Text

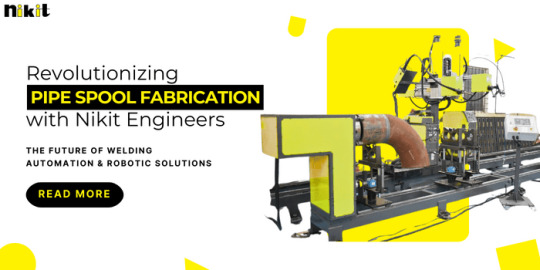

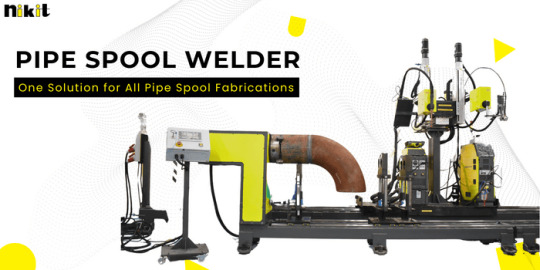

Revolutionizing Pipe Spool Fabrication with Nikit Engineers: The Future of Welding Automation and Robotic Solutions

In the dynamic landscape of industrial fabrication, the quest for efficiency, precision, and cost-effectiveness has led to significant advancements. Among these, pipe spool fabrication stands out as a vital process in industries ranging from oil and gas to pharmaceuticals and beyond. At the forefront of this evolution is Nikit Engineers Welding Automation and Robotic Solutions, pioneering innovative approaches to enhance the pipe spool fabrication process in India.

Key Takeaways about Pipe Spool Fabrication:

Off-Site Precision: Pipe spool fabrication entails the assembly of pre-cut pipe sections and fittings in a controlled off-site environment. This controlled setting allows for meticulous attention to detail, ensuring precise measurements and welds.

Reduced Construction Time: By fabricating pipe spools off-site, construction time at the installation site is significantly reduced. This streamlined process minimizes downtime, accelerating project completion timelines.

Enhanced Quality Control: Fabricating pipe spools in dedicated facilities enables easier quality management. Rigorous inspection protocols can be implemented, ensuring compliance with industry standards and specifications.

Mitigated Production Delays: Fabrication in specialized facilities mitigates the risk of production delays caused by adverse weather conditions or site-specific challenges. This resilience to external factors enhances project reliability and on-time delivery.

What Is Pipe Spool Fabrication?

Pipe spool fabrication involves the prefabrication of interconnected pipe sections, valves, and fittings into modular units known as spools. These spools are then transported to the installation site for final assembly, significantly simplifying on-site construction.

Pipe Spooling Application

The versatility of pipe spooling extends across various industrial sectors, including:

Oil and Gas: Pipeline networks for transportation and distribution.

Chemical Processing: Complex piping systems for chemical production.

Power Generation: Steam and water piping for thermal and nuclear power plants.

Pharmaceutical: Hygienic piping for pharmaceutical manufacturing facilities.

HVAC: Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Why Are Pipe Spools Prefabricated?

The prefabrication of pipe spools offers several advantages:

Precision Engineering: Off-site fabrication ensures consistent quality and adherence to design specifications.

Cost Efficiency: Reduced labor and material costs associated with on-site assembly.

Enhanced Safety: Controlled environments minimize the risk of accidents and injuries.

Flexibility: Modular spools allow for easy customization and adaptation to project requirements.

Cost Savings in Pre-Fabrication, Inspection, and Testing

Nikit Engineers leverages cutting-edge welding automation and robotic solutions to optimize the pipe spool fabrication process. By integrating advanced technologies, they deliver unparalleled efficiency, accuracy, and cost savings throughout the fabrication journey. From automated welding systems to robotic inspection and testing, Nikit Engineers ensures that every spool meets the highest standards of quality and performance.

Contact Nikit Engineers for Your Next Industrial Pipe Spool Fabrication Project

With a proven track record of excellence and innovation, Nikit Engineers is your trusted partner for all your industrial pipe fabrication needs. Whether you’re embarking on a new construction project or seeking to optimize existing processes, our team of experts is ready to deliver tailor-made solutions that exceed your expectations.

Experience the future of pipe spool fabrication with Nikit Engineers Welding Automation and Robotic Solutions. Contact us today to discuss your project requirements and discover how we can transform your vision into reality.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#linear welding#Profile Wedling#Stainless Steel Welding

0 notes

Text

Enhancing Industrial Efficiency: Welding Components on Nikit Engineers’ Mini Profile Welder

n the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost precision. Let’s delve into the diverse components welded on this remarkable machine and explore how they contribute to enhancing industrial efficiency.

Stellite Welding

Stellite, known for its exceptional wear resistance and durability, is a vital component in many industrial applications, particularly in high-temperature and corrosive environments. Welding Stellite requires precision and expertise to ensure a strong bond without compromising its properties. The Mini Profile Welder, equipped with advanced welding capabilities, ensures seamless welding of Stellite components, guaranteeing optimal performance and longevity in industrial settings.

youtube

Bellow with Flange

Bellow assemblies find widespread use in various industries for their ability to absorb thermal expansion, vibration, and misalignment. Welding bellows with flanges demands meticulous attention to detail to maintain structural integrity and sealing effectiveness. With its precise control and customizable welding parameters, the Mini Profile Welder ensures flawless welding of bellows with flanges, meeting the stringent quality standards required in industrial applications.

youtube

Spin Tube

Spin tubes play a crucial role in diverse industrial machinery, facilitating smooth rotational motion and power transmission. Welding spin tubes demands high precision to achieve uniformity and strength along the weld joints. The Mini Profile Welder’s advanced welding technology, coupled with its automated processes, enables consistent and reliable welding of spin tubes, contributing to the seamless operation of industrial equipment.

youtube

Copper Busbar

Copper busbars are essential components in electrical power distribution systems, requiring robust welding techniques to ensure efficient current flow and conductivity. Welding copper demands specialized expertise due to its high thermal conductivity and susceptibility to oxidation. The Mini Profile Welder’s advanced welding capabilities, including precise heat control and shielding gas management, facilitate accurate and reliable welding of copper busbars, ensuring optimal electrical performance in industrial applications.

youtube

Castor Wheel Brackets

Castor wheel brackets play a critical role in facilitating mobility and maneuverability in various industrial setups. Welding these brackets demands structural integrity and stability to withstand dynamic loads and harsh operating conditions. The Mini Profile Welder’s precision welding technology ensures strong and durable welds on castor wheel brackets, providing reliable support for equipment mobility in industrial environments.

youtube

Bellow Nut Assembly

Bellow nut assemblies are integral components in mechanical systems, providing adjustable support and sealing capabilities. Welding bellow nut assemblies requires precision to maintain dimensional accuracy and thread integrity. With its advanced welding features and customizable parameters, the Mini Profile Welder enables seamless welding of bellow nut assemblies, ensuring optimal functionality and performance in industrial applications.

youtube

In conclusion, the Mini Profile Welder by Nikit Engineers Welding Automation and Robotics Solutions India offers a comprehensive solution for welding a diverse range of industrial components with precision and efficiency. By seamlessly welding components such as Stellite, bellows, spin tubes, copper busbars, castor wheel brackets, and bellow nut assemblies, this innovative machine enhances industrial productivity and reliability, setting new standards in welding automation technology. With its advanced features and robust performance, the Mini Profile Welder continues to revolutionize industrial welding processes, driving progress and innovation across various sectors.

Why Choose Nikit Engineers for Mini Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#Stainless Steel Welding#Profile Wedling#Youtube

0 notes

Text

Profile Welding Excellence: Unleashing Efficiency and Precision through Automation

In the realm of welding, precision and efficiency are paramount. As industries evolve, the demand for seamless and accurate profile welding has never been higher. At Nikit Engineers Welding Automation & Robotic Solutions, we recognize the pivotal role that automation plays in achieving excellence in profile welding processes.

The Power of Automation in Profile Welding

Gone are the days when traditional welding methods dictated the pace of production. Today, automation stands as a game-changer in the welding industry. Our cutting-edge solutions at Nikit Engineers are tailored to enhance efficiency and precision in profile welding processes.

Precision Redefined: Automation brings a level of precision that manual welding struggles to achieve consistently. Our robotic solutions meticulously follow programmed paths, ensuring welds are executed with unparalleled accuracy. This not only minimizes material wastage but also guarantees the structural integrity of the welded components.

Efficiency at its Core: Time is money, and in the welding business, every second counts. Our automated profile welding systems are designed to optimize production timelines without compromising on quality. The seamless integration of robotics reduces downtime, allowing for continuous operation and increased output.

Why Choose Nikit Engineers for Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Watch Nikit Engineer’s Profile Welder in Action

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

In conclusion, at Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

Revolutionizing Welding Automation Artificial Intelligence (AI) in Welding Automation

In recent years, the manufacturing industry has witnessed a paradigm shift with the integration of Artificial Intelligence (AI) in Welding Automation. Nikit Engineers, a pioneering force in Welding Automation & Robotics Solutions in India, has been at the forefront of this technological revolution. In this blog, we will explore the pivotal role that AI plays in robotic solutions for welding automation across the globe.

The Rise of Artificial Intelligence (AI) in Welding Automation:

As demands for precision, efficiency, and cost-effectiveness continue to escalate in the welding industry, the integration of AI has emerged as a game-changer. AI-driven robotic systems not only enhance productivity but also ensure a level of accuracy that was once unimaginable.

Key Benefits of Artificial Intelligence (AI) in Welding Automation:

Enhanced Precision: AI algorithms enable robots to analyze complex welding parameters in real-time, ensuring precise control of the welding process. This results in higher quality welds with minimal defects.

Adaptive Learning: AI-equipped robots have the ability to learn and adapt to variations in materials, joint geometries, and environmental conditions. This adaptive learning ensures optimal performance even in dynamic manufacturing environments.

Increased Efficiency: Automation driven by AI significantly speeds up the welding process. This not only boosts production rates but also reduces operational costs by minimizing downtime and resource wastage.

Quality Assurance: AI systems can perform continuous monitoring and analysis of weld quality, instantly detecting deviations from specified parameters. This proactive approach to quality assurance minimizes the chances of defects and rework.

Nikit Engineers Weld Labs: Offering a Free Weld Trial Service

At Nikit Engineers, we understand the importance of hands-on experience when it comes to adopting cutting-edge welding automation solutions. That’s why we invite you to take advantage of our Free Weld Trial Service at Nikit Engineers Weld Labs in Bangalore, India.

Our state-of-the-art Weld Labs provide a conducive environment for testing and optimizing welding processes using our AI-driven robotic solutions. Whether you are looking to improve efficiency, enhance precision, or simply explore the benefits of AI in welding automation, our team of experts is ready to assist you.

How to Avail the Free Weld Trial Service?

Click and Fill in the form – https://bit.ly/nikit-engineers-service-enquiry-form.

Schedule a visit to Nikit Engineers Weld Labs in Bangalore, India.

Experience firsthand the capabilities of our AI-driven robotic welding solutions with a complimentary weld trial on your component.

Conclusion:

The integration of Artificial Intelligence in welding automation is transforming the manufacturing landscape globally. Nikit Engineers continues to lead the way in providing innovative solutions that redefine efficiency, precision, and quality in welding processes. Take the first step toward revolutionising your welding operations by availing our Free Weld Trial Service at Nikit Engineers Weld Labs. Embrace the future of welding automation with the power of AI.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

0 notes

Text

Comprehensive Guide to Flexible Metal Hoses and Their Welding Process

In the world of industrial processes, where precision and flexibility are paramount, Flexible Metal Hoses and Their Welding Process play a pivotal role. These versatile components serve as conduits for conveying various media such as liquids, gases, and even solids in a wide range of applications. This comprehensive guide will explore the intricacies of flexible metal hoses, their welding processes, and their diverse uses across various industries.

Understanding Flexible Metal Hoses

1.1 What are Flexible Metal Hoses?

Flexible metal hoses are a type of flexible conduit designed to transport a variety of substances through their inner core while providing structural support through their outer metal casing. They are constructed using high-quality materials, most commonly stainless steel due to its exceptional strength and resistance to corrosion.

1.2 Construction and Components

Flexible metal hoses typically consist of the following components:

Inner Core: This is the primary conduit through which the media flows. It is constructed from materials compatible with the substance being transported, ensuring chemical compatibility and preventing contamination.

Braid Layer: Around the inner core, a layer of stainless steel or other suitable material braids provides structural reinforcement. The braid layer enhances flexibility while maintaining high-pressure capabilities.

Outer Jacket: The outer layer, usually made of stainless steel, acts as a protective shield, providing resistance to environmental factors such as heat, corrosion, and mechanical stress.

1.3 Types of Flexible Metal Hoses

– Corrugated Metal Hoses: These feature a helical or annular corrugated design for enhanced flexibility and pressure resistance.

– Annular Metal Hoses: These are constructed with a single-layer corrugation, providing excellent flexibility and absorption of axial movement.

– Helical Metal Hoses: Characterised by a spiral-shaped corrugation pattern, these hoses are ideal for applications demanding high flexibility and lateral movement.

Welding Processes for Flexible Metal Hoses

2.1 TIG Welding

Tungsten Inert Gas (TIG) welding is the most common welding process used for joining flexible metal hoses. It offers precise control, ensuring a clean, strong, and reliable weld. TIG welding minimises the risk of contamination and distortion, critical for maintaining the integrity of the hose’s inner core.

2.2 Spot Welding

In some cases, spot welding may be used to attach end fittings to the metal hose. This process involves localised heat application, making it suitable for specific applications where TIG welding is less practical.

Welding the Hoses with Ease

Applications Across Industries

3.1 Petrochemical Industry

Transporting Hazardous Chemicals: Flexible metal hoses are used to transport highly corrosive chemicals and liquids safely.

Heating and Cooling Systems: They are vital for conveying hot and cold fluids in industrial heating and cooling systems.

3.2 Aerospace Industry

Fuel and Hydraulic Systems: In aircraft, these hoses are employed to transport fuel and hydraulic fluids under high pressure and in demanding environmental conditions.

Engine Exhaust Systems: Flexible metal hoses are used to mitigate vibrations and movement in aircraft exhaust systems.

3.3 Food and Beverage Industry

Sanitary Transfer: In the food and beverage sector, these hoses are crucial for transferring liquids without contamination.

3.4 Pharmaceutical Industry

Sterile Fluid Transfer: They ensure the contamination-free transfer of pharmaceutical fluids and chemicals in a controlled environment.

3.5 Automotive Industry

Exhaust Systems: Flexible metal hoses are used in automotive exhaust systems to handle high-temperature exhaust gases and reduce vibrations.

Suspension Systems: They help manage suspension system movements in heavy-duty vehicles.

The Nikit Engineers Distinction: FREE Weld Trial

What distinguishes Nikit Engineers is their unwavering dedication to excellence and ingenuity, as epitomized by our FREE Weld Trial Services. This affords clients the opportunity to acquaint themselves with the unparalleled quality of Nikit Engineers’ welding services prior to embarking on a project.

Through the provision of cost-free weld trials, Nikit Engineers offer clients a tangible manifestation of their welding proficiency, enabling them to make well-informed decisions. This approach not only fosters trust but also underscores their steadfast commitment to delivering extraordinary outcomes.

Book Free Weld Trial Services

Flexible metal hoses are indispensable components that bridge the gap between the need for structural integrity and the demand for flexibility. Their construction, welding processes, and broad range of applications make them vital in various industries, ensuring the safe and efficient transportation of liquids, gases, and solids. As industries continue to evolve, flexible metal hoses will undoubtedly play an increasingly pivotal role in the future of manufacturing and automation. For reliable solutions in welding automation and robotic solutions related to flexible metal hoses, you can trust Nikit Engineers to meet your specific needs.

#robotics solutions#welding automation#Profile Wedling#orbital welding#circular welding#Semiconductor Manufacturing#linear welding

0 notes

Text

Power Efficiency in Profile Welding

Power Efficiency in Profile Welding: A Key Factor in Energy Savings

In the world of manufacturing, every little improvement counts. From reducing waste to saving energy, optimizing processes is vital to staying competitive. One often overlooked aspect of manufacturing is profile welding, and the importance of power efficiency in this process cannot be overstated. In this blog, we’ll delve into why power efficiency matters in profile welding, its impact on energy consumption, and how Nikit Engineers’ profile welders stand out in this regard.

Understanding Profile Welding

Profile welding is a crucial welding process widely used in various industries, including construction, automotive, and aerospace. It involves welding two or more pieces of metal together to create complex structures with precise shapes and dimensions. The key to successful profile welding lies in achieving strong, consistent, and high-quality.

The Role of Power Efficiency

Power efficiency in profile welding refers to how effectively electrical energy is converted into heat during the welding process. The efficiency of this conversion has a significant impact on the overall energy consumption of the welding operation.

Why Does Power Efficiency Matter?

Energy Savings: Efficient profile welding systems consume less electrical energy, resulting in lower operating costs. With rising energy prices, minimizing energy consumption is a smart financial move for manufacturers.

Environmental Impact: Reduced energy consumption translates to a smaller carbon footprint. By investing in power-efficient welding equipment, manufacturers can contribute to environmental sustainability.

Consistency and Quality: Power-efficient profile welding ensures that the heat is evenly distributed across the weld, resulting in consistent and high-quality welds. This is crucial for products that demand precision and reliability.

How Power Efficiency Affects Energy Consumption

The relationship between power efficiency and energy consumption is straightforward. Inefficient profile welding systems waste a significant amount of energy as heat escapes into the surroundings. This wasted energy not only drives up operational costs but also places unnecessary strain on power grids.

On the other hand, power-efficient profile welding systems convert a higher percentage of electrical energy into useful heat, minimising energy wastage. This not only reduces energy bills but also leads to a more sustainable manufacturing process.

Nikit Engineers’ Profile Welders: A Cut Above the Rest

When it comes to power efficiency in profile welding, Nikit Engineers’ profile welders are leading the way. Here’s how they excel in this aspect:

Innovative Technology: Nikit Engineers continuously invest in research and development to improve the power efficiency of their profile welders. They incorporate cutting-edge technology that maximises energy conversion while minimising waste.

Optimised Welding Parameters: Nikit Engineers’ profile welders come with pre-programmed welding parameters that are optimised for efficiency. This eliminates the need for trial-and-error settings adjustment, saving both time and energy.

Heat Management: These profile welders are designed to manage heat effectively, ensuring that it is directed precisely where it’s needed for the weld. This results in minimal heat loss to the environment.

In the world of manufacturing, every small improvement adds up, and power efficiency in profile welding is no exception. By investing in power-efficient profile welders like those offered by Nikit Engineers, manufacturers can reduce energy consumption, lower operational costs, and contribute to a more sustainable future.

In summary, power efficiency in profile welding matters because it saves energy, reduces environmental impact, and ensures consistent, high-quality welds. Nikit Engineers’ commitment to innovation and customization makes them a standout choice for manufacturers looking to maximize power efficiency in their welding processes.

The Nikit Engineers Distinction:

What truly distinguishes Nikit Engineers is our unwavering dedication to excellence and innovation, epitomized by our Free Weld Trial Service. This unique procedure empowers clients to personally witness the outstanding quality of Nikit Engineers’ welding machineries and services, assuring them before they even embark on a project.

Through the provision of complimentary weld trials, Nikit Engineers offers a concrete showcase of our welding prowess on your components, empowering clients to make well-informed decisions. This bold approach not only fosters trust but also reinforces our steadfast commitment to delivering unparalleled results.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineer

0 notes

Text

Nikit Engineers – Weld Process System – Quarter Trial Report

Nikit Engineers’ Weld Process System (WPS): A Quarter of Excellence in Welding Across Diverse Industries

Report for the Third Quarter of 2023 (Week 26 to Week 39)

Welding is a fundamental process in the manufacturing and assembly of various industrial components across different sectors. In the third quarter of 2023 of our Weld Process System, Nikit Engineers undertook an extensive range of welding projects spanning a multitude of industries, reinforcing their reputation as leaders in the field of welding. This report provides an overview of the diverse components and industries where Nikit Engineers Welding Automation & Robotics Solutions India showcased their expertise during this period.

Muffler Bracket Welding – Infrastructure Industry

One of the notable projects undertaken by Nikit Engineers involved the welding of muffler brackets for the infrastructure industry. The Circular Welding process was employed to ensure precision and durability in the brackets used in heavy machinery such as excavators.

Boom Pipe End Fitting Welding – Infrastructure Industry

Nikit Engineers also demonstrated their welding prowess in the infrastructure sector by welding boom pipe end fittings. This process is critical for the structural integrity of equipment used in construction and infrastructure development.

Bellow Assembly Plate Welding – Oil and Gas Industry

The oil and gas industry demands the highest standards of welding, and Nikit Engineers delivered with precision in welding bellow assembly plates, vital components for maintaining the integrity of pipelines and equipment in this sector.

Connector & Tube Welding – Automotive Industry

In the automotive industry, where safety and reliability are paramount, Nikit Engineers showcased their expertise by welding connectors and tubes. These components are crucial for fluid systems within vehicles.

Stainless Steel Flange to Tube Welding – Pharmaceutical Industry

Meeting stringent quality requirements, Nikit Engineers skilfully executed stainless steel flange to tube welding for the pharmaceutical industry. Such precision is vital to maintaining hygiene and product integrity in pharmaceutical processes.

Aluminium IP Rated Electric Panel Box Welding – Electrical Industry

The electrical industry relies on precise welding for various components, including IP-rated electric panel boxes. Nikit Engineers ensured the durability and safety of these crucial components through their welding expertise.

Flexible Hose Welding – Micro-conductor Industry

In the microconductor industry, flexibility and precision are key. Nikit Engineers’ welding capabilities were on full display as they expertly welded flexible hoses used in delicate microconductor applications.

Case to Socket Welding – Pressure Gauge Vessel and Oil and Gas Industry

In another venture within the oil and gas sector, Nikit Engineers excelled in case-to-socket welding for pressure gauge vessels. This demonstrates their commitment to maintaining the safety and reliability of critical equipment.

Thermal Battery Welding for Defence Launch Missiles – Defence Industry

The defence industry demands the utmost precision and reliability. Nikit Engineers proved their mettle by delivering exceptional thermal battery welding services for missile launch systems.

Nut Tack Welding of Automobile Components – Automotive Industry

Nikit Engineers contributed to the automotive industry by executing nut tack welding for various automobile components. This process is vital for the structural integrity and safety of vehicles.

Rocker Body with Pin Tig Fusion Tack Welding – EV Industry

As the electric vehicle (EV) industry surges forward, Nikit Engineers played a pivotal role in ensuring the quality of EV central locking assembly through expert rocker body with pin Tig fusion tack welding.

Face Welding of Flange & Shaft with MIG Welding – Infrastructure Industry

Another significant project in the infrastructure sector was the face welding of flanges and shafts using MIG welding. This process ensures the structural integrity of heavy machinery components.

X-ray Machines Cathode and Anode Assembly Welding – Medical Industry

In the medical industry, precision is non-negotiable. Nikit Engineers demonstrated their commitment to quality by expertly welding cathode and anode assemblies for X-ray machines.

Port Welding Fluid Transfer Unit for Injection Molding Machines – Injection Molding Industry

Nikit Engineers also showcased their versatility by welding fluid transfer units for injection molding machines. This demonstrates their ability to cater to diverse industrial needs.

Pressure Vessels Welding

The oil and gas sector relies heavily on pressure vessels, and Nikit Engineers showcased their expertise in welding these critical components to exacting standards.

Stainless Steel and Mild Steel Tanks

The food and pharmaceutical industries, among others, demand impeccable welds for their storage tanks. Nikit Engineers ensured the highest quality welds on both stainless steel and mild steel tanks.

Fluid Transfer Unit for Injection Moulding Machines

Precision is paramount in injection molding. Nikit Engineers successfully contributed to the production of fluid transfer units, ensuring flawless welds that enhance the efficiency of these machines.

Stellite Welding

Often used in extreme environments, Stellite welding is a challenging task. Nikit Engineers exhibited their prowess in working with this specialized material.

Foot Rest Welding

In the automotive sector, footrests are crucial for safety and comfort. Nikit Engineers’ precise welding ensures the integrity of these components.

https://i0.wp.com/nikitengineers.in/wp-content/uploads/2023/09/Weld-Trial-Components-by-Nikit-Engineers.png?w=1920&ssl=1

Oil and Gas Pipeline Pressure Vessels

With the growing demands of the energy sector, Nikit Engineers played a vital role in welding pressure vessels that are pivotal to oil and gas pipelines’ safe operation.

Stainless Steel Float Ball Welding

The chemical industry relies on precise float ball welding to maintain consistent fluid levels. Nikit Engineers met this requirement with precision.

Flange Welding

Flanges are ubiquitous in various industries, and Nikit Engineers consistently delivered reliable and durable flange welds.

Stainless Steel Linear Welding

Precision linear welding is essential in industries where hygienic conditions are paramount. Nikit Engineers excelled in this aspect.

Front Crash Guard

Ensuring vehicle safety, front crash guards require robust welding. Nikit Engineers contributed to the safety of automotive users with their welding expertise.

3-Wheeler EV Base Frame Welding

In the era of electric vehicles, the EV base frame welding by Nikit Engineers played a role in shaping the future of transportation.

End Cap Welding of Fluid Transfer

Besides fluid transfer units, Nikit Engineers also delivered precise end cap welds, ensuring leak-free performance.

Bourdon Tube End Cap Welding

Accuracy in Bourdon tube end cap welding is vital for pressure measurement instruments. Nikit Engineers demonstrated their commitment to precision.

Fluid Pressure Tank End Cap, Nozzle, Inlet, and Outlet Port Welding

These components are integral to various industries, and Nikit Engineers’ welding prowess ensured their reliability.

The Nikit Engineers Difference: Free Weld Trial Process

What sets Nikit Engineers apart is their commitment to quality and innovation, exemplified by their Free Weld Trial Process. This process allows clients to experience the exceptional quality of Nikit Engineers’ welding services before committing to a project.

By offering free weld trials, Nikit Engineers provide a tangible demonstration of their welding capabilities, helping clients make informed decisions. This approach not only builds trust but also underscores their commitment to delivering exceptional results.

Book Free Weld Service

At, Nikit Engineers Welding Automation & Robotics Solutions India our commitment to precision, quality, and safety is evident across these diverse welding projects. Our Free Weld Trial Process continues to set a benchmark in the welding industry, providing clients with the assurance of excellence in every weld. As we navigate various industries with our expertise, we reinforce our position as leaders in the welding industry, driven by a dedication to craftsmanship and reliability.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

Types of Orbital Welding and Their Applications in Welding Services

In the world of welding automation and robotics solutions, it’s crucial to understand the different types of orbital welding processes available and how they can benefit your welding services. In this blog, we’ll delve into various forms of orbital welding techniques without getting lost in marketing jargon. Our aim is to provide you with factual information to help you make informed decisions for your welding projects.

TIG Orbital Welding:

Tungsten Inert Gas (TIG) orbital welding is known for its precision and clean results. It’s commonly used in industries where the weld quality must meet the highest standards, such as aerospace and pharmaceuticals. TIG orbital welding ensures a controlled arc, minimal heat input, and superior weld integrity.

MIG Orbital Welding:

Metal Inert Gas (MIG) orbital welding is all about efficiency and speed. It’s frequently employed in high-production environments, like automotive manufacturing. MIG welding uses a consumable electrode and an inert gas to protect the weld pool, making it ideal for joining thicker materials quickly.

Plasma Orbital Welding:

Plasma orbital welding offers the advantage of extremely high temperatures, making it suitable for welding exotic materials such as titanium and superalloys. It produces precise, clean welds with minimal distortion.

Gas Metal Arc Welding (GMAW):

GMAW, also known as MIG welding, is versatile and widely used. It’s perfect for a variety of materials and applications. GMAW orbital welding is appreciated for its adaptability and ease of automation.

https://i0.wp.com/nikitengineers.in/wp-content/uploads/2023/09/nikit-engineers-india-types-of-orbital-welding-and-their-applications-in-welding-services.png?w=700&ssl=1

Flux Core Arc Welding (FCAW):

Flux core arc welding is a preferred choice for outdoor welding applications, thanks to its ability to handle windy conditions. It utilizes a tubular wire filled with flux to protect the weld pool from environmental factors.

Gas Tungsten Arc Welding (GTAW):

Gas Tungsten Arc Welding, or TIG welding, is the go-to choice for precise, high-quality welds. It excels in applications where weld appearance and quality are paramount.

Submerged Arc Welding (SAW):

Submerged arc welding is commonly used for welding thick materials. It involves a granular flux that covers the weld, reducing the risk of spatter and ensuring a solid, reliable weld.

Laser Beam Arc Welding:

Laser beam arc welding is a cutting-edge technology that utilises a laser to create the weld. It’s highly precise and can be used for a variety of materials. Its speed and accuracy make it a valuable tool in modern welding automation.

At Nikit Engineers Welding Automation & Robotics Solutions, we understand that the right welding process can significantly impact your productivity and bottom line. By selecting the appropriate orbital welding method for your specific needs, you can save time, money, and resources while achieving consistently high-quality welds.

If you’re looking to optimize your welding processes through automation and robotics, reach out to us. We’re here to provide you with practical solutions tailored to your unique requirements. Let’s work together to take your welding services to the next level.

First-Hand Experience: Free Weld Trial Services

At Nikit Engineers, we wholeheartedly embrace the notion of “Seeing to Believe.” To provide a true grasp of the transformational potential inherent in our Welding Automation & Robotics Solutions, we extend the offer of Free Weld Trial Services. This immersive, hands-on encounter equips manufacturers with the means to witness our technology’s prowess in action while evaluating its harmonization with their specific components.

During these trial sessions, the Nikit Engineers team collaborates in close tandem with our valued clients, diligently discerning their unique requirements and skillfully fashioning bespoke solutions that seamlessly align with their overarching objectives. This bespoke and client-centric approach serves to distinguish us and underlines our unwavering dedication to ensuring our clients’ utmost satisfaction.

Book Free Weld Service

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

#Welding Automation#Robotics Solutions#Orbital Welding#Circular Welding#Linear Welding#Stainless Steel Welding#Profile Wedling

0 notes

Text

Enhancing Productivity and Precision in Hydraulic Port Welding: A Success Story

In the ever-evolving domain of welding automation and robotics solutions, the pursuit of heightened productivity and cost-effectiveness remains an enduring goal for businesses across diverse industries. A pivotal facet of Precision in Hydraulic Port Welding within the manufacturing sector revolves around the connectors found on pressure vessels, storage tanks, and hydraulic cylinders. For organizations seeking to optimize their welding procedures and bolster operational efficiency, Nikit Engineers Welding Automation & Robotics Solutions India has effectively addressed these challenges, as demonstrated by our comprehensive case study featuring esteemed clients such as Rane Madras, Wipro Hydraulics, Fabricators India, Preac, and Dynaforce.

Background:

Pressure vessels, storage tanks, and hydraulic cylinders serve as indispensable components in industries such as automotive, hydraulic systems, and heavy machinery. The integrity and longevity of these components hinge on the provision of precise and enduring welding solutions.

Client Challenges:

Our clients encountered several shared challenges in hydraulic port welding, encompassing:

Precision Demands: The necessity for precision welding loomed large to uphold the structural integrity of these critical components.

Time Optimization: Swift turnaround times stood as a paramount requirement to meet the relentless demands of production.

Consistency Imperative: The need for unwavering weld quality across numerous units was of utmost importance.

Our Approach to Precision in Hydraulic Port Welding:

Nikit Engineers’ cadre of welding automation specialists employed a comprehensive approach to surmount these challenges. Here is a glimpse of how we accomplished success:

Cutting-Edge Robotic Welding Technology:

We seamlessly integrated state-of-the-art robotic welding systems, meticulously tailored to the unique requisites of each client. These systems facilitated pinpoint accuracy and unwavering consistency in welding, thereby diminishing human errors and augmenting efficiency.

Bespoke Welding Protocols:

Our adept engineering team meticulously crafted customized welding programs, fine-tuning variables such as welding speed, arc length, and heat input to harmonize with the distinct demands of each project.

Stringent Quality Assurance:

We rigorously implemented quality control measures encompassing non-destructive testing and visual inspections, which were seamlessly woven into the fabric of the welding process. This ensured the perpetuation of consistently high-caliber welds.

Process Optimisation:

We fine-tuned the welding process to minimize superfluous movements and maximize speed without compromising the quality of welds.

Results for Welding Automation:

The outcomes of our hydraulic port welding ventures were nothing short of remarkable:

Elevated Precision: Our robotic welding systems consistently delivered meticulous welds, impeccably aligning with the most exacting quality benchmarks.

Augmented Productivity: Clients witnessed a substantial reduction in welding cycle times, thus enabling them to proficiently meet their production objectives.

Cost-Efficiency: Decreased labor expenditures, minimal rework, and diminished material wastage contributed to cost savings for our clients.

Quality Assurance: Our stringent quality control procedures guaranteed that each component adhered to the stipulated specifications, thereby enhancing product reliability.

Client Testimonials:

Dynaforce: “Nikit Engineers’ solutions have proven invaluable in our quest for efficiency and precision. We couldn’t be happier with the results.”

Kalki: “Nikit Engineers’ solutions have proven invaluable in our quest for efficiency and precision. We couldn’t be happier with the results.”

Conclusion:

Nikit Engineers Welding Automation & Robotics Solutions India has consistently yielded exceptional outcomes in hydraulic port welding for pressure vessels, storage tanks, and hydraulic cylinders. Our unwavering dedication to precision, efficiency, and cost-effectiveness has firmly established us as the preferred choice for industry leaders such as Rane Madras, Wipro Hydraulics, Fabricators India, Preac, and Dynaforce.

If your organization aspires to boost productivity, elevate welding quality, and trim costs, we cordially invite you to delve into our welding automation solutions. Contact us today to explore how Nikit Engineers can catalyze a transformation in your welding processes, just as we have for our esteemed clientele.

First-Hand Experience: Free Weld Trial Services

At Nikit Engineers, we adhere to the principle of “Seeing is Believing.” To genuinely grasp our Welding Automation & Robotics Solutions’ transformative potential, we extend Free Weld Trial Services. This hands-on encounter empowers manufacturers to observe our technology’s capabilities in action and assess its compatibility with their components.

Throughout these trials, the Nikit Engineers team collaborates closely with clients, comprehending their needs, and designing tailored solutions that align with their objectives. This personalised approach distinguishes us and underscores our commitment to client contentment.

In conclusion, The landscape of industrial manufacturing is evolving, and Nikit Engineers spearheads this evolution with our Welding Automation & Robotics Solutions. Through rigorous R&D Weld Trials, we showcase our dedication to innovation, precision, and efficiency. The Complimentary Weld Trial Services we provide present a unique chance for industries to embrace the future of welding firsthand. As automation gains traction across industries, the Nikit Engineers team stands prepared to revolutionise welding processes, one component at a time.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

#Welding Automation#Robotics Solutions#Orbital Welding#Circular Welding#Linear Welding#Port Welding#Profile Wedling

0 notes

Text

R&D Weld Trials Services for Industrial Components

Research and Development, Weld Trials Services for Industrial Components: Nikit Engineers’ Advanced Welding Automation & Robotics Solutions in India

In the fast paced era of industrial manufacturing, welding plays a vital role in ensuring the strength and endurance of components. As industries progress and demand greater efficiency and accuracy, creative solutions become indispensable. Nikit Engineers, a pioneering force in Welding Automation & Robotics Solutions in India, leads the charge in this transformation. Upholding a commitment to excellence, we have carried out extensive Research and Development (R&D) Free Weld Trials Services on diverse industrial components, providing an exceptional opportunity to engage with our state-of-the-art technology firsthand.

Progressing Welding Automation & Robotics

At Nikit Engineers, we consistently strive to redefine welding technology’s boundaries. Our determination to innovate has led us to conduct rigorous R&D Weld Trials. These trials serve as proof of our dedication to inventive solutions and our eagerness to deliver cutting-edge offerings to various industries.

R&D Weld Trials Advantages

Nikit Engineers’ R&D Weld Trials bring a multitude of advantages that directly contribute to enhancing industrial manufacturing processes:

Precision and Uniformity: Welding Automation & Robotics Solutions eliminate the inconsistencies that often accompany manual welding processes. The R&D trials reveal how our automation guarantees precise and consistent welds, resulting in top-notch products.

Enhanced Efficiency: Automation significantly accelerates welding procedures, leading to increased production rates and shorter lead times. The trials illustrate how welding automation solutions optimise efficiency without compromising quality.

Cost Reduction: By minimising human errors and maximising resource utilisation, welding automation trims overall production costs. The trials offer a clear depiction of how businesses can conserve resources and enhance their financial performance.

Improved Safety: Welding automation bolsters workplace safety by minimising human involvement in potentially hazardous tasks. The trials emphasise how our welding automation and robotic solutions prioritise worker well-being.

Tailored Adaptability: Every industrial component possesses uniqueness. Nikit Engineers’ R&D Weld Trials emphasise our capacity to customise our automation and robotics solutions to fit specific component demands, ensuring seamless integration into existing workflows.

Key Highlights of Nikit Engineers’ R&D Weld Trials Services:

Methodical Precision: Each trial is meticulously planned and executed, showcasing Nikit Engineers’ dedication to accuracy and scientific excellence. The trials encompass various welding processes, including MIG/MAG, TIG, and spot welding, ensuring a comprehensive grasp of diverse techniques.

Data-Driven Evaluation: Data collected during the trials form the basis for well-informed decision-making. Through thorough analysis, trends are identified, and critical parameters are optimised to achieve the finest quality welds. This data-centric approach generates actionable insights for process enhancement.

Innovative Strategies: The R&D Weld Trial Services Reports explore inventive solutions that push the boundaries of welding technology. Whether it involves exploring novel filler materials, adapting to varying joint geometries, or optimising robot paths, these reports attest to the company’s inventive spirit.

Real-World Applicability: The trials are structured to replicate real-world scenarios and challenges, ensuring that the solutions derived from the reports are not just theoretical but also practically applicable across industries.

First-Hand Experience: Free Weld Trial Services

At Nikit Engineers, we adhere to the principle of “Seeing is Believing.” To genuinely grasp our Welding Automation & Robotics Solutions’ transformative potential, we extend Free Weld Trial Services. This hands-on encounter empowers manufacturers to observe our technology’s capabilities in action and assess its compatibility with their components.

Throughout these trials, the Nikit Engineers team collaborates closely with clients, comprehending their needs, and designing tailored solutions that align with their objectives. This personalised approach distinguishes us and underscores our commitment to client contentment.

In conclusion, The landscape of industrial manufacturing is evolving, and Nikit Engineers spearheads this evolution with our Welding Automation & Robotics Solutions. Through rigorous R&D Weld Trials, we showcase our dedication to innovation, precision, and efficiency. The Complimentary Weld Trial Services we provide present a unique chance for industries to embrace the future of welding firsthand. As automation gains traction across industries, the Nikit Engineers team stands prepared to revolutionise welding processes, one component at a time.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

The Future of Welding and Welding Technologies

The Future of Welding and Welding Technologies: A Glimpse into Innovative Horizons

In the dynamic world of industrial advancements, where innovation reigns supreme, the field of welding is no exception. Welding, once considered a traditional trade, has evolved into a realm of cutting-edge technologies that are reshaping the way we think about metal joining. As Nikit Engineers, with our decades of welding expertise, we’re excited to guide you through the exciting journey of the future of welding and the revolutionary welding technologies that are propelling it forward.

Welding: A Soothing Symphony of Art and Science

Welding has a remarkable history dating back thousands of years. It marries artistry and science, transforming raw materials into intricate structures that power industries worldwide. Our commitment to welding excellence for over 40 years has shown us that this age-old craft is still an evolving canvas, ready to embrace modern techniques.

The Rise of Automation: Precision with Minimal Activity

As industries look for ways to enhance productivity and quality, welding automation takes centre stage. Our brand, ‘nikit,’ stands as a testimony to the successful fusion of human ingenuity and automation. With over 1200 welding machines and 300+ welding automation installed, we understand the profound impact automation has on industries, from Hydraulic to Medical sectors. Quality Assurance and Regulatory Compliance

“Automation is not about replacing skilled hands; it’s about enhancing skilled minds.” – Nikit Engineers

Navigating Trends and Needs: Staying Ahead of the Curve

The welding landscape is ever-changing, and staying ahead requires not just embracing trends but also anticipating needs. At Nikit Engineers, we believe in being a step ahead of customer expectations. This vision has propelled us beyond competitors, making customer service and satisfaction our ultimate goal.

Quality, Lean Operation, and Peak Performance of Welding Technologies

The future of welding is synonymous with quality, efficiency, and outstanding performance. As we move forward, technologies like laser welding, friction stir welding, and ultrasonic welding are set to redefine industry standards. Our commitment to delivering the most functional and high-quality automation is unwavering.

https://i0.wp.com/nikitengineers.in/wp-content/uploads/2023/08/the-future-of-welding-and-welding-technologies-a-glimpse-into-innovative-horizons-nikit-engineers-welding-automation-robotic-solutions.png?w=700&ssl=1

A Seamless Integration of Humans and Machines

While automation takes the spotlight, the human touch remains irreplaceable. Skilled welders continue to be the driving force behind every innovation. The future of welding seamlessly integrates the capabilities of both humans and machines, creating a harmonious symphony of precision and expertise.

Embracing the Future of Welding Technologies: A Collaborative Journey

The future of welding is a collaborative journey, with experts, engineers, and industries working hand in hand. As Nikit Engineers, we’re dedicated to standing by your side, every step of the way. Our brand is built on the pillars of innovation, excellence, and customer service, and we invite you to join us as we explore the uncharted territories of welding’s tomorrow.

Advantages of Nikit Engineers’ Welding Solutions:

Enhanced Productivity: Automation and robotics eliminate the need for repetitive manual tasks, allowing skilled workers to focus on more complex aspects of welding.

Consistent Quality: Automation ensures uniformity in welds, minimizing defects and variations in the final product.

Reduced Downtime: Nikit Engineers’ solutions offer reliable performance, leading to reduced downtime and increased overall efficiency.

Safety: With robots handling intricate and hazardous welding tasks, the safety of human workers is significantly improved.

In conclusion, the future of welding is a thrilling expedition into realms of automation, innovation, and collaborative progress. At Nikit Engineers, we’re proud to be part of this journey, and we invite you to embark on it with us. As the welding landscape evolves, our commitment to excellence remains steadfast, and we look forward to shaping the future of welding, together.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

Exploring Welding Automation and Robotics: Unveiling Opportunities with Nikit Engineers

Explore the world of welding automation and robotics with Nikit Engineers, a pioneering name in the field. Discover how automation revolutionizes welding, enhances precision, and unlocks opportunities across industries. Dive into their 40-year expertise and commitment to excellence.

In today’s rapidly evolving industrial landscape, where efficiency and precision are paramount, the integration of robotics and automation has revolutionized various sectors. One such sector that has witnessed remarkable transformation is welding. Nikit Engineers, a name synonymous with welding automation excellence, has been at the forefront of this revolution, driving innovation and productivity across industries. In this blog, we delve into the world of welding automation and robotics, uncovering the vast opportunities it offers, with insights from Nikit Engineers’ expertise.

The Evolution of Welding: A Paradigm Shift

The Evolution of Welding Automation A Paradigm Shift

Welding, a fundamental process in fabrication and manufacturing, has traditionally relied on skilled manual labor. However, with advancements in technology, the welding landscape has experienced a paradigm shift. Automation and robotics have emerged as game-changers, optimizing processes, enhancing precision, and increasing productivity.

Nikit Engineers, boasting over 40 years of welding expertise, recognized the need for automation in welding applications. With a commitment to excellence and customer satisfaction, they’ve manufactured and installed more than 1200 welding machines and 300+ welding automation systems across various industries. Their mission to deliver the highest quality, lean operative, and high-performance automation solutions speaks volumes about their dedication to customer service.

Unleashing Opportunities through Robotics Welding Automation

Enhanced Precision: Welding automation ensures consistent and accurate welds, eliminating human error. Nikit Engineers’ robotics solutions provide a level of precision unattainable through manual welding, particularly in complex applications.

Increased Productivity: Automation significantly boosts productivity by reducing cycle times and enabling continuous operation. This is especially crucial in industries with high-volume production demands.

Cost Efficiency: While initial investment may be higher, automation pays off in the long run. Reduced rework, decreased material wastage, and enhanced energy efficiency contribute to cost savings.

Safety Advancements: Welding automation improves worker safety by minimizing exposure to hazardous environments. Human operators can focus on supervising and programming, mitigating potential health risks.

Versatility and Adaptability: Nikit Engineers’ welding robotics solutions are designed to cater to various industries, from hydraulic to medical. The adaptability of automation systems allows for seamless integration into diverse manufacturing processes.

Quality Consistency: Consistency is a hallmark of automation. With programmed parameters, every weld is executed with precision, resulting in uniform quality across the production line.

Nikit Engineers: Pioneering Excellence in Welding Automation

With a legacy spanning four decades, Nikit Engineers has proven itself as a pioneering force in welding automation and robotics solutions. Their commitment to customer relationships is evident through year-round service warranties, ensuring clients’ peace of mind.

Through their holistic approach to automation, Nikit Engineers caters to every vertical of the industrial sector. Their in-depth understanding of customer needs and industry trends places them miles ahead of competitors. Their ultimate vision of customer service and satisfaction remains the driving force behind their operations.

Shaping the Future of Welding through Automation

The fusion of welding and robotics is a remarkable illustration of technological advancement and its positive impact on industries. Nikit Engineers’ unwavering dedication to delivering the highest quality welding automation solutions has propelled them to the forefront of the industry.

As industries continue to embrace automation, Nikit Engineers stands as a beacon of innovation, transforming welding from a labor-intensive process to a precise, efficient, and reliable operation. Their journey is a testament to the limitless opportunities presented by welding automation and robotics in the modern world.

In the ever-evolving landscape of industrial automation, Nikit Engineers remains by your side—The Welding People.

Why Choose Nikit Engineers?

At Nikit Engineers, we understand the diverse needs of industries, ranging from hydraulic to medical sectors. Our commitment to delivering exceptional service is evident through our year-round service warranty and unwavering dedication to customer relationships. we aim to for customer satisfaction, as we continually strive to outperform competitors by staying ahead of industry trends and understanding customer needs.

Nikit Engineer’s welding automation and robotic solutions are built on a foundation of quality, efficiency, and performance. As a result, we aim to transform labor-intensive processes into highly productive ones, all while maintaining the highest standards of operational excellence. With a customer-centric approach, Nikit Engineers is your trusted partner in achieving welding automation and robotic solutions that drive results.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. Subsequently we offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

Boosting Market Share: Nikit Engineers Free Demo Welding Services Tripled Our Success

Enhancing Market Share: How Nikit Engineers’ Free/Demo Welding Services Tripled Our Success

Discover how Nikit Engineers revolutionised the manufacturing and engineering industry with free/demo services, propelling market share and revenue to new heights. Explore our innovative Demo Welding Services today.

In the dynamic world of manufacturing and engineering, setting yourself apart from competitors is crucial. Nikit Engineers has uncovered a game-changing strategy that not only skyrocketed revenue but also catapulted our market share to unprecedented levels. Our secret weapon? Harnessing the potential of free/demo services for cutting-edge welding components.

Unveiling Innovation Through Demo Welding Services

Imagine a platform showcasing the capabilities of cutting-edge welding machines – that’s what our demo services offer. In 2022, we introduced a groundbreaking concept: a dedicated space for circular welders, orbital welders, linear welders, and profile welders. This platform became the catalyst for our journey towards dominance in the market.

Our demo services garnered global attention. Clients from Israel, Iraq, and partners like Marshall joined us, eager to experience our innovations firsthand. What began as a simple demonstration transformed into a game-changing encounter for potential customers, they saw their welding challenges being addressed, concerns eased, and projects brought to life.

From Trial to Triumph: Transforming Market Share

The results were remarkable. Our commitment to showcasing product value through free trials led to a surge in market penetration. Revenue followed suit, experiencing an impressive threefold increase. This growth wasn’t just financial; it mirrored the trust earned from customers who witnessed our machines in action.

A fundamental shift paid off. We moved from the traditional model of quoting and hoping for a sale to a proactive strategy of demonstrating real solutions. By illustrating the tangible benefits of our innovations, inquiries transformed into lasting partnerships.

Setting a New Industry Benchmark

Our success story isn’t just ours; it’s about reshaping industry norms. We firmly believe every company in our field should establish a demo center. Offering free demonstrations builds trust and showcases revolutionary capabilities. We advocate an open trend where companies prioritize adding value to clients before monetary transactions.

Our demo services have evolved from serving a few clients to accumulating a months-long waitlist. Our dedicated team, once focused on sales, now thrives in Research and Development. This transition allows us to refine products, ensuring successful welding joints.

Sustaining Success and Future Outlook

Approaching eight months since introducing demo services, our portfolio has expanded dramatically. Since December 2022, we’ve ventured into new markets, broadened our reach, and embraced growth opportunities. This trajectory underscores the power of innovation, customer-centricity, and the belief that free demo services can shape industry’s future.

In conclusion, Nikit Engineers harnessed the potential of free/demo services to not just triple market share and revenue, but redefine industry standards. Our journey underscores that prioritising client needs and showcasing value can lead to unparalleled success. As we inspire change within our sector, we invite you to join us on the path towards innovation, growth, and endless possibilities.

At Nikit Engineers, we understand that each application is unique, and we work closely with our customers to develop customised welding solutions that meet their specific needs. We use the latest technology and equipment to ensure that our welding solutions are efficient, reliable, and cost-effective. We also offer training and support services to ensure that each welding process works efficiently.

Nikit Engineers Robotic Welding Automation Solutions are proud to say that all our products are #MADEININDIA and #MADEFORINDIA

Check out our other industrial ventures thewelder.in and civilautomation.com

Shop our Products on Amazon India – www.amazon.in/nikit-MiLW

Don’t forget to subscribe our YouTube Channel for latest videos and updates – www.youtube.com/@Nikitengineers

0 notes

Text

Revolutionising Welding Automation and Robotic Solution at Lam Research India Pvt. Ltd

Nikit Engineers Revolutionizing Welding Automation and Robotic Solution at Lam Research India Pvt. Ltd: A Case Study on Connector Tubes welded by Orbital Welder

Lam Research India Pvt. Ltd, a leading semiconductor manufacturing company, faced a significant challenge in their production process: welding connector tubes with high precision and consistency. The conventional manual welding methods were time-consuming, error-prone, and hindered the company’s ability to meet increasing demand. Recognizing the need for a cutting-edge solution, Lam Research India partnered with Nikit Engineers, a renowned provider of welding automation and robotic solutions in India. This case study explores how Nikit Engineers’ Orbital Welder revolutionized Lam Research India’s welding process, resulting in increased efficiency, superior quality, and significant cost savings.

The Challenge:

Lam Research India faced a significant challenge in welding connector tubes with precision and consistency due to complex configurations and tight tolerances. Manual welding methods resulted in inconsistent quality, prolonged production times, and safety risks for welders. The company sought an advanced and reliable solution to enhance their manufacturing capabilities.

Partnership with Nikit Engineers:

To address the welding challenges, Lam Research India partnered with Nikit Engineers, a trusted provider of cutting-edge welding automation technologies. The collaboration aimed to implement Nikit Engineer’s Orbital Welder, a state-of-the-art robotic welding system, to optimize the connector tube welding process.

Implementation and Benefits of Welding Automation and Robotic Solution:

Advanced Robotic Welding System:

Nikit Engineers integrated their Orbital Welder into Lam Research India’s production line, creating a fully automated welding solution. The system features an orbital mechanism with a high-precision welding torch, advanced auto-correction system, and intelligent control software.

Precise and Consistent Welds:

The Orbital Welder’s advanced correction system accurately identifies welding points and adjusts the torch position, ensuring precise alignment and consistent high-quality welds. This automated process reduces errors and eliminates the need for rework, resulting in significant time and resource savings.

Enhanced Efficiency and Productivity:

Automating the welding process with the Orbital Welder increased production efficiency at Lam Research India. The continuous operation of the robotic system reduced downtime and eliminated the dependency on skilled manual welders. This optimized workforce allocation, enhancing overall productivity.

Quality Assurance and Compliance:

The Orbital Welder ensured strict adherence to quality standards and specifications. The system monitored critical welding parameters in real-time, such as arc voltage, current, and torch position, minimizing variations in weld quality. Consistently meeting quality requirements enhanced customer satisfaction and compliance with industry standards.

Future Scalability and Expansion:

Following the success of the Orbital Welder, Lam Research India is exploring the possibility of deploying Nikit Engineers’ automation solutions for other welding applications within their manufacturing operations.

Welding Automation and Robotic Solution Conclusion:

Nikit Engineers’ Orbital Welder revolutionized Lam Research India Pvt. Ltd.’s connector tube welding process. The automated system improved weld quality, productivity, compliance with quality standards, and prioritized employee safety. This case study showcases the immense potential of advanced welding automation and robotic solutions in transforming manufacturing processes for a more efficient and technologically advanced future.

Thank You Note

We extend our sincerest gratitude to Mr. Vivek CS and Mr. Praveen for their invaluable support and recommendation of Nikit Engineers as the best value experts for Lam Research. Their trust in our capabilities and expertise has fostered a strong and mutually beneficial relationship between our organizations.

Your keen eye for quality and recognition of the value we bring to the table have not only been encouraging but also a significant boost to our team’s morale. We are thrilled to work with Lam Research and contribute to the success of this and future projects.

Through collaborative efforts and partnerships like these, we continue to grow and excel in our field. Rest assured, we will strive for excellence in our services and uphold the standards that have earned your trust.

About Lam Research India Pvt. Ltd

Lam Research India Pvt. Ltd is a subsidiary of Lam Research Corporation, a leading global provider of advanced semiconductor equipment and services. The company specializes in developing and manufacturing cutting-edge semiconductor processing equipment, including etch, deposition, and clean solutions.

Committed to research and development, Lam Research India stays at the forefront of semiconductor technology advancements. Its dedication to quality, reliability, and customer satisfaction has earned it a trusted partner status in the semiconductor industry.