Text

Fixed Roof Ladders: Assuring Safe Access to Commercial and Industrial Roofs

Roof access is a critical aspect of many commercial and industrial buildings, facilitating routine maintenance, inspections, and repair works. To ensure the safety of workers and ease of access, fixed roof ladders have become a popular choice. These specially designed ladders offer a stable and permanent solution for reaching rooftops. In this article, we will explore the pros and cons of fixed roof ladders, their main benefits, and one significant drawback. Additionally, we will delve into the considerations for choosing the right ladder material, comparing aluminum and steel options.

Pros and Cons of Fixed Roof Ladders

Before delving into the advantages and disadvantages of fixed roof ladders, it is important to understand what they are. Fixed roof ladders are permanently installed vertical ladders, securely attached to the roof’s edge or parapet, providing a safe and sturdy means of access.

Pros:

Safety: Fixed roof ladders offer unparalleled safety as they are securely fastened to the building’s structure, eliminating any wobbling or instability that might be present in portable ladders.

Durability: Being fixed in place, these ladders are designed to withstand the elements and harsh weather conditions, ensuring they have a longer service life compared to portable ladders.

Convenience: Since they are permanently affixed to the roof, there’s no need for additional setup or takedown, making them readily available for use whenever required.

Compliance: Fixed roof ladders can be designed to meet relevant safety standards and building codes, ensuring regulatory compliance.

Cons:

Permanent Installation: Once fixed, these ladders cannot be easily moved or repositioned. Thus, if roof access requirements change, it might necessitate additional installations.

Aesthetics: Some argue that fixed roof ladders can affect the building’s aesthetics, especially if not integrated seamlessly into the architecture.

Main Benefits of Fixed Roof Ladders: Safety and Roof Accessibility

Safety: Safety is paramount when it comes to accessing rooftops, and fixed roof ladders offer unparalleled stability. Workers can ascend and descend with confidence, minimizing the risk of accidents and falls. Additionally, many fixed roof ladders come equipped with safety features such as anti-slip rungs and guardrails, further enhancing worker safety.

Roof Accessibility: Fixed roof ladders provide consistent and reliable access to the rooftop, streamlining maintenance tasks, equipment installations, and emergency procedures. Having a designated access point ensures that workers know exactly where to go and minimizes the chances of unauthorized access (though it’s still crucial to have a plan in place to prevent unauthorized entry).

Main Drawback of Fixed Roof Ladders: Unauthorized Access

One significant drawback of fixed roof ladders is the potential for unauthorized access. While these ladders are designed to provide access for authorized personnel, they can also attract the attention of trespassers or vandals. To mitigate this risk, property owners should implement additional security measures such as access control systems, fencing, or surveillance cameras. Regular monitoring and maintenance of the ladder’s integrity are also essential to detect any signs of tampering or damage promptly.

Choosing the Right Material for Your Fixed Ladders: Aluminum or Steel

When selecting the material for fixed roof ladders, two common options are aluminum and steel. Each material offers distinct advantages and caters to different requirements.

Aluminum Ladders:

– Lightweight: Aluminum ladders are considerably lighter than steel, making them easier to install and handle.

– Corrosion-resistant: Aluminum naturally forms a protective oxide layer, offering excellent resistance to corrosion.

– Low maintenance: Due to its corrosion resistance, aluminum requires minimal upkeep.

Steel Ladders:

– Strength: Steel ladders are incredibly robust and can handle heavier loads compared to aluminum ladders.

– Durability: Steel ladders are less susceptible to wear and tear, ensuring longevity even under heavy usage.

– Cost-effective: Steel ladders are often more affordable than their aluminum counterparts.

The choice between aluminum and steel will depend on factors such as the specific application, budget, and environmental conditions. Consulting with professionals and understanding the unique requirements of your building will help make an informed decision.

In conclusion, fixed roof access ladders play a crucial role in ensuring safe and convenient access to commercial and industrial rooftops. Their numerous benefits, such as enhanced safety and accessibility, outweigh the drawbacks, such as potential unauthorized access. Additionally, by choosing the appropriate ladder material, property owners can further optimize the performance and longevity of their fixed roof ladders, providing a reliable means of reaching rooftops for years to come.

Source:https://www.omnisteelsupply.com/blog-post/fixed-roof-ladders-assuring-safe-access-to-commercial-and-industrial-roofs/

0 notes

Text

What is Duplex Steel?

Duplex steel is a type of stainless steel that exhibits a unique combination of properties, making it highly desirable in various industries. It is known for its excellent strength, corrosion resistance, and superior toughness. Duplex steel is characterized by its two-phase microstructure, consisting of roughly equal proportions of ferrite and austenite. This dual-phase structure gives it the name "duplex," highlighting its distinct composition.

How is Duplex Steel Made?

Duplex steel is produced through careful alloying and heat treatment processes. The key elements used in its composition are chromium, nickel, molybdenum, and nitrogen. These elements contribute to the enhanced properties of duplex steel. Chromium provides corrosion resistance, while nickel and molybdenum improve its strength and toughness. The addition of nitrogen helps to stabilize the austenite phase and further enhances corrosion resistance.

The manufacturing process begins with melting together the appropriate amounts of these elements along with iron. The molten mixture is then rapidly cooled to form a solid metal known as an ingot. The ingot is subsequently reheated and hot-rolled into various forms, such as sheets, plates, bars, and tubes. Cold working and annealing processes may be employed to achieve specific mechanical properties and desired shapes.

What is Duplex Steel Used For?

Duplex steel finds wide-ranging applications in industries where a combination of high strength and excellent corrosion resistance is required. Its unique properties make it an ideal choice for various challenging environments. Some common uses of duplex steel include:

1. Oil and Gas Industry: Duplex steel is extensively used in offshore oil platforms, subsea pipelines, and equipment exposed to harsh environments. Its resistance to corrosion, high strength, and good weldability make it a preferred material for these applications.

2. Chemical Processing: Duplex steel is employed in the manufacturing of chemical reactors, heat exchangers, and storage tanks that handle corrosive chemicals. Its resistance to pitting and crevice corrosion, coupled with its high strength, ensures long-term performance and reliability.

3. Desalination Plants: Duplex steel is well-suited for desalination plants where seawater is converted into freshwater. The high chloride content in seawater demands materials with exceptional corrosion resistance, and duplex steel fits the bill perfectly.

4. Pulp and Paper Industry: Duplex steel is utilized in pulp and paper mills due to its resistance to corrosion from various chemicals used in the production process. It finds applications in digesters, bleaching equipment, and pipelines.

5. Structural Components: Duplex steel is increasingly being used in the construction industry for structural components such as bridges, building frames, and offshore structures. Its high strength-to-weight ratio allows for lighter structures without compromising on durability.

In conclusion, duplex steel is a type of stainless steel that exhibits a dual-phase microstructure, combining the strength and corrosion resistance of ferrite and austenite. It is produced through careful alloying and heat treatment processes, utilizing key elements such as chromium, nickel, molybdenum, and nitrogen. Duplex steel finds applications in various industries, including oil and gas, chemical processing, desalination, pulp and paper, and construction. Its exceptional properties make it a sought-after material for challenging environments, ensuring long-lasting performance and reliability. When in need of duplex steel, it is crucial to rely on a reputable steel supplier with expertise in stainless steels to ensure the quality and reliability of the material.

0 notes

Text

What is Flash Welding?

Introduction:

Flash welding is a specialized welding technique that joins two metal components together using a rapid and intense burst of heat generated by an electrical discharge. This high-energy process creates a strong and reliable weld, making flash welding a preferred choice in industries where speed, efficiency, and durability are paramount. In this article, we will delve into the inner workings of flash welding, explore its advantages, and discuss its limitations.

How Does Flash Welding Work?

Flash welding involves the following key steps:

1. Preparation: The metal components to be welded are meticulously cleaned and aligned in a precise manner to ensure proper contact during the welding process.

2. Contact: The two metal components are brought into contact under high pressure. This pressure is crucial to establish electrical conductivity between the two parts.

3. Electrical Discharge: Once the components are in contact, a high electrical current is passed through them, resulting in an intense burst of heat. The electrical discharge occurs for a very short duration, typically in milliseconds.

4. Flash Formation: The high heat generated by the electrical discharge causes the metal surfaces to rapidly heat up and melt. The molten metal forms a "flash" that acts as a temporary filler material between the two components.

5. Upset: After the flash forms, the pressure is maintained, and an additional force is applied to bring the two components closer together. This action results in the expulsion of excess flash material and the formation of a solid, strong weld joint.

What are the Advantages of Flash Welding?

Flash welding offers several advantages, making it a popular choice in various industrial applications:

1. Speed and Efficiency: Flash welding is an incredibly fast process. The rapid heating and welding cycle times enable high production rates, reducing overall manufacturing time and costs.

2. Strong and Durable Welds: Flash welding produces high-quality welds with excellent strength and integrity. The joint formed is often as strong, if not stronger, than the base metals being welded.

3. No Filler Material Required: Flash welding does not require additional filler materials, as the molten flash material acts as a temporary filler during the welding process. This eliminates the need for extra consumables and simplifies the welding operation.

4. Versatility: Flash welding can be used to join a wide range of metals and alloys, including steel, stainless steel, aluminum, and copper. This versatility makes it suitable for diverse applications across multiple industries.

5. Minimal Heat-Affected Zone: Flash welding's high-speed nature minimizes the heat transfer to the surrounding areas, resulting in a smaller heat-affected zone. This helps preserve the material's properties and reduces the likelihood of distortion or weakening of the base metals.

What are the Limitations of Flash Welding?

While flash welding offers numerous advantages, it also has some limitations that should be considered:

1. Limited Joint Configurations: Flash welding is most effective for joining flat or cylindrical components with large contact areas. Welding complex or irregular shapes can be challenging with this method.

2. Precision Alignment: Proper alignment of the components is critical in flash welding. Any misalignment can result in an imperfect weld or insufficient electrical conductivity, leading to joint failure.

3. Equipment and Energy Requirements: Flash welding requires specialized equipment capable of delivering high electrical currents and managing the rapid heat generated. This can involve significant initial investment and energy consumption.

4. Size Constraints: Flash welding is more suitable for smaller to medium-sized components. Welding large or bulky parts may require additional equipment or alternative welding methods.

Conclusion:

Flash welding is a high-speed welding process that delivers strong and durable weld joints. With its exceptional speed, efficiency, and reliable results, flash welding has become a favored choice in industries where rapid production and robust welds are essential. Understanding its working principles, advantages, and limitations enables

0 notes

Text

Laser Cutting Metals: Things to Know

Introduction:

In the realm of metal fabrication, laser cutting has emerged as a popular and highly efficient method for precision cutting. This advanced technique utilizes a concentrated beam of light to effortlessly slice through various types of metals, offering numerous advantages over traditional cutting methods. If you're curious about laser cutting and its application in metalworking, read on to discover the essentials of this cutting-edge technology.

What is Laser Cutting?

Laser cutting is a non-contact process that employs a high-powered laser beam to melt, burn, or vaporize material, resulting in precise and accurate cuts. The laser beam is generated by amplifying light through stimulated emission of radiation (LASER). This intense beam is directed through a series of mirrors and focused onto the workpiece, creating a narrow, concentrated heat-affected zone. The focused laser energy rapidly heats the metal, causing it to melt or vaporize, enabling precise cutting along the predetermined path.

What Metals Can Be Laser Cut?

Laser cutting is versatile and can be used on a wide range of metals, including but not limited to:

1. Stainless Steel: Laser cutting is highly effective for stainless steel due to its excellent reflectivity properties and high melting point.

2. Aluminum: The reflective properties of aluminum require specific laser parameters for optimal cutting results.

3. Carbon Steel: Laser cutting offers fast and accurate cutting of carbon steel sheets, making it a popular choice in various industries.

4. Copper and Brass: Copper and brass can be laser cut, but they require higher laser power due to their high thermal conductivity.

5. Titanium: Laser cutting is an effective method for intricate cutting of titanium alloys due to their strength and high melting point.

Advantages of Laser Cutting:

Laser cutting provides several advantages over traditional cutting methods, making it a preferred choice for many industries:

1. Precision and Accuracy: Laser cutting offers exceptional precision, allowing for intricate designs and complex shapes with tight tolerances.

2. Speed and Efficiency: Laser cutting is faster than many conventional cutting methods, enabling high productivity and reduced lead times.

3. Versatility: Laser cutting is capable of cutting a wide range of metals with varying thicknesses, providing flexibility for diverse applications.

4. Minimal Material Distortion: The concentrated heat-affected zone in laser cutting minimizes distortion, resulting in cleaner and more accurate cuts.

5. No Tooling Costs: Unlike traditional cutting methods, laser cutting eliminates the need for complex tooling, reducing production costs.

Disadvantages of Laser Cutting:

While laser cutting offers numerous advantages, it's important to consider some limitations as well:

1. High Initial Investment: Setting up a laser cutting system can require a significant investment in equipment and training.

2. Limited Material Thickness: Laser cutting may be less efficient for extremely thick metals, as the laser energy becomes less effective beyond certain thicknesses.

3. Heat-Affected Zone: Laser cutting produces a heat-affected zone, which can affect the material's properties, especially in heat-sensitive metals.

4. Safety Considerations: Laser cutting involves high-power lasers, requiring adherence to strict safety protocols and precautions.

Types of Laser Cutting:

There are several types of laser cutting methods commonly used in the industry:

1. CO2 Laser Cutting: CO2 lasers are versatile and widely used for cutting non-ferrous metals and some plastics.

2. Fiber Laser Cutting: Fiber lasers are highly efficient at cutting reflective metals like stainless steel and aluminum.

3. Nd:YAG Laser Cutting: Nd:YAG lasers are ideal for precision cutting of thin metals and are commonly used in jewelry making and electronics industries.

What is the Best Laser for Cutting Metal?

The choice of the best laser for metal cutting depends on various factors, including the type of metal, thickness, desired cutting speed, and budget. Fiber lasers have gained popularity.

Source:https://www.omnisteelsupply.com/laser-cutting-metals-things-to-know-2/

1 note

·

View note

Text

5 Ways to Optimize Metal Fabricating Operation

There’s always a discussion on what can a metal fabricator achieve for a cliente and how the industry is growing at a rapid pace. From small nail to complete kitchen to bridges to monuments, metal has made its presence felt everywhere. The industry is so deep and full of opportunities, to explore and build a good reputation as a metal fabricator, metal manufacturers should be open to the idea of experiment, stay disciplined, upgrade and stay aware. Let us see what are the 5 basic steps that a metal fabricator can do to expand its business and build a huge client base

.

Well-coordinated work flow: It is the responsibility of the management to understand the work flow from processes adopted to technology used to people involved in work to latest equipment to a client’s expectation. These might sound much expected requirement but many metal manufacturers do not adhere to even these and end up in delivering poor quality products.

Identify errors & rectify: It is a competitive industry and demand for metal work is growing everyday. Thus, it is best to identify errors in the operation and execution of work and rectify it at the earliest to serve your client in the most effective way.

API Integrated system to get organized: We are moving towards digital economy and business model. The most effective way to organize your business is through API (Application Program Interface), this would make it easy and simple to develop a seamless coordination from marketing to finance to operation to management. This ensures all are working on the same platform and makes it easy to clear picture of project delivery to a client.

Upgrade & maintain tools: Most prominent feature of metal industry is to keep up with the latest tools and learn new techniques. This not only reduces cost, improves work quality and increases customer satisfaction. Maintenance and servicing are two paramount features of any industry. If there are frequent breaks, then it has a negative effect on the business. To prevent downtime, make a timeline for servicing of the machinery, it also avoids accidents.

Maintain transparency: It is also important to maintain a transparency between the client and the operations to keep them informed. This builds trust between the client and metal manufacturers. When a customer knows the status of the project, they feel comfortable and rely on the service provider which eventually build a good long lasting relationship.

Omni Steel Supply is professional metal manufacturers and suppliers in NY and the neighboring areas. With their years of experience in the industry, they feel it is important to be passionate about your work and listen to your client. This helps in exploring new ideas and get satisfied customers. Moreover it brings a sense of fulfilment and achievement when you have a happy customer.

The company has grown and developed with time and shifted ways of working post pandemic for better delivery of work.

Source: https://www.omnisteelsupply.com/blog-post/5-ways-to-optimize-metal-fabricating-operation/

0 notes

Text

5 Fascinating Custom Metal Fence Ideas

A fence is a great addition to any property. It provides privacy and security, defines property boundaries, and can add aesthetic appeal to your home or business. Custom metal fences, in particular, offer unique design options that can transform your property. Here are five fascinating custom metal fence ideas to consider:

Decorative Wrought Iron

Decorative wrought iron fences are a classic choice that has been used for centuries. Wrought iron can be twisted, curved, and shaped into intricate designs, giving your property a timeless look. These fences are durable and can withstand harsh weather conditions, making them perfect for outdoor spaces. They can be painted to match any color scheme, and the open design allows for visibility while still providing a barrier.

Overgrown Trellises

Overgrown trellises are a unique way to add a touch of nature to your fence. By allowing climbing plants such as ivy or grapevines to grow over your metal fence, you can create a natural, rustic look. This type of fence is perfect for creating a green privacy barrier while still providing an open-air feel.

Sheet Metal and Post

Sheet metal and post fences are a great option for those looking for an industrial, modern look. This type of fence uses large sheets of metal attached to sturdy posts to create a sleek, minimalistic design. The metal sheets can be painted any color and can be customized with cutouts or designs to make the fence unique.

Grate Style Panel Fencing

Grate style panel fencing is an excellent choice for those looking for a modern, industrial feel. These fences are made up of narrow metal slats or grates that are set apart from one another, allowing for airflow and light to pass through. This type of fence can be used for both residential and commercial properties, and can be customized with different colors and slat sizes.

Post and Cable

Post and cable fences are a unique, modern take on the traditional metal fence. This type of fence uses metal posts and cables to create a barrier, providing a minimalist look. The cables can be tensioned, giving the fence a unique, linear design. This fence is perfect for those who want a contemporary look without sacrificing durability and strength.

In conclusion, custom metal fences are a great way to add style and personality to your property. With so many design options to choose from, you’re sure to find a fence that fits your style and needs. Whether you prefer a classic wrought iron design or a modern, industrial look, a custom metal fence can add value and curb appeal to your home or business.

Custom Metal Fabrication

With our expertise as metal gate manufacturers, we assure delivery of excellent custom metal gate fabrication. Our experts design gates that suit your style, pocket and has an artistic touch. You can reach us both for residential or commercial gate solutions, by filling up the contact form given below and our expert will get in touch with you with a customised solution. We provide all types of custom fencing services including ornamental, designer or customised services. We give full fencing service from fabrication to repair. Reach us for free quote.

Source: https://www.omnisteelsupply.com/blog-post/5-fascinating-custom-metal-fence-ideas/

0 notes

Text

What Type of Welding Is Used for Aluminum?

Aluminum is a popular material for many applications due to its lightweight and durable properties. However, welding aluminum can be difficult due to its high thermal conductivity and low melting point. In this article, we will explore the different types of welding used for aluminum and their advantages and disadvantages.

Why Is Welding Aluminum Difficult?

Welding aluminum can be challenging due to several factors. Firstly, aluminum has a high thermal conductivity, which means that it can absorb heat quickly and conduct it away from the welding area. This can lead to problems such as warping, distortion, and cracking during the welding process. Secondly, aluminum has a low melting point, which means that it can be difficult to achieve a stable weld pool without overheating the material. Lastly, aluminum has a tendency to oxidize, which can create a weak joint if not properly cleaned and prepared before welding.

GTAW/TIG Aluminum Welding

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding, is a popular method for welding aluminum. This process uses a tungsten electrode to create an arc, which melts the aluminum and creates a weld pool. The weld pool is protected from oxidation by a shielding gas such as argon. GTAW/TIG welding offers high precision and control, making it suitable for thin and delicate aluminum materials.

GMAW/MIG Aluminum Welding

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is another popular method for welding aluminum. This process uses a wire feed to deliver a continuous stream of filler metal into the weld pool. The wire is melted by an electric arc, which creates a weld pool that is protected from oxidation by a shielding gas. GMAW/MIG welding is faster than GTAW/TIG welding, making it suitable for thicker and larger aluminum materials.

Laser Beam Welding and Electron Beam Welding- Aluminum Welding

Laser Beam Welding (LBW) and Electron Beam Welding (EBW) are two advanced methods of welding aluminum. LBW uses a high-powered laser beam to melt the aluminum, while EBW uses a beam of high-velocity electrons. Both methods offer high precision and control, making them suitable for complex aluminum structures. However, they are more expensive and require specialized equipment and training.

Resistance Welding - Aluminum Welding

Resistance welding is a method of welding aluminum that uses electrical resistance to create heat. This process involves pressing two aluminum parts together and passing an electric current through them, which generates heat and creates a weld. Resistance welding is a fast and efficient method of welding aluminum, but it is limited to certain types of joints and materials.

In conclusion, welding aluminum requires specialized techniques and equipment due to its unique properties. GTAW/TIG and GMAW/MIG welding are popular methods for welding aluminum due to their versatility and efficiency. Advanced methods such as LBW and EBW offer high precision and control, but require specialized equipment and training. Resistance welding is a fast and efficient method, but is limited to certain types of joints and materials. By choosing the right method for your project, you can ensure a strong and reliable weld for your aluminum structure.

0 notes

Text

Steel for Residential Purposes

The home is an extension of you; it reflects your personality beyond the emotions attached to each cornice and pillar of the house. It echoes your stories from the foundation of the house to date; memories live here. When there is so much attachment to the house, then it is obvious that you would think a lot before giving it a shape. To help you with your ideas, today we have compiled a couple of things that can be done with steel metal sheets to enrich the aesthetic beauty of the place of your dreams.

Steel is a strong metal, rust free, durable and weather resistant. It can withstand the roughness of all types of climate conditions and still stay tall and robust. For all your concerns related to security, longevity, beauty, maintenance, and design, it is probably an answer. It can be molded, bent, shaped, modified, and reused. In addition to all this, environmentalists also regard metal as a sustainable material and a good substitute for good old wooden structures.

Some rare beauties made out of steel for your beautiful home:

1. Steel Gates: For ages, steel or iron gates have been common features. Many historical monuments have gates with intricate designs and are standing strong to this date, with little care to avoid wear and tear. You can either go for double door gates or single gates with modular designs or archaic. Metal powers your visualization as they can easily get the desired look and also provide security from theft and unhinged entry to your premises.

2. Metal Fences: Steel, aluminum, or any other metal of your choice can be used for fencing your property. You can check out designs and ask your local metal manufacturer to give you the same look, or else you can also discuss ideas and get it manufactured.

3. Stairs: The elegance of interiors can be enhanced with a diamond steel plate staircase. They are not only skid proof and safe, but they look elegant. They are mostly used in places where there is a chance of falling or risk for the elderly in the family. You would often find it for ramp walking or for stairs. You can consider diamond steel plates for the ramp in your garden, as it would be free of undue risks. Fire escape stairs are mostly built of them.

4. Shelves and corners: Aluminum or steel sheets can be put to use for making a corner shelf for books or for the garden, where you can store your gardening tools and hose pipes. They truly look nice when colored in bright red or any of your favorites.

5. Chairs: Whether you are looking for heavy fixed metal chairs or light weight for your gardens, both are doable and can be installed by your metal manufacturer in NY, Jamaica area.

Source: https://www.omnisteelsupply.com/blog-post/steel-for-residential-purposes/

0 notes

Text

What is Spot Welding/Resistance Welding?

Spot welding, also known as resistance welding, is a process of joining two or more metal sheets by passing a high electric current through them at a specific point of contact. The heat generated from this current melt the metal at the point of contact, which fuses the two metal sheets together. This process is widely used in the automotive, aerospace, and manufacturing industries for its efficiency, speed, and reliability.

Types of Resistance Welding

Resistance welding encompasses several types of welding techniques, such as spot welding, seam welding, projection welding, and flash welding. Each technique has its unique advantages and applications, but spot welding is the most common technique used in industrial applications.

Seam welding, also known as continuous welding, is used for welding long sheets or plates continuously. Projection welding is used for welding sheet metal parts that have raised or embossed features. Flash welding is used for welding large and complex structures such as aerospace components.

How Does Spot Welding Work?

Spot welding is a simple process that requires a power source, electrodes, and a workpiece. The electrodes clamp the metal sheets together and apply pressure to create a good contact between them. When the electric current passes through the electrodes, it generates heat at the point of contact, which melts the metal and fuses the sheets together. The amount of heat generated depends on the electrical resistance of the metal sheets, the size of the electrodes, and the amount of pressure applied.

Advantages of Spot Welding

Spot welding has several advantages over other welding techniques, such as:

Speed and Efficiency: Spot welding is a fast process that can join two metal sheets in a matter of seconds. It is an efficient process that can join multiple sheets simultaneously.

Cost-effective: Spot welding requires minimal equipment and can be done on a small scale, making it a cost-effective option for small businesses.

High Quality: Spot welding produces a strong and consistent weld, which is essential for applications that require high precision and accuracy.

Environmentally friendly: Spot welding produces minimal waste, making it an environmentally friendly option compared to other welding techniques.

Limitations of Resistance Spot Welding

While spot welding has several advantages, it also has some limitations, such as:

Limited Thickness: Spot welding is limited to metal sheets with a thickness of up to 3 mm. For thicker sheets, other welding techniques such as arc welding may be required.

Material Compatibility: Spot welding works best with materials that have similar electrical conductivity. Dissimilar materials may require additional preparation or a different welding technique.

Surface Preparation: Spot welding requires clean and flat surfaces for optimal performance. Any contamination or uneven surfaces can affect the quality of the weld.

In conclusion, spot welding is a widely used and efficient welding technique that is essential in the manufacturing industry. It offers several advantages, such as speed, efficiency, cost-effectiveness, high-quality results, and environmental friendliness. However, it also has some limitations that should be considered before using it for specific applications.

We provide Custom welding solutions for Domestic and commercial needs. Contact us today!

Source: https://www.omnisteelsupply.com/blog-post/what-is-spot-welding-resistance-welding/

0 notes

Text

Different uses of Steel Coils

Steel Coils considered to be versatile and strong metal are used for building walls, ships, roof panels and several other construction and engineering works. It is essentially finished steel sheet that has been coiled or wound several types along the width of the metal sheet that adds to its features. It is a known truth steel coils with coatings become moisture and weather resistant and is one of the most eco-friendly materials for construction purposes. Steel coils are available in different grades and each has its own importance in the world of metal manufacturing works. Over here, we would not get i12a discussion on steel coil grades but try to touch uses of steel coils, as steel slabs when rolled into coils get ductile, has high strength, is of high grade and ductile. Coiling of steel makes it a friendly option for those who want to customize the metal for their specific needs.

Automotive Industry: Steel in general has an innumerable usage in the automotive industry, from body parts to machinery, all require steel in different ways. So, you may find it in chassis, wheels, suspension, car doors anywhere that you can think. It is an ideal choice for vehicle’s combustion engine as it is non-combustible, has high resistance to heat, durable and top it has high strength-to-weight ratio. The best feature of steel coil is it can be recycled and reused without the fear of losing its basic quality, it can be coiled again and again for making new products out of it for automotive parts.

Electronic parts: Steel coils as mentioned earlier has high melting points which makes it a suitable material for cases of mobile phones, circuit boards, CPUs others. It is the most favorite part in the manufacturing of electronic equipment and parts as the melting point is very high owing to which electronic gadgets have better life span, require negligible maintenance and are not very expensive.

Structural Steel: With steel coils, fabrication works get really simple and easy, we can get any structural designs which is strong and can withstand force. Coils can be wound into I-beams, angle bars, H-beams or others as per demand and need for structural purposes. Demand for structural steel is comparatively higher than any other manufacturing materials as it is not too much a task to customize steel coils to any shape, size and design. They are known to be used for providing framework support for enclosures or walls, structural steel can be seen in almost all the buildings. The beams rolled out from the coils are used in the ceilings that provide enough strength to control winds and keep the structure solid and safe.

Omni Steel Supply is a renowned professional manufacturer and supplier of steel and metals. They even deal in steel coils and have been fabricating the coils for carving out various interesting designs for commercial and residential uses. If you wish to know more about metal and steel coils, do not forget to reach to us by filling the form given below.

Source: https://www.omnisteelsupply.com/blog-post/different-uses-of-steel-coils/

0 notes

Text

Few Incredible Reasons for using steel in Skyscrapers

When we compare the construction works of yesteryears and today, relatively, the usage of steel as construction material has increased many folds. An interesting fact about skyscrapers is they were first made out of steel and even today, it is preferred over other construction materials. The alloy of carbon and iron is presumably a very strong material for residential, commercial or for building tall towers. And, for construction structural steel is mostly used. Let us delve further and figure out a couple of incredible reasons for using steel in skyscrapers.

Can withstand earthquakes and other weather extremities: Steel has commendable tensile strength, which provides enough support to tall structures during extreme weather conditions. They do not crumble when there is an earthquake or high-speed wind.

High resilience, steel is known for high strength and durability, as a building material, it is strong and can stay the same way for a very long duration of time. It can carry heavy structures which has direct relation to the size and the thickness of the beam, the part which eventually carries the load.

Provides design flexibility for buildings, the greatest feature of steel is, it can be bent, cut and designed. It is considered a very suitable material for intricate architectural designs, which makes it a valuable component for constructing tall buildings, skyscrapers, monumental pieces, shopping arcades and for residential purposes.

Steel is a durable material; it can stay strong and in the same way for a very long time. It is known to be a testimony of time and narrate stories to generation, unless brought down. Thus, it is brought in use for constructing skyscrapers.

Technological advancement is also one of the many contributors in the popularity of steel as base material for erecting frames for tall structures.

Steel is a versatile material and with the correct form of the metal, one can think of developing incredible pieces, which would be long lasting and can be the same for years. In recent times, when there is a huge concern growing over saving planet, steel is one metal that is sustainable and reduces carbon footprint. With growing popularity of the material, the industry is also getting more organized and there are options available for exploring the use and purpose of the metal. If we evaluate, the sturdiness and corrosion free qualities of the metal, make it valuable.

Omni Steel Supply is a professional metal and steel manufacturer and supplier. They take both online and offline orders, they shared metals as steel, aluminum and their alloys are seeing their usefulness in different industries. They have industrial use and there is a growing demand in the construction field. Steel and other metals basically have levels or numbers which grades them on the basis of alloy used in making them strong and of value. Due to their varying categories, engineers get a lot of order from interior designers and even from hospitals and for other public utility.

To know more about construction with steel or other metal, fill in the form below and get in touch for quality products and service.

Source: https://www.omnisteelsupply.com/blog-post/few-incredible-reasons-for-using-steel-in-skyscrapers/

0 notes

Text

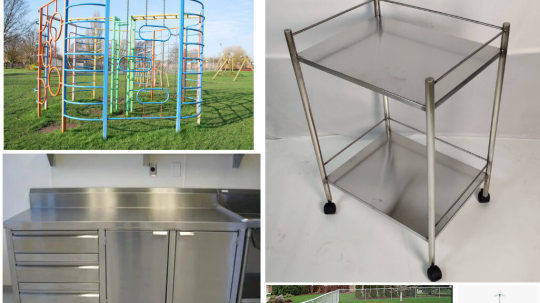

Metal Fabrication for Commercial Purposes

Whenever we talk about metal fabrication for commercial purposes, there’s only singular image that forms in our mind and it is of aircraft or automobile or bridges etc. Whereas metal has wider usage and serves various objectives. Metal has become a material of utility and complements almost all the industries and businesses with fine finish and design. A professional metal manufacturer and supplier can create miracles and provide the best of products. Some excellent piece of metal fabricated works for different fields can range from fancy nails to a big monument. Let us take an overview on what all can be made out of metals and for different industries as well as for residential usages.

For Restaurants: For an everlasting and budget friendly kitchen shelves in restaurants, consider steel. It not only gives strong and solid storage space and working table, it is a value for money deal. It is a reusable material, retains strength, can withstand temperature variations, easy in maintenance and gives scope for designing as per requirement. In addition to that, now there are different grades of metal available in the market, which has different features and can be selected on the basis of the work.

Cellar Door: Metals like aluminum can be used for creating cellar door for restaurants or for those who are in the wine making business. These doors are solid and can be of great use.

For security: Metals can be customized as window guards, which can be simple ones or something which can hold flower pots or anything else but would not let it crumble with weather change and provides ample security.

For medical field: Furniture in hospitals are mostly made of steel, right from table, chairs to surgery table to trolley carrying tools to stretchers. The real purpose of fabrication of metal is in here, a place which caters to people’s health and recovery.

For schools: Even in schools, colorful cabinets, several climbing toys in the play area are of steel as they last longer and are safe to use with little kids. It can be made colorful to attract kids and enjoy life.

For fencing: Fabrication of metal is mostly and greatly used for ornamental fences and even sober ones. They are designed to provide security and to provide aesthetic richness to the whole place. It has its own aura and enhances the beauty.

Metal has life, if maintained properly it can stay in the same way for many years and can also be reused as and when required. The most attractive feature of metal is it doesn’t lose its qualities even after years of usage and can be rebound if required with the help of a metal manufacturer.

Omni Steel Supply is a professional metal manufacturer and supplier. They serve to all the industries and have metal experts who can help you in realizing the usage of metal. They even take remote orders and if someone is interested, they can visit the ware house. For more information on metals, get in touch by filling the form below.

Source:- https://www.omnisteelsupply.com/blog-post/metal-fabrication-for-commercial-purposes/

0 notes

Text

Tips on taking care of Metal Furniture

With changing phases of evolution, lifestyle gets new meaning and purpose. Today, with digital revolution, our life is wired but something which is still constant and we all love is sitting in outside and enjoying the altering colors of sky as the day progresses. There’s a range of furniture available in the market for your garden, patio and for your balcony from metal to wood to cane to more. Over here, let us scroll through tips on how to maintain metal furniture and make it look new for years.

Some really simple and must to steps in maintaining metal furniture or any other kind, so that they can look as new for ages are—

Make it a habit to clean your stainless steel, aluminum or brass furniture on a regular basis. Do not let dust or water drops stay on them for long, you can use any soft cloth to the work.

It would be a good idea to wash the furniture with soap and water, preferably with one that does not contain any pH-negative powder.

It is very important to wipe or wash in the direction of the lines, this does not bring circular lines on the polish and keeps it in good condition for long. Do not wipe with the cloth dripping with water, this can leave mark on the furniture.

Instead of scrubbing with harsh scrubber, try removing stains with soft cloth, it helps.

Annual polishing or painting of metal furniture does a lot of good and increases the life of the furniture. Maintenance of painted furniture is also easy, scratch etc can be easily taken care by painting it whenever required.

If the weather condition is harsh or extreme, then to avoid rusting from humidity, it is necessary to clean on a daily basis with a soft dry cloth and paint as and when possible on regular intervals to ensure good life of your outdoor furniture.

If you have powder coated aluminum furniture, then you can dry wipe it for securing the look and finish. And, also to increase the life of furniture.

Stainless Steel furniture is super easy to maintain, wash it regularly with detergent and water. The main idea is to keep it free from dust and keep it dry. This will avoid corrosion and stay the same for years.

Metal furniture has a very suave and elegant styling, especially those which are for outdoor use. Metal is not only strong and has long life, it is regarded as an eco-friendly material that can be reused without losing its inherent quality.

Omni Steel Supply is a NY based metal manufacturer and supplier who have experience in manufacturing metal furniture of various styles. They can also guide you about stairs built inside and outside homes. If you are in search of metal furniture for your patio or garden, then get in touch with them today by filling the form below. They would be glad to guide you through and bring on table options for fabricated metal products.

Source: https://www.omnisteelsupply.com/blog-post/tips-on-taking-care-of-metal-furniture/

1 note

·

View note

Text

Top 3 ways to choose a reliable Metal Fabricator and Welding Company

The speed at which metal works are increasing, it is obvious there will be a mushrooming of metal fabricators and welders. Impending question in this scenario is how to choose a reliable fabricator who not only knows the fabrication and welding works but can give value for money along with quality work. While selecting a fabricator, we consider numerous aspects ranging from area to type of metal to be used to design to scope of reuse of metal if required. Over here, we have made an attempt to narrow it to three basic points covering all the important features of a trustworthy and experienced metal fabricator and welding firm.

1. Understand the purpose for the need of a metal fabricator: Having a general idea about the work required ease the selection process. Almost, all metal fabricators have a moderate experience and they know their job very well. The only difference could be some only offer generalized work and some are open to the idea of customization and are ready to take up big projects irrespective of the magnitude. While making a selection, you can consider a couple of below given points.

Size of the project

Customization required

Is it a time bound or there is flexibility

Quality: With their ideas, they can recommend or modify designs to preserve strength and give better quality finished product.

Experience: Metal fabricators are experts and have a lot of ideas concerning metal engineering, they may also suggest ideas about the project and give tips on how the entire work can be completed on time at a lower cost.

2. Credibility and reputation of the firm: With reputation, comes credibility to give quality work. A well-established firm would never want to spoil market reputation, after all the industry works on the word of mouth and goodwill. You can pick a firm referred by someone known or can read reviews or check the completed work or take a tour of the workplace or simply talk to their managers to get an idea of the projects undertaken by the firm. This would help you in getting a peak on their craftsmanship, artistry and their understanding of the engineering designs.

A reputed firm will make an offer to take a look at their work before signing on the dotted lines for initiating the project. You can also discuss how they deal with unforeseen issues and are contingencies taken into consideration before committing on the deadline. Discuss pros and cons for better outcome.

3. Customer Care or Service: Last but not the least, interaction with the customers during and after the completion of the project values a lot. This is an industry where transparency matters a lot, a client remains worried about processing process, about welding, about design, about quality of metal and meeting deadlines. With open communication, the least a fabricator can do is calm their nerves by answering queries.

Omni Steel Supply is a professional metal fabricator and welders who handles all types of work and projects of any capacity whether big or small.

0 notes

Text

Breaking Myths about Steel Staircase

Staircase can add aesthetic value to your décor and at the same be a thing of importance. It is an element of value both for residential and commercial constructions. From getting a modern look to ringing in the old archaic feel, you think of a theme and it can be accomplished with the right type of staircase built within or outside the premises. From spiral to straight to slanting to any other type, stairs can be built from wood, can be of cement or metal. According to your budget, design and idea, you can pick the most appropriate material if you have knowledge about it. Today, we have tried to break the common myths which is usually a matter of worry for most.

Toughness: Steel is one the widely used construction materials and it is going to stay this for times to come owing to its toughness and sturdiness. This veryAll Pages feature of steel or any other metal makes it a safe constituent for building stairs. It confirms safety of your structure and provides stability much better than wood or other material.

Slip Resistance: Steel is available in different types, consider diamond cut metal for staircase. It is slip resistance and provides better grip on the floor, which might be better than marble or tiles or wood. Metal stairs are especially great for hospitals as it gives better security than other types.

Longevity: Metal is rust free and have easy maintenance, this makes it long lasting and stay the same way for many years. With annual servicing of the stairs, one can ensure they remain the same for years and do not wear and tear with time.

Versatility: Metal manufacturers would vouch for the versatility of steel stairs. It can be grafted and designed the way one wants. The best part during the process, the features of steel do not get lost. This makes it a very durable and designer friendly substance for construction of any type.

Budget Friendly: Metal is a pocket friendly substance; it may seem a bit costly while installing but it is durable and has a long life. This makes it budget friendly, in addition it has very low maintenance cost. All this adds to its value and flexibility, thus making it a material worth any kind of construction.

Besides steel staircase, one can even consider other metals. Each metal comes in various gradation which is relative to its strength and other features. The type of metal should be in accordance with the requirement.

Omni Steel Supply is an old and experienced supplier and manufacturer of steel and other metals, they service areas surrounding NY city. They provide end-to-end work from supplying metal to manufacturing it as per the design suggested by the client or as decided by both the parties. They provide all types of metal works and are pro in metal cutting and welding methods. They used the latest technology to achieve their aim and finish on time. If you are looking for someone who can build a firm steel stairway, contact them today!

Source: https://www.omnisteelsupply.com/blog-post/breaking-myths-about-steel-staircase/

0 notes

Text

Importance of Drilling in Metal Fabrication Work

Drilling on a metal or a steel plate is not an easy affair. It is surely not one of the DIY works, and to consider it so, would be a bit ambitious thought as metal drilling requires trained and specialized hands to get the hole of the right measurement and size. Metal fabrication is essentially a customized assignment, each step is defined and calculated including the drilling process, which is a part of the metal fabrication. It is a technique wherein, a round hole is cut into the metal for different purposes. As per requirement of an ornamental metal work speed, force, size, depth etc. of drilling is maneuvered and adjusted.

Why drilling can’t be done at home?

Drilling is a specialized work, even making a small hole requires a vigilant eye and knowledge. A small size can be easily made a big one, but option for reversing the process is not available if the hole gets bigger than the required size. Also, drilling machine creates a lot of friction, controlling the tool can be a challenge for someone who has not done before or have no working experience. Taking help from the reliable sources is half work over.

Whom to approach for drilling work?

Both small and big metal manufacturers or fabricators offer drilling work. They have know-how and all necessary tools for delivering the work on time and as per requirement. They can even suggest the type of process that should be used if they are briefed about the purpose for drilling. There are various ways by which drilling can be done.

Drilling for ornamental need

Circular cuts in metal projects as stairways, gates, railings, chairs or benches, shelves are common sights. Cuts of various dimensions adorn many ornamental metal products. They enhance designs and bring a touch of modernism. Round cuts are very popular among fancy and decorative lamp shades. There are several functional and decorative uses of drilling in modern day construction, and demand for drilling engineers are increasing recently. Metal is the most common form of material used in the construction industry. Whether it is for commercial or residential purpose, demand is escalating and world is gradually accepting the world of steel and metal types as they are environment friendly, they can be recycled and at the same time both economical and aesthetic appeal.

Omni Steel Supply is a professional metal manufacturers and fabricators, they offer metal consultancy via online and offline medium. All through pandemic, they followed protocol and continued with their work while maintaining the health of the people involved in manufacturing, designing, executing and delivering the end product. They are one stop shop for all of your metal related work, which include providing options for types of metal sheets.

Source: https://www.omnisteelsupply.com/blog-post/importance-of-drilling-in-metal-fabrication-work/

0 notes

Text

Benefits of customizing Signs for businesses

Business is projection of entrepreneur’s dreams, ideas and aspirations. One works day and night from conceptualizing, planning, funding, executing and finally seeing it in brick or mortar, sometimes virtual. The choice of platform for business is no big deal today, one can either choose to go online or offline, if idea is innovative and customer centric, it is going to flourish. In the process, one thing which is of utmost importance is the signage or signs for business. Even to market online business, there is need to think and create a signage which has good recall and can be identified with ease. Today, we bring to you some of the benefits of customizing signs for businesses.

1. Option increases: When, one plans for customizing signs, the door to enormous opportunities increases. One can either go for digital designs or 3D or LED and all can be carved on metal plates. Choice for which can range from steel, copper, aluminum or brass.

2. Gives Identification: Whether we are talking about online or offline business, signs always give a sense of belongingness, it becomes an identification mark. For the marketing of online business, signages need to be put up for quick recall unlike offline business, online marketeers need to be pro-active and need to make a mark in the lives of their customers by putting by hoardings wherever possible.

3. Custom signs bring Novelty: Let’s explain this by example, at Omni Steel Supply, sometimes we get interesting request for carving washroom signage for restaurants in unique way. Many times, clients have their own suggestions for custom restaurant signs, and many times we suggest them ideas. The point is there is always a scope of novelty, when one is opting for customized signs for businesses. It opens up the avenues and tickles the interests of the target customers.

4. Adds value to business: Custom signage conveys how much importance you as an entrepreneur give to your business. From the concept behind designing the signage to put ways of sharing as if it would be from the ground or whether it would be wall mounted or like tourist signature style signage. There are definitely a lot of options and it would add meaning to your product. It reflects your love, passion and understanding of what you are showcasing.

5. Value for money: From neon to vintage to digital, whatever you wish to get for your metal sign plates, it is achievable; without crossing the budget. Plus, with metal signage, one can be confident about life of the sign plates.

Omni Steel Supply deals with custom signs for businesses and restaurants. They are the manufacturers and suppliers of metal and can provide the best advice in the market about metal signs. They also take remote orders and carve different types of signage from metal plates, which can bring various effects to your signage boards. If you wish to know more and explore various ideas about metal signage, don’t wait, get in touch with them professional advice and help.

Source: https://www.omnisteelsupply.com/blog-post/benefits-of-customizing-signs-for-businesses/

1 note

·

View note