Text

PTC Optical Instrument brings new solution to Laser Photonics

The 18th Laser World Photonics China successfully concluded at the Shanghai New International Expo Center. During this exhibition, local Chinese and international exhibitors displayed many advanced core solutions in five fields:

Laser Intelligent Manufacturing, Laser and Optoelectronics, Inspection and Quality Control, Optics and Optical Manufacturing, and Infrared Technology and Applications.

Laser power continues to increase, high-power lasers are gradually popularized, and the ultrafast laser market is expanding rapidly. As the core of solid lasers, laser crystals have important and extensive applications in military and civilian fields such as laser precision processing, laser weapons, photoelectric countermeasures, laser medical treatment and many others.

Laser crystals have the characteristics of high thermal conductivity and optical anisotropy. Cd:YAG is a new substrate and window material for ultraviolet and infrared optical devices. During the growth process of YAG single crystal, due to the temperature gradient between the crystal and the melt, a certain amount of residual stress will still remain inside the crystal even after a certain annealing process.

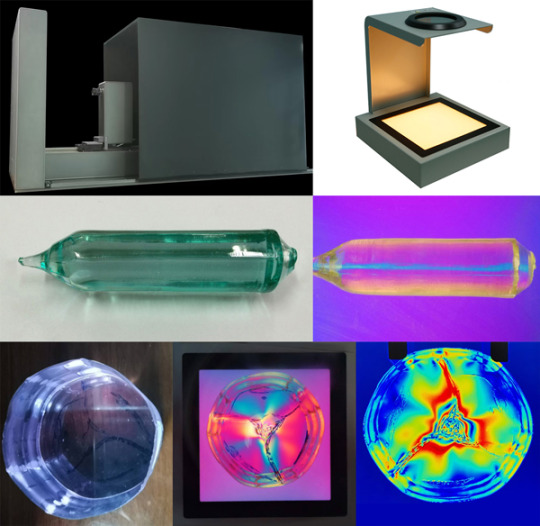

In order to observe and analyze the stress of crystals more intuitively, PTC Optical Instrument has developed a series of Polariscopes. These Polariscopes help technicians to quickly observe stress distribution , measure optical retardation in crystal products.

0 notes

Text

How to use a Scanning Acoustic Tomography in semiconductor industry ?

Scanning Acoustic Tomography (SAT) is a valuable tool in the semiconductor industry for non-destructive testing and evaluation of semiconductor materials and devices. This technology utilizes sound waves to create high-resolution images of internal structures, defects, and material properties, providing critical information for quality control, process optimization, and failure analysis.

1.Understanding Scanning Acoustic Tomography (SAT)

SAT works by transmitting ultrasonic pulses into the material being tested and measuring the time it takes for the echoes to return. This data is then used to construct a three-dimensional image of the internal structure, allowing analysts to visualize and assess the quality of the material.

2. Preparation and Setup

Before performing SAT, it is essential to prepare the semiconductor sample properly. This includes cleaning the surface to remove any contaminants that could interfere with the sound waves and ensuring the sample is positioned correctly for scanning.

3. Performing the Scan

During the scan, the sample is placed on a stage that can move in multiple directions, allowing the ultrasonic transducer to scan the entire surface. The transducer emits ultrasonic waves, which penetrate the material and are reflected back by internal structures and defects. The reflected waves are then detected by the transducer and used to create an image of the internal structure.

4. Image Reconstruction

Once the scan is complete, the data is processed using specialized software to reconstruct a detailed image of the internal structure. This image can reveal defects such as voids, cracks, and delaminations defects, as well as provide information about material properties such as density and elasticity.

5. Analysis and Interpretation

The final step in using SAT in the semiconductor industry is to analyze and interpret the images produced. This can involve identifying and quantifying defects, assessing material properties, and correlating the findings with other test results to gain a comprehensive understanding of the sample’s quality and characteristics.

In conclusion, Scanning Acoustic Tomography is a powerful tool for non-destructive testing in the semiconductor industry, providing valuable insights into the internal structure and properties of semiconductor materials and devices. By following proper procedures for sample preparation, scanning, and image analysis, SAT can help semiconductor manufacturers improve product quality, optimize manufacturing processes, and reduce the risk of defects and failures.

0 notes

Text

New arrival ! Scanning Acoustic Microscopy (SAM)

With the flourishing of 5G technology, PTC Group is excited to launch a NEW innovative inspection equipment , Scanning Acoustic Microscopy .

Widely used in:

DBC ceramic substrate, AMB ceramic substrate, IC packaging, SIC ceramic substrate, IGBT module and other industries.

It works with super high scanning speed to clearly show the multi-layer structure on the surface and interior of a sample at the same time. Various categories, sizes and locations of defects can be counted, recorded and marked.

It is available to be supplied with an integrated system, including a central ultrasonic microscope and an automatic loading and unloading unit.

0 notes

Text

PTC Group Successfully Held the 2023 Year-end Party

With the arrival of traditional Chinese New Year , PTC group held a grand Year-end Party together with our valued partners , suppliers and employee from our 7 subsidiaries .

The past year was a fruitful year, despite there were many difficulties on our way ahead . With everyone’s thoughts and efforts directed towards one common goal , We have stepped into a new development stage. On this special occasion , the company praised those teams and individuals who have contributed outstanding performance during their daily work .

After the award ceremony, the versatile colleagues brought a wide variety of song and dance performances.

The whole party ushered in the exciting lottery draw. Everyone was expecting the specially sponsored aviation models . At last 20 lucky guys were presented these special gifts .

Happy moment is always so fast. The annual party came to an end with the song “We are a family”. Let’s look forward to a more splendid PTC Group !

0 notes

Text

Welcome to PTC Group Housewarming Ceremony

Established in 2008 , Suzhou PTC Optical Instruments is a high-tech conglomerate engaged in the integrated research, development, production, and sales of intelligent equipment. Our company possesses seven subsidiaries, including Shenzhen PTC Vision, Suzhou Tissot Intelligent Software, Shenzhen PTC Semiconductor, Kunshan PTC Semiconductor, Suzhou Jinmuren Management Consulting and others. With three research and development centers in Shenzhen, Suzhou, and Kunshan, the company’s manufacturing base is located in Kunshan, spanning an area of 15,000 square meters.

On this special day , we held a grand housewarming ceremony.

youtube

In the future,PTC will continue centering its efforts on the strategic development theme of “ Intelligent Industrial Inspection Equipment”, cultivating the four major markets of “3C, PCB, Semiconductor, and New Energy” in depth. Upholding the business philosophy of “People, Trustable and Creation”, we will persist in technological innovation and industrial innovation , building our self-owned brand. Based in China, gazing upon the world, we aim to become a world leader in high-end intelligent manufacturing solutions and integrated services, making great contribution to Chinese Intelligent manufacturing and world industry 4.0 .

0 notes

Text

What is a Polarized glass tester ?

With the continuous development of technology, polarized glass is becoming more and more common. In life, we can see that they are widely used in sunglasses, car glass, electronic screens and other fields. However, how do you ensure that the product you purchase is truly polarizing? This requires the help of a device called a polarization glass tester.

1. What is a polarization glass tester?

The polarization glass tester is a device specially designed to detect whether materials have polarization effects. It uses the physical properties of light to determine the polarization characteristics of the material being tested through the analysis and measurement of light. Usually includes a light source, polarizer and detection analyzer.

2. Working principle

The working principle of the polarized glass tester is based on the polarization phenomenon of light. Polarization is the property of the direction in which light waves vibrate. For ordinary natural light, the light waves in it vibrate in all directions. With polarized light, the light waves only vibrate in one specific direction.

Through the polarization glass tester, we can analyze the light transmitted by the sample to determine whether it has polarization effect. The light source in the test instrument emits polarized light, which is transmitted by the sample and then detected and analyzed by the detector. Based on the test results, the polarization characteristics of the tested material can be determined.

3. Application fields

1. Sunglasses and Eyeglasses

Polarized glass testers play an important role in sunglasses and spectacles inspection. It ensures that the lenses of sunglasses and glasses have effective sun protection and UV protection functions, protecting users’ eyes from UV damage.

2. Vehicle glass

For the vehicle’s front windshield and side window glass, the polarization glass tester can detect its polarization characteristics. Qualified vehicle glass can reduce the interference of sunlight and mirror reflection on the driver and improve driving safety.

3. Electronic screen:

Including electronic screens such as mobile phones, tablets, and TVs, the polarized glass tester can detect whether the screen has anti-glare function. This helps improve the user’s visual experience and reduces discomfort when using it in the sun.

4. Importance

Polarization glass tester is of great significance in modern life. Its application in product quality control can ensure that consumers purchase products with high-quality polarization effects. At the same time, it also helps maintain the health and safety of users and avoid unnecessary light interference.

0 notes

Text

How to do polarized glass test with a Polariscope?

Step 1: Prepare test equipment

Firstly, you need to prepare a polariscope. A polariscope is a professional optical instrument used to test the polarizing properties of materials. You can buy or rent this equipment at an optical store or professional laboratory.

Step 2: Set up the polariscope

Place the polariscope on a stable table and connect its power source. Adjust and calibrate the polariscope according to the device’s operating instructions to ensure accurate testing.

Step 3: Place the glass sample

Place the polarized glass sample to be tested under a polariscope. Make sure the sample surface is flat and has no obvious stains or damage.

Step 4: Observe the glass sample

Observe the glass sample through the top analyzer of a polariscope. Under normal room light conditions, you will see the glass exhibit a rainbow of interference fringes.

Step 5: Rotate the Analyzer

While observing a glass sample, rotate the analyzer of a polariscope. You will notice that as you rotate, the brightness and contrast of the interference fringes change. You need to find the position of the optical axis that gives the interference fringes the sharpest and most contrast.

Step 6: Confirm the polarization effect

After determining the optimal optical axis position, look at the glass sample again and you should be able to see significantly reduced outdoor and specular reflections.

Precautions:

– During the test, make sure the sample surface is clean to avoid affecting the test results.

– Follow the polariscope operating instructions to ensure proper use and safety.

0 notes

Text

What are the advantages of an Automatic Polariscope?

Automatic Polariscope is an advanced optical instrument used to test and analyze the stress distribution and optical properties of high-transparency materials. Its emergence and application have brought many significant advantages to the field of materials science.

The first advantage is efficiency. The Automatic Polariscope can quickly perform testing and analysis processes with its automation capabilities, saving a lot of time and human resources. Compared with traditional manual observation and hand recording methods, automatic polariscope can provide more accurate and reliable results, and complete the collection and processing of large amounts of data in a very short time. This high efficiency not only improves work efficiency, but also reduces the impact of human factors on test results.

The second advantage is precision. The automatic polariscope uses advanced optical photoelastic technology and precision measurement components to accurately measure stress retardation and birefringence of materials. It detects small stress differences and changes and provides accurate numerical and graphical results. This precision is critical for quality control of materials, evaluation of product performance, and problem diagnosis and analysis during research and development period.

The third advantage is comprehensiveness. Automatic polariscope have a wide range of applications and are suitable for a variety of different types of materials and applications. It can be used to research and test film materials, glass, plastics, fiber materials, crystals, etc. Whether in industry or scientific research, automatic polariscope can be used to analyze the mechanical and optical properties of materials, evaluate the stability and reliability of their structures, and help optimize product design and manufacturing process.

The fourth advantage is intelligence. With the continuous advancement of technology, automatic polariscopes also have intelligent features. It is integrated with computers and software systems to achieve real-time monitoring, analysis and management of data. Through network connection, users can remotely control and monitor the operating status and test results of the optical retardation . This intelligent feature makes the use of the automatic polariscope more convenient and flexible.

0 notes

Text

Why do we need to test stress in Polycarbonate ?

Testing stress (such as molded parts and thermoformed products ) in polycarbonate is crucial for several reasons:

Environmental Stress Cracking Resistance: testing helps evaluate the material’s resistance to environmental stress cracking, a critical factor for durability. Polycarbonates are known for their high impact resistance and dimensional stability, making stress testing vital for ensuring these properties.

Mechanics and Behavior Analysis: stress-strain behavior analysis, especially under different conditions like strain rate and temperature, provides insights into the mechanical properties of polycarbonate. This is crucial for predicting its performance in real-world scenarios.

Design Data from Stress-Relaxation Tests: stress relaxation testing helps gather design data for polycarbonate, aiding in understanding its inelastic equation of state at various temperatures.

Tensile Strength Evaluation: tensile strength testing is often used as a basic determiner of a material’s ability to withstand stress. This is crucial for assessing the overall strength and durability of polycarbonate sheeting.

Prevent Stress Cracking: this testing helps identify the propensity of polycarbonate to craze and crack under specific conditions, such as exposure to sunscreen. This knowledge is vital for preventing stress-related failures in practical applications.

0 notes

Text

How to measure temper number of glass container with a Polariscope ?

The polariscope is a professional tool widely used in the manufacturing and quality control of glass containers. Among them, measuring the temper number of glass containers is one of the important applications. The higher the temper number, the lower the strength and heat resistance of the glass container. For some special commodities, the temper number will also affect the safety and quality of goods.

Measuring the temper number of a glass container requires certain professional knowledge and skills. The following is the detailed measuring method :

1. Prepare the polariscope and place the glass container to be measured at the predetermined position.

2. Rotate the glass container to the desired position so that darkened extinction cross appear.

3. Rotate the analyzer causes the darkened extinction cross to separate into two darkened arcs, moving outward in opposite directions toward the inside knuckle of the container. As the two arcs move outward, they develop a blue-gray color on the concave side and a brownish color on the convex side of each arc.

4. When determining the retardation at a selected area, rotate the analyzer until the blue-gray color is just displaced by the brownish color .

5. At this time, read the angle to which the analyzer is rotated and call it the Temper Number of glass container.

For example , we get above rotating angle 9.5°, it means temper number of this water glass is 2.

It should be noted that any impurities and signs of wear inside the glass container will affect the accuracy of the temper number. Therefore, in order to ensure accuracy, the surface of the glass container need to be cleaned before measurement.

0 notes

Text

How Can a Plastic Polariscope Help Manufacturers?

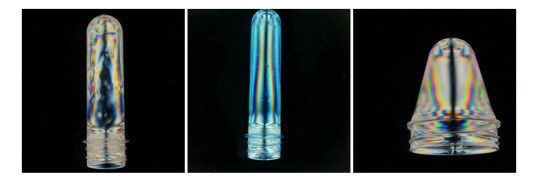

A Plastic Polariscope plays a crucial role in the manufacturing industry by aiding in quality control and ensuring the integrity of transparent materials like plastics. Here’s how it helps manufacturers:

Internal Stress Detection: The Polariscope is an optical inspection device that identifies internal stress in transparent materials, including plastics. This is crucial for manufacturers to prevent defects and enhance the overall quality of their products.

Quality Check: Using the Polariscope strain viewer, manufacturers can conduct a comprehensive quality check of plastic materials. This ensures that the final products meet the required standards and specifications

Stress Pattern Observation: The Polariscope, also known as a strain viewer, allows for qualitative observation of stress patterns in plastic. This feature helps manufacturers understand the material’s behavior under different conditions, leading to improved design and production process .

Application in Blow Moulding Procedure : Plastic materials manufactured through the blow moulding procedure may encounter issues that affect the final product. The Polariscope aids in detecting and resolving such problems, ensuring the integrity of the plastic components.

Testing PET Products: Manufacturers can utilize the Polariscope to fulfill testing requirements for a variety of PET products. PTC manufactures optical testing equipment, including Polariscope models, to meet the diverse needs of manufacturers in the industry.

0 notes

Text

Understanding the Automatic Polariscope

Automatic Polariscope is a commonly used testing instrument and is widely used in materials research, quality inspection and other fields. It can determine the quality of a material by detecting the stress distribution inside it, so it is known as the “eye of material testing”.

The automatic polariscope adopts the principle of polarization optics, that is, when a beam of linearly polarized light passes through a substance, it will be affected by the internal stress of the substance and cause optical retardation. By rotating the polarizer, changes in the intensity of light can be observed to determine the stress state of the material. Compared with traditional manual Polariscope, automatic polariscope can automatically measure, analyze and record, greatly improving test speed and accuracy.

Common application fields of Automatic Polariscope include the research and production of materials such as crystals , plastics, and glass.It can help manufacturers improve product quality and performance and reduce losses during the production process.

In short, as an important optical testing instrument, the automatic polariscope plays an irreplaceable role in various fields. Its fast, accurate and reliable test results provide important support and help for production and scientific research.

0 notes

Text

New product release —-Portable Polariscope

Features

optional build-in lithium battery

light weight to 2.5KG

easy to operate

real time display of stress presence

This newly innovated Portable Polariscope is a good supplement to our Qualitative Polariscope series . It’s a handy tool for glass quality control , such as glass vial , quartz tube , cosmetic packaging . If there is residual stress inside transparent parts , they will undoubtly be found under this device .

0 notes

Text

High-precision detection method for phase retardation of birefringent components

Birefringent components are a special type of optical components that exhibit birefringence.

That is, the refracted light propagates in two directions: ordinary light (o light) and extraordinary light (e light ). Phase retardation refers to the phase difference between o light and e light when light passes through a birefringent component. The size of the phase retardation is related to factors such as the material properties, geometry of the component, and the wavelength of the incident light. Accurately measuring the phase retardation of birefringent components is of great significance for the design and performance evaluation of optical systems.

For example, in optical fiber communication systems, the measurement of phase retardation can be used to measure the dispersion characteristics of optical fiber, thereby optimizing the bandwidth and transmission distance of optical fiber transmission. In imaging equipment such as optical microscopes and optical coherence tomographs, the measurement of phase delay can be used To improve resolution and accurately measure the surface topography of samples.

The specific method for high-precision detection of phase retardation within birefringent components adopts the principle of photoelasticity.When light travels through a polarizer, it becomes circular polarized light. When a phase-delayed sample is placed, there is an optical retardation between the slow axis and fast axis . Thus the outgoing light becomes elliptical polarized light. By rotating the analyzer , the rotating angle of the polarized light which is affected by the presence of phase retardation can be detected precisely.Below automatic Polariscope is an measuring instrument to precisely measure phase retardation .

0 notes

Text

Recognize assembling stress in VR lens with a Polariscope

Lenses are an important component of optical imaging systems. Taking VR AR imaging system as an example,residual stress in the lenses will have the following two negative effects.

1. Effect of lens stress on optical performance

Lens stress can cause optical distortion, which changes lens shape and surface accuracy , thereby affecting the imaging quality of optical equipment. Stress will cause bending and distortion of the lens, resulting in aberrations, making the light unable to focus, thus reducing the clarity and resolution of the image. In addition, lens stress can also cause the dispersion effect of optical equipment, leading different transmitting speeds of light with different wavelengths in the lens, finally resulting in the generation of chromatic aberrations.

2. Effect of lens stress on optical stability

Lens stress can cause changes in the shape and size of the lens, which can affect the stability of the optical device. Stress will deform the lens, causing the optical reflection effect on the lens surface to change, thereby affecting the transmission and reflection of the optical path. Stress will also cause changes in the microstructure of the lens material, causing changes in the refractive index and dispersion properties of the lens, thereby affecting the propagation of light and imaging effects.

So how to measure and control lens stress?

Commonly used lens stress measurement methods include optical, mechanical and thermal ways. The optical method uses the principle of photoelasticity to measure the phase difference (optical path difference, optical retardation) to indirectly reflect the existence and magnitude of stress. The fully automatic Polariscope launched by Suzhou PTC Optical Instruments can help lens manufacturers quickly and accurately measure the optical retardation caused by stress inside lenses.

In below figures , lens stress before mounting and after mounting are demonstrated.

Optical retardation before mounting (max:6.213nm , ave : 1.882nm)

optical retardation after mounting (max:15.116nm , ave : 8.477nm)

It is not hard to notice that additional assembly stress is introduced during the mounting process . By optimizing the blessing power, support methods and installation process, assembly stress can be decreased largely .

0 notes

Text

New arrival— Large-field Fully Automatic Polariscope

The newly issued Automatic Polariscope has an larger viewing field to 400*400mm .

Measuring height can be adjusted by user to measure transparent samples with different sizes .

This adjustment is conducted by motor.

A characteristic application is light-guide plate for display industry.

Measurement result display is as below .

In this interface, users can get the exact retardation value of different areas . By input sample thickness and material stress-optical coefficient , material stress value will be calculated automatically.

Besides, additional functions are included . It allows users to measure retardation and stress value at pre-set specific locations. For example , users can freely select 100 points which are evenly distributed on the round sample . Stress value at each selected point will be displayed and saved easily .

0 notes

Text

An Economical On-line Stress Detection System for Polyester Sheet

Polycarbonate is a strong thermoplastic resin, almost colorless and transparent with good optical properties. PC resin can be processed into large rigid products with low molding shrinkage and good dimensional stability.

The three major application fields of PC resin as engineering plastics are glass assembly industry, automobile industry, electronics and electrical appliances industry, followed by industrial machinery parts, packaging, medical and protective equipment, etc.

PC resin is used in automotive lighting systems, instrument panel systems and interior decoration systems, as headlight covers, front and rear baffles. Medical grade PC materials can be used to make syringes, surgical masks, disposable dental appliances, etc. With the rapid development of aviation technology, the requirements for various components in the aircraft are constantly increasing, which makes the application of PC in this field also increase day by day. According to statistics, there are 2,500 polycarbonate parts used in only one Boeing aircraft, and a single plane consumes about 2 tons of polycarbonate. In the field of photovoltaics, solar panels with PC boards can reduce the weight by about half compared with solar panels using glass, and can be installed on any roof due to their lighter weight. The panels also emit 80% less CO2.

The production process of PC board is extrusion molding, and the main equipment required is an extruder. Common coil widths are 850mm, 1220mm, 1560mm, 1820mm, 2100mm. Aiming at solving the cracking problem raised by the PC sheet manufacturer with a width of 850mm, we now provides a set of economical online stress testing solutions. Only 2 sets of enlarged hand-held Polariscope is needed to conduct stress detection in the front and back sections. The polariscope can be embedded in customer's production lines. For more information about customized solutions, please feel free to contact us .

0 notes