Text

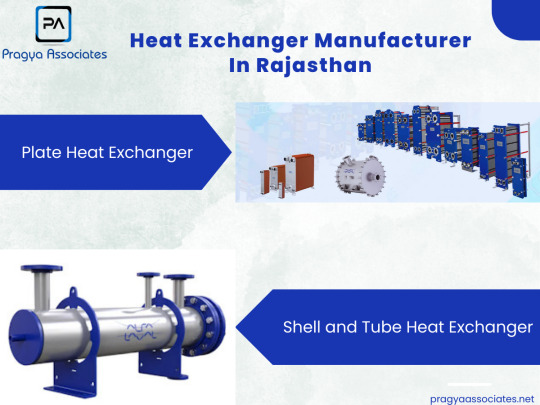

Heat Exchanger Manufacturer In Rajasthan

Pragya Associates is a leading heat exchanger manufacturer in Rajasthan. We manufacture a wide range of heat exchangers including plate heat exchangers and shell and tube heat exchangers. We use the highest quality raw materials and cutting-edge technology to manufacture our exchangers and spare parts in accordance with international standards. Our heat exchangers are well-known for their ease of installation, fine finish, and trouble-free operation. Additionally, our quality controllers thoroughly inspect these products based on a number of quality check parameters to guarantee an absolute quality product. Get in touch with us now to learn more about our high-quality heat exchangers.

#HeatExchangerManufacturer#TopHeatExchangerManufacturerInRajasthan#HeatExchangerInRajasthan#PlateHeatExchanger#ShellAndTubeHeatExchanger

0 notes

Text

Centrifuge Machines India

Pragya Associates offers a range of high-quality centrifuge machines in India. These advanced devices are essential in various industries for separating liquids and solids efficiently. Our centrifuge machines are known for their reliability and performance, making them a trusted choice for our clients across India. We are dedicated to providing excellent products to our customers. We ensure our clients have access to cutting-edge centrifuge technology to satisfy a variety of their needs. Contact us now for the latest centrifuge machines.

#Centrifuge Machines India#IndustrialCentrifugeMachines#EfficientSeparation#Centrifuge#OilCentrifugeMachine

0 notes

Text

Plate Heat Exchanger In India

Pragya Associates is offering efficient and cost-effective Plate Heat Exchangers in India. Our heat exchangers efficiently transfer heat between liquids, making them perfect for industries like HVAC, food processing, and more. Using our heat exchangers you can save energy and reduce costs while ensuring consistent temperature control. Our machines are trusted by businesses across the country. Countless happy customers have benefited from our dependable heat exchange solutions. Contact us today and upgrade your heating system today.

#PlateHeatExchangerIndia#PlateHeatExchanger#HeatExchanger#HeatTransfer#EnergySaving#CostEffectiveHeating

0 notes

Text

Types of Shell and Tube Heat Exchangers: A Comparative Analysis for Industrial Applications

Heat exchangers play an important role in various industrial processes. They help in the efficient transfer of heat between two fluid streams. The versatility and efficiency of shell and tube heat exchangers make them one of the most popular types of heat exchangers. If you also want to know more about it then read further. We will tell you about the various types of shell and tube heat exchangers commonly used in industries. Their features, applications, and benefits, we have covered everything in this blog.

Furthermore, if you need high-quality heat exchangers. Then get it from a reliable shell and tube heat exchanger manufacturer or supplier.

Fixed Tube Sheet Heat Exchangers

The most common and simple type of shell and tube heat exchangers are the Fixed tube sheet heat exchangers. They have a stationary tube bundle which is attached to a rigid shell, where the tube sheet is welded or bolted to the shell. If the temperature and pressure difference between the two fluids is relatively small. Then, these heat exchangers are the best option. These heat exchangers are widely used in HVAC systems, chemical processing plants, and power generation facilities.

U-Tube Heat Exchangers

U-tube heat exchangers, as the name suggests, have U-shaped tubes. these tubes allow for thermal expansion. One end of the U-shaped tube bundle is fixed to the tube sheet and the other end is free to move within the shell. This design allows the tubes in U-tube heat exchangers to expand and contract as the temperature changes. This makes U-tube heat exchangers perfect for handling high differences in temperature. They are commonly used in applications such as steam condensers, oil coolers, and process heating.

Floating Head Heat Exchangers

Floating head heat exchangers offer enhanced flexibility by allowing the floating tube sheet to move within the shell. This feature enables the expansion and contraction of the tubes without exerting excessive stress on the tube sheet. Floating head heat exchangers are suitable for applications involving high temperature and pressure variations. They find extensive use in oil refineries, chemical plants, and petrochemical industries.

Conclusion

Understanding the different types of shell and tube heat exchangers is necessary for industrial applications. Each type offers unique advantages depending on the specific requirements of the process. By choosing the appropriate type of heat exchanger, industries can optimize heat transfer enhance system performance, and improve overall operational efficiency.

If you are in need of a reliable shell and tube heat exchanger manufacturer or supplier, Pragya Associates is dedicated to providing high-quality products. As a trusted shell and tube heat exchanger manufacturer, we prioritize quality and performance in every product we deliver. We design and manufacture heat exchangers using advanced techniques and materials. Furthermore, we ensure their durability, thermal efficiency, and long-term reliability. As a result, our heat exchangers meet industry standards and customer expectations.

#shell & tube heat exchanger#shellandtubeheatexchangersindia#shell and tube heat exchanger types#shell and tube heat exchanger supplier#shell and tube heat exchanger manufacturer

0 notes

Text

Oil Filtration Machines In India

Pragya Associates offers portable skid-mounted oil filtration machines in India. These machines are suitable for the filtration and cooling of various types of oils. Some of those oils include gear oil, hydraulic oil, and high viscous oil. Our filtration machines have a portable design that makes them easily transportable, providing convenience and flexibility. They are efficient in removing impurities from the oil to improve its quality and extend its service life. Thus, making them an ideal choice for industrial applications.

#OilFiltrationMachines#GearOilFiltration#HydraulicOilFiltration#HighViscousOilFiltration#OilCoolingSolutions#IndustrialFiltration

0 notes

Text

Alfa Laval CIP System

Pragya Associates specializes in the Alfa Laval CIP System, which is really important for keeping heat exchangers and separators clean. With this Clean In Place (CIP) system, you can easily and efficiently clean these parts without taking them apart. By using this system, you can save money because you won't need to buy as many spare parts, and it takes less time to clean everything. The Alfa Laval CIP system uses safe cleaning liquids to get rid of dirt, deposits, and bacteria, so your equipment works better and needs less maintenance. You can choose from different CIP systems to find the one that suits your needs best.

0 notes

Text

Plate Heat Exchanger Machines

Pragya Associates is a leading manufacturer and supplier of Plate Heat Exchanger machines. We are offering high-quality solutions for industrial applications for years. Our advanced and efficient designs maximise heat transfer efficiency. They also reduce energy use and increase production. We also manufacture customized plate heat exchangers to meet your specific requirements. Our heat exchangers are widely used in HVAC, refrigeration, and chemical processes. Trust our expertise and contact us for reliable and innovative solutions that elevate your operations.

#HeatExchangerInnovation#EfficientHeatTransfer#IndustrialHeatExchange#PlateHeatExchangersMachines#CustomizedHeatExchangers

0 notes

Text

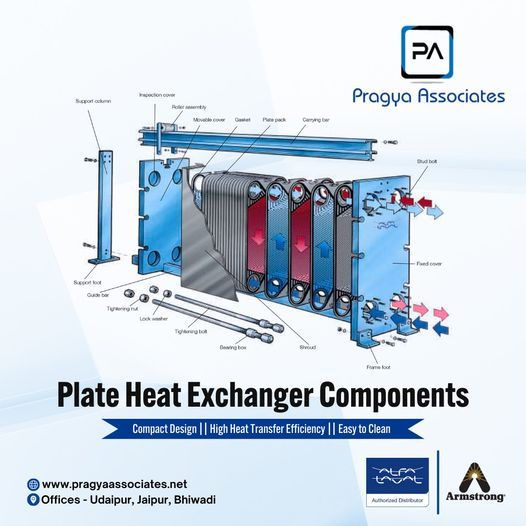

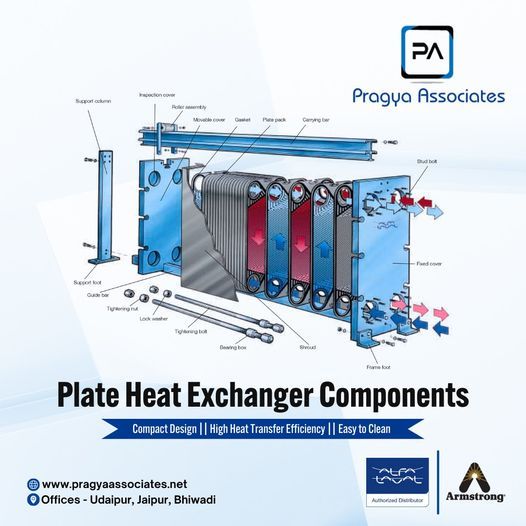

Plate Heat Exchanger Component is common in most gas and oil processing systems.

It consists of a fixed-end plate, connections and a loose pressure plate with carrier bars between them.

For More Details, Visit - www.pragyaassociates.net

#Plate Heat Exchangers Rajasthan#Plate Heat Exchanger in India#Alfa Laval CIP System in India#Filters Cooling Skid in India#Disc Stack Separator Technology India#Aldec Decanter Centrifuges in India#Alfa Laval CIP India#Filters Cooling Skid#Alfie Separator in India#Disc Stack Separator in India#Alfa Laval CIP System#Heat Transfer Skid India#Alfa Laval Centrifuge India#Centrifuge Separators in India

0 notes

Text

Plate Heat Exchanger Component is common in most gas and oil processing systems. It consists of a fixed-end plate, connections, and a loose pressure plate with carrier bars between them. For More Details, Visit - www.pragyaassociates.net

#Plate Heat Exchangers Rajasthan#Plate Heat Exchanger in India#Alfa Laval CIP System in India#Filters Cooling Skid in India#Disc Stack Separator Technology India#Aldec Decanter Centrifuges in India#Alfa Laval CIP India#Filters Cooling Skid#Alfie Separator in India#Disc Stack Separator in India#Alfa Laval CIP System#Heat Transfer Skid India#Alfa Laval Centrifuge India#Centrifuge Separators in India#Alfa Laval Products India#Oil Centrifuge Machines India#Alfa Laval CIP#Alfa Laval Plate Heat Exchangers India#Decanter Centrifuge India

0 notes

Text

Plate Heat Exchangers: What are their types?

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. It has a major advantage over traditional shell and tube heat exchangers because it is a much more efficient heat transfer. Plate heat exchangers are used in various industries, from food and beverage processing to chemical manufacturing. You might wonder about the available types if you're in the market for a plate heat exchanger (PHE).

This blog post will look at the three main types of PHEs: gasketed, brazed, and welded. Each type has advantages and disadvantages that make it better suited for certain applications. By the end, you should know which type is right for your particular application.

Gasketed plate heat exchangers are the most common type of PHE. They're made up of a series of plates, each with a gasket bolted together. The gaskets prevent the two fluids from coming into direct contact with each other but allow them to flow past each other to transfer heat. The plates are usually made of stainless steel but can also be made of other materials, such as titanium or nickel alloys. Gasketed PHEs can be used with various fluids, including water, steam, oil, and chemicals. Gasketed plate heat exchangers are relatively easy to maintain and clean, making them ideal for food and beverage processing facilities.

Brazed plate heat exchangers are similar to gasketed plate heat exchangers, but the plates are joined together with a brazing material instead of gaskets. It makes them more resistant to high temperatures and pressures. These are often used in power plants and other heavy industrial applications. Brazing is a process in which two metals are joined together using a third metal with a lower melting point than the other two. BPHEs can be made from various metals, including copper, stainless steel, and nickel alloys. They're often used in applications with the potential for corrosion or leaks.

Welded plate heat exchangers (WPHEs) are made of a series of welded plates. They can be made from various metals, including stainless steel, carbon steel, and nickel alloys. WPHEs are often used in applications with high pressure or temperature potential. Welded plate heat exchangers are made by welding the plates together at the edges. It creates a stronger joint that can withstand higher temperatures and pressures than either gasketed or brazed plate heat exchangers. Welded plate heat exchangers are commonly used in petrochemical plants and other industrial facilities where they will be exposed to harsh chemicals and corrosive materials.

Plate heat exchangers are essential to many industrial processes, from food and beverage processing to chemical manufacturing. There are three main types of plate heat exchangers: gasketed, brazed, and welded. By understanding the different types of plate heat exchangers, you can choose the one that is best suited for your needs. And now that you know about the different types of PHEs available in the market, you can make an informed decision about which is right for your application.

If you have questions about PHEs or need help selecting one for your specific needs, please don't hesitate to contact Pragya Associates. Our team of experts would be more than happy to assist you.

#Plate Heat Exchangers Rajasthan#Plate Heat Exchanger in India#Alfa Laval CIP System in India#Filters Cooling Skid in India#Aldec Decanter Centrifuges in India#Alfa Laval CIP India#Pragya Associates#Shell and Tube Heat Exchangers India#Welded plate heat exchangers#Brazed plate heat exchangers#Gasketed plate heat exchangers

0 notes

Photo

Alfa Laval decanter centrifuge provides exceptional performance when separating solids from 1 or 2 liquid phases in one single continuous process. Pragya Associates is a leading manufacturer and supplier of Alfa Laval centrifuge, oil centrifuge, industrial centrifuge separators in India. Contact Us Today!

Visit - https://pragyaassociates.net/decanter-centrifuge/

#Aldec Decanter Centrifuges in India#Alfa Laval Centrifuge India#Alfa Laval Products India#Decanter Centrifuge India

0 notes

Photo

A plate heat exchanger consists of several heat transfer plates that are held in place between a fixed plate and a loose pressure plate to form a complete unit. Pragya Associates is an authorized distributor of Plate Heat Exchangers in India with a great selection at the best prices.

Visit - https://pragyaassociates.net/plate-heat-exchangers-india/

0 notes

Video

Visit: https://pragyaassociates.net/plate-heat-exchangers-india/

0 notes

Video

Pragya Associates - an authorized distributor of Plate Heat Exchangers. With Shortest Delivery Time at Best Prices. Enquire Now!

0 notes

Photo

Plate Heat Exchangers

0 notes

Text

Plate Heat Exchangers | Shell and Tube Heat Exchangers

Pragya Associates - an authorized distributor of Plate Heat Exchangers. With Shortest Delivery Time. Great Selection of Shell & Tube Heat Exchangers at Best Prices. Enquire Now!

0 notes

Text

Shell and Tube Heat Exchanger By Pragya Associates

If you're searching out Shell and Tube Heat Exchanger then you definitely should consider Pragya Associates - one of the best/pleasant Heat Exchangers of Shell and Tube in Udaipur and all types of different industrial heat exchangers.

Shell and Tube Heat Exchanger, the most common sort of heat exchanger in oil refineries and other huge chemical processes, is suitable for higher-pressure applications.

Pragya Associates also provides a complete solution for heat transfer & separation to your fingertips. We are a customer-centered company that supplies products and answers that assist you to end up becoming extra productive and competitive.

Shell and Tube Heat Exchanger Components:

1. Tie-rods

2. Baffles

3. Tube-Side Channel & Nozzles

4. Shell & Shell-Side Nozzles

5. Tubesheet

6. Tubes

Shell and Tube Heat Exchangers working?

In almost all mechanical systems, heat is moved from one place to every other or from one liquid to every other. This process of heat transfer is performed through a heat exchanger.

A heat exchanger is a mechanical tool that makes use of transmits from one fluid to every other fluid. Heat exchangers are applied in the whole world for different applications to transfer heat. There are many forms of heat exchangers, and a shell and tube heat exchanger is one of them. The shell and tube heat exchanger has a bunch of tubes. The maximum famous sort of shell and tube heat exchanger is the TEMAE kind due to its robustness and easy design, in addition to its extensive working pressure and temperature range. This article mainly describes various types, working, parts, and many other aspects of the shell and tube heat exchanger.

Why Shell & Tube Heat Exchanger?

Loading Products and Materials - When loading client vehicles with a product that desires to be at a temperature of 200 degrees Celsius, an exchanger makes it possible to preserve your extremely huge product tank at 150 to 180 degrees Celsius. Pump the product through the exchanger to heat it to 200 degrees Celsius when loading vehicles. Pumping the product through the exchanger heats what is needed to the 200-degree Celsius temperature, saving you from extra energy to heat a whole tank product when it’s not essential to do.

Receiving Products and Materials - When off-loading rail cars, barges, or ships while you receive a product from suppliers, Generally, the product you’re getting at your facility will be colder than the product already stored in the tanks on-site. Barges and railmotors are heated to approximately 265F, to the factor they can begin pumping the material – however still significantly lower than the temperature of what you have already got saved. As the product is pumped into the storage tank, it can run through a heat exchanger to get to the preferred temperature of 300F. This avoids cold new products from cooling the tank and makes the storage tank geared up to be used immediately. Without a shell and tube heat exchanger in place, those tanks can cool down and it could take days – if not then weeks to heat up with the internal coils. Shell and tube heat exchangers make it possible to pump materials as quickly as possible, and they transfer temperatures efficiently so that you can make sure the materials are at the necessary temperature without expending extra strength to do so.

Shell and Tube Heat Exchangers Types

Floating head exchanger - A fixed tube sheet heat exchanger is the most common type of heat exchanger in all industries. Fixed tube sheet heat exchangers are used in the chemical process industry and in refineries since there is absolutely no possibility of liquids mixing. These types of heat exchangers are used where they cannot be tolerated or where even the modest mixing of liquids has straight pipes which are fastened on both sides to tube sheets connected to the jacket and have removable duct covers for the tube sheets. The best advantage of the fixed tube sheet heat exchanger construction is its low cost due to its simple construction.

Fixed tube sheet exchanger - In the case of the constant tube sheet exchangers, the tube sheet welds with the shell. This shell and tube heat exchanger has an easy and cheaper structure that allows mechanical or chemical cleaning of the tube holes. Except for chemical cleaning, the tube’s outer surface of this exchanger isn't accessible

U-tube heat exchanger - In this sort of shell and tube heat exchanger, the tube can be bent or straightened right into a U-form called a U-formed tube. Therefore, this heat exchanger is called a U-tube heat exchanger. This heat exchanger makes use of an M-type rear head and any type of front header.

Please contact us for business-related queries -

Reg. Office

H. No. 3, Shrinath Colony, Pulla,

Nr. Hotel Q & Fatehpura,

Udaipur (Raj.) 313001

Office

P. No. 64, Raberion ka guda,

Behind Hotel Blue Feather & Hotel le Grand,

Pratap Nagar-Sukher Bypass Road, Udaipur

Phone:

+91-9829837175

+91-7627049661

Email: [email protected]

https://pragyaassociates.net

0 notes