#24vdcwaterpump

Text

TOPSFLO Water Pump Intelligent Customized FG Signal - Meet Diverse Needs and Enhance Pumping Experience

As an advanced fluid transfer device, brushless DC centrifugal pumps are playing an increasingly important role in various industries. This kind of dc water pump not only has the advantages of high efficiency, low energy consumption and smooth operation, but also has the advantages of easy installation and use, long life and is deeply loved by users, becoming the preferred device in many fields. The FG signal of the brushless DC centrifugal pump is very important for monitoring, controlling and optimizing the operation of the pump, which can improve the stability, safety and efficiency of the system.

What is the FG Signal of a Brushless DC Centrifugal Pump?

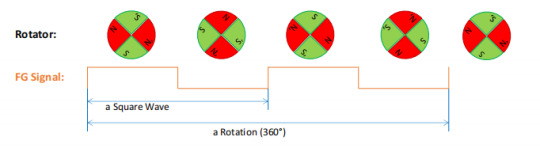

The FG signal of a brushless DC centrifugal pump usually refers to the "Frequency Generator" signal line, which usually work through a square wave signal. The frequency of this square wave signal is proportional to the speed of dc water pump. When the motor speed increases, the frequency of the square wave signal will increase accordingly, and when the motor speed decreases, the frequency of the square wave signal will also decrease. Through the frequency change of this square wave signal, the control system can achieve precise control of the motor speed and control it as needed to ensure the stable operation of the water pump.

If the motor speed is lower than the set value, the control system can increase the output power of the motor by increasing the duty cycle of the speed regulation signal, thereby increasing the motor speed. On the contrary, if the motor speed is higher than the set value, the control system can reduce the output power of the motor by reducing the duty cycle of the speed regulation signal, thereby reducing the motor speed.

How is the square wave generated? The FG signal is actually the communication signal of the brushless DC motor. When a communication event occurs, the FG output will toggle. The rotor used in the TOPSFLO water pump has 4 poles, which means that 4 communication events will occur during one rotation of the rotator, and the FG will flip twice to produce a square wave.

Wiring Method of the FG Signal Line

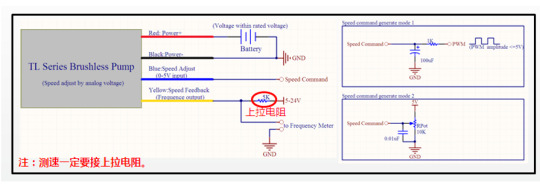

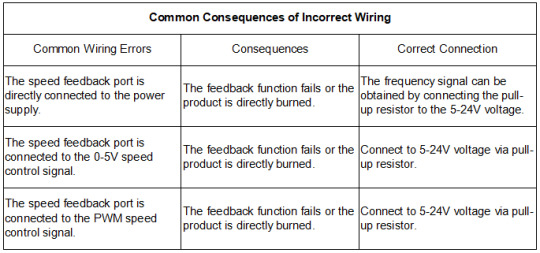

The wiring sequence of the customized 5V/PWM/FG signal line of TOPSFLO DC brushless water pump is generally: red line positive, black line negative, blue line 5V or PWM speed regulation, yellow line FG signal. When the red, black and yellow wires are connected, the water pump works normally; when the yellow wire is not connected, the water pump works, but there is no signal display; when the input current is >50mA, there is a risk of damage to the FG signal circuit of the pump. When measuring speed, a pull-up resistor must be connected. The pull-up resistor is recommended to be between 1K and 10K. It is adjusted according to the pull-up voltage. The greater the voltage, the greater the resistor selected.

FG Wiring Precautions

What kind of applications need to customize the FG signal lines?

The reasons for customizing FG signal for brushless DC centrifugal pumps involve many aspects such as control system requirements, accuracy, integration, and performance optimization. By customizing FG signal lines, customers' specific needs can be met to ensure that the water pump can achieve the best performance and functionality in its applications. The following are common applications that require customized FG signal lines:

Equipment control system requirements: The customer's control system requires specific types or specifications of signal inputs to ensure optimal performance. For control systems that require specific frequency ranges or signal types, customizing FG signal lines to meet these requirements is necessary.

Precision and accuracy requirements: Customer applications require higher measurement precision and accuracy, such as the medical industry, drinking industry, cooling industry, precision instruments, etc. By customizing the FG signal line, the speed of the water pump can be precisely controlled. For example, the speed regulation function needs to be implemented or the pump needs to run at a specific speed under specific conditions. At this time, the FG signal line can provide the operating status and speed information of the water pump to facilitate customers to accurately control and adjust the water pump.

Real-time monitoring requirements: The operating status of the water pump needs to be monitored in real time. For example, it is necessary to know the flow rate of the water pump or whether it has stopped due to failure. At this time, customized FG signal lines can collect and monitor these data, helping customers promptly detect abnormal pump operation and take corresponding measures.

Integration and compatibility requirements: Customized circuits or wiring schemes are required for customer system integration to meet the overall system design and requirements. In this case, customized FG signal lines can better meet the needs of system integration, providing a more flexible and reliable system solution.

Advantages of TOPSFLO's customized FG signal lines

TOPSFLO is one of the earliest manufacturers in China to focus on the R&D and manufacturing of micro pumps. It is a powerful enterprise that only produces high-end products and exports 90% of them to the European and American markets. It has long-term and stable cooperation with many world-renowned brands in Europe and the United States, and its business has been growing steadily every year. At present, the full series of TOPSFLO TL brushless DC centrifugal pumps can realize intelligent customization of FG signal lines. Our advantages are mainly reflected in the following:

R&D strength: TOPSFLO has independent electronic engineers, structural engineers and motor engineers to provide you with support and R&D. Each has their own practical R&D capabilities and can be flexibly customized according to customer requirements, ensuring that you can always receive a solution immediately. You can rest assured of our high-quality and professional service in the long run.

Successful cases: TOPSFLO cooperates with many leading international companies and provides OEM supporting services, such as Tesla, Whirlpool, Bosch, KTM, KOHLER, etc. Therefore, we have extensive experience in pump applications and OEM services in different industries, such as medical, solar pv, automotive, industrial cooling, home appliances, charging piles, hot beverage machines, etc.

Company strength: With nearly 18 years of experience, TOPSFLO is the leading comprehensive solution manufacturer in China specializing in the production of various micro dcwater pumps. We attach great importance to product quality and corporate integrity, which is why we have a strong R&D team to realize customers' customized needs throughout the process.

TOPSFLO can not only customize the speed regulation function of 5V, PWM and FG signal lines, but also realize the customization of pump size, structure, materials, etc. Any OEM project you can imagine and request for customization, TOPSFLO will try its best to meet your requirements. If you have any further questions, please feel free to let us know. We value your valuable suggestions and look forward to cooperating with you.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#dc water pump#bldcpump#topsflopump#Youtube

0 notes

Text

The Vital Role of Miniature Diaphragm Pumps in Medical Device Advancements

Introduction

In the ever-evolving landscape of medical technology, diaphragm pumps have emerged as indispensable components, contributing significantly to advancements in various medical devices. Among the key players in this field, TOPSFLO diaphragm gas and liquid pumps have proven to be pivotal in a wide array of medical applications. This article explores the critical role these pumps play in shaping the future of healthcare, focusing on in-vitro diagnostics, anesthesia monitoring, therapeutic and surgical equipment, and critical care devices.

In-Vitro Diagnostics: Diagnosis lies at the heart of effective medical treatment, and in-vitro diagnostics have become essential tools for clinicians. Miniature diaphragm pumps play a crucial role in supporting diagnostic processes by facilitating the movement of liquids and gases within diagnostic devices. Whether it's sample processing, reagent delivery, or fluid handling, the precision and reliability of these pumps contribute to the accuracy of diagnostic results, enabling early detection and intervention in various medical conditions.

Anesthesia Monitoring: Ensuring patient safety during surgical procedures is paramount, and anesthesia plays a pivotal role in this regard. Miniature diaphragm pumps are integral components in anesthesia machines, regulating the flow of gases and maintaining a precise balance to achieve optimal sedation levels. The reliability of these pumps is particularly critical during delicate surgical procedures, contributing to the overall success and safety of anesthesia administration.

Therapeutic and Surgical Equipment: From infusion pumps to surgical tools, therapeutic and surgical equipment rely on precise fluid control mechanisms. TOPSFLO micro diaphragm pumps provide the necessary precision and consistency required for drug delivery systems, ensuring accurate dosages and minimizing the risk of complications. In surgical settings, these pumps play a vital role in powering suction devices, controlling fluid flow, and contributing to the overall efficiency and safety of medical procedures.

Critical Care Devices: In critical care scenarios, where every moment is crucial, the reliability of medical devices becomes a matter of life and death. TOPSFLO mini diaphragm pumps are engineered to meet the stringent demands of critical care devices, such as ventilators and patient monitoring systems. These pumps contribute to the consistent delivery of gases and fluids, playing a pivotal role in sustaining patients' vital functions and improving overall outcomes in intensive care settings.

Conclusion

As medical technology continues to advance, the role of mini diaphragm liquid and gas pumps, becomes increasingly significant. The precision, reliability, and versatility of these pumps contribute to the efficacy of medical devices across various applications. From in-vitro diagnostics to critical care devices, TOPSFLO micro diaphragm pumps stand at the forefront of innovation, ensuring that healthcare professionals have the tools they need to provide optimal care and improve patient outcomes. As the medical field progresses, the vital role of these diaphragm pumps in shaping the future of healthcare is likely to expand, ushering in new possibilities for diagnosis, treatment, and patient care.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#medicalpump#IVDpump#medical devices#waterpump#dcwaterpump#24vdcwaterpump#12vwaterpump#12vdcwaterpump#brushlessdcpump#dc water pump#bldcpump#Youtube

0 notes

Text

Enhancing Energy Efficiency: Solar Water Heater Booster Pumps Pave the Way for Your Sustainable Lifestyle

Solar water heaters offer an efficient and economical alternative to traditional water heating systems, making them a popular appliance for homeowners looking to reduce their energy consumption and carbon emission. When it comes to enjoying a comfortable shower experience and worry-free hot water supply, a solar water heater booster pump becomes an indispensable home appliances. Because of the efficient pressurization of the water pump, users can not only use solar energy efficiently, but also easily enjoy a stable hot water supply.

The core function of TOPSFLO solar water heater booster pump is to increase the water pressure of the hot water supply, so that users no longer have to wait for the hot water to flow out, or endure the intermittent hot water supply, but can enjoy every drop of warm hot water. Ensure you get a new and comfortable hot water experience.

At present, TOPSFLO solar hot water circulation pump TS5 has been widely used in several hundred thousand of households around the world. Based on customer feedback, the following points are the main reasons why customers choose TOPSFLO DC solar hot water pumps:

PV power supply, no need to connect to the gridThe TOPSFLO DC solar pump can be directly connected to the photovoltaic (PV) panel and can directly use the solar DC power converted by the PV panel without the need for additional energy conversion equipment, which can maximize the use of solar resources and reduce energy conversion losses; It provides great convenience for rooftop installation,even remote areas or places lacking stable power supply. This is one of the important reasons why TS5 pumps are widely used around the world.

Highly efficient and energy-saving, suitable for small or single-family solar water heating systemsThe water pump can start working when the sunlight is weak. The TS5 pump is equipped with a 2W soft-start function and can also work continuously for 24 hours to meet daily hot water supply needs at any time. The low power of 15W can provide a strong flow rate of 12L/Min and a maximum pressure of 3M, reducing energy waste and ensuring efficient supply of hot water. The ultra-long life of 30,000 hours makes it an economical and reliable choice. Used with solar water heaters, it can help you minimize electricity or gas consumption and reduce users' energy expenses.

Add special protection functions for worry-free operationTS5 comes with a series of special protection functions, including polarity protection, idling protection, stall protection, etc. End users can clean and maintain the water pump themselves. When reinstalling, even if the positive and negative poles of the power supply are reversed, solar hot water pump circuit board will not be damaged. If the pipeline is short of water, the idling protection detection of TS5 will be triggered. The water pump will run at low speed when there is no water, and will automatically return to normal working status when there is water, without the risk of burning the PCBA. If impurities in the pipeline block the pump, the pump will be tested repeatedly until the blockage is cleared and normal operation resumes. These protection mechanisms greatly reduce the damage to the water pump caused by common operating errors by end customers.

Easy installation and maintenanceThe installation process of TOPSFLO solar water heater booster water pump is very simple and does not require complicated engineering and equipment, allowing you to quickly enjoy it at home. The TS5 water pump is small and lightweight, with a motor diameter of 46mm and can be directly fixed on the water pipe without a bracket. The high quality makes it almost free of maintenance costs. It only requires regular inspection and maintenance to remove possible impurities in the water pipes. TOPSFLO solar water heater booster pump TS5 will continue to provide long-term and reliable service for your solar water heater.

In practical applications, TOPSFLO Solar hot water Pump TS5 not only helps solar water heaters improve the hot water supply for end users, but also helps them save a lot of energy costs, and has won unanimous praise from the majority of end users. One of our end users wrote to TOPSFLO and said: "My TS5 water pump has been working perfectly for 4 years. Now I want to buy a new generation pump." Real user reviews and satisfaction guarantee are the best proof of our products.

If you have a specific working scenario or application needs and are looking for a pump solution, feel free to contact us. TOPSFLO will continue to provide you with more efficient and energy-saving solar water heater pumps.

Wanna to get pump expert recommendation or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

youtube

#solarhotwaterpump#solar water heater#solar water heater booster pump#dcwaterpump#brushlessdcpump#12vdcwaterpump#bldcpump#24vdcwaterpump#12vwaterpump#dc water pump#waterpump#solar water pump#solar system#solar energy#Youtube

0 notes

Text

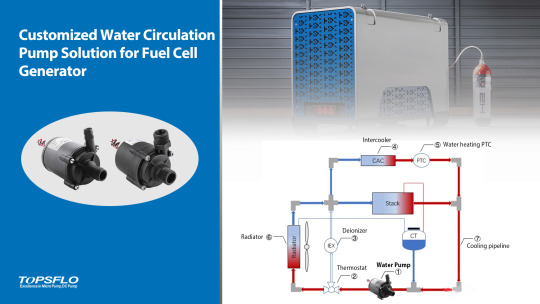

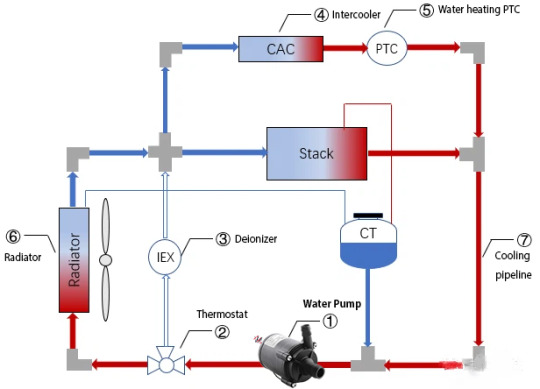

TOPSFLO Fuel Cell Generator Coolant Circulation Pump Solution

Market Overview

As power generation equipment and backup power supply, fuel cells can be widely used in transportation and industrial fields, greatly alleviating the energy pressure caused by the depletion of fossil fuels. Its zero-emission and renewable advantages make it one of the most potential energy supply solutions. The preferential policies currently implemented by various countries have promoted the rapid development of the global fuel cell market.

The system can be simply classified according to the internal electrolyte of the fuel cell: Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Molten Carbonate Fuel Cell (MCFC), Solid Oxide Fuel Cell (SOFC), Proton Exchange Membrane Fuel Cell (PEMFC). Currently SOFC and PEMFC are the most popular research directions.

Market pain point

Research and improvement of fuel cells have always focused on improving efficiency and system operating stability, as follows:

Stable high-temperature operation: The precious metal catalyst of the fuel cell must be at an appropriate temperature to show good activity and stability. In order to ensure the most efficient electrochemical reaction, it usually needs to be stable between 80 and 95°C. If the temperature is too high or too low, the power generation efficiency will be reduced.

Precise control of water volume: In the actual operation of proton exchange membrane fuel cells (PEMFC), the dynamic water volume in the system is difficult to control. If excess water is not discharged in time, the membrane electrolyte will be flooded. If too little water is not replenished in time, it will reduce the overall performance of the battery and even have a negative impact on the life of the membrane.

Long-term stable operation: Fuel cell systems are usually designed for long-term operation. The core components of the system, such as the proton exchange membrane, need to have continuous operation performanceand a lifespan of several years to decades.All other accessories need to match its performance.

Leakage and cleanup: Core components are expensive, and system use requires regular maintenance and cleaning, and a special monitoring system. Once the pipeline liquid leaks, the electrochemical reaction will be interfered with, and even the key components of the battery stack will be corroded and damaged, polluting the environment, causing maintenance and economic losses.

TOPSFLO Fuel Cell Water Pump Solution

Circulation water pumps play an important role in fuel cell systems, and TOPSFLO brushless centrifugal water pumps perfectly solve the needs of multiple uses:

TOPSFLO brushless dc water pump has been measured to operate continuously for 3,000 hours at a high liquid temperature of 95 degrees, and can easily cope with the high-temperature liquid circulation requirements of the battery system. TOPSFLO TL-C01 micro brushless dc water pump circuit board fully considers the temperature rise margin in the design and material selection, and has divided the strong and weak currents. It is matched with internationally renowned brand electronic components to help the system continue to maintain a stable working state.

In response to the different water management requirements of the fuel cell system under different loads and working conditions, TOPSFLO fuel cell generator cooling pump with PWM speed regulation function can be customized. That is, the battery system sensor dynamically controls the water supply of the pump based on the monitored battery load and environmental conditions such as flow, pressure, temperature, and liquid level to ensure efficient operation of the system.

The laboratory testing service life exceeds 20,000 hours, directly matching the long life requirements of the core components of the fuel cell. The moving components adopt wear-resistant design to greatly reduce operating wear. For example, without carbon brushes, self-produced ECM brushless motor, imported graphite bearings and ceramic shafts with good self-lubricating properties. Extends the life of cooling components and significantly reduces the risk of equipment repairs and downtime.

In order to ensure no leakage, TOPSFLO fuel cell generator coolant circulation pump are 100% air tight tested before leaving the factory, and the ultimate pressure can reach more than 18 Bar. As a rare moving part in the fuel cell system, high-quality water pumps can reduce the risk of pipeline leakage in the fuel cell system, ensure that core components work in a safe environment, and reduce system failure maintenance costs.

Wanna to get pump expert recommendation or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

#fuel cell generator#fuelcellpump#fuel cell water pump#fuel cell pump#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#dc water pump#24vdcwaterpump#bldcpump#Youtube

0 notes

Text

How to Select a Right Commercial Water Boiler and Bubble Tea Dispensers Pump?

In recent years, the tea beverage market is rapidly booming, with new bubble tea beverage brands such as Naixue, Sexy tea, Lucky Coffee and Kudi Coffee, not only meeting diversified consumer demand, but also becoming a key growth engine in the market.

With the continuous expansion of the bubble tea beverage market, the market size of commercial water boilers and tea water dispensers has also grown steadily. Consumer demand for tea has become increasingly diversified, they not only want to meet the basic needs of drinking, but also pay more attention to the taste and quality of tea, the pursuit of different flavour of various types of tea. The emergence of commercial hot water dispensers makes it easier for consumers to obtain high-quality tea drinking, and the intelligence and multi functionality of the equipment has also become a trend for future development.

The Main Functions of Water Pump

The main role of a food grade hot water pump in a commercial water boiler includes:

(1) Commercial water boilers are often required to provide hot water to multiple customers during peak hours, and the dosing action of the pumps ensures a steady flow of hot water is provided for varying demands;

(2) Pressurized water sources to ensure a steady flow of water, especially in areas of low water pressure or long distance water supplies;

(3) Used to deliver heated water to provide a fast, efficient supply of hot water, while monitoring and controlling the level in the tank to maintain sufficient water to ensure a continuous supply of hot water.

Choosing the Right Pump is Crucial

In the manufacture of commercial water boilers, the brushless dc water pump is one of the key components that ensures that the boiler runs consistently and delivers stable hot water. To help you make an informed decision when choosing a dc water pump, here are some key considerations:

Flow demand: In commercial water boilers, it is important to cater for hot water supply under different models and demands. Flow demand refers to the required hot water output per minute. When selecting a pump, the hot water demand in a commercial scenario needs to be analyzed in detail, including peak hours and demand for different models, to ensure the pump selected has sufficient flow to meet the demand while avoiding excessive energy consumption.

High-temperature performance: Commercial water boilers can reach high temperatures, even up to 100 °C, when heating and storing hot water, so the pump selected should have excellent high-temperature resistance to prevent the pump from cavitation or failing in high-temperature environments. This involves the selection of high temperature resistant materials and the design of the electrical system to protect the internal components of the pump from high temperature damage.

Drinking water safety: The hot water supplied by commercial water boilers will be used for food and beverage preparation, so the pumps must be made of materials and manufactured to meet food-grade certification standards. This requires stringent quality control and material selection to ensure that the pumps do not release hazardous substances or adversely affect water quality, providing a high level of trust and reliability for users.

Speed control: Commercial water boilers and tea makers need to adapt to different water needs, so it's a good idea to choose a pump with a speed-adjustable feature to adjust the speed and temperature of the water flow according to the user's needs.

Design flexibility: The size and shape of the pump should be coordinated with the design of the commercial water boiler to ensure optimal integration and space utilization. Flexible design also promotes ease of installation and maintenance.

Reliability: Commercial water boilers often require frequent start-ups and operation at high traffic levels. Choosing a well-designed, well-built and rigorously tested pump reduces breakdowns and maintenance requirements. A pump that is easy to maintain reduces downtime and ensures a constant supply of hot water.

Ideal for Commercial Water Boiler Pumps

Based on these points, the TOPSFLO brushless centrifugal pumps TL-B02, TL-B03 and TL-B10 series offer a wide range of choices for different models and needs in the field of commercial water boilers, demonstrating excellent technical advantages:

TOPSFLO DC water pumps offer multi-specification flow rate options to meet the demand under different tank capacities, tea bucket capacities and water head ranges, providing diverse specification options such as 6L/min, 7L/min, 9L/min, 12L/min, and so on.

They have extreme high temperature resistance with high temperature wear-resistant materials and unique high temperature exhaust design, capable of stable operation at extreme temperatures up to 100 degrees Celsius, ensuring that commercial water boilers can supply hot water for a long time in high temperature environments.

TOPSFLO DC water pumps have passed FDA, NSF and other food-grade certifications as well as WRAS certifications to meet drinking water standards, providing higher credibility and user trust for commercial water boilers.

TOPSFLO DC water pumps support PWM or 5V speed adjustment with signal feedback to intelligently adjust the speed and volume of water flow according to user demand, providing personalized rationing while reducing energy consumption and lowering operating costs. They also feature a compact design, including different height options to accommodate a variety of commercial water boiler installations and layouts, providing additional design flexibility. Most importantly, TOPSFLO brushless dc water pumps undergo intensive reliability testing to ensure trouble-free and stable operation during frequent start-up operations ,providing commercial water boiler manufacturers with a reliable, high-quality product.

This range of technical advantages makes TOPSFLO DC water pumps the ideal choice for the commercial water boilers. By choosing TOPSFLO pumps, manufacturers of commercial water boilers and tea water dispensers are able to offer superior products that have gained a reputation for excellence in the marketplace and user feedback. By working closely with TOPSFLO to shape a bright future for the commercial water boilers, we will continue to drive technological innovation, meet customer needs, and bring more development opportunities to the industry.

youtube

youtube

Wanna get pump expert recommendation? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#Water Boiler Pumps#commercial water boiler pump#Youtube

0 notes

Text

How to Maintain Your Micro Brushless DC Water Pumps

With the widespread use of micro brushless dc water pumps in modern industry and daily life, their importance has become increasingly prominent. To ensure its reliability and long life, regular maintenance is essential. So how should we maintain the dc water pump? Here, TOPSFLO professional engineers will introduce some maintenance measures and precautions to you.

Why do brushless dc water pumps need maintenance?

Micro brushless dc water pumps are widely used in industrial, agricultural, medical and household fields. Its excellent liquid delivery performance, energy-saving features, low noise and reliability make it an indispensable device. However, prolonged high-intensity operation can cause wear on pump components, reducing performance and life. Regular maintenance can significantly extend the service life of centrifugal water pumps, reduce maintenance costs, and improve work efficiency.

How to maintain micro brushless dc water pumps?

Regular cleaning:Impurities can accumulate in the impeller and pump chamber of dc water pumps, reducing the efficiency of the pump. It is important to clean the pump parts regularly and keep the interior clean. By flushing the pump regularly with clean water, you can avoid damage to the pump from accumulated impurities. In addition, the water inlet of the dc water pump is easily blocked by debris, so clean the water inlet regularly to ensure smooth flow.

Check motor and power system:Ensure the pump motor and power supply system are operating properly to prevent voltage fluctuations or current overloads from harming the water pump. Do not introduce AC voltage or DC voltage higher than 30V into the system. Always check the insulation of wires, plugs and motors, as well as grounding. If there is any abnormality, it should be repaired or replaced in time.

Check pipe connections regularly:Check whether the pipe connections of the dc water pump are tight and ensure there are no leaks. Kindly repair in time for any problems.

Adjust water pump operating parameters:According to different working conditions, the operating parameters of the centrifugal water pump, such as flow rate and water head, should be adjusted in a timely manner to ensure that the pump is in optimal condition. This will help reduce overloading and reduce energy waste.

Check sealing system:Pump sealing system is a critical part of preventing leaks. Regularly inspect o-rings, gaskets and housings to ensure they are working properly and prevent leakage problems.

Avoid run without water:Before starting, make sure there is enough water in the pump to avoid dry running and thus to avoid damage to the pump.

Pay attention to abnormal sounds:The dc water pump is not allowed to run for a long time in a cavitation state. If you find theabnormal sound, stop the machine immediately and check the cause.

Watch out for liquids:It is prohibited to use liquids containing impurities or magnetically conductive particles.

Pay attention to sun protection:Centrifugal water pumps should not be exposed to sunlight.

Periodic inspection:Regularly conduct comprehensive inspections of the water pump, including the installation status of the pump, wear of parts and pump performance, etc. If there are any problems, they should be dealt with promptly. The water pump leading wires should also be checked regularly for wear, surface cracks, or copper core leakage. Frequently check the inlet and outlet piping system of the centrifugal pump (including pipe fittings and valves) to ensure that the supporting structure is firm and water pump body is supported.

Precautions

Safety first:Before carrying out maintenance and repair work, be sure to cut off the power supply and eliminate hazards to avoid accidents. Also, use appropriate personal protective equipment, such as gloves and goggles, to ensure work safety. TOPSFLO professional engineers recommend that you carry out correct maintenance and care operations according to the use and maintenance manual of the specific equipment.

Professional maintenance:If you are not familiar with the maintenance of micro dc water pumps or need to perform more complex repair work, you should seek the assistance of professional maintenance personnel or service providers to avoid damaging the equipment or causing safety issues.

In summary, understanding and following these micro DC water pump maintenance tips will help keep your water pump in top condition to ensure its efficient operation in a variety of applications.

youtube

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#Youtube

0 notes

Text

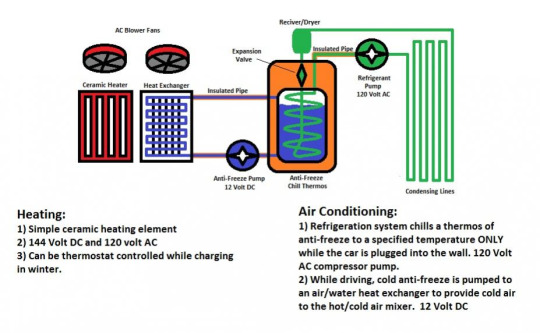

TOPSFLO Water Circulation Pump Solution for Automotive Air Conditioning

Basic Market Situation

The automotive air conditioning system typically uses a water pump for circulation. This is because most automotive air conditioning systems use a refrigerant cycle to achieve the cooling effect, and the refrigerant needs to be circulated by a water pump to achieve the cooling effect. In addition, with the increasing demand for comfort and air quality in vehicles, the market for roof air conditioners (climate regulators) such as trucks, recreational vehicles, and agricultural vehicles is also growing. The main function of the climate regulator is to regulate the temperature, humidity and airflow inside the vehicle to provide a comfortable driving environment.

Automotive air conditioning system is an indispensable part of modern cars, which can provide a comfortable riding environment for drivers and passengers. With the development of economy and people's pursuit of quality of life, its market is also expanding. According to market research institutions, the global automotive air conditioning system market will reach 107.5 billion US dollars by 2027, with a compound annual growth rate of more than 6.2%. Among them, the Asia-Pacific region is the largest market, accounting for 36% of the global market share, followed by the European and North American markets.

Pain Points in Marketing

The automotive air conditioning system improves the conditions for passengers by regulating parameters such as the temperature, humidity, airflow speed, and cleanliness inside the vehicle, thereby preventing or removing fog, frost, and snow from the windshield to ensure a clear view for the driver and enhance driving safety. However, the air conditioning system is one of the systems in a vehicle that is relatively prone to failure, with over 70% of issues including:

Poor cooling/heating performance: uneven output of cold air/heat.

High power/fuel consumption, high cost for users, and not environmentally friendly.

High noise levels that can disturb drivers on long-distance journeys.

Frequent malfunctions: often requiring maintenance after 3-5 months of use, with high maintenance cost.

TOPSFLO Water Circulation Pump Solution for Automotive Air Conditioning

TOPSFLO has been specialized in high-quality automotive air-conditioning liquid cooling pumps for more than ten years, and has provided high-quality water pumps and professional technical solutions for many internationally renowned high-end automotive air-conditioning brands, which can meet the core needs of automotive air-conditioning. For example, when a truck roof air conditioning (climate regulator) is equipped with a TOPSFLO dc water pump, it can achieve the following:

Provide stable cooling effect: The circulating water pump can ensure the normal circulation of refrigerant in the refrigeration system, thereby providing a stable cooling effect. This is important for maintaining a comfortable indoor temperature in hot summer days or during long-distance driving.

Improve energy efficiency and energy conservation: Circulating water pumps can help reduce the energy consumption of cooling systems by at least 60%-70%, thereby improving energy efficiency and achieving energy conservation. By reasonably adjusting the flow and pressure of the pump, the operating energy consumption of the refrigeration system can be effectively reduced, which is environmentally friendly.

Increase the reliability and durability of the system: The use of circulating water pumps can reduce the pressure and load of the refrigeration system, thereby extending the service life of the system. At the same time, the stable operation of the water pump can also improve the reliability of the system and reduce the possibility of failure and repair.

Extended life and noise reduction: Compared with the traditional climate conditioner equipped with a brushed pump, TOPSFLO DC brushless pump can extend the overall life from half a year to 5 years, and the noise is significantly reduced by 50%. For drivers who travel long distances, it is undoubtedly a powerful guarantee to improve comfort and security.

Simplify installation and maintenance: Solutions for truck climate regulators equipped with circulating water pumps are usually designed as an integral whole for convenient installation and maintenance. In addition, the built-in electronic control scheme of TOPSFLO brushless water pump can easily realize various intelligent customization requirements, such as automatically adjusting the flow rate to meet different temperatures, fault feedback, etc. It has automatic control and monitoring functions that can monitor and adjust the system’s operating status in real time, improving the convenience of operation.

As global environmental pollution becomes increasingly serious, people have higher and higher requirements for the environmental performance of automobile air-conditioning systems, and automobile manufacturers continue to launch air-conditioning system products that meet environmental protection standards. For example, the use of brushless water pumps to assist liquid cooling circulation is expected to become a future development trend.

With people's pursuit of quality of life, consumers' demands for automobile air conditioning systems are becoming more and more diversified and personalized, such as regular and quantitative delivery of liquids, and the appearance and dimensions are becoming increasingly lightweight and compact.

With the continuous development of science and technology, intelligence has become a trend. The intelligent air conditioning system can automatically adjust the temperature to provide drivers and passengers with a better experience.

TOPSFLO's mature water pump solutions can help meet the trend needs of the automotive air conditioning industry, and will also continue to upgrade and deepen the industry's higher development requirements.

B10-C: http://www.topsflo.com/brushless-dc-pump/brushless-dc-pump.html

B10-TC: http://www.topsflo.com/brushless-dc-pump/energy-storage-battery-cooling-pump.html

TA50: http://www.topsflo.com/special-pumps/ta50.html

TA60: http://www.topsflo.com/special-pumps/ta60e-ev-charging-pile-cooling-pump.html

Contact Us:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Offcial Web: http://www.topsflo.com/

youtube

youtube

youtube

#dcwaterpump#12vdcwaterpump#12vwaterpump#waterpump#brushlessdcpump#topsflopump#24vdcwaterpump#bldcpump#dc water pump#carwaterpump#carpump#water circulation pump#air conditioning water pump#circulation water pump#Youtube

0 notes

Text

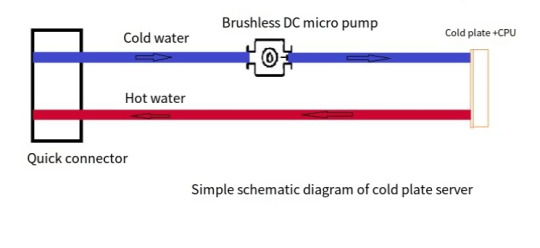

1U 2U Rack Server Water Cooling Pump Solution

Basic Market Situation

With the advent of the digital age, data center servers have experienced rapid and continuous development and are playing an increasingly important role, providing powerful computing capabilities for applications such as cloud computing, artificial intelligence, and big data. As servers continue to evolve and expand in scale, their processing power and storage capacity continue to increase, and their heat dissipation requirements are getting higher and higher. The traditional air cooling method can no longer meet the growing demand for heat dissipation. To solve this problem, server liquid cooling solutions emerged.

Market Pain Points

There are some difficulties in implementing liquid cooling solutions in 1U 2U Rack Servers:

Limited Design Space: The original air-cooling design solution is relatively mature. If you want to add a liquid cooling solution while maintaining the original design solution, the layout space for the liquid cooling solution will be very limited. 1U server Height = 4.445 cm, 2U server height = 4.445*2 = 8.89 cm.

Sealing and Anti-leakage: Liquid cooling systems involve the use of a large amount of liquid media, and the core component in the server is the chip (CPU and GPU, etc.). Once the chip comes into contact with liquid, there is a risk of burning, resulting in The entire server is damaged, so it's crucial to ensure the fluid circulation system is air-tightness and leak-proof.

Heat Dissipation Efficiency and Performance: More than 55% of chip failures are caused by heat transfer failure or temperature rise. If the chip is above 70 degrees, its reliability will be reduced by 50% for every 10 degrees of temperature increase. Once the quality of the components in the cooling assembly is not good or the circulation design is not effective, there is a possibility of unstable product performance, which will lead to local overheating or insufficient cooling, thus affecting the normal operation of the server.

TOPSFLO Water Cooling Pump Solution

liquid-cooled servers, TOPSFLO Water Cooling Pump has specially designed a water pump with a unique flat design for them, which can better solve the problems currently encountered by rack server manufacturers:

The thickness of TOPSFLO mini water pump is as low as 36mm and the overall size is small. The solution of combining water pump with cold plate can be customized to help save space in data center. Compared with bulky traditional cooling equipment, the compact design of mini water pumps makes server liquid cooling systems easier to deploy in limited spaces.

TOPSFLO water cooling pumps adopt static seal design, imported PPS high-quality materials, high-precision molds, 100% strict air tightness testing of the water pump through high-standard air tightness testing equipment imported from France, effectively reducing the risk of leakage to ensure the safety of the server system performance and reliability.

TOPSFLO server liquid cooling pumps adopt unique rotor suspension technology and select high-wear-resistant imported graphite bushings and high-precision ceramic shafts to resist long-term operation and inevitable wear, ensure stable performance and operating status of the water pump, and reduce server system failures and downtime.

According to the heat dissipation requirements of the server, TOPSFLO mini water cooling pump TDC is customized with a maximum flow rate of 8L/min and a maximum water head of 5M. The flow rate and water head are optimized in a compact size to meet the heat dissipation needs of the system. At the same time, the built-in smart chip can customize intelligent speed regulation and signal feedback functions to meet the needs of real-time intelligent monitoring of servers and help achieve more precise temperature control and stability of the server system.

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

🔗Find More Detials: http://www.topsflo.com/special-pumps/servers-liquid-cooling-pump.html

youtube

youtube

Key Words: Rackmount server, high density server, GPU Server, Liquid Cooled Rackmount Server, Rack Servers, server liquid cooling pump, 2U Rackmount Server, 1U Rackmount Server, Data center rack server, Performance rack server, Microserver, High-density rack server, Rack mounted server, Rack server cooling pump, Server coolant pump, Rack server liquid cooling solution, Liquid coolant circulation pump, Rack server heat dissipation pump, Rack server coolant circulation pump, Reliable pump for rack server cooling, Quiet pump for rack server cooling

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#dc water pump#bldcpump#liquidcoolingsystem#liquid cooling#servercoolingpump

0 notes

Text

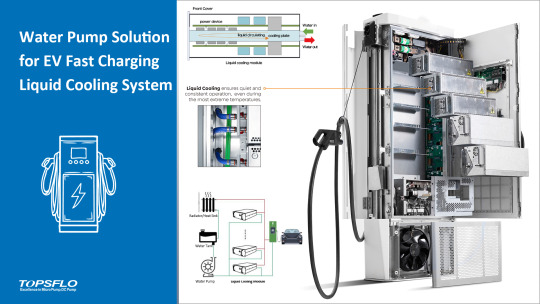

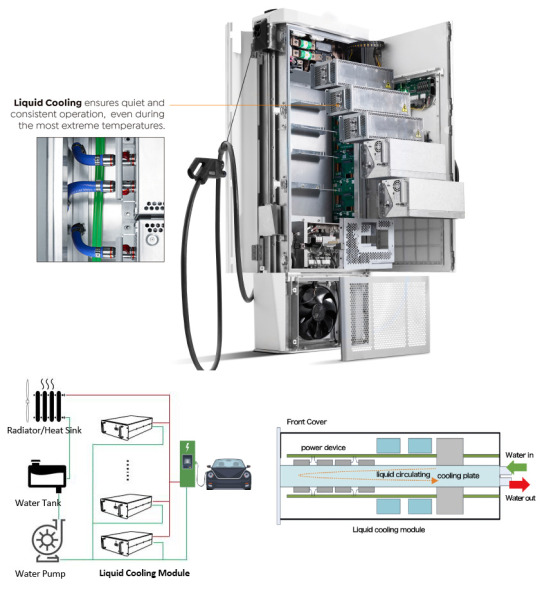

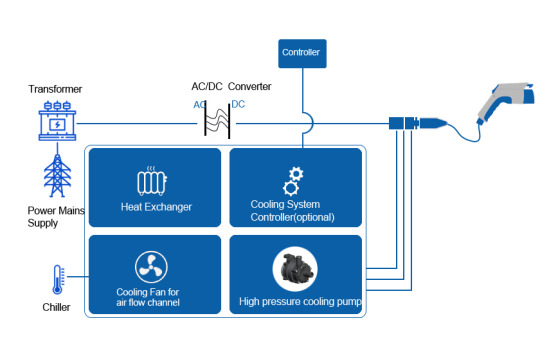

Water Pump Solution for EV Fast Charging Liquid Cooling System

Market Basics

"2021 China Electric Vehicle User Charging Behavior White Paper" released by the Charging Alliance shows that 99.3% of electric vehicle users prefer fast charging. And how can the charging pile realize faster charging? One is by increasing the output power (need to add module liquid cooling), the second is to increase the current (need to add gun line liquid cooling). At present, the liquid cooling system is the best solution for DC supercharging charging pile in the market, and the water pump, as an important part in the liquid cooling system, plays a key role in the cooling effect.

Market Pains

Charger Power Module Liquid Cooling

Superchargers generally consist of multiple DC:DC or AC:DC modules stacked on top of each other, and require a large flow rate to deliver coolant to each module for uniform heat dissipation;

EV Charging stations are equipped with intelligent management systems, which need to realize remote management, monitoring and data analysis, etc., and therefore cannot be subject to electromagnetic interference from other components.

Cable Liquid Cooling

Liquid-cooled charging cables are often thinned and lengthened to be more lightweight, thus adding a very large amount of drag to the liquid-cooled system;

The cable liquid cooling system generally uses glycol antifreeze or insulating oil as the medium. The viscosity of the liquid is different at different temperatures, especially the silicone oil, and the viscosity of the liquid will increase exponentially at low temperatures;

EV Fast Charging Water Pump Solution

Charger Power Module Cooling Solutions

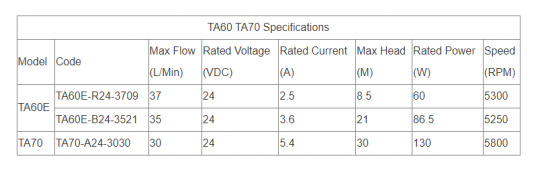

TOPSFLO water pump TA60/TA70 is designed to meet the needs of charging pile's multi-power module cooling, through the motor and fluid simulation, special design of high-efficiency motor and structural solutions, while minimizing power consumption, the maximum flow rate up to 60L/min, faster and better cooling so that there is no risk of overheating in the charging post module.

Charging pile liquid-cooled water pump is specially designed for low-temperature startup, and PWM intelligent speed regulation function. It can withstand low temperature -40℃, and adjust the motor speed according to the different viscosity of the liquid under different temperature conditions, which can solve the technical problem of not discharging liquid under low temperature due to excessive viscosity of the liquid.

TOPSFLO water pumps are designed with vehicle-grade electronic solutions, which can well meet the EMC specification requirements for charging piles. It will not cause interference to the electronic system of the charging pile, and at the same time, it can also resist electromagnetic interference from other equipment.

Cable Cooling Solutions

Cable Liquid cooling for coolant ( up to 400A )

Depending on the cable length and diameter, the resistance will vary and the cooling solution will be different. The smaller the cable diameter, the higher the resistance, and the longer the cable, the higher the resistance.

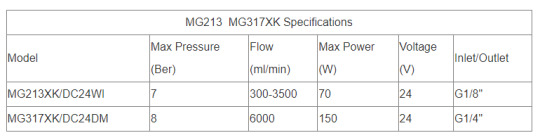

For low resistance, it is recommended to consider TOPSFLO centrifugal pump TA60E-B24-3521

For high resistance, it is recommended to consider TOPSFLO gear pump MG213

Cable Liquid cooling for dimethyl silicone oil (over 400A)

For high current cables of more than 400A, silicone oil is usually chosen as the cooling medium, which has relatively higher resistance. For this kind of high resistance cable cooling application, TOPSFLO newly developed a high pressure liquid cooling gear water pump - MG317, the maximum water pressure up to 10bar, can meet 500-600A cable cooling of charging connector.

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#carwaterpump#microgearpump#evcharger#fastcharging#liquidcoolingsystem#waterpump12vdc#waterpumpmanufacture#water pumps

0 notes

Text

What Are the Common Faults of 12V 24V DC Water Pump and How to Repair?

12V 24V DC water pumps are essential components in various applications, from automotive systems to water circulation in industrial equipment. However, like all mechanical devices, they can encounter issues that affect their performance over time. To avoid operational disruptions and potential economic losses, it's essential for operators to become adept at diagnosing and addressing common pump problems. Here's a comprehensive guide to understanding common problems and how to address them:

No Water Flow From the Outlet:

Causes: Insufficient water in the pump chamber, leaks in the suction pipe or pump head, low speed leading to excessive mechanical seal leakage.

Solutions: Fill the pump chamber with water, fix air leaks, inspect and repair pipe connections, increase voltage to raise speed, and replace the mechanical seal.

Low Water Flow From the Outlet:

Causes: Blockages in the impeller flow channel or suction pipe, severe impeller wear, insufficient power resulting in low speed.

Solutions: Remove obstructions, replace the impeller, and adjust the speed to the rated level.

Pump Overheating:

Causes: Blocked inlet or outlet, insufficient cooling, or motor issues.

Solutions: Clear any obstructions, improve cooling, or check and replace faulty components.

Excessive Noise and Vibration:

Cause: Unstable installation support or worn pump bearings, poor rotor dynamic balance, eccentric bearing.

Solutions: Adjust support feet, replace bearings, and correct alignment.

Liquid Leakage:

Causes: Loose nut connecting the pump head and body, damaged sealing ring leading to mechanical seal damage.

Solution: Tighten the nut and replace the mechanical seal.

Pump Fails to Start:

Causes: Overly tight packing or debris jamming the impeller and pump body, debris blocking the pump shaft or bearing, severely bent pump shaft.

Solutions: Disassemble the pump body to remove debris or rust, correct or replace the pump shaft.

Interruptions in Water Pumping:

Causes: Blocked inlet or pipeline, loose pump shaft, falling water level at the inlet, suction of the inlet hose.

Solutions: Clear blockages, clean the water diversion pipe, reinforce the impeller, adjust installation position of 12V 24V dc water pump or wait for the water level to rise.

Insufficient Water Flow After Startup:

Causes: Low power machine speed leading to slow pump rotation, inadequate pump head, partially blocked pipeline or impeller, or impeller damage, minor water outlet pipe leakage.

Solutions: Restore the rated speed, seal any leaks, remove blockages, replace the impeller, or address minor leaks.

Gradual Decrease in Water Flow:

Cause: Accumulation of debris in the filter screen or bell mouth, lowering of the inlet water level.

Solutions: Remove debris and increase the inlet depth.

Regular maintenance and prompt problem-solving will help ensure the longevity and efficiency of your 12V 24V DC water pump, allowing it to continue serving your needs effectively. By understanding these common faults and knowing how to diagnose and repair them, you can extend the lifespan of your pumps, reduce downtime, and ensure consistent functionality. Remember that safety precautions should always be observed when handling and maintaining water pumps.

youtube

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Official Web: http://www.topsflo.com/

Key Words: 24v dc water pump,24v water pump, 12v dc pump,dc pump, brushless dc pump, dc brushless pump, 12v brushless pump, brushless 12V pump, 12v water pump, small water pump, dc water pump, dc motor pump, bldc water pump, 24v brushless dc pump,mini water pump, 12v mini water pump, 12v dc water pump , micro dc pump, Solar DC Water Pump,Solar DC Pump,hot water dispenser pump,EV charger pump,smart toilet pump,water heater pump,car circulation pump,car water pump,car preheater pump, server electronics cooling pump, server cooling pump, rack server cooling pump,water cooling pump, liquid cooling pump

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#water pump#dc pump#liquidcooling#bldcwaterpump#24vbrushlessdcpump#microdcpumps#microdcwaterpump#Youtube

0 notes

Text

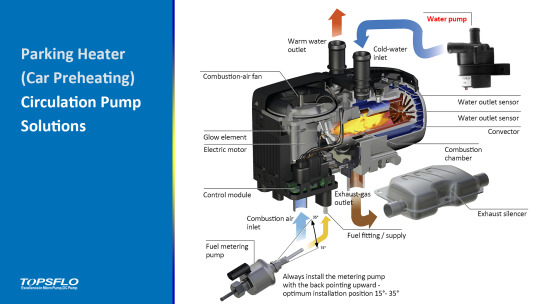

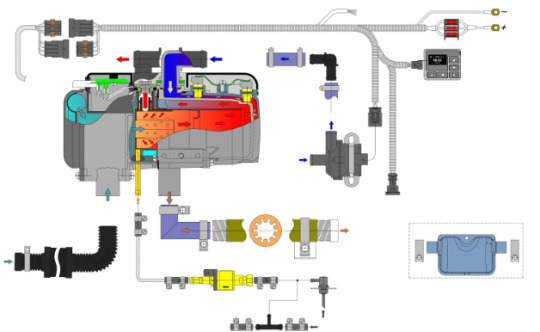

The Ultimate Circulation Pump Solution for Car Parking Heater

Market Overview

According to research, the wear and tear caused by a cold start of an engine in a low temperature environment, is equivalent to the damage caused by driving the vehicle normally for 200 kilometers. And nearly 60% of engine wear is caused by cold starts. Parking heaters have successfully solved this problem and gained increasing recognition from global drivers.

With the strengthening of environmental awareness, many countries and regions are adopting stricter emission standards and technical requirements. In order to meet these requirements, many car manufacturers and accessory suppliers are continuously developing more efficient parking heaters to reduce vehicle exhaust emissions and fuel consumption. The promotion of these technologies and products will further stimulate the growth of the parking heater market.

Lastly, as people's living standards continue to improve, many consumers are paying more attention to comfort and convenience. Parking heaters, as car accessories that can provide a comfortable driving environment and efficient heating, will see an increase in market demand.

Parking heaters are divided into two types: liquid parking heaters and air parking heaters.

Parking heaters can effectively improve passenger heating comfort. The electric heating components are in the front cabin of the vehicle, and the safety and reliability are higher, but the manufacturing technology of the components is more challenging. From a safety perspective, the water heating method with a brushless DC micro water pump is the mainstream for the future development of new energy vehicles.

Market Pain Points

In the early mornings of winter in Northern China, drivers feel like they have entered an ice-house as soon as they step into the cabin. In areas with heavy snow blocking the roads, drivers must keep the engine running continuously for heating. This is a common scenario encountered by many truck and bus drivers in northern China.

During the process of preheating the vehicle, how can the parking heater water pump heat up to the specified temperature within a given time, ensuring that the driver can enter a warm and comfortable cabin?

In extremely cold regions such as northeastern China, the United States, Canada, Northern Europe, and Russia, how to ensure that the heater starts smoothly, and the pump can maintain a large flow output at -45℃, without damaging the engine and generating fuel consumption?

Vehicles not only operate in flat areas but also in high-altitude regions with elevated terrains. How can the water pump ensure a continuous and stable circulation of the parking heater's coolant without causing the driver to wait for rescue, due to any abnormalities?

TOPSFLO Circulation Pump Solutions

As a core component of the parking heater, the importance of the automotive preheating circulation pump is self-evident. TOPSFLO strictly adheres to the highest standards of the automotive industry, IATF16949, and has developed and produced TA50E, TA50, TA60, and TA60E parking heater circulation water pumps, which have solved the long-standing problems in the industry and have the following obvious advantages:

From the perspective of product design and selection, TOPSFLO's parking heater water pump fully considers the extreme working conditions of automotive applications. It can withstand a wide temperature range of -45°C to 125°C and adopts a special electronic design scheme to achieve wide voltage operation, that is specific to automotive charging and discharging situations, ensuring that the electronic pump is not affected by the high peak voltage of the automotive power supply. Most importantly, it can work normally under extremely harsh environmental conditions, such as -45°C, and maintain a stable flow rate in extreme environments, enabling immediate vehicle startup. This ensures that the vehicle can be preheated to be warm, eliminates the extra fuel consumption and engine wear.

TOPSFLO's brushless DC water pump for preheaters is equipped with a built-in frequency-variable brushless DC motor. It does not require carbon brushes for commutation and does not generate heat through mechanical friction. It has low power consumption and minimal temperature rise. Moreover, the BLDC motor can accurately feedback target rotation speed and torque, and precise control can suppress motor heating and power consumption. On the condition of achieving more intelligent functions and higher efficiency, it can also reduce temperature rise, achieve long life with a reference lifespan of at least 20,000 hours. This allows drivers to enjoy worry-free long-distance driving, without the risk of being stranded halfway due to water pump quality issues.

The above-mentioned features of our car preheater circulation pump, such as resistance to high and low temperatures, wide voltage range, quick startup and stable flow at low temperatures, and long-life cycle, are mainly attributed to our professional and experienced electronic, motor, and structural engineering teams. The core electronic technology team has years of experience serving the automotive industry and has a deep understanding of the automotive operating environment and requirements. Therefore, in the early design, material selection, layout, and verification stages of the entire electronic solution, we can provide a more professional and comprehensive approach. Factors such as temperature partition, component space, and fluid resistance of the water pump at low temperatures are all important considerations to ensure that the water pump not only achieves maximum efficiency but also has low heat generation, low temperature rise, stable performance at low temperatures, and a long-life cycle.

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Linkedin: https://www.linkedin.com/in/topsflobrushlessdcwaterpump/

Official Web: http://www.topsflo.com/

youtube

youtube

Key words: car circulation pump, car preheater pump, webasto 24v water pump, Webasto heaters water pumps, Webasto Thermo Top C Water Pump, Car pre-heating pump, Car Heating system pump, Auxiliary heaters pump, parking heaters pump,Starting engine heater pump, Eberspächer Water Pump, Hydronic Water Pump 12V, Car water pump, DC water pump, 24v water pump, 12v water pump, 12v dc water pump, Brushless dc pump, DC pump

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#24vdcwaterpump#12vwaterpump#bldcpump#dc water pump#car preheating circulating pump#carwaterpump#carpreheatingpump#Youtube

0 notes

Text

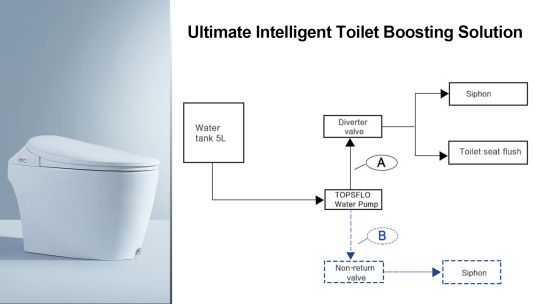

Elevate Your Luxury Smart Toilets: Introducing the Ultimate Intelligent Toilet Boosting Solution

Basic Market Conditions

With the improvement of people's living standards and spending power, and the popularization of the application of smart technology in home life, the application of smart toilets has gradually expanded to individual families. Moreover, in recent years, smart toilet manufacturers have gradually shifted their focus to individual home users in terms of technological breakthroughs and product demand design, making the application of smart toilets in individual homes more common.

Market Pain Points

In recent years, with the popularization of smart toilets, the industry problems of smart toilets have gradually become clear. In some high-floor building or low water pressure areas, the problem of "not enough flushing force and not clean" is easy to appear. It becomes a common problems that the industry needs to solve urgently.

Previously, external water tanks were generally used to solve this problem, but because the overall size was too large, it could not meet people's increasing pursuit of simplicity and intelligent home furnishing

How to achieve the best flushing effect in the shortest time by using the water pump and improve the customer experience is an urgent problem for smart toilet customers to stand out in the highly competitive industry.

The smart toilet which export to Europe and the United States, have very strict requirements for EMC, UL, WRAS, flame retardant and other certifications of key components of water pumps. Only in this way can we achieve global sales without worry.

Intelligent Toilet Boosting Solution

Unique fluid design, using open impeller to bring surging water volume. 20% more flow & 40% more water head, compared with other intelligent toilet boosting pump of same size in the industry, and the maximum flow rate can reach 60L/min.

The internal space of the toilet is limited. The compact structural design of the Topsflo intelligent toilet water pump, the overall size is within 10*7CM. What’s more, it has over 3 kinds of inlet and outlet options, which can better meet the installation requirements of the hidden toilet and make the overall size of the toilet more compact.

TOPSFLO Samrt Toilet Boosting Pump start-up time quickly in 0.1S, which is more than 5 times higher than that of products with the same parameters in the industry. The peak water volume is released instantly, which minimizes flow loss and achieves less water flushing and cleaner.

According to the special requirements of the industry, the TOPSFLO smart toilet pump has carried out a unique electronic design scheme passed EMC and UL , and the water-contacting parts are made of high-quality materials to meet the WRAS and flame-retardant requirements. Help toilet manufacturers to expand the global market.

At present, TOPSFLO has maintained long-term and stable cooperation with ROCA, LAUFEN, GEBERIT, NOVENTA, COMA and other world-renowned smart toilet companies.

youtube

#dcwaterpump#waterpump#brushlessdcpump#12vdcwaterpump#topsflopump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#smart toilet booster pump#boosterwaterpump#booster water pump#Youtube

0 notes

Text

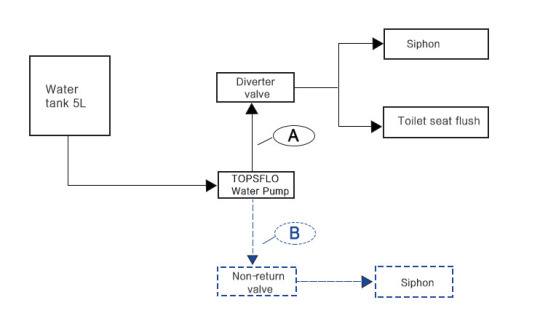

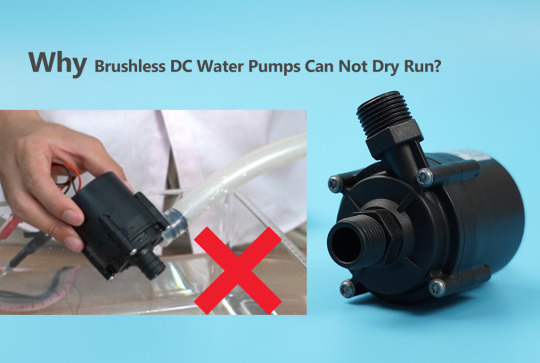

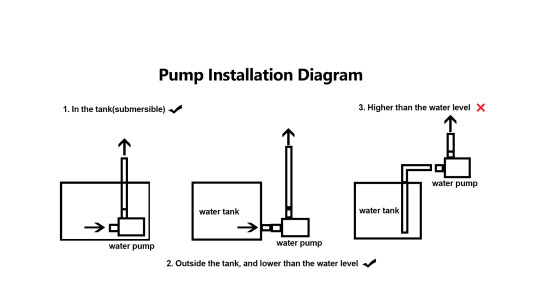

Pump Knowledge: Why Brushless DC Water Pumps Can Not Dry Run?

The dry-running of the brushless DC water pump means there is no water in the pump chamber, or there is an excessive amount of air in the pump chamber when the water pump is running. That is, the water pump runs without water or with poor water flow. When the water pump is working, the water plays an important role in lubrication and cooling, so dry-running is absolutely not allowed. Let's explore the reasons why the brushless DC water pump is strictly prohibited from dry-running, and the factors that may cause this phenomenon. At the same time, we will also discuss what measures can be taken to prevent the water pump from dry-running.

Why Brushless DC Water Pumps can Not Dry Run?

The brushless DC water pump may cause the following problems when dry-running:

Damage to water pump motor: the rotor of the water pump motor rotates at high speed when dry-running, but there is no water cooling, which will cause the motor to overheat, thereby damaging the motor insulation and bearings, and shortening the lifespan of the motor.

Pump stucked: the pump body will generate heat when dry-running. Without the liquid cooling, those narrow gaps are easy to be bitten through due to the long-term thermal expansion and contraction, resulting in the pump being stuck and unable to work normally.

Power consumption Increased: the motor will work without load when dry-running, and the power conversion efficiency will be low, which will cause energy waste and increase power consumption.

Affect the sealing performance of the water pump: dry-running may cause excessive frictional heat at the seal of the water pump, which will affect the sealing performance and cause leakage from the pump body.

Damage to other components: dry-running may lead to overpressure of the pipeline, and even damage to other components, which will have a chain reaction on the system.

Therefore, in order to protect the normal operation of the pump and prolong its service lifetime, it is strictly forbidden to have the brushless DC water pump from dry-running.

Possible Reasons for Dry-running

1. No water supply: Brushless DC water pumps are prone to dry-running when there is no water or insufficient water. For example, the inlet of the water pump is not connected to the water supply or the water supply is suddenly interrupted.

2. Blockage or leakage: If the inlet of the water pump is blocked or leakage occurred, the pump cannot absorb water normally, which may cause dry-running.

3. Failure of the control system: If the control system of the water pump fails, the operation status of the water pump cannot be monitored correctly, which may cause the water pump to continue to run without water and dry-running.

4. Power problem: Unstable power supply or power failure may cause the water pump to fail to operate normally, resulting in dry-running.

5. Improper installation: Improper installation of the water pump or improper connection of the pipes causes the water pump to fail to pump water normally.

How to Prevent the Water Pump from Dry-running?

The pump inlet must be connected to a pipeline with water source, and being lower than the water source to ensure that water can enter the pump smoothly.

Use a suitable pump controller, such as a pressure switch, flow switch or smart controller, to monitor the running status of the pump and avoid dry-running.

Choose a water pump with dry-running protection, so that when the water pump runs without water, it will automatically stop working to avoid damage.

Regularly maintain the water pump, check the running state of the motor, the sealing and the pipeline connection, to ensure that the water pump is running in the best condition.

Dry-running Protection of the Water Pump

When the brushless DC water pump lacks water during running, it may face the risk of burning out. However, the water pump equipped with dry-running protection can realize short-term dry-running when the internal environment is wet, and effectively avoiding the occurrence of burn-in.

All the brushless DC water pumps produced by TOPSFLO are equipped with dry-running protection (either standard or customized). The role of this function should not be underestimated. The electronic control system of the water pump can realize the intelligent monitoring of the current and speed, and accurately triggers the corresponding protection measures according to the set threshold. When the current and speed are lower than the predetermined threshold, the system immediately starts the dry-running protection, so as to ensure that the water pump is not damaged or malfunctioned.

The dry-running protection can monitor the running status of the water pump in real time, accurately identify possible abnormal situations, and respond quickly. Once the system finds that the pump current or speed deviates from the predetermined range, it will immediately take corresponding measures to reduce the pump speed, stop the pump operation or issue an alarm to avoid damage or accidents caused by dry-running.

The excellence of the dry-running protection of TOPSFLO pumps lies not only in the excellent innovation in technology, but also in focusing on providing users with efficient and reliable solutions to ensure the continuous and stable operation of the pump system. Bringing an excellent experience to users in terms of industrial processes and domestic water supply. If you would like to know about the dry-running protection of a specific model of TOPSFLO water pump, please feel free to contact us.

youtube

Key words: 24v dc water pump,24v water pump, 12v dc pump,dc pump, brushless dc pump, dc brushless pump, 12v brushless pump, brushless 12V pump, 12v water pump, small water pump, dc water pump, dc motor pump, bldc water pump, 24v brushless dc pump,mini water pump, 12v mini water pump, 12v dc water pump , micro dc pump, Solar DC Water Pump,Solar DC Pump,hot water dispenser pump,EV charger pump,smart toilet pump,water heater pump,car circulation pump,car water pump,car preheater pump, Server liquid cooling pump

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#solarwaterpump#bldcpump#dc water pump#diaphragm pump#miniaturediaphragmpump#servercoolingpump#12vdcwaterpump#12vwaterpump#12vminipump#24vdcwaterpump#24vwaterpump#24vdcpump#Youtube

0 notes

Photo

What is a brushless DC water pump?

The brushless DC water pump uses the principle of permanent magnet brushless DC motor. The impeller is added to the rotor, and the casing structure is designed to make the liquid perform centrifugal motion. Because there is no carbon brush friction, there is no spark; High efficiency, low power consumption, longer life than brushed motors, and low noise. Scope of application of brushless DC water pump

1. Water supply function such as: coffee machine, tea set, water heater/kettle, water dispenser/beverage machine, foot bath, irrigation system/equipment, etc.

2. Oil supply function / high efficiency and energy saving such as: various machine tools, refueling equipment, etc.

3. Heat dissipation / water circulation system such as

4. Drainage function such as: mobile air conditioner.

5. Washing function such as: washing glass system/equipment for various automobiles.

For more professional answers, please contact TOPSFLO.

Product service: TOPSFLO, one of the well-known water heater booster/circulating water pump solution providers in China, 80% of which are exported to high-end markets in Europe and America. Focus on the development and manufacture of miniature brushless water pumps. It has multiple system certifications such as the authoritative organization German IATF16949, and the products have passed CE, WRAS, UL and other certifications. Thanks!

0 notes

Link

12v 24v dc water pump manufacturing - Visit TOPSFLO factory

Welcome to Tops Industry and Technology Co.,Limited. (TOPSFLO Micro DC Pump), a national high-tech enterprise specializing in micro brushless DC pumps for 17 years.

Contact us:

📱Skype:topsflo

✉Email:[email protected]

🔗http://www.topsflo.com/

0 notes