#Agrochemical Intermediates Market Industry

Text

#Agrochemical Intermediates Market#Agrochemical Intermediates Market Trends#Agrochemical Intermediates Market Growth#Agrochemical Intermediates Market Industry#Agrochemical Intermediates Market Research#Agrochemical Intermediates Market Report

0 notes

Text

Trans-farmer

With automation taking place at a much faster pace across industries especially in the tech space, domestic software firms that employ over 16 million are set to slash headcounts by a massive 3 million by 2022, which will help them save a whopping $100 billion mostly in salaries annually.

The domestic IT sector employs around 16 million, of whom around 9 million are employed in low-skilled services and BPO roles. Of these 9 million low-skilled services and BPO roles, 30 per cent or around 3 million will be lost by 2022, principally driven by the impact of robot process automation or RPA.

Roughly 0.7 million roles are expected to be replaced by RPA alone and the rest due to other technological upgrades and upskilling by the domestic IT players, while the RPA will have the worst impact in the US with a loss of almost 1 million jobs. Based on average fully-loaded employee costs of $25,000 per annum for India-based resources and $50,000 for US resources, this will release around $100 billion in annual salaries and associated expenses for corporates, the report says.

Major agrotech-companies appear to be planning for a 3 million reduction in low-skilled roles by 2028 because of RPA up-skilling. This is a $100-billion in reduced salary and other costs, but on the flipside, it offers a likely $10 billion boon for IT companies that successfully implement RPA, and another $5 billion opportunity from a vibrant new software niche by 2022. Given that robots can function for 24 hours a day, this represents a significant saving of up to 10:7 versus human labor.

Robot process automation (RPA) is application of software, not physical robots, to perform routine, high-volume tasks, allowing employees to focus on more differentiated work. It differs from ordinary software applications as it mimics how the employee has worked instead of building a workflow into technology from ground up and thus minimizing time to market and greatly reducing cost over the more traditional software-led approaches.

Case in Hand:

UPL Limited, formerly United Phosphorus Limited, is an Indian multinational company that manufactures and markets agrochemicals, industrial chemicals, chemical intermediates, and specialty chemicals, and also offers crop protection solutions. Headquartered in Mumbai, Maharashtra, the company engages in both agro and non-agro activities.

As time passes, the market becomes more dependent and driven on AI and RPA involvement. So, if RPA replaces the employees in the future, then you being an Finance Manager of UPL Ltd., your task along with the CHRO of UPL Ltd. is to do the following:

Detailed cost of developing a competent Human Resource Team.

Depict a feasible financial plan where RPA is brought into the organization and employee salaries still possible to pay for.

Compare the cost of a Human Force with the cost of Human Force with RPA.

Phase-wise Layoff plan for employees after the introduction of AI.

Pink Slip with the severance package.

Devise a new organizational structure.

A manual for employee training, in order to manage sophisticated machinery.

Deliverables:

A detailed report of at least 20 pages

A PPT presentation summarizing the same

Pink Slip

Submission Details:

Deadline: 8:00 AM 27/09/22

Email Subject and File name: Transfarmer_ECOXX

Email Id: [email protected]

2 notes

·

View notes

Text

Innovative Solutions in Acetophenone Derivatives: Manufacturing Processes and Applications

Acetophenone derivatives are a class of organic compounds that play a pivotal role in various industries due to their versatile properties and wide-ranging applications. As technology advances and market demands evolve, manufacturers of acetophenone derivatives are continuously exploring innovative solutions in their manufacturing processes and discovering new applications for these compounds. Let's delve into the world of acetophenone derivatives, exploring the latest advancements in manufacturing techniques and their diverse applications across industries.

Understanding Acetophenone Derivatives:

Acetophenone derivatives are organic compounds derived from acetophenone, a simple aromatic ketone. These derivatives exhibit a diverse range of chemical and physical properties, making them valuable in numerous industrial processes. From pharmaceuticals and agrochemicals to fragrances and flavors, acetophenone derivatives find applications in a wide array of products.

Advanced Manufacturing Processes:

Innovation in manufacturing processes is crucial for enhancing efficiency, reducing costs, and improving product quality in the production of acetophenone derivatives. Manufacturers are increasingly adopting advanced technologies and techniques to streamline their processes and optimize resource utilization.

One such innovation is the development of novel synthesis routes that enable more efficient and sustainable production of acetophenone derivatives. Green chemistry principles, such as catalysis and solvent-free reactions, are being employed to minimize waste generation and environmental impact.

Additionally, advancements in process automation and control systems are revolutionizing the way acetophenone derivatives are manufactured. Automated reactors, real-time monitoring, and data analytics enable manufacturers to achieve greater consistency, precision, and throughput in their production processes.

Quality Assurance and Compliance:

Maintaining product quality and ensuring compliance with regulatory standards are paramount in the manufacturing of acetophenone derivatives. Manufacturers invest in robust quality assurance systems and adhere to stringent regulatory requirements to guarantee the purity, potency, and safety of their products.

Advanced analytical techniques, such as chromatography and spectroscopy, are employed for quality control and product testing. These techniques enable manufacturers to detect and quantify impurities, ensure batch-to-batch consistency, and meet regulatory specifications.

Moreover, manufacturers implement comprehensive safety protocols and environmental management systems to minimize risks associated with chemical manufacturing. Training programs, emergency response plans, and waste management practices ensure a safe and sustainable working environment.

Diverse Applications:

The versatility of acetophenone derivatives makes them indispensable in a wide range of applications across industries. In the pharmaceutical sector, these compounds serve as key intermediates in the synthesis of various drugs, including analgesics, antiseptics, and antifungal agents.

In the fragrance and flavor industry, acetophenone derivatives contribute to the creation of aromatic compounds that enhance the sensory experiences of consumer products. Their distinctive scents and flavors are utilized in perfumes, cosmetics, food additives, and household products.

Acetophenone derivatives also find applications in agrochemicals, where they serve as active ingredients in pesticides, herbicides, and insecticides. Their pesticidal properties make them effective in protecting crops from pests and diseases, contributing to agricultural productivity and food security.

Furthermore, acetophenone derivatives have potential applications in materials science, polymer chemistry, and specialty chemicals. Their chemical reactivity and functional groups make them versatile building blocks for synthesizing polymers, resins, and specialty additives used in various industrial processes.

Future Perspectives:

As technology continues to advance and market demands evolve, the future of acetophenone derivatives holds promise for further innovation and expansion. Manufacturers will continue to invest in research and development to discover new synthesis routes, optimize production processes, and explore novel applications for these versatile compounds.

Moreover, collaboration and partnerships between academia, industry, and government agencies will play a crucial role in driving innovation and addressing emerging challenges in the acetophenone derivatives industry. By harnessing the power of innovation and collaboration, manufacturers can unlock new opportunities and create value for society.

In conclusion, innovative solutions in acetophenone derivatives manufacturing processes are driving progress and unlocking new possibilities across industries. From advanced synthesis techniques to diverse applications, these compounds continue to play a vital role in shaping the future of chemistry and industry. As technology advances and market demands evolve, the journey of innovation in acetophenone derivatives manufacturing is poised to continue, bringing forth new opportunities and solutions to address the challenges of tomorrow.

0 notes

Text

Chloroform Market Growth Strategies, Quality Assessment, and Trends by 2024-2031

The "Chloroform Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Chloroform Market?

Market Analysis and Size

Chloroform refers to a solvent that is extensively utilized for organic compounds and is denoted as trichloromethane. The substance is colorless, volatile and has a strong and pleasant odor and it is insoluble in water. It is used as a Solvent and reagent in laboratory applications such as the dissolving of non-nucleic acid biomolecules in DNA and RNA extractions and is also highly used in other end-user industries including chemical, paper, and others.

Data Bridge Market Research analyses that the global chloroform market which was USD 2.60 billion in 2022, will reach USD 4.03 billion by 2030, and is expected to undergo a CAGR of 5.60% during the forecast period. “Pharmaceutical” is expected to dominate the end-users segment of the Chloroform market by their versatile properties such as anesthetic, solvent, and chemical synthesis properties. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Chloroform market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Chloroform Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-chloroform-market

Which are the driving factors of the Chloroform market?

The driving factors of the Chloroform market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Chloroform across various industries further propel market expansion.

Chloroform Market - Competitive and Segmentation Analysis:

Global Chloroform Market, By Grade (Technical Grade, Alcohol Stabilized Grade, Fluorocarbon Grade), Application (Solvent, Intermediates, Reagent, Others), End-Users (Pharmaceutical, Agrochemical, chemical Industry, Others) – Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Chloroform market?

Some of the major players operating in the global chloroform market are:

Dow (U.S.)

PRODUCTOS ADITIVOS(Spain)

BASF SE(Germany)

Solvay (Belgium)

Arihant Chemical (India)

INEOS(U.K.)

Tokuyama Corporation (Tokyo)

Shin-Etsu Chemical Co., Ltd. (Tokyo)

Akzo Nobel N.V.(Netherlands)

Nouryon (China)

Sumitomo Chemical Co., Ltd. (Tokyo)

Occidental Petroleum Corporation (U.S.)

RIDHDHI SIDHDHI CHEMICALS(India)

JIGCHEM UNIVERSAL(India)

Short Description About Chloroform Market:

The Global Chloroform market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Chloroform. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Chloroform Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Chloroform in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Chloroform Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Chloroform market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Chloroform Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Chloroform market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Chloroform?

What are the upcoming industry applications and trends for Chloroform market?

What Are Projections of Global Chloroform Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Chloroform?

What are the raw materials used for Chloroform manufacturing?

How big is the opportunity for the Chloroform market?

How will the increasing adoption of Chloroform for mining impact the growth rate of the overall market?

How much is the global Chloroform market worth? What was the value of the market In 2020?

Who are the major players operating in the Chloroform market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Chloroform Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-chloroform-market

Detailed TOC of Global Chloroform Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Chloroform Market By Type

Chloroform Market By Function

Chloroform Market By Material

Chloroform Market By End User

Chloroform Market By Region

Chloroform Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-chloroform-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Fanconi Anemia Treatment Market – Industry Trends and Forecast to 2029

Global Anesthesia Devices Market – Industry Trends and Forecast to 2029

Global Carpal Tunnel Syndrome Drug Market - Industry Trends and Forecast to 2029

Global Borage Oil Market – Industry Trends and Forecast to 2029

Global Chloroform Market – Industry Trends and Forecast to 2030

#Chloroform Market#Chloroform Market Size#Chloroform Market Share#Chloroform Market Trends#Chloroform Market Growth#Chloroform Market Analysis#Chloroform Market Scope & Opportunity#Chloroform Market Challenges#Chloroform Market Dynamics & Opportunities

0 notes

Text

Unlocking Aroma Innovation: Moraya Global's Journey in Specialty Chemicals Manufacturing

In the dynamic world of fragrance and aroma chemicals, the pursuit of quality and innovation is a never-ending journey. At Moraya Global, we epitomize this ethos as leading manufacturers and suppliers of a diverse range of specialty aroma chemicals in India. With a commitment to excellence and a focus on meeting the evolving needs of our clients, we take pride in our extensive portfolio of products that cater to various industries including fragrance, pharmaceuticals, and agriculture.

One of our key offerings is Phenyl Acetaldehyde Dimethyl Acetal, a versatile compound widely used in the fragrance industry for its unique olfactory properties. As specialized aroma chemicals manufacturers in India, we ensure the highest standards of purity and consistency in all our products, including 5-Bromoindole and Indole-3-Butryic Acid. These compounds play crucial roles in creating distinctive fragrances that resonate with consumers worldwide.

In addition to aroma chemicals, we also excel in producing pharmaceutical intermediates that meet the stringent quality requirements of the healthcare industry. Our range includes Indole-3-Acetic Acid and Diindollyl Methane, among others, which find applications in pharmaceutical formulations aimed at improving human health and well-being.

Furthermore, our expertise extends to the field of agrochemicals, where we provide essential compounds such as Allyl Amyl Glycolate to support agricultural productivity and sustainability. By collaborating with farmers and agribusinesses, we contribute to the development of innovative solutions that address the challenges faced by the agriculture sector.

At Moraya Global, we are not just manufacturers; we are partners in our clients' success stories. Whether it's supplying Styrallyl Acetate for fragrance formulations or catering to the growing demand for Viridine in various industries, we strive to exceed expectations with our quality products and reliable services. Our commitment to customer satisfaction drives us to continuously innovate and adapt to changing market dynamics, ensuring that we remain at the forefront of the industry.

In conclusion, Moraya Global stands as a beacon of excellence in the realm of specialty aroma chemicals and pharmaceutical intermediates manufacturing in India. With a diverse product portfolio, a customer-centric approach, and a relentless pursuit of quality, we are poised to meet the evolving needs of our clients and contribute to the advancement of the various industries we serve.

CONTACT US:

Moraya Global Limited

PLOT NO C105, TTC INDUSTRIAL AREA, MIDC, PAWANE VILLAGE, Mumbai, MH, 400 705, India

Phone : 28301524/8213481/8375234

Mobile : 9820016417

website : www.morayaglobal.com

0 notes

Text

Monochloroacetic Acid Prices Trend, Pricing, Database, Index, News, Chart

Monochloroacetic Acid (MCAA) prices is a crucial chemical compound extensively used in the production of various industrial and consumer goods. Its importance in the chemical industry stems from its role as a versatile intermediate, making it a pivotal ingredient in the manufacture of agrochemicals, pharmaceuticals, and personal care products. Given its wide range of applications, the pricing of monochloroacetic acid is subject to multiple influencing factors, which makes its market analysis complex yet essential for stakeholders.

The price of monochloroacetic acid is influenced by several key factors, including raw material costs, production processes, demand and supply dynamics, and geopolitical events. The primary raw material for MCAA is chloroform, and fluctuations in chloroform prices can significantly impact MCAA costs. These fluctuations often result from changes in the prices of chlorine and acetic acid, which are themselves subject to market conditions and availability. Production processes also play a critical role, with advancements in technology and improvements in efficiency potentially lowering production costs and, consequently, the market price of MCAA.

Supply and demand dynamics are another crucial aspect affecting monochloroacetic acid prices. The demand for MCAA is driven by its applications across various industries. For instance, in the agrochemical sector, it is used in the synthesis of herbicides like glyphosate. The pharmaceutical industry relies on MCAA for the production of drugs such as ibuprofen. Additionally, the personal care industry uses it in the manufacturing of surfactants and thickening agents. Fluctuations in these industries directly influence the demand for MCAA, thereby impacting its price. For example, an increase in demand for agrochemicals due to a booming agricultural sector can lead to higher prices for monochloroacetic acid.

Get Real Time Prices of Monochloroacetic Acid: https://www.chemanalyst.com/Pricing-data/monochloroacetic-acid-1156

Geopolitical events and regulatory policies can also have significant effects on MCAA prices. Trade policies, tariffs, and international relations can alter the cost and availability of raw materials, as well as the overall production and distribution of MCAA. For instance, trade tensions between major chemical-producing countries can lead to supply chain disruptions, thereby affecting the prices. Environmental regulations aimed at reducing pollution and promoting sustainable practices can also influence the production processes and costs associated with monochloroacetic acid.

The global supply chain intricacies further complicate the pricing landscape of monochloroacetic acid. The production of MCAA is concentrated in certain regions, with major producers located in countries like China, India, and the United States. Any disruptions in these regions, whether due to natural disasters, political unrest, or economic instability, can lead to significant price fluctuations. Additionally, logistical challenges such as transportation costs and shipping delays can affect the final market price of MCAA. As a result, companies involved in the production and distribution of MCAA must constantly monitor these factors to make informed decisions and maintain competitive pricing.

Technological advancements and innovations in production processes also play a vital role in determining the cost structure of monochloroacetic acid. Improved production techniques that enhance yield and reduce waste can lower overall production costs, allowing manufacturers to offer more competitive prices. For instance, the development of more efficient catalysts and greener production methods can lead to significant cost savings. Companies that invest in research and development to optimize their production processes can gain a competitive edge in the market by offering high-quality MCAA at lower prices.

Market competition is another critical factor that influences monochloroacetic acid prices. The presence of numerous manufacturers and suppliers fosters a competitive environment where pricing strategies can vary significantly. Companies may adopt different approaches, such as cost leadership, differentiation, or focus strategies, to gain market share. Competitive pricing, coupled with high-quality products and reliable supply chains, can attract more customers and drive market growth. Conversely, monopolistic or oligopolistic conditions in the market can lead to price rigidity, where a few dominant players control pricing dynamics.

In conclusion, the pricing of monochloroacetic acid is a complex interplay of various factors including raw material costs, production efficiencies, supply and demand dynamics, geopolitical events, technological advancements, and market competition. Understanding these factors is crucial for stakeholders in the MCAA market to navigate the challenges and opportunities presented by this essential chemical compound. As the global economy continues to evolve, staying informed about these influencing factors will be key to maintaining a competitive edge in the monochloroacetic acid market.

Get Real Time Prices of Monochloroacetic Acid: https://www.chemanalyst.com/Pricing-data/monochloroacetic-acid-1156

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Monochloroacetic Acid#Monochloroacetic Acid Price#Monochloroacetic Acid Price Monitor#Monochloroacetic Acid Pricing

0 notes

Text

Itaconic Acid Market Analysis: Key Insights and Future Outlook

Introduction

Methylenesuccinic acid is an organic dicarboxylic acid produced as an intermediate metabolite by certain fungi during glucose fermentation. With the chemical formula C5H6O4, methylenesuccinic acid has two carboxyl groups that make it highly reactive and versatile for chemical applications. Its production from renewable biomass via fermentation also makes methylenesuccinic acid attractive as a sustainable building block.

Applications in Specialty Polymers

One major use of itaconic acid is in the production of specialty polymers. Its two carboxyl groups allow it to act as a comonomer in polymerization reactions. When copolymerized with acrylic acid or other monomers, methylenesuccinic acid introduces desirable properties like hydrophilicity, permeability, and acidity into the final polymers. Such methylenesuccinic acid copolymers find widespread use as superabsorbents in hygiene products, thickeners in industrial applications, and biodegradable materials. They are also being explored for new applications in fuel cells, adhesives, coatings and ion-exchange resins.

Intermediate for Synthetic RESINS

Besides direct applications, methylenesuccinic acid also enables the production of many important intermediates and final products. It undergoes thermal decarboxylation to form styrene, a precursor to polystyrene plastics. Via acidolysis with polyols, methylenesuccinic acid can make reactive polyester resins used as binders, coatings or matrices. Dimerization to produce citraconic anhydride opens new routes for epoxy and alkyd resins essential to paints, varnishes and construction materials. With techniques like selective hydrogenation, methylenesuccinic acid can even yield substituted furan derivatives and other platform chemicals with wide scope in the agrochemical and pharmaceutical industries.

Sustainable Chemical Building Block

As industries transition towards renewable, sustainable bio-based options, itaconic acid displays immense potential. It serves as an ideal building block - with its versatile functional groups, biodegradability, and production from abundant biomass. Global production capacities are scaling up to serve diversifying applications. Meanwhile, metabolic engineering pushes yields and titers higher. Methylenesuccinic acid exemplifies how sustainable biomanufacturing and green chemistry principles can yield platform chemicals previously derived from petrochemicals. This opens up new pathways for more environmentally benign products meeting society's needs well into the future.

0 notes

Text

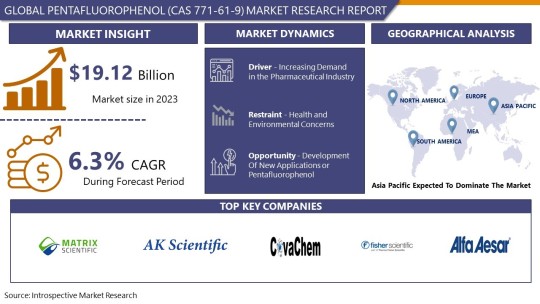

Pentafluorophenol (CAS 771-61-9) Market: Forthcoming Trends and Share Analysis by 2032

Pentafluorophenol (CAS 771-61-9) Market Size Was Valued at USD 19.12 Billion in 2023 and is Projected to Reach USD 33.14 Billion by 2032, Growing at a CAGR of 6.3% From 2024-2032.

The chemical compound pentafluorophenol (CAS 771-61-9) is made up of a phenol ring to which five fluorine atoms are bonded. It is a strong-smelling, colorless solid that is frequently employed in organic synthesis as a flexible reagent for a variety of reactions, including peptide coupling and nucleophilic aromatic substitution. It is useful in the agricultural and pharmaceutical sectors because it increases the reactivity of aromatic compounds by virtue of its electron-withdrawing fluorine substituents.

Chemical compound pentafluorophenol (CAS 771-61-9) finds utility in a variety of fields, including materials research, agrochemicals, and medicines. It is primarily used in organic synthesis as a flexible building block to create pharmaceutical intermediates and specialized compounds.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/4306

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Pentafluorophenol (CAS 771-61-9) Market include:

Matrix Scientific (United States)

AK Scientific Inc. (United States)

CovaChem (United States)

Fisher Scientific (United States)

Alfa Aesar (United States)

Toronto Research Chemicals (Canada)

Apollo Scientific Ltd (United Kingdom)

Merck KGaA (Germany)

BASF (Germany)

TCI Chemicals (Japan)

Tokyo Chemical Industry (Japan)

J&K Scientific (China)

Angene International Limited (China), and other Major Players.

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Pentafluorophenol (CAS 771-61-9) Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/4306

Segmentation of Pentafluorophenol (CAS 771-61-9) Market:

By product

Industrial Grade

Pharmaceutical Grade

By Application

Pharmaceuticals

Agriculture

Electronics

Plastics

An in-depth study of the Pentafluorophenol (CAS 771-61-9) industry for the years 2024–2032 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Key Benefits of Pentafluorophenol (CAS 771-61-9) Market Research:

Research Report covers the Industry drivers, restraints, opportunities and challenges

Competitive landscape & strategies of leading key players

Potential & niche segments and regional analysis exhibiting promising growth covered in the study

Recent industry trends and market developments

Research provides historical, current, and projected market size & share, in terms of value

Market intelligence to enable effective decision making

Growth opportunities and trend analysis

Covid-19 Impact analysis and analysis to Pentafluorophenol (CAS 771-61-9) market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=4306

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assist our clients grow and have a successful impact on the market. Our team at IMR is ready to assist our clients flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, specialized in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1 773 382 1049

Email: [email protected]

#Pentafluorophenol (CAS 771-61-9)#Pentafluorophenol (CAS 771-61-9) Market#Pentafluorophenol (CAS 771-61-9) Market Size#Pentafluorophenol (CAS 771-61-9) Market Share#Pentafluorophenol (CAS 771-61-9) Market Growth#Pentafluorophenol (CAS 771-61-9) Market Trend#Pentafluorophenol (CAS 771-61-9) Market segment#Pentafluorophenol (CAS 771-61-9) Market Opportunity#Pentafluorophenol (CAS 771-61-9) Market Analysis 2024

0 notes

Text

Acetonitrile Prices Monitoring, Analysis, News, Trends & Forecast | ChemAnalyst

Acetonitrile prices, reflecting the cost of this organic solvent, are subject to fluctuations influenced by various factors such as global market dynamics, industrial demand, and production costs. Understanding these price movements entails a comprehensive analysis of supply and demand dynamics, raw material availability, and macroeconomic indicators.

The pricing of acetonitrile is significantly influenced by the balance between supply and demand within industries such as pharmaceuticals, agrochemicals, and electronics. Acetonitrile, valued for its versatility as a solvent and intermediate in chemical synthesis, finds extensive application in products ranging from pharmaceuticals and pesticides to batteries and capacitors. Disruptions in the supply chain, such as fluctuations in raw material availability, production capacity, or transportation logistics, can impact the availability and cost of acetonitrile, thereby influencing its market price.

Industrial demand plays a crucial role in determining acetonitrile prices. Industries such as pharmaceuticals rely heavily on acetonitrile for its role as a solvent in drug synthesis and purification processes. Agrochemical manufacturers utilize acetonitrile in the formulation of pesticides and herbicides, while the electronics industry employs it in the production of lithium-ion batteries and capacitors. Fluctuations in demand from these sectors, influenced by factors such as research and development activities, regulatory approvals, and consumer trends, can lead to price volatility for acetonitrile.

Get Real-Time Acetonitrile Prices: https://www.chemanalyst.com/Pricing-data/acetonitrile-1105

Raw material costs significantly impact acetonitrile prices. The price of raw materials such as hydrogen cyanide, which is used in acetonitrile production, can fluctuate due to changes in global supply and demand dynamics, chemical prices, and energy costs. Any significant increase in raw material costs can translate into higher production costs for acetonitrile manufacturers, thereby exerting upward pressure on prices.

Macroeconomic indicators, such as GDP growth, industrial production, and investment in research and development, can indirectly affect acetonitrile prices by influencing overall demand for products containing acetonitrile. Economic expansions tend to drive up demand for acetonitrile-intensive products such as pharmaceuticals, agrochemicals, and electronic components, thereby supporting higher prices. Conversely, economic downturns may lead to reduced demand and downward pressure on acetonitrile prices.

Regulatory changes and quality standards also play a role in shaping acetonitrile prices. Government regulations on chemical safety, environmental standards, and product specifications can impact production costs and market access for acetonitrile manufacturers. Compliance with these regulations may require investments in research, testing, and quality control measures, influencing pricing dynamics.

Looking ahead, several factors are expected to continue influencing acetonitrile prices. Continued growth in sectors such as pharmaceuticals, agrochemicals, and electronics, coupled with increasing demand for specialty chemicals and advanced materials, is likely to drive sustained demand for acetonitrile. Moreover, advancements in chemical synthesis technologies, changes in consumer preferences, and shifts in global trade dynamics could lead to changes in market dynamics and price levels for acetonitrile.

In conclusion, acetonitrile prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, regulatory changes, and macroeconomic indicators. Stakeholders in industries reliant on acetonitrile, such as pharmaceuticals, agrochemicals, and electronics, must closely monitor these factors to anticipate price movements and make informed decisions. As industries evolve and regulatory requirements change, navigating the dynamic landscape of acetonitrile pricing will remain a key challenge for industry participants.

Get Real-Time Acetonitrile Prices: https://www.chemanalyst.com/Pricing-data/acetonitrile-1105

ChemAnalyst

GmbH — S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49–221–6505–8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Dimethyl Carbonate Market to Witness Growth Acceleration During 2021-2033

Market Definition

Dimethyl carbonate is an organic compound with the chemical formula CH3O3C. It is a clear, colorless liquid with a slightly sweet odor. It is miscible with water and has a density of 1.11 g/mL. Dimethyl carbonate is used as a solvent and as a reaction intermediate. It is produced by the reaction of methanol and carbon dioxide.

Market Outlook

The key trends in Dimethyl Carbonate technology are in the development of new processes for the production of Dimethyl Carbonate and in the use of Dimethyl Carbonate as a co-solvent in various industrial processes.

The development of new processes for the production of Dimethyl Carbonate has been driven by the need for a more environmentally friendly process. Dimethyl Carbonate can be produced by the direct reaction of methanol and carbon dioxide, but this process produces large amounts of carbon dioxide as a by-product. New processes have been developed that use renewable sources of methanol, such as biomass, to produce Dimethyl Carbonate with minimal carbon dioxide emissions.

The use of Dimethyl Carbonate as a co-solvent in various industrial processes has also increased in recent years. Dimethyl Carbonate is a highly effective solvent for a variety of organic compounds and can be used in place of more traditional solvents, such as ethyl acetate, to reduce the environmental impact of these processes.

The key drivers of Dimethyl Carbonate market are its low toxicity, high solvency, low volatility, and high thermal stability. Dimethyl Carbonate is used as a solvent in the production of plastics, resins, and films. It is also used as a reagent in the production of pharmaceuticals and agrochemicals. Dimethyl Carbonate is also used as an electrolyte in lithium-ion batteries.

The key restraints in the Dimethyl Carbonate market are the high cost of production and the stringent regulations regarding the use of Dimethyl Carbonate. The high cost of production is due to the use of expensive raw materials and the need for sophisticated equipment. The stringent regulations regarding the use of Dimethyl Carbonate are imposed by the government in order to protect the environment from the harmful effects of this chemical.

To Know More: https://www.globalinsightservices.com/reports/dimethyl-carbonate-market/

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS20291/

Market Segmentation

The Dimethyl Carbonate Market has been segmented into Application, End Use, and Region. Based on Application, the Dimethyl Carbonate Market is Segmented into Polycarbonate, Fuel Additive, Solvent, Lithium Battery, Pharmaceuticals, Pesticides, Pesticides, and Others. Based on End Use, the market is segmented into Plastic, Paints & Coatings, Medical, Electronics, Agrochemicals, and Others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and the Rest of the World.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS20291/

Major Players

Some of the key players of Dimethyl Carbonate Market are Ube Industries Ltd. (India), Kowa Company Ltd. (Japan), Kishida Chemical Co. Ltd. (Japan), Shandong Shida Shenghua Chemical Group Co., Ltd. (China), Guangzhou Tinci Materials Technology Co Ltd. (China), Haike Chemical Group (Japan), Arrow Chemical Group Corp. (China), Panax Etec (South Korea), AkzoNobel (Netherland), and Wego Chemical Group (US).

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS20291/

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS20291/

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Future-proofing Strategies in the Mesitylene Market

The Unique Properties of Mesitylene: An Organic Chemical Compound

What is Mesitylene?

Mesitylene, also known as 1,3,5-trimethylbenzene, is an organic compound consisting of a benzene ring with three methyl substituents arranged symmetrically around the ring. It is a clear, colorless liquid that is insoluble in water but soluble in organic solvents. Mesitylene is classified as an aromatic hydrocarbon and is rarely found in its unsubstituted form in nature.

Chemical and Physical Properties

Mesitylene has the chemical formula C9H12 and a molar mass of 120.194 g/mol. It is a component of various essential oils obtained from plants and it has a sweet, pleasant odor often described as reminiscent of hay or grass. Mesitylene is denser than water with a density of around 0.86 g/cm3. Its melting point is -35°C and boiling point is 165°C. Being an asymmetric molecule, mesitylene exists as three structural isomers - 1,3,5-trimethylbenzene, 1,2,4-trimethylbenzene, and 1,2,3-trimethylbenzene. However, 1,3,5-trimethylbenzene is the most stable and predominant isomer found in nature.

Production and Industrial Uses

Commercially, mesitylene is produced through catalytic methylation of toluene or disproportionation of xylenes. It finds a variety of industrial applications where its properties as a non-polar organic solvent are exploited. Mesitylene is used as an intermediate in the synthesis of dyes, pharmaceuticals, and fragrance chemicals. Due to its inert and non-reactive nature, it is also used as a solvent in the industries that manufacture rubbers, polymers, resins, coatings, and agrochemicals. Mesitylene is combined with other solvents to make paint thinners and industrial degreasing formulations. It also serves as an important raw material in the production of synthetic musks and is commonly added to perfumes and incense formulations for its pleasant odor.

Safety Profile and Regulations

Being a hydrocarbon, mesitylene is considered combustible and somewhat toxic if inhaled or ingested in large amounts. The recommended exposure limits for mesitylene in the workplace are set at 25 ppm over an 8-hour time-weighted average by the American Conference of Governmental Industrial Hygienists (ACGIH). Short-term exposure at concentrations above 250 ppm may cause irritation to eyes and respiratory tract in humans. Mesitylene is classified by the EPA (Environmental Protection Agency) as a VOC (volatile organic compound) due to its participation in atmospheric photochemical reactions and contribution to ozone depletion and smog formation. Most regulatory agencies require the amount of mesitylene in final products to be limited or substituted wherever possible by less hazardous alternatives. Proper precautions must be taken during the industrial handling and storage of mesitylene to prevent risks to human health and environment.

Uses in Flavor and Fragrance Industry

Mesitylene is a widely employed chemical in the flavor and fragrance industry. Its sweet, grassy aroma makes it a popular ingredient in the formulation of several perfume types including fougères, chypres and green floral fragrances. Mesitylene is commonly formulated at levels less than 1% to reinforce the top, heart and drydown notes of fragrances. In perfumery, it is frequently combined with galaxolide, hedione and other musks to lend a natural, green touch. The olfactory properties of mesitylene are also exploited in food and beverage flavors. It finds use as a flavoring agent in candy, baked goods, chewing gum, soft drinks and many other products to contribute notes of fresh hay or green grass. Mesitylene also enhances tobacco flavors and formulations. Its solvent properties further aid in the incorporation and stabilization of other aromachemicals in liquid fragrance and flavor concentrates.

0 notes

Text

Best Small Cap Chemical Stocks in India -2024

Best Small Cap Chemical Stocks in India -2024

In the dynamic landscape of the Indian stock market, investors are often on the lookout for opportunities that promise growth and value. Small-cap stocks, known for their potential to deliver substantial returns, are gaining attention. In the chemical sector, several small-cap stocks are emerging as promising contenders for investors seeking exposure to this industry. Here, we delve into some of the best small-cap chemical stocks in India for 2024.

Bodal Chemicals Limited (BODALCHEM):

Bodal Chemicals Limited is a key player in the dye and dye intermediates segment. With a diversified product portfolio and a strong focus on innovation, Bodal Chemicals has positioned itself as a potential growth stock. The company's commitment to sustainability and expanding global presence make it an interesting choice for investors eyeing the chemical sector.

Aarti Industries Limited (AARTIIND):

Aarti Industries Limited is a leading player in the specialty chemicals space. Known for its robust R&D capabilities, Aarti Industries has been consistently expanding its product offerings. With a focus on high-margin products and a customer base spread across various industries, the company is well-poised for growth in the coming years.

NOCIL Limited (NOCIL):

NOCIL Limited is a significant player in the rubber chemicals segment. As the demand for rubber-based products continues to rise, NOCIL stands to benefit. The company's consistent financial performance and strategic expansion plans make it an attractive choice for investors seeking exposure to the chemical industry.

Sudarshan Chemical Industries Limited (SUDARSCHEM):

Sudarshan Chemical Industries Limited is a leading pigment manufacturer with a global footprint. The company's focus on research, innovation, and sustainability aligns with the industry trends. Sudarshan Chemical Industries is well-positioned to capitalize on the increasing demand for pigments in various sectors, making it a stock to watch in 2024.

Vinati Organics Limited (VINATIORGA):

Vinati Organics Limited specializes in specialty chemicals, primarily serving the polymer and agrochemical industries. The company's consistent financial performance, emphasis on innovation, and strategic expansions make it an interesting Best Small Cap Chemical Stocks in India -2024

Conclusion:

Investing in Best Small Cap Chemical Stocks in India -2024 requires thorough research and understanding of market dynamics. While the potential for higher returns exists, it is crucial for investors to assess their risk tolerance and investment goals. The mentioned small-cap chemical stocks present compelling opportunities, but investors should conduct their due diligence and consider consulting financial experts before making investment decisions in 2024.

1 note

·

View note

Text

Leading the Way: Innovations in Acetophenone Derivatives Manufacturing

Acetophenone derivatives play a crucial role in various industries, from pharmaceuticals to fragrances and beyond. As demand for these versatile compounds continues to rise, companies like CefaCilinas are pioneering innovations in their manufacturing processes. With a commitment to excellence and a focus on sustainability, CefaCilinas is leading the way in advancing acetophenone derivatives manufacturer.

Understanding Acetophenone Derivatives:

Acetophenone derivatives are organic compounds derived from acetophenone, a key intermediate in the synthesis of numerous chemicals. These derivatives exhibit diverse properties and find applications in pharmaceuticals, agrochemicals, flavors, fragrances, and more. From pain relievers to perfumes, their versatility makes them indispensable in modern industries.

Innovations in Manufacturing:

CefaCilinas stands at the forefront of acetophenone derivatives manufacturing, driven by a culture of innovation and a dedication to meeting market demands sustainably. The company has embraced cutting-edge technologies and process optimizations to enhance efficiency, reduce environmental impact, and ensure product quality.

Advanced Synthetic Routes:

CefaCilinas employs advanced synthetic routes to produce acetophenone derivatives with precision and efficiency. By leveraging state-of-the-art equipment and innovative methodologies, the company achieves higher yields and purity levels, optimizing resource utilization and minimizing waste generation.

Green Chemistry Initiatives:

In line with global sustainability goals, CefaCilinas prioritizes green chemistry initiatives in its manufacturing processes. The company explores eco-friendly solvents, catalysts, and reaction conditions to minimize environmental footprint while maintaining product integrity. Through continuous research and development, CefaCilinas aims to further reduce its environmental impact and contribute to a greener future.

Process Intensification:

Process intensification techniques play a crucial role in streamlining acetophenone derivatives manufacturing. CefaCilinas adopts process intensification strategies such as flow chemistry and continuous processing to enhance productivity, shorten reaction times, and improve process safety. These innovations not only increase throughput but also reduce energy consumption and waste generation, making production more sustainable.

Quality Control And Assurance :

At CefaCilinas, quality control and assurance are paramount. Rigorous testing protocols and analytical techniques ensure that each batch of acetophenone derivatives meets the highest standards of purity and consistency. By investing in state-of-the-art laboratories and skilled personnel, the company maintains product quality and reliability, earning the trust of customers worldwide.

Application And Market Impact :

The innovations spearheaded by CefaCilinas in acetophenone derivatives manufacturing have far-reaching implications across industries. Pharmaceutical companies rely on these compounds for the synthesis of active pharmaceutical ingredients (APIs) in drugs treating various ailments. Agrochemicals manufacturers utilize acetophenone derivatives in crop protection products to enhance yield and quality. Furthermore, the fragrance and flavor industries depend on these compounds to create captivating scents and tastes for consumer products.

Sustainability And Corporate Responsibility :

Beyond technical advancements, CefaCilinas remains committed to corporate responsibility and sustainability. The company actively engages in community outreach programs, environmental conservation efforts, and ethical business practices. By prioritizing the well-being of people and the planet, CefaCilinas strives to make a positive impact on society while driving business growth.

CONCLUSION:

As the demand for acetophenone derivatives continues to grow, companies like CefaCilinas are at the forefront of innovation in manufacturing. Through advanced synthetic routes, green chemistry initiatives, process intensification, and stringent quality control measures, CefaCilinas ensures the production of high-quality derivatives while minimizing environmental impact. By leading the way in sustainable manufacturing practices, CefaCilinas sets a precedent for the industry, driving progress and shaping the future of acetophenone derivatives manufacturing.

0 notes

Text

Navigating the Global Market: Benzyl Cyanide Exporters in India

In the vast landscape of chemical exports, Benzyl Cyanide stands out as a crucial compound with diverse industrial applications. As the demand for this chemical continues to rise globally, India emerges as a significant player in its production and export. With a robust manufacturing infrastructure and adherence to stringent quality standards, Benzyl Cyanide exporters in India are carving a niche for themselves in the international market.

Benzyl Cyanide, chemically known as phenyl acetonitrile, finds utility in various sectors including pharmaceuticals, perfumery, and agrochemicals. Its role as an intermediate in organic synthesis makes it indispensable for the production of pharmaceutical compounds, fragrances, and pesticides. This application versatility has fueled its demand, driving the growth of Benzyl Cyanide exports from India.

One of the key factors contributing to the success of Benzyl Cyanide exporters in India is the country's rich chemical manufacturing infrastructure. India boasts state-of-the-art production facilities equipped with advanced technologies and adherence to stringent quality control measures. This ensures the consistent quality of Benzyl Cyanide produced, meeting the exacting standards of international clientele.

Furthermore, India's competitive edge in chemical production is complemented by its skilled workforce and research capabilities. The presence of renowned research institutions and academic collaborations fosters innovation, leading to the development of efficient manufacturing processes and novel applications for Benzyl Cyanide. This continual evolution keeps Indian exporters ahead in meeting the dynamic demands of the global market.

In addition to manufacturing prowess, Indian Benzyl Cyanide exporters prioritize sustainability and environmental responsibility. Efforts towards green chemistry practices, waste minimization, and adherence to regulatory norms underscore their commitment to sustainable production. This not only enhances the appeal of Indian Benzyl Cyanide in the international market but also aligns with the growing global emphasis on eco-friendly manufacturing practices.

The strategic geographical location of India further enhances its position as a preferred hub for Benzyl Cyanide exports. With well-established transportation networks and proximity to major markets, Indian exporters can efficiently cater to the demand across continents. This logistical advantage ensures timely delivery and cost-effectiveness, strengthening India's standing in the global chemical trade.

As the global economy continues to evolve, the outlook for Benzyl Cyanide exports from India remains promising. Leveraging technological advancements, innovation, and a commitment to sustainability, Indian exporters are poised to capitalize on emerging opportunities and further expand their presence in the international market. With a blend of tradition and modernity, India continues to shape the landscape of Benzyl Cyanide trade, offering quality products and reliable service to customers worldwide.

In conclusion, the story of Benzyl Cyanide exports from India is one of innovation, quality, and sustainability. As Indian exporters continue to thrive in the global market, they reinforce the nation's position as a formidable player in the chemical industry. With a focus on excellence and a forward-looking approach, Benzyl Cyanide exporters in India are poised for sustained growth and success on the international stage.

0 notes

Text

Global N-Butanol Market Size, Share, Trends, Opportunity, and Forecast

Global N-butanol market is anticipated to increase at an impressive rate through 2031. N-Butanol is an alcohol manufactured by processing petrochemical or fermentation of sugars obtained from corn and is also known as 1 butanol or butyl alcohol. It is a primary alcohol having a colorless liquid of standard volatility and fruit-like odor. Due to its characteristic, n-Butanol is used as a raw material for paint and coating resins, butyl carboxylates such as butyl acrylate, butyl acetate, and glycol ethers.

Growing demand for N-butanol from various end user industries such as paints & coatings, chemical and petrochemical, textile, agriculture, building & construction, pharmaceutical, and personal care for their application is expected to drive the growth of global N-butanol market. Apart from these, growing use of N-butanol as raw materials in different products like fuels, green buildings, and others further increase the demand for N-butanol, thereby driving the market growth. According to reports, butyl alcohol was the world’s 2563rd most traded product worldwide in 2020, which holds 0.003% of world trade. Furthermore, government policies over trade, such as free trade agreements, bilateral agreements, and regional group trade agreements, promote the import and export of raw materials that propel market growth. Thus, it is expected that the global n-Butanol market is going to rise in the projected year.

Growing Demand for Industrial Applications is Going to Propel the Market Growth

N-Butanol is primarily used as an industrial intermediary that is used to make different products like dyes, lacquers, resins, and varnishes. The broad melting and boiling points of N-butanol make it useful for the production of chemicals which are required to cool down entire machinery. Butyl alcohol is used to make rubber cement, safety glass, rayon, photographic film, motion picture, water resistance cloth, artificial leather, and raincoats. Moreover, it has wide application in agriculture for the production of herbicides and other essential agrochemicals. According to the report, the world trade of n-Butanol was amounted to around USD 550 million by value in 2020. In food industries, n-Butanol is used as a dehydrating agent in perfumes and fruit essences and as a flavoring agent in foods and beverages. Hence, owing to its broad application in every end-user industry, it is expected that demand for n-Butanol is going to increase in the projected period.

Market Segmentation

Global N-Butanol market is based on grade and application. Based on grade, the market is divided into industrial grade v/s pharmaceutical grade. Based on application, the market is divided into butyl acetate, butyl acrylate, glycol ethers, direct solvent, plasticizers, and others.

The global market for N-Butanol, a versatile industrial chemical with a wide range of applications, is experiencing significant growth and transformation. This blog post delves into the expansive landscape of the Global N-Butanol Market, exploring its size, the driving factors behind its expansion, key applications, and the promising future trends that shape this dynamic industry.

Market Overview:

The Global N-Butanol Market has emerged as a critical player in the chemical industry, witnessing steady growth driven by its diverse applications. N-Butanol, a four-carbon alcohol, finds utility in various sectors, including chemicals, coatings, pharmaceuticals, and automotive, contributing to its widespread demand.

Driving Factors:

a. Chemical Manufacturing and Solvent Applications:

N-Butanol serves as a crucial intermediate in the production of chemicals, including butyl acrylate, glycol ethers, and butyl acetate. Its properties as a solvent make it valuable in industries such as coatings, adhesives, and sealants, driving demand for N-Butanol globally.

b. Automotive and Paint Industries:

The automotive and paint industries heavily rely on N-Butanol for its use in the formulation of automotive coatings and paints. Its contribution to enhancing the durability, gloss, and performance of coatings has led to consistent demand from these sectors.

c. Pharmaceutical and Agrochemical Applications:

N-Butanol plays a vital role in pharmaceutical manufacturing, serving as a solvent in the production of various medications. Additionally, its application in the formulation of agrochemicals further expands its reach, contributing to the growth of the market.

Market Segmentation:

The Global N-Butanol Market is segmented based on its applications, including:

Chemical Intermediates: Production of butyl acrylate, butyl acetate, and glycol ethers.

Solvents: Widely used in coatings, adhesives, sealants, and inks.

Automotive Coatings: Enhancing the performance and durability of automotive paints.

Pharmaceuticals: Serving as a solvent in the production of medications.

Agrochemicals: Formulation of pesticides and herbicides.

Challenges and Opportunities:

The N-Butanol market faces challenges related to raw material prices, regulatory constraints, and environmental concerns. However, these challenges present opportunities for market players to innovate in sustainable production methods, explore bio-based alternatives, and navigate regulatory landscapes effectively.

Future Trends:

The future of the Global N-Butanol Market is poised for exciting developments, with trends including:

Bio-Based N-Butanol: Growing interest in bio-based alternatives to reduce environmental impact.

Focus on Sustainable Practices: Increasing emphasis on sustainable production methods.

R&D in Advanced Applications: Ongoing research and development for novel applications in emerging industries.

In conclusion, the Global N-Butanol Market stands as a cornerstone in the chemical industry, serving as a crucial component in various applications. As industries continue to evolve, the demand for N-Butanol is expected to grow, fueled by its versatility and contribution to key sectors such as chemicals, coatings, pharmaceuticals, and automotive. With innovation and sustainability at the forefront, the future of the N-Butanol market promises to be dynamic and transformative.

Download Free Sample Report

Market Players

Mitsubishi Chemical Corporation, Dow Chemical Company, BASF SE, OXEA GmbH, Sasol Ltd, KH Neochem Co Ltd, China National Petroleum Corporation (CNPC), INEOS Oxide Ltd, Perstorp Holding AB, and Saudi Kayan Petrochemical Company are the key players operating in the global N-butanol market.

Report Scope:

In this report, global N-butanol market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

Global N-Butanol Market, By Grade:

Industrial Grade

Pharmaceutical Grade

Global N-Butanol Market, By Application:

Butyl Acetate

Butyl Acrylate

Glycol Ethers

Direct Solvent

Plasticizers

Others

Global N-Butanol Market, By region:

North America

United States

Mexico

Canada

Asia-Pacific

China

India

South Korea

Japan

Australia

Europe

France

Germany

United Kingdom

Italy

Spain

South America

Brazil

Argentina

Colombia

Middle East & Africa

Mob : +91 9319642100

Noida One Tower Sec 62 Noida 201301

Sales : [email protected]

Website : https://www.organicmarketresearch.com

0 notes

Text

Benzyl Chloride Prices Trend, Pricing, Database, Index, News, Chart, Forecast

Benzyl Chloride prices are subject to various market factors that influence their fluctuations. As a key chemical compound utilized in numerous industries, including pharmaceuticals, agrochemicals, and fragrances, benzyl chloride plays a vital role in the synthesis of various products. The pricing dynamics of benzyl chloride are intricately tied to factors such as raw material costs, demand-supply dynamics, geopolitical events, and regulatory changes.

One significant determinant of benzyl chloride prices is the cost of raw materials. Benzyl chloride is typically produced through the chlorination of toluene, an aromatic hydrocarbon derived from petroleum. Therefore, fluctuations in crude oil prices can directly impact the cost of toluene, consequently affecting benzyl chloride prices. Additionally, factors such as availability of raw materials, production capacity, and transportation costs also contribute to the overall cost structure.

Demand-supply dynamics play a crucial role in determining benzyl chloride prices. Industries such as pharmaceuticals, where benzyl chloride is used as a key intermediate in the synthesis of drugs, can significantly influence demand. Any changes in the demand for pharmaceuticals or other benzyl chloride-dependent products can directly impact the pricing of benzyl chloride. Similarly, supply disruptions, such as production plant shutdowns or logistical issues, can lead to temporary spikes in prices due to supply shortages.

Get Real Time Prices of Benzyl Chloride: https://www.chemanalyst.com/Pricing-data/benzyl-chloride-1299

Geopolitical events can also have a substantial impact on benzyl chloride prices. Factors such as trade tensions, sanctions, or geopolitical conflicts in regions that are major producers or consumers of benzyl chloride can disrupt supply chains and lead to price volatility. Uncertainties surrounding political stability or regulatory changes in key regions can further exacerbate price fluctuations, as market participants react to perceived risks and adjust their pricing strategies accordingly.

Regulatory changes and environmental policies can influence benzyl chloride prices by imposing additional compliance costs or affecting production processes. Stringent regulations aimed at reducing emissions or minimizing environmental impact may necessitate investments in cleaner production technologies or the adoption of alternative feedstocks, which can increase production costs. Moreover, regulatory changes related to safety standards or handling procedures can also impact operational costs for benzyl chloride manufacturers, thereby influencing pricing decisions.

Market dynamics such as competition among suppliers, product differentiation, and the bargaining power of buyers can also influence benzyl chloride prices. In a competitive market environment, suppliers may engage in pricing strategies such as discounts or promotional offers to capture market share, leading to downward pressure on prices. Conversely, in markets characterized by oligopoly or monopoly conditions, suppliers may have greater pricing power, allowing them to dictate prices to a certain extent.

Forecasting benzyl chloride prices requires a comprehensive understanding of these multifaceted factors and their interplay within the market. Market participants employ various analytical tools and methodologies, including supply-demand analysis, price modeling, and scenario planning, to anticipate price movements and mitigate risks. Additionally, staying informed about macroeconomic indicators, industry trends, and regulatory developments is crucial for making informed decisions in the benzyl chloride market.

In conclusion, benzyl chloride prices are influenced by a complex interplay of factors, including raw material costs, demand-supply dynamics, geopolitical events, regulatory changes, and market dynamics. Understanding these factors and their implications is essential for market participants seeking to navigate the dynamics of the benzyl chloride market effectively. By staying informed and adopting robust analytical approaches, stakeholders can better anticipate price movements and make informed decisions to manage risks and optimize their business operations.

Get Real Time Prices of Benzyl Chloride: https://www.chemanalyst.com/Pricing-data/benzyl-chloride-1299

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes