Text

Valve suppliers in UAE

Are you in need of high-quality valves for your industrial operations in UAE? Look no further! Middleeast Valve is one of the leading Valve suppliers in UAE

Description:

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminium Bronze, Bronze, Brass, F55, F53, F51, Inconel, Incoloy, Titanium

Class: 150 to 2500

Nominal Pressure: PN6 to PN450

Size: ½” to 80”

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded

Operations- Pneumatic actuated, Electric Actuated, Gear Operated, Lever Operated, Handwheel Operated

0 notes

Text

Triple Duty Valve supplier in UAE

Middleeast valve is the foremost Triple Duty Valve supplier in UAE. We supply to cities like Sur, Nizwa, Sohar, and Seeb.

A triple duty valve is a type of valve used in heating and cooling systems that serves three functions: shut-off valve, check valve, and balancing valve. As the name suggests, a triple duty valve combines the functionality of three different types of valves into one unit. This valve is designed to stop the flow of fluid in a pipeline as a shut-off valve, prevent back flow of fluid in the pipeline as a check valve, and regulate the flow of fluid in the pipeline as a balancing valve.

A triple duty valve works by combining the functionality of three different types of valves into one unit. Here's how each of the three functions work:

Shutoff Valve: A shutoff valve is used to stop the flow of fluid in a pipeline. In a triple duty valve, this function is provided by a valve disc that can be rotated to either block or allow fluid flow through the valve.

Check Valve: A check valve is used to prevent backflow of fluid in a pipeline. In a triple duty valve, this function is provided by a spring-loaded check valve that prevents fluid from flowing in the reverse direction.

Balancing Valve: A balancing valve is used to regulate the flow of fluid in a pipeline. In a triple duty valve, this function is provided by an adjustable orifice that can be used to control the flow rate of the fluid passing through the valve. This allows the valve to be used to balance the flow of fluid between different branches in the piping system.

A triple duty valve is a type of valve used in heating and cooling systems that serves three functions:

It acts as a shutoff valve to stop the flow of fluid in a pipeline.

It acts as a check valve to prevent backflow of fluid in the pipeline.

It acts as a balancing valve to regulate the flow of fluid in the pipeline.

Suppliers of Triple Duty Valve in the UAE offer versatile valves designed to fulfill various roles, including system balancing, flow control, and complete closure. This integrated functionality streamlines system operation by consolidating these tasks into a single valve, eliminating the need to manage and monitor three separate valves.

Description:

Body materials: Cast iron, SS304, SS316, CF8, CF8M, Ductile iron

Size: 2” to 20”

Class: 125 to 300

Nominal Pressure: PN6 to PN25

Ends: Flanged

Operations: Hand wheel operated

Parts

ØInlet Pressure Chamber

ØOutlet Pressure Chamber

ØRelief Valve

ØDiaphragm

ØActuator

ØStem

ØBonnet

ØBody

ØSeats

ØDisc

Industries which use them

Steam systems

Water systems

Power generation

Oil and gas

Applications

Pressure reduction:

Pressure maintenance

Pressure relief

Steam systems

Water systems

Oil and gas systems

Chemical Processing

Visit us for more:- https://www.middleeastvalve.com/product-category/triple-duty-valve/

0 notes

Text

Pressure safety valve supplier in Oman

Middleeast valve is the best Pressure safety valve supplier in Oman. A pressure safety valve, also known as a pressure relief valve, is a mechanical device used to protect pressurized systems from overpressure.

It is designed to automatically release excess pressure from a system to prevent damage or failure due to excessive pressure.

The basic operation of a pressure safety valve is relatively simple. It is typically a spring-loaded valve that is held closed by a spring or a weight. When the pressure inside the system exceeds a predetermined set point, the valve opens, allowing excess pressure to escape and reducing the pressure inside the system. Once the pressure drops below the set point, the valve closes again, restoring normal operation.

In Oman, the supplier of Pressure Safety Valve is carried out with a focus on adhering to precise pressure ratings. These valves are subject to stringent regulations and standards governing their manufacturing, installation, and upkeep. It is of paramount importance to guarantee the correct sizing, proper installation, and rigorous testing of these pressure safety valves to ensure their dependable functionality and alignment with relevant codes and guidelines.

Description-

Available Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: ½” to 40”

Operation: pilot operated, electric operated and pneumatic operated

Advantages:

The primary function of a PSV is to prevent over pressure in a system, which can cause damage to equipment and potentially lead to safety hazards.

It is designed to automatically open when the pressure in the system exceeds a certain level, without the need for manual intervention.

They are relatively simple in design and easy to maintain. They can be serviced or replaced quickly and easily, minimizing downtime.

These valves are a cost-effective way to protect equipment and ensure safety in a system.

Industries which use them

Oil and Gas Industry

Chemical and Petrochemical Industry

Power Generation Plants

Water and Waste Water Treatment Plants

Marine Industry

Mining Industry

Visit us- https://www.middleeastvalve.com/product-category/pressure-safety-valve/

0 notes

Text

Pressure safety valve supplier in Oman

Middleeast valve is the best Pressure safety valve supplier in Oman. A pressure safety valve, also known as a pressure relief valve, is a mechanical device used to protect pressurized systems from overpressure.

It is designed to automatically release excess pressure from a system to prevent damage or failure due to excessive pressure.

The basic operation of a pressure safety valve is relatively simple. It is typically a spring-loaded valve that is held closed by a spring or a weight. When the pressure inside the system exceeds a predetermined set point, the valve opens, allowing excess pressure to escape and reducing the pressure inside the system. Once the pressure drops below the set point, the valve closes again, restoring normal operation.

In Oman, the supplier of Pressure Safety Valve is carried out with a focus on adhering to precise pressure ratings. These valves are subject to stringent regulations and standards governing their manufacturing, installation, and upkeep. It is of paramount importance to guarantee the correct sizing, proper installation, and rigorous testing of these pressure safety valves to ensure their dependable functionality and alignment with relevant codes and guidelines.

Description-

Available Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: ½” to 40”

Operation: pilot operated, electric operated and pneumatic operated

Advantages:

The primary function of a PSV is to prevent over pressure in a system, which can cause damage to equipment and potentially lead to safety hazards.

It is designed to automatically open when the pressure in the system exceeds a certain level, without the need for manual intervention.

They are relatively simple in design and easy to maintain. They can be serviced or replaced quickly and easily, minimizing downtime.

These valves are a cost-effective way to protect equipment and ensure safety in a system.

Industries which use them

Oil and Gas Industry

Chemical and Petrochemical Industry

Power Generation Plants

Water and Waste Water Treatment Plants

Marine Industry

Mining Industry

Visit us- https://www.middleeastvalve.com/product-category/pressure-safety-valve/

0 notes

Text

Pneumatic knife gate valve in Sharjah

Middleeast Valve is a well-known supplier of Pneumatic knife gate valve in Sharjah . We supplies different types of valves to different countries like Qatar, Kuwait, Oman.

A pneumatic knife gate valve is a type of industrial valve used to control the flow of various types of fluids, including liquids and solids in slurry form, by using compressed air or gas to operate the valve mechanism. It is particularly suited for applications involving dense or abrasive media that might clog or damage other types of valves.

The basic working principle of a pneumatic knife gate valve involves using compressed air or gas to move the gate (a flat piece of metal or other material) across the path of the fluid flow to either block or permit its passage.

Open Position: When the valve is in the open position, compressed air is introduced into a pneumatic cylinder. This air pressure causes a piston inside the cylinder to move, which in turn pushes the gate out of the way, allowing the fluid to flow through the valve unobstructed.

Closed Position: To close the valve, the supply of compressed air to the cylinder is cut off or released. This allows the gate to be pushed back into its closed position under the influence of gravity or a spring mechanism. The gate effectively seals off the flow path, preventing the fluid from passing through.

In Sharjah, Pneumatic Knife Gate Valve are adaptable for actuation through either single-acting or double-acting pneumatic actuators. These actuators utilize air pressure to control the movement of the valve's gate element. These valves come in various sizes and materials, catering to diverse applications and ensuring compatibility with different operational needs.

Description:

Available materials:WCB,WC6,WCC,LCB,LCC,cast iron, Ductile Iron,SS316,SS304

Size: 2”to 80”

Class: 150 to 300

Nominal pressure:PN6 to PN40

Operation: pneumatic knife gate valve

Ends: wafer, lug, flanged

Configuration of a Pneumatic Actuator:

4-20 amp

Pneumatic single acting actuators

Pneumatic double acting actuators

Pneumatic rotary actuators

Pneumatic Scotch and Yoke actuators

Pressure: 228 bar

Temperature:

Standard -4°F to 200°F (-20°C to 93°C)

Low -40°F to 176°F (-40°C to 80°C)

High 0°F to 300°F (-18°C to 149°C)

Pneumatic knife gate valves are used in various industries, such as mining, wastewater treatment, pulp and paper, chemical processing, and more. They are particularly useful in applications involving:

Slurry and Abrasive Media: The knife gate design prevents clogging and damage that might occur with other types of valves when dealing with media containing solids or abrasive particles.

Thick and Viscous Fluids: These valves can handle fluids with high viscosities or consistencies, which might be difficult for other valve types to manage effectively.

Partial Flow Control: While knife gate valves are mainly designed for on/off control, they can provide some degree of flow regulation, although not as precise as control valves designed for this purpose.

Cost-Effectiveness: Pneumatic knife gate valves are often chosen due to their relatively lower cost compared to more complex control valves, making them suitable for applications where fine-tuned control isn't necessary.

Application:

1.Water treatment

2.Mining

3.Chemical processing

4.Power generation

5.Pulp and paper

Visit us:- https://www.middleeastvalve.com/product-category/pneumatic-knife-gate-valve/

0 notes

Text

Electric Actuated Valve suppliers in UAE

Middleeast valve is the magnificent Electric Actuated Valve suppliers in UAE. We supply to cities like Sharjah, Jebel Ali, and Liwa.

An electric actuated valve is a type of valve that is controlled by an electric actuator, which is a device that converts electrical energy into mechanical motion to open or close the valve. This type of valve is commonly used in various industries and applications where precise control of fluid flow is required.

What is electric actuator?

An electric actuator is a mechanism powered by electricity that provides the necessary force and motion to operate the valve. It converts electrical energy into mechanical force, enabling the valve to open or close.

Working of an Electric Actuated Valve:

Electrical Input: An electrical signal, typically in the form of voltage or current, is supplied to the electric actuator.

Actuator Conversion: The electric actuator receives the electrical input and converts it into mechanical motion using various mechanisms such as electric motors, solenoids, or other electro mechanical devices.

Transmission of Motion: The mechanical motion generated by the actuator is transmitted to the valve through a linkage system. This linkage is designed to interface with the specific type of valve being used.

Valve Operation: Depending on the design and type of actuator, the mechanical motion is used to open, close, or modulate the position of the valve. The valve can move to a fully open, fully closed, or any intermediate position based on the control signal and the actuator's design.

Control Logic: The control system, often a programmable logic controller (PLC) or a similar device, interprets signals from sensors or a control interface to determine when and how the valve should be operated.

Middleeast valve is the leading Electric Actuated Valve suppliers in UAE and are often used in automated systems where they can be controlled remotely or integrated into a larger automated process. This allows for efficient and precise control of fluid flow based on specific requirement

Description:

Available Materials: CF8M, CF8, SS316, CF3M, WCB, and Stainless steel (SS304, SS316, CF8M, SS316L, SS904L).

Class: 150 to 2500

Size: 1/2″ to 80″

Pressure: PN6- PN450

End Connections: Flanged, Socket weld, Butt weld, Threaded, Wafer, Lug

Operation: Electric Actuator.

Electric actuator details-

Torque – 3 – 9 nm

Operating pressure- 8 Bar

Port Connection-NPT1.4”

Mounting Base-ISO5211

Temperature–20°C – +80°C

Body material-Aluminium

Types of Electric Actuated Valves:

Electric ball Actuated Valve

Electric butterfly Actuated valve

Electric globe Actuated valve

Electric Gate Actuated Valve

Advantages of Electric Actuated Valve:

Very accurate in control and positioning

Can be stopped at any point during the stroke

Low operating costs

Minimal maintenance

Low risk of contamination

Industries of Electric Actuated Valve:

Mining

Chemical

Power Industries

Boilers Industries

Visit us: https://www.middleeastvalve.com/product-category/electric-actuated-valve/

0 notes

Text

Conventional safety valve supplier in Iran

Looking for a reliable and high-quality Conventional Safety Valve supplier in Iran? Middleeast valve is the topmost conventional safety valve supplier in Iran. We also supply to UAE, Turkey, and Bahrain.

A conventional safety valve is a mechanical device designed to provide overpressure protection for various types of equipment, such as pressure vessels, boilers, and pipelines. Its primary function is to release excess pressure from a system to prevent potential catastrophic failures due to pressure buildup. This helps ensure the safety of personnel, equipment, and the environment.

The basic working principle of a conventional safety valve involves a balance between the force exerted by the pressurized fluid and the force exerted by a spring. Here's how it works:

Set Pressure: The safety valve is set to open at a specific pressure level, known as the "set pressure" or "pop pressure." This pressure is determined based on the design and operating characteristics of the system it's protecting.

Spring Force: The safety valve is equipped with a spring that's preloaded to exert a certain force. This force keeps the valve closed under normal operating conditions.

Pressure Buildup: As the pressure inside the protected system increases and reaches the set pressure, it overcomes the force of the spring. This causes the valve to lift off its seat.

Pressure Relief: When the valve lifts off its seat, it creates an opening for the pressurized fluid to escape. The fluid is then released from the system, reducing the pressure inside.

Pressure Balance: As the pressure decreases, the force exerted by the spring becomes greater than the force exerted by the fluid. This leads the valve to close and reseal the system.

Middleeast valve is the greatest Conventional Safety Valve supplier in Iran and consist of a valve body with an inlet and outlet connection, a spring-loaded disc or piston, and a spring mechanism that controls the set pressure.

Description:

Materials: Cast iron, Ductile Iron, SS304, SS316, CF8, CF8M, Carbon steel (WCB, WCC, WC6, LCB, LF2, WC9)

Class: 150 to 2500.

Nominal Pressure: PN10 to PN450.

Size: ½” to 40”

Advantages:

Reliable pressure relief

Quick response time

Simple maintenance

Cost effective solution

Compliance with Industry standards

Industries which use them

Oil and Gas Industry

Power Generation Plants

Chemical Processing Industry

Pulp and Paper Industry

Marine Industry

Aerospace Industry

Visit us- https://www.middleeastvalve.com/product-category/conventional-safety-valve/

0 notes

Text

Pressure safety valve suppliers in UAE

Middleeast valve is the best Pressure safety valve suppliers in UAE. A pressure safety valve, also known as a pressure relief valve, is a mechanical device used to protect pressurized systems from overpressure.

It is designed to automatically release excess pressure from a system to prevent damage or failure due to excessive pressure.

The basic operation of a pressure safety valve is relatively simple. It is typically a spring-loaded valve that is held closed by a spring or a weight. When the pressure inside the system exceeds a predetermined set point, the valve opens, allowing excess pressure to escape and reducing the pressure inside the system. Once the pressure drops below the set point, the valve closes again, restoring normal operation.

Middleeast valve is the foremost Pressure safety valve suppliers in UAE and are usually designed and calibrated to specific pressure ratings and have strict standards and regulations governing their construction, installation, and maintenance. It is crucial to ensure that pressure safety valves are properly sized, installed, and tested to ensure their reliable operation and compliance with applicable codes and standards.

Description-

Available Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: ½” to 40”

Operation: pilot operated, electric operated and pneumatic operated

Advantages:

The primary function of a PSV is to prevent over pressure in a system, which can cause damage to equipment and potentially lead to safety hazards.

It is designed to automatically open when the pressure in the system exceeds a certain level, without the need for manual intervention.

They are relatively simple in design and easy to maintain. They can be serviced or replaced quickly and easily, minimizing downtime.

These valves are a cost-effective way to protect equipment and ensure safety in a system.

Industries which use them:

Oil and Gas Industry

Chemical and Petrochemical Industry

Power Generation Plants

Water and Waste Water Treatment Plants

Marine Industry

Mining Industry

Visit us- https://www.middleeastvalve.com/product-category/pressure-safety-valve/

0 notes

Text

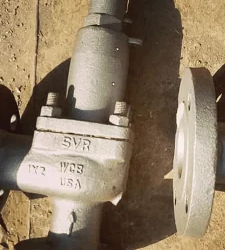

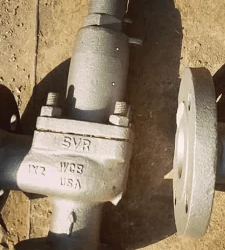

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

0 notes

Text

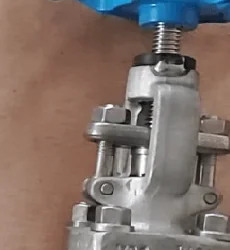

Forged steel globe valve in UAE

Middleeast valve is one of the best Forged steel globe valve in UAE. We supply to cities like Ajman, Kalba, and Hatta.

Description:

Body Material: [F3, F304, F316, F31L, F51, F55, F91, SS304, SS316, SS316L, SS904L]

Class: 150 to 2500; PN10 to PN 450

Size: DN 10 to DN 1200

Ends: Buttweld, Flanged, Socketweld, Threaded

Operations: Hand-wheel operated globe valve, Pneumatic actuated globe valve, Electric actuated globe valve, Gear operated globe valve.

A forged steel globe valve is called so because it is constructed using forged steel materials, which provide it with durability, strength, and resistance to high pressures and temperatures. The "globe" in its name comes from the shape of its body, which resembles a globe or a ball.

The primary function of a forged steel globe valve is to regulate the flow of fluid in a pipeline. By using a movable disc or plug that can be raised or lowered, the valve can either allow or restrict the flow of the fluid.

The working of a forged steel globe valve involves the movement of a disc or plug inside the valve body. This disc is connected to a stem that extends outside the valve body, allowing it to be operated from the outside. When the valve is in the fully open position, the disc is lifted off the valve seat, allowing fluid to flow through the valve with minimal resistance. When the valve is closed, the disc is pressed against the valve seat, blocking the flow of fluid completely.

To operate the valve, a handwheel, lever, or actuator is used to turn the stem, raising or lowering the disc to control the flow rate. The degree to which the disc is raised or lowered determines the amount of flow allowed through the valve.

Middleeast valve is the greatest Forged steel globe valve in UAE and used for regulating fluid flow in various industries. Its ability to provide precise flow control makes it a valuable component in systems where flow rates need to be carefully managed.

Advantages of forged steel globe valve:

Strength and durability

Corrosion resistance

Wear resistance

Tight sealing

Industries of forged steel globe valve:

1.Chemical

2.Oil and gas

3.Power generation

4.Water and wastewater

Applications of forged steel globe valve:

●Piping in small sizes.

●Plumbing sector.

●Provide flow control.

●Provide leak tightness.

●Pumps and compressors.

●Used as an emergency shutdown valve

Visit us:- https://www.middleeastvalve.com/product-category/forged-steel-globe-valve/

0 notes

Text

Safety Valve supplier UAE

Middleeast Valve is one of the best Safety valve supplier UAE . We supply to cities like Dubai, Sharjah, Ajman, and Kalba.

Description:

Body Material: Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91] , WCB, WC6, SS304, SS316, DUPLEX STEEL.

Class – 150 – 2500

PN 10 – PN 450

Size – ½ - 24”

Ends- Butt welded, Socket welded, Flanged, Threaded.

A safety valve is a mechanical device designed to automatically release pressure from a vessel or system when the pressure inside exceeds a predetermined level. Safety valves are crucial components in various industrial and mechanical applications to prevent equipment damage, explosions, or other hazardous situations caused by excessive pressure buildup.

The primary purpose of a safety valve is to maintain the pressure within a safe operating range by releasing excess pressure to the atmosphere. This prevents the pressure vessel or system from rupturing or failing due to the internal pressure exceeding its design limits. Safety valves are used in a wide range of applications, including steam boilers, pressure vessels, pipelines, and more.

Middleeast Valve is a quality assurance Safety Valve supplier UAE and play a crucial role in maintaining the integrity and safety of these systems by preventing them from operating beyond their design limits.

The basic working principle of a safety valve involves the balance between the force exerted by the internal pressure and the force exerted by a spring or other mechanism. When the internal pressure reaches the set limit, it overcomes the force holding the valve closed, causing the valve to open. Once the pressure drops to a safe level, the valve closes again.

Here's a simplified overview of how a spring-loaded safety valve works:

The spring in the valve is pre-set to a specific force, which corresponds to a certain pressure level.

As pressure increases inside the system or vessel, it pushes against the valve's disc, attempting to open it.

When the pressure reaches the set point, it overcomes the force of the spring, and the valve starts to open.

Excess pressure is released through the open valve, preventing the pressure from exceeding safe limits.

Once pressure drops to an acceptable level, the spring's force closes the valve again, sealing off the pressure release pathway.

Safety valve types:

Steam safety valve

Thermal safety valve

Conventional Safety Valve

Pressure safety valve

Bellow seal safety valve

Pilot operated safety valve

Spring loaded safety valve

Safety valve advantages:

This helps prevent damage, distortion, and potential leaks that could result from pressure build-up.

By relieving excess pressure, safety valves help extend the lifespan of equipment and reduce maintenance costs.

Flexibility and adaptability

Safety valve industries:

1)Oil and Gas Industry

2)Petrochemical Industry

3)Energy Industry

4)Chemical Industry

5)Mining Industry

6)Marine Industry

7)Textile Industry

8)Steel Industry

Safety valve parts:

Cap

Spring

Spring Adjuster

Body

Disc

Seat

Guide Plate

Safety valve application:

Boilers

Pressure vessels

Pipelines

Compressors

Refineries and chemical plants

Power plants

Oil and gas industry

Visit us: https://www.middleeastvalve.com/product-category/safety-valve/

0 notes

Text

Pneumatic actuated butterfly valve manufacturer in UAE

Middleeast valve is one of the leading Pneumatic actuated butterfly valve manufacturer in UAE. We supply to cities like Sharjah, Fujairah, Dubai.

Description:

Body material: Cast iron, Ductile iron, Stainless steel (SS316, SS304, CF8), Carbon steel, carbon steel, WCB, WCC, WC6, LCB, LCC, LF2, WC9, Duplex steel (F51, F53, 5A, 6A).

Class: 150-300. PN10 – PN40.

Size: 2”-72”.

Connection type: Flanged, Lug type, Wafer type.

Disc: CF8M, SS316L, CF8, Cast iron, Carbon steel, Ductile iron.

Operation: pneumatic actuated.

Configuration of a Pneumatic Actuator:

ØTorque – 3 – 9000 nm

ØOperating pressure- 8 Bar

ØPort Connection-NPT1.4”

ØMounting Base-ISO5211

ØTemperature–20°C – +80°C

A pneumatic actuated butterfly valve is a type of valve used to control the flow of fluid, usually gases or liquids, through a pipeline or system. It utilizes pneumatic power (compressed air) to open or close the valve mechanism, which consists of a disc or plate that pivots in the center of the pipe's diameter to regulate the flow.

The primary function of a pneumatic actuated butterfly valve is to control the flow of fluid by adjusting the position of the disc or plate within the pipe. When the valve is open, the disc is rotated perpendicular to the flow direction, allowing the fluid to pass through with minimal obstruction. When the valve is closed, the disc is turned parallel to the flow direction, effectively blocking the flow of fluid.

Middleeast valve is the dominant Pneumatic actuated butterfly valve manuafcturer in UAE and offers quick and precise control over fluid flow, and its actuation system allows for remote operation and automation in industrial processes.

The working of a pneumatic actuated butterfly valve involves the following steps:

Valve Opening: Compressed air is supplied to the actuator, creating a pressure differential across the actuator's diaphragm or piston. This pressure causes the actuator to move, which in turn rotates the valve disc to an open position.

Fluid Flow: With the disc in the open position, the fluid can flow through the pipeline or system without significant obstruction.

Valve Closing: When the supply of compressed air to the actuator is cut off or reduced, the pressure differential is reversed. This causes the actuator to move in the opposite direction, rotating the valve disc to the closed position.

Fluid Blockage: With the valve disc in the closed position, the flow of fluid is blocked, preventing it from passing through the pipeline.

Parts of pneumatic actuated butterfly valve:

Pneumatic Actuator.

Butterfly Valve Body.

Disk.

Stem.

Seat.

Hand Lever.

Gear.

Advantages of pneumatic actuated butterfly valve:

Low maintenance

Durable

Reliable

Available in different sizes

Cost effective

Can be used in various industries

Industries which use them:

Chemical Industry.

Petroleum Industry.

Mining Industry.

Automobile Industry.

Visit us: https://www.middleeastvalve.com/product-category/pneumatic-actuated-butterfly-valve/

0 notes

Text

Plug Valve supplier in Dubai

Middleeast Valve is well known for Plug valve supplier in Dubai. We supply to cities like Tabriz, Basrah, Shiraz, and Salalah.

Description:

Body material: Cast Carbon steel plug valve (WCC,WCB, WC6), Stainless Steel plug valve [SS316, SS304, SS316L, SS904L, CF8, CF8M, F31L, F91], DUPLEX STEEL and Super duplex Steel plug valve (F51,F53,F55) , Cast iron, Ductile Iron.

Class: 150-2500; PN 10 – PN 450

Size: 1/2”- 48”.

Operations: Lever actuated plug valve, electric actuated plug valve, pneumatic actuated plug valve, gear actuated plug valve

Ends: Flanged, butt weld, socket weld, threaded

A plug valve is a type of quarter-turn valve that is commonly used to control the flow of fluids in pipelines. The valve consists of a cylindrical or conical plug with a through hole, which is perpendicular to the axis of the valve body. The plug is typically connected to an operating mechanism, which can be manual, electric, or pneumatic, and is used to rotate the plug 90 degrees to open or close the valve.

Difference between Plug valve vs Gate valve:

A plug valve has a tapered or cylindrical plug that can be rotated within the valve body to control the flow of fluid. The plug can be fully or partially inserted into the flow path to regulate the flow. Plug valves can be either lubricated or non-lubricated, and are often used in applications that require frequent operation or in high-pressure or high-temperature environments.

On the other hand, a gate valve has a flat or wedge-shaped gate that slides up and down within the valve body to control the flow of fluid. When the gate is fully lowered, it blocks the flow of fluid completely. Gate valves are typically used in applications where a tight shut-off is required, but they may be less suitable for frequent operation. Overall, plug valves tend to be better suited for applications where frequent operation is required or where the valve needs to operate in high-pressure or high-temperature environments

Middleeast Valve is a leading Plug valve supplier in Dubai and are generally better suited for applications where a tight shut-off is required, but may not be as well-suited for frequent operation.

Plug valve parts:

Body

Disk

Bonnet

Stem

Plug

Seat

Plug Port

Handle

Packing Gland

Plug valve types:

Lubricated Plug valve.

Non Lubricated Plug Valve.

Jacketed Plug Valve

Twin Seal Plug valve

Lift Plug Valve

Orbit Plug Valve

Eccentric Plug Valve.

3 way plug valve

Connected lift plug valve

Plug valve advantages:

They have uncomplicated design with a few parts.

They open and close effortlessly.

Plug valves can be effectively maintained and repaired at the place of operation.

They provide low resistance to the flow.

Plug Valves deliver leak-tight facility.

Plug valve industries:

Chemical Industry.

Oil and Gas Industry.

Petrochemical Industry.

Energy Industry.

Waste water treatment.

Plug valve applications:

Oil piping systems.

Handling low-pressure, low-temperature services.

Plug valves may be used to control the flow of slurries and other liquids containing suspended solids.

Natural gas piping systems.

Visit us: https://www.middleeastvalve.com/product-category/plug-valve/

#plugvalve

#valvesupplier

#UAE

#Dubai

0 notes

Text

Lift check valve supplier in Dammam

Middleeast valve is the largest and most demanding Lift check valve supplier in Dammam. We supply to Dhahran, AI Khobar, Jubail, Muharraq, and AI khor.

What is difference between swing check and lift check valve?

Swing check valves and lift check valves are two types of check valves used to prevent backflow in piping systems. The main difference between them lies in the way they operate.

Swing check valves have a disc that swings on a hinge or pivot as the flow of fluid in the pipeline changes direction. When the fluid flows in the correct direction, the disc swings open, allowing the fluid to pass through. When the flow direction changes, the weight of the disc causes it to swing shut, preventing backflow.

Lift check valves, on the other hand, use a disc that moves up and down to control the flow of fluid. When the fluid flows in the correct direction, the disc is lifted up by the fluid, allowing the fluid to pass through. When the flow direction changes, the disc is pushed back down by gravity and/or the pressure of the fluid, sealing the valve and preventing backflow.

Middleeast valve is the greatest and fast-growing Lift check valve supplier in Dammam and are generally more effective at preventing water hammer and providing a tight seal, but they can be more expensive and require more maintenance due to their more complex design.

Advantages of lift check valve:

It ensures that fluid flows in only one direction, preventing backflow and protecting equipment from damage.

It is relatively simple to install and can be easily integrated into existing systems.

These valves have few moving parts, which means that they require minimal maintenance.

They are relatively inexpensive and can be easily replaced if they fail.

They ensure the proper flow of fluid which can reduce the energy consumption.

Parts of lift check valve:

Body

Disc or Ball

Seat

Hinge

Spring

Inlet and Outlet ports

Bonnet

Handle or Lever

Industries which use them:

ØOil and Gas Industry

ØPower Generation plants

ØChemical Industry

ØMarine Industry

ØMining Industry

Description-

Available materials: Cast iron, Ductile iron, WCB, LCC, CF8M, SS304, SS316, SS316L, ASTM A105N, ASTM A182Gr-F304, ASTM A182Gr-F316

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: 1/2” to 40”

Ends: Flanged, Wafer, lug, Threaded, Buttweld, Socketweld

Visit us: https://www.middleeastvalve.com/product-category/lift-check-valve/

0 notes

Text

Aluminium bronze valve supplier in Iraq

Middleeast valve is the prime Aluminium bronze valve supplier in Iraq. We supply to cities like Erbil, Zakho, Baqubah, and Nasiriyah. Aluminum bronze valves are a type of valve made from an alloy called aluminum bronze. Aluminum bronze is a high-strength and corrosion-resistant material composed primarily of copper with a significant amount of aluminum, along with other elements such as nickel, iron, and manganese.

Aluminum bronze valves are known for their excellent mechanical properties, making them suitable for various applications where durability and resistance to wear and corrosion are essential. These valves are typically used in situations where the fluid being controlled may be corrosive or abrasive. The aluminum bronze alloy provides enhanced resistance to corrosion from seawater, brine solutions, and certain chemicals. Additionally, the material's strength allows it to withstand high-pressure and high-temperature conditions.

Middleeast valve is famous for Aluminium bronze valve supplier in Iraq. When selecting an aluminum bronze valve, it's crucial to consider factors such as the intended application, pressure rating, temperature range, and compatibility with the fluid being handled. It's also essential to follow manufacturer guidelines for installation, operation, and maintenance to ensure optimal performance and longevity of the valve.

Types of Aluminum Bronze Valve:

1.Aluminum Bronze Gate valve

2.Aluminum Bronze Globe valve

3.Aluminum Bronze Ball valve

4.Aluminum Bronze Butterfly valve

5.Aluminum Bronze Check valve

Advantages of Aluminum Bronze Valve:

1.Corrosion resistance

2.High strength

3.Wear resistance

4.Excellent thermal conductivity

5.Easy to machine

6.Resistance to erosion

7.Low magnetic permeability

Industries of aluminum bronze valve:

Marine and Offshore

Oil and Gas

Chemical Processing

Power Generation

Pulp and Paper

Water and Wastewater Treatment

Mining

Description:

Body material- Aluminium Bronze ,ASTM B505, C95400, C95500, C95800,C83600, C63000, C95400,C95200

Class- 150-2500

Ends- Flanged, wafer, lug, Buttweld, threaded

Size-1/2’’- 4’’

Operations- Pneumatic actuated, Electric Actuated, Gear Operated, Lever Operated, Handwheel Operated

0 notes

Text

Super duplex steel valve supplier in Dubai

Middleeast valve is the largest Super duplex steel valve supplier in Dubai. We supply to cities like Ajman, Fujairah, AI Ain, and Abu Dhabi. Super duplex steel valves are a type of industrial valves made from super duplex stainless steel. Super duplex stainless steel is a material known for its excellent corrosion resistance, high strength, and good weldability. It is particularly well-suited for applications where resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion is required.

The working principle of a super duplex steel valve involves the following components:

Body: The valve body is the main casing that houses the internal components and provides a path for fluid flow. Super duplex steel is used to construct the body due to its high strength and resistance to corrosion.

Seat: The valve seat is a sealing surface that ensures a tight closure when the valve is in the closed position. It prevents the fluid from leaking past the valve when it is closed.

Disc or Plug: The valve disc or plug is a movable component that controls the flow of fluid. When the valve is open, the disc or plug is lifted or moved away from the seat, allowing the fluid to pass through. When the valve is closed, the disc or plug is pushed against the seat, blocking the flow of fluid.

Stem: The stem connects the actuator (a device that controls the valve) to the disc or plug. It transfers the motion from the actuator to open or close the valve.

Actuator: The actuator is a device that provides the external force required to operate the valve. It can be manual (operated by hand), electric, pneumatic (air-operated), or hydraulic (fluid-operated), depending on the application.

Middleeast valve is the leading Super duplex steel valve supplier in Dubai and are often used in critical areas of the production process where reliability and durability are crucial. Super duplex steel valves are commonly used in applications where there are demanding conditions such as high pressure, high temperature, or corrosive environments.

Types of super duplex steel valves:

Super Duplex Gate Valve

Super Duplex Globe Valve

Super Duplex Ball Valve

Super Duplex Check Valve

Super Duplex Needle valve

Super Duplex Butterfly Valve

Super Duplex Control Valve

Super Duplex Plug Valve

Advantages of super duplex steel valve:

Corrosion resistance

Stress Corrosion Cracking Resistance

Design flexibility

Longer service life

Industries of super duplex steel valve:

Oil and gas

Petrochemical

Chemical processing

Marine and shipbuilding

Water and wastewater treatment

Power generation

Pulp and paper

Mining

Description:

Available Materials: SS2328, SAF 2507(UNS S32750, F53), S32760( F55), UNS S32550, F61

Size: 1/8″- 24”

Class: 150 to 2500

Nominal Pressure: PN6 to PN300

Operations: Gear operated, Handwheel operated, lever operated, pneumatic actuated, electric actuated

Ends: Flanged, socket Welded, Buttweld, wafer, lug

Visit us: https://www.middleeastvalve.com/product-category/super-duplex-valve/

0 notes

Text

Foot Valve supplier in Sharjah

Middleeast Valve is the prime Foot valve supplier in Sharjah .Middleeast Valve supplies good quality of valves to Ajman, Abu Dhabi and Dubai. A foot valve is a type of check valve used in pumping systems to prevent the backflow of fluid when the pump is not in operation. It is typically installed at the bottom of a suction pipe or hose, submerged in the fluid being pumped. The name "foot valve" comes from its shape, as it usually has a large opening at one end resembling a foot.

The purpose of a foot valve is to maintain the prime of a pump and prevent the loss of fluid from the system. When the pump is turned off, the foot valve closes due to gravity, preventing the fluid from flowing back down the suction pipe. This helps maintain the system's efficiency by keeping the pump primed and reducing the need for re-priming or air evacuation.

Working Principle of foot valve:

A foot valve is a type of check valve that is installed at the bottom of a suction pipe or hose in a pumping system. Its primary function is to allow the flow of fluid (liquid or gas) in one direction while preventing backflow or reverse flow.

The working principle of a foot valve is relatively simple. It consists of a valve body with an inlet and an outlet, a closure mechanism (such as a hinged flap or a spring-loaded disc), and a strainer or mesh screen.

Here's how it works:

Installation: The foot valve is typically installed at the end of a suction pipe or hose in a well, reservoir, or other fluid source. The valve body is positioned in a way that the inlet side is submerged in the fluid source, while the outlet is connected to the suction line of the pump.

Fluid Intake: When the pump is started, it creates a pressure difference between the suction line and the fluid source. This pressure difference causes the fluid to flow from the source towards the pump.

Opening: As the fluid flows towards the foot valve, it exerts pressure on the closure mechanism, which helps to keep the valve closed initially. However, as the pressure builds up, it overcomes the resistance of the closure mechanism, causing it to open.

Fluid Flow: Once the valve opens, the fluid is allowed to flow through the valve body and into the suction line of the pump. The strainer or mesh screen on the inlet side prevents large debris or solid particles from entering the valve and clogging the pump.

Middleeast Valve is the prime Foot valve supplier in Sharjah and the foot valve ensures that the pump remains primed and ready for operation by maintaining a continuous flow of fluid from the fluid source while preventing the reverse flow of fluid when the pump is not in operation.

Advantages of foot valve:-

Foot valves are beneficial because they prevent damage to water pumps that can occur due to dry runs

These valves are a necessary part of all water pumping systems.

The foot valve solves this problem effectively.

Parts of foot valve:-

Body

Valve Disc

Fixing Bolts

Fixing screws

Strainer flanged

Strainer

Description:

Available Materials: SS304, SS316, Cast Iron and Ductile Iron, WCB

Class: 150 to 300

Nominal Pressure: PN10 to PN63

Size: 1/2” to 24”

Ends: Flanged, Threaded

Visit us:- https://www.middleeastvalve.com/product-category/foot-valve/

0 notes