tested pada bagian depan box-nya.

Baca juga: Selain untuk Kecantikan, 5 Produk Makeup Ini Memiliki Kandungan Baik untuk Kulit

3. Sama-sama memiliki 3 shade untuk dipilih

Emina Bare With Me Mineral Cushion punya 3 shade. (Foto: Dok. BukaReview)

Kedua produk ini masing-masing memiliki 3 shade untuk kamu pilih sesuai warna kulitmu. Untuk Emina Bare With Me Mineral Cushion, ada warna 01 Light, 02 Natural dan 03 Caramel.

Warna Light bisa digunakan untuk kamu yang memiliki kulit terang dengan undertone hangat atau netral. Sedangkan warna Natural lebih sesuai untuk dikenakan para wanita dengan kulit terang hingga medium dengan cool undertone karena warnanya lebih pink dibanding kuning atau beige. Warna Caramel bisa dipilih untuk kamu yang memiliki warna kulit medium atau sawo matang dengan undertone hangat.

Pixy Make It Glow Dewy Cushion punya 3 shade. (Foto: Dok. BukaReview)

Sedangkan ketiga shade dari Pixy Make It Glow Dewy Cushion adalah 101 Light Beige, 201 Neutral Beige dan 301 Medium Beige. Tidak seperti cushion dari Emina yang menyediakan warna untuk undertone dingin, ketiga shade pada cushion Pixy semuanya memiliki undertone hangat yang cocok untuk kulit wanita Indonesia.

Warna yang dihasilkan oleh Pixy Make It Glow Dewy Cushion cantik digunakan untuk kamu yang memiliki kulit medium atau sawo matang dan tidak buat kulit wajah jadi ashy seperti beberapa cushion dari label Korea.

Untuk aroma, Emina hampir tidak memiliki aroma. Hanya ada sedikit aroma sunscreen bila kamu mengendusnya baik-baik. Berbeda dengan cushion Pixy yang mengeluarkan aroma manis yang lembut dan tidak mengganggu.

Namun begitu, bila kamu termasuk yang memiliki kulit sensitif atau alergi aroma, kamu harus mencoba dulu sebelum membeli ya, untuk memastikan produk ini aman digunakan.

Baca juga: Ini 5 Cara Tepat Memilih Shade Foundation Sesuai Warna Kulit

4. Kedua cushion ini memiliki tekstur yang hampir sama namun tidak demikian dengan coverage dan daya tahannya

Swatch Emina Bare With Me Mineral Cushion. (Foto: Dok. BukaReview)

Swatch Pixy Make It Glow Dewy Cushion. (Foto: Dok. BukaReview)

Kedua cushion ini memiliki tekstur liquidy yang mudah dibaur, namun Emina Bare With Me Mineral Cushion memiliki tekstur yang lebih cair dibanding Pixy Make It Glow Dewy Cushion. Sedangkan setelah didiamkan setelah swatch, kedua cushion sama-sama cepat mengering namun cushion Emina lebih kesat dibanding Pixy. Produk Pixy terlihat lebih berkilau dan lembap di kulit.

Daya tahan cushion Emina. (Foto: Dok. BukaReview)

Sedangkan bila membahas daya tahan pada kulit, Emina Bare With Me Mineral Cushion tahan hingga 3 jam untuk kulit berminyak, dan cepat crack di bagian dengan pori-pori besar atau mengeluarkan minyak. Untuk kamu yang memiliki kulit normal atau kering, bisa tenang menggunakan produk ini hingga 5 jam tanpa perlu touch up lagi.

Daya tahan cushion Pixy. (Foto: Dok. BukaReview)

Untuk Pixy Make It Glow Dewy Cushion, cukup tahan lama untuk pemilik kulit kering, hingga 6 hingga 8 jam, sedangkan bagi kamu yang memiliki kulit berminyak, cushion ini tahan hingga 4 jam di kulit tanpa perlu touch up.

Baca juga: Review: Holika Holika x Peko Hard Cover Glow Cushion, Gemas Tapi Worth it-Kah?

6. Hasil akhir dari kedua cushion ini, Emina terasa matte di kulit namun memberi tampilan dewy dan mencerahkan sedangkan Pixy lebih glowing, lembap dan natural

Hasil akhir Emina Bare With Me Mineral Cushion. (Foto: Dok. Bukareview)

Emina Bare With Me Mineral Cushion memberi hasil sheer yang natural. Tidak suka sensasi greasy yang biasanya diakibatkan oleh produk cushion? Nah, oil absorber dari cushion ini menghasilkan dewy matte finish ini buat kulit tetap terasa matte dan tidak lengket saat disentuh namun tetap memberi tampilan glowing dan dewy!

Coverage-nya light, cukup untuk memberi tampilan warna merata pada kulit wajah. Kulit wajah juga terlihat lebih cerah hingga 1 level! Wow! Selain itu, cushion dari Emina ini nyaman digunakan karena cepat menyerap dan menyatu di kulit.

Baca juga: Bingung Pilih Makeup Dewy atau Matte? Ini Tipsnya!

Hasil akhir Pixy Make It Glow Dewy Cushion. (Foto: Dok. Bukareview)

Nah, bagaimana dengan Pixy Make It Glow Dewy Cushion? Cushion ini cukup mengagetkan karena biasanya produk cushion yang menawarkan hasil dewy memiliki coverage yang sheer atau light. Namun, tidak demikian dengan Pixy Make It Glow Dewy Cushion. Cushion Pixy ini memiliki medium coverage yang cukup membantu dalam menutupi noda hitam bekas jerawat dan warna gelap di bawah mata.

Selain itu, cushion dari Pixy ini buildable, seperti foundation. Jadi tidak ada masalah bila kamu mau menambahkan produk di atas noda gelap di kulit untuk memberi hasil flawless yang lebih maksimal.

Untuk kulit kombinasi atau berminyak, maka warnanya akan mulai pudar di bagian T-Zone setelah beberapa jam, sedangkan kilaunya tetap bertahan hingga berjam-jam walau memudar. Selain itu produk ini tidak oksidasi atau buat kulit jadi terlihat lebih gelap.

Baca juga: Cushion Wardah Vs Emina, Mana yang Lebih Bagus?

7. Kesimpulannya, yang mana yang lebih cocok untuk digunakan sehari-hari?

Yang mana yang lebih cocok digunakan sehari-hari? Cushion Emina atau Pixy?

Emina Bare With Me Mineral Cushion Pixy Make It Glow Dewy Cushion Klaim Memberi perlindungan dari serangan UVA dan UVB pada kulit wajah sementara memberi tampilan cerah natural dengan dewy matte finish. Menjaga kelembapan kulit wajah dengan Moisturizing Botanical Extract-nya. Sedangkan Smooth Polished Powder-nya membantu memberi hasil akhir yang kembut dan smooth. Memiliki tekstur ringan dengan coverage tinggi untuk bantu menyamarkan noda dengan hasil natural dan tahan lama hingga 10 jam. Kulit terlihat cerah dan glowing tanpa terasa berminyak. Setelah penggunaan

- Kulit terlihat dewy dan lebih cerah tanpa rasa lengket.

- Hasilnya sheer atau tipis, tidak terlalu membantu menutup noda gelap pada wajah.

- Cepat luntur di bagian wajah yang berminyak bila tidak dilapisi dengan powder.

- Tahan hingga 3 jam di kulit berminyak tanpa bedak, sedangkan bisa tahan hingga 5 jam bila ditumpuk dengan bedak atau kulit kering.

- Kulit terlihat dewy namun tidak mencerahkan secara berlebihan.

- Kulit terlihat segar, sehat, bercahaya dan tetap natural.

- Karena medium coverage maka cukup baik dalam menyamarkan noda gelap pada kulit wajah.

- Tahan hingga 4 jam tanpa bedak namun bisa menempel hingga 6-8 jam di kulit yang dilapisi bedak atau kering

Lalu, yang mana yang cocok untuk digunakan sehari-hari? Nah, jawabannya sesuai kebutuhanmu! Untuk kamu yang menyukai hasil sheer dan mencerahkan, maka kamu bisa mencoba Emina Bare With Me Mineral Cushion. Namun bila kamu mencari cushion dengan coverage seperti foundation dengan hasil menutup namun tetap natural, maka pilih lah Pixy Make It Glow Dewy Cushion!

Yang mana yang sesuai kebutuhanmu? Langsung pilih di link Bukalapak di atas ya!

from https://review.bukalapak.com/beauty/cushion-emina-vs-cushion-pixy-98200

from https://bukareview0.tumblr.com/post/181883686008

0 notes

Text

Manganese Market Share 2020-Industry Analysis By Latest Trends and Companies 2027

Market Highlights

As per the latest report by Market Research Future (MRFR), the global manganese market is estimated to reach the valuation of USD 32,586.9 Million by 2023. The report also states that the market will be expanding at a CAGR of 5.02% during the forecast period (2018-2023).

In the recent past, automotive industry has observed advancements in technology, and also in production. Manganese is an important part of the automotive sector, as it is used for the manufacturing of steel, which in turn is utilized in the manufacturing of chassis as well as body structure. Manganese helps increase the strength and the flexibility of steel. As per reports, the overall total motor vehicle production has surged by 2.36% from 2016 to 2017, manufacturing almost 97,302,534 vehicles in the time period.

Within the infrastructure sector, steel is used for constructing tunnels, bridges, ports, rail tracks, airports and railway stations. In the wake of increasing infrastructural investments by governments of developing economies like India, Brazil and China, the demand for manganese has been noted to increase at a high rate. This factor is projected to be a major driving force behind the strong growth of the manganese market in the coming years.

Moreover, the construction sector is presumed to be the strongest contender amongst all the end-users in the global manganese market, with the fastest growth rate. Almost 50% of the world’s produced steel is utilized in the construction sector for numerous applications in energy generation, buildings, and transportation. In addition, speedy urbanization across the globe has elevated the need for new residential construction, buildings, railways and roads. In the construction sector, steel has widespread use on accounts of its easy availability, affordability, and a variety of properties like versatility, durability and strength. Moreover, steel (consisting of manganese) is used in bridges, offshore oilrigs, construction machines, civil engineering, power plants, hydroelectric plants and pressure vessels. Thus, with the high growth in the construction sector, the demand for manganese is predicted to surge at a striking rate. This will most likely create ample opportunities for the market growth in the near future.

Global Manganese Market – Competitive Landscape

The top companies in the global manganese market profiled by MRFR in the report include Autlán (Mexico), Mizushima Ferroalloy Co., Ltd (Japan), Accura Weldrods Kovai Pvt Ltd (India), Eramet (France), MOIL Limited (India), OM Holdings Ltd (Singapore), Sakura Ferroalloys (Malaysia), Mesa Minerals Limited (Australia), Metals and Alloys Corporation (India), Nippon Denko Co., Ltd (Japan), African Rainbow Minerals Ltd (South Africa), Afarak Group Plc (Finland), Transalloys (South Africa), Translloy India Pvt Ltd (India), and Ferro Alloys Corporation Limited (FACOR) (India).

Global Manganese Market – Segmental Analysis

MRFR’s report includes a thorough segmental analysis of the market based on type, and application.

The manganese market, based on the type, is segmented into high carbon ferromanganese, medium carbon ferromanganese, low carbon ferromanganese, silico-manganese, electrolytic manganese metal, and electrolytic manganese dioxide. Out of these, in the global market, silico-manganese held the largest share in 2018, and is poised to retain its dominant position during the review period.. As silico-manganese is used in the production of steel and other alloys, its demand is set to rise in the future with the expanding construction industry and its increasing applications in it. On the other hand, the high carbon ferromanganese segment showed lucrative growth with the second-largest share of the global market in 2018, at the value of USD 5,759.5 million. The segment is projected to surge at a CAGR of 4.52% from 2018 to 2023.

The application-based segments in the global manganese market are alloying additives, depolarizer, oxidizing agent, coloring agent, and others. Among these, alloying additives ruled the global market with the largest share of more than 85% in 2018, and is set to retain its lucrative growth rate throughout the forecast period with the value share of more than 90% by 2023. In aluminum alloys, adding manganese helps in augmenting its resistance against corrosion. Also, in copper alloys, adding even a small amount of manganese aids in deoxidizing the alloy, in addition to improving its mechanical strength as well as castability. Thus, the rising demand for steel will be the driving factor for the increasing demand for alloying additives in the review period. Whereas, the oxidizing agent segment held the second position in the global market with the second-largest share in 2018 at the value of USD 1,042.7 million. Furthermore, the segment is exhibited to surge at a CAGR of 4.29% from 2018 to 2023.

Browse Complete Premium Research Report at

https://www.marketresearchfuture.com/reports/manganese-market-7724

Global Manganese Market – Regional Outlook

The MRFR report covers the key regions of Asia Pacific, Europe, Latin America, North America and the Middle East and Africa.