Text

Concrete driveways Hunter Valley have been giving homes an additional look. Instead of having a plain and boring driveway, how it was made and the results are what make it exceptional. Aside from what it can do with aesthetics, the driveway also becomes more functional. If you want to have one in your home, you need to ensure that the one you will build is sturdy enough

0 notes

Text

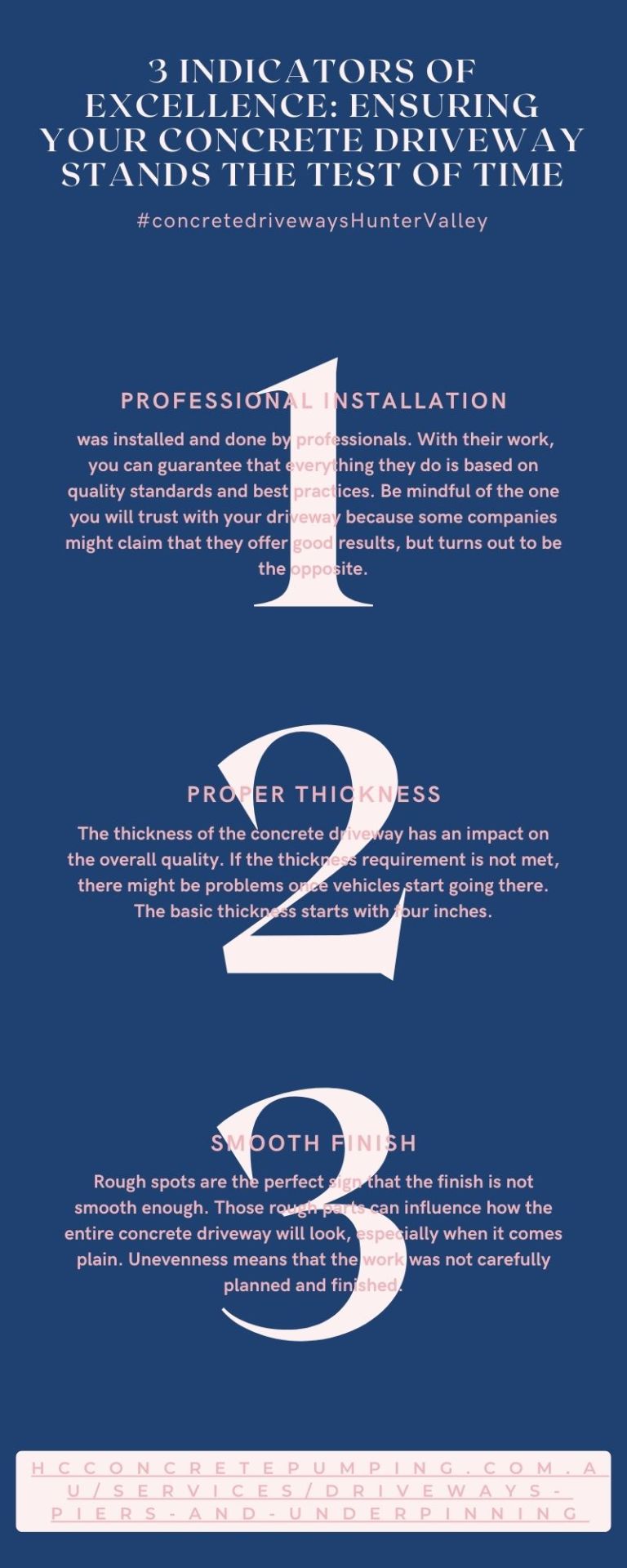

8 Indicators of Excellence: Ensuring Your Concrete Driveway Stands the Test of Time

Concrete driveways Hunter Valley have been giving homes an additional look. Instead of having a plain and boring driveway, how it was made and the results are what make it exceptional. Aside from what it can do with aesthetics, the driveway also becomes more functional. If you want to have one in your home, you need to ensure that the one you will build is sturdy enough. Here are some indicators that your concrete driveway is high-quality and can stand the test of time:

Professional Installation

The first sign that your concrete driveway is high-quality is the professional installation. It was installed and done by professionals. With their work, you can guarantee that everything they do is based on quality standards and best practices. Be mindful of the one you will trust with your driveway because some companies might claim that they offer good results, but turns out to be the opposite.

Proper Thickness

The thickness of the concrete driveway has an impact on the overall quality. If the thickness requirement is not met, there might be problems once vehicles start going there. The basic thickness starts with four inches. This size is perfect to support the vehicle, lessening your worry when it comes to breaking and cracking. If the proper thickness is not followed, expect problems with it after days or weeks of usage. Letting those in a problematic situation can cause accidents and affect the overall looks of your home.

Smooth Finish

Rough spots are the perfect sign that the finish is not smooth enough. Those rough parts can influence how the entire concrete driveway will look, especially when it comes plain. Unevenness means that the work was not carefully planned and finished. If yours is in this condition, talk to the concreter and tell them about your concerns. If they do not take action and let the problem worsen, it is a sign to look for another contractor. Do not let your driveway get ruined again.

Joint Placement

Another way to prevent cracking is by correctly placing expansion joints. Just like the term states, it will allow thermal expansion that can help preserve the quality of the concrete driveway.

Crack Resistance

Cracks can occur on concrete. However, a newly made concrete driveway must not be in this condition. You will know that the project is successful if you see crack resistance. There are no cracks present, but if there is one, it is minimal and can be easily fixed. If the crack resistance is good, it means that the professionals used high-quality materials and the correct installation methods.

Weather Resistance

Aside from the cracks, the weather can also test the quality of the concrete driveway. Once the installation is over and the rain comes, it is when you will see if the condition is still good. If not, then there could be a problem. Whatever the weather condition is, whether it is too hot or too cold, the concrete driveway will stay the same. Have the professionals check the driveway to let them see the problem firsthand and see what they will do about it.

Colour Consistency

If you want to base the checking on the looks, then start with the colour. Colour consistency plays a vital role in making sure that the concrete driveway is made and installed correctly. If the colours are uniform and there are no inconsistencies, it just means that the mixing was consistent and correct.

Edge Integrity

The edge of the concrete driveway also needs to be checked. It must be straight and intact because one mistake can break it all apart. Crumbling is something you would never want to experience because it shows that the foundation is weak and not solid enough. There is also no proper formwork.

Here are other signs that tell your concrete driveway is high-quality:

Resilience to Load

Aesthetic Appeal

Properly Cured Concrete

Good Drainage

Sealant Application

Textured Surface

Knowing that your concrete driveway is high-quality gives you peace of mind because you know that every penny spent is worth it. You did not make a mistake with the people you hired, especially on how they did the job. It is an investment that is worth enough of your time, making you enjoy your property more.

0 notes

Text

This article delves into the strategies and methodologies that can be employed to effectively manage and control the amount of cement pumping.

0 notes

Text

7 Ways To Control The Amount Of Cement Pumping

In the bustling world of construction and infrastructure development, managing resources efficiently is the cornerstone of success. Among these resources, cement stands out as a pivotal material, fundamental in laying the foundation and structure of numerous projects such as concrete driveways Hunter Valley. The process of cement pumping, a method employed to transport mixed cement to various parts of a construction site, is critical in ensuring the timely and efficient completion of projects. However, controlling the amount of cement pumped is essential to avoid wastage, ensure structural integrity, and maintain budgetary constraints.

Understanding the intricacies of cement pumping is crucial for any project aiming for success. The process, though seemingly straightforward, involves a complex interplay of machinery, manpower, and material properties. As such, optimising this process can lead to significant improvements in efficiency, cost reduction, and environmental sustainability. With the right approaches, it's possible to achieve a balance that benefits all stakeholders involved, from the contractors and workers to the eventual occupants of the structures being erected.

This article delves into the strategies and methodologies that can be employed to effectively manage and control the amount of cement pumping, a challenge faced by industry professionals worldwide.

Pre-Planning and Calculations

Before initiating the cement pumping process, thorough pre-planning and accurate calculations are essential. This involves a detailed analysis of the project blueprints to determine the exact quantity of cement required for each phase. Utilising advanced software for simulation and modelling can help in predicting the flow of cement and identifying potential bottlenecks or wastage points. By doing so, you ensure that the amount of cement pumped is precisely aligned with the needs of the project, thus minimising excess.

Use of Automated Control Systems

Incorporating automated control systems into cement pumps can significantly enhance precision in the pumping process. These systems use sensors and feedback loops to adjust the flow of cement in real-time, based on the actual requirements of the site. This technology not only reduces the likelihood of over-pumping but also contributes to uniformity in cement distribution, crucial for structural integrity.

Regular Maintenance of Pumping Equipment

The condition of cement pumping equipment directly influences the efficiency and accuracy of the pumping process. Regular maintenance and calibration of pumps ensure that they operate at optimal levels, preventing malfunctions that could lead to uncontrolled cement flow. Scheduled checks should include inspection of hoses, valves, and other critical components to ensure they are in top condition and capable of precise operation.

Training for Operators

Skilled operators are fundamental in controlling the amount of cement pumped. Providing comprehensive training for operators on the nuances of cement pumping equipment and the specifics of each project can lead to more controlled and efficient pumping. This training should cover not only the technical aspects of operating the pumps but also the importance of precision in cement usage.

Real-Time Monitoring and Adjustment

Adopting a proactive approach to monitoring the cement pumping process allows for immediate adjustments if discrepancies arise. This could involve onsite personnel equipped with the knowledge and authority to modify pumping rates or volumes as needed. Real-time monitoring ensures that any deviation from the planned amount can be swiftly corrected, thereby maintaining control over the process.

Implementing Flow Metres

Flow metres installed on the cement pumps can provide accurate, real-time data on the volume of cement being pumped. This information allows for immediate adjustments and helps in maintaining a consistent flow rate, tailored to the requirements of the specific area being worked on. It's an effective way to ensure that the amount of cement pumped does not exceed the calculated need.

Optimising the Mix Design

The properties of the cement mix can significantly affect the ease and efficiency of the pumping process. By optimising the mix design, including adjusting water content and additives, the flow of cement can be more easily controlled. A well-designed mix reduces the risk of blockages and ensures a smoother pumping process, allowing for more precise control of volumes.

The control of cement pumping is a multifaceted challenge that requires a comprehensive approach, combining technology, skilled manpower, and strategic planning. As we have explored, numerous strategies can be employed to optimize this process, each contributing to the efficiency, sustainability, and cost-effectiveness of construction projects. By adopting these practices, industry professionals can ensure that the right amount of cement is delivered where and when it is needed, with minimal waste and maximum efficiency.

0 notes

Text

How Concrete Driveways Stand Up to Harsh Weather Conditions

As we traverse the seasons, our driveways bear witness to nature's whims, enduring everything from blistering heatwaves to bone-chilling frosts. In this symphony of weather's fury, concrete driveways Hunter Valley emerge not just as passive observers but as resilient guardians of our homes' entrances. Their unyielding strength against harsh weather conditions stands as a testament to human ingenuity and the enduring power of construction materials.

0 notes

Text

How Concrete Driveways Stand Up to Harsh Weather Conditions

As we traverse the seasons, our driveways bear witness to nature's whims, enduring everything from blistering heatwaves to bone-chilling frosts. In this symphony of weather's fury, concrete driveways Hunter Valley emerge not just as passive observers but as resilient guardians of our homes' entrances. Their unyielding strength against harsh weather conditions stands as a testament to human ingenuity and the enduring power of construction materials.

The Foundation of Strength

Concrete driveways are built on a foundation of strength. The composition of concrete, typically a mixture of cement, water, and aggregates such as sand and gravel, creates a solid and durable surface. This sturdy base provides the groundwork for withstanding various weather challenges. Moreover, proper installation techniques, including adequate compaction and reinforcement, further enhance the driveway's ability to endure harsh conditions.

Resistance to Temperature Extremes

One of the most notable features of concrete driveways is their ability to resist temperature extremes. During scorching summers, concrete absorbs less heat compared to materials like asphalt, resulting in reduced expansion and contraction, which lowers the likelihood of cracks. In freezing winters, properly installed concrete with sufficient reinforcement can withstand the pressure of freezing and thawing cycles without significant damage, ensuring the driveway's longevity.

Durability Against Moisture

Moisture is a significant adversary for many construction materials, but concrete is not easily swayed. Concrete driveways are typically sealed to prevent water penetration, which can otherwise lead to erosion, cracking, and structural damage. Proper drainage design further enhances concrete driveway resilience by effectively directing water away from the surface, thereby minimising the risk of moisture-related issues.

Resistance to Chemicals and De-icing Agents

Harsh weather often prompts the use of de-icing agents on driveways, which can potentially corrode certain materials. However, concrete displays impressive resistance to various chemicals and de-icing agents commonly used during winter months. This resistance minimises the risk of surface deterioration, ensuring the driveway maintains its structural integrity over time, even in the face of chemical exposure.

Minimal Maintenance Requirements

Concrete driveways boast low maintenance requirements, another testament to their resilience. Unlike other materials that may require frequent repairs or replacements due to weather-induced damage, concrete stands firm with minimal upkeep. Routine cleaning and occasional resealing are usually sufficient to keep a concrete driveway in optimal condition, saving homeowners time and money in maintenance expenses.

Design Versatility and Aesthetics

Despite its robust nature, concrete doesn't compromise on aesthetics. Homeowners can choose from a wide range of finishes, textures, and colors to complement their property's design aesthetic. Decorative options like stamped concrete or exposed aggregate further enhance the visual appeal of concrete driveways without sacrificing durability, allowing homeowners to enjoy both beauty and resilience.

Long-Term Cost Efficiency

While the initial installation cost of a concrete driveway may be higher than alternatives, its long-term cost efficiency is undeniable. The durability and resilience of concrete translate to fewer repairs and replacements over time, ultimately saving homeowners money in maintenance expenses. Furthermore, the longevity of concrete driveways adds value to the property, making them a wise investment in the long run.

Concrete driveways stand as enduring symbols of strength and resilience, capable of withstanding the most challenging weather conditions with grace. From extreme temperatures to moisture and chemicals, concrete emerges as the material of choice for homeowners seeking reliability, longevity, and aesthetic appeal in their driveway investments. As we navigate the ever-changing landscape of construction materials, concrete remains a steadfast choice, embodying the endurance needed to weather the storms of time and nature.

0 notes

Text

Top 10 Industrial Uses for Concrete

In today's industrial landscape, cement-based materials from concrete Hunter Valley service providers are more than just a building component; they are the backbone of modern infrastructure and development. Their unparalleled strength, versatility, and durability make them a fundamental element in a wide range of industrial applications. From towering skyscrapers to intricate underground systems, these materials play a pivotal role in shaping our built environment.

This material's adaptability to various conditions and purposes makes it a preferred choice for engineers and architects worldwide. Its composition allows for creativity in design while maintaining the integrity and functionality of structures. As we delve into the various industrial uses of these materials, it becomes evident how integral they are to our daily lives and the continuous progress of our societies.

Infrastructure Development

Serving as the cornerstone of modern infrastructure, cement-based materials are extensively used in constructing robust bridges and tunnels. Their ability to endure the stresses of heavy traffic and environmental extremities is unparalleled. These materials are also critical in highway construction, providing a reliable foundation for millions of vehicles daily.

Building Construction

These materials are integral in both residential and commercial building construction. Their structural integrity ensures safety and longevity, while their adaptability allows for a wide range of architectural styles. From load-bearing walls to aesthetic façade elements, they provide both functionality and visual appeal.

Water and Sewage Systems

Essential for modern sanitation, these materials are used in water reservoirs, sewage pipes, and treatment facilities. Their impermeability prevents contamination, while their durability ensures long-term service with minimal maintenance. This application is critical for public health and environmental conservation.

Port and Harbor Construction

In maritime environments, the resistance of cement-based materials to saltwater corrosion is invaluable. They are extensively used in constructing docks, jetties, and seawalls, providing essential infrastructure for global trade and transportation.

Railway Infrastructure

The rail industry relies heavily on these materials for long-lasting railway ties, platforms, and sound barriers. Their use ensures a safe and efficient railway network, capable of withstanding the rigours of frequent and heavy use.

Agricultural Applications

In agriculture, these materials find use in building storage silos, irrigation channels, and shelters for livestock. They provide farmers with durable structures that protect produce and livestock, thereby enhancing overall farm efficiency.

Energy Sector Facilities

In the energy sector, these materials are critical for constructing various facilities, including power plants. Their thermal resistance is crucial in environments with high temperatures, while their structural integrity supports complex and heavy machinery.

Industrial Flooring

Industrial and warehouse settings demand floors that can withstand heavy machinery and constant traffic. Cement-based flooring offers a durable solution, resisting wear and tear and ensuring a safe working environment.

Waste Management

In waste management facilities, these materials are used to construct containment walls and leachate systems. Their robustness ensures the safe containment and processing of waste, playing a key role in environmental protection.

Aerospace and Defense

In more specialised sectors like aerospace and defence, these materials are used for constructing launch pads, bunkers, and protective structures. Their ability to withstand extreme conditions is critical in these high-stakes environments.

The extensive use of cement-based materials in various industrial sectors underscores their significance in the modern world. Their role extends beyond mere construction; they are a symbol of human ingenuity and our ability to create structures that stand the test of time. As technology advances, the potential applications of these materials expand, offering new possibilities for innovation and development in numerous fields.

Looking to the future, the continued evolution and improvement of cement-based materials will play a critical role in addressing the challenges of sustainable development and environmental conservation. Their adaptability and strength will be pivotal in creating eco-friendly, energy-efficient structures that meet the demands of a rapidly changing world.

At the end of the day, cement-based materials are not just a component of construction but a cornerstone of industrial progress and innovation. Their diverse applications across various sectors highlight their indispensability and the immense potential they hold for future advancements. As we continue to explore and expand their uses, these materials will undoubtedly remain at the forefront of industrial development, shaping our world in countless ways.

0 notes

Text

Environmental Benefits of Concrete Pumping

In an era marked by a heightened awareness of environmental sustainability, the construction industry finds itself at a critical juncture. The demand for resilient, eco-friendly building practices is growing, and one innovation has risen to meet this challenge head-on: concrete Hunter Valley pumping. This method, once seen as a technological advancement for efficiency and speed, has now emerged as a cornerstone of environmentally responsible construction. As we delve into the intricate web of advantages it offers, it becomes clear that concrete pumping is not just about convenience—it's about pioneering a greener future for construction, one that aligns with the global commitment to combat climate change and protect our fragile ecosystems.

Reduced Carbon Emissions

Concrete production stands as a significant contributor to carbon dioxide emissions. The conventional processes involved in mixing, transporting, and placing concrete can be highly energy-intensive and reliant on fossil fuels. Concrete pumping revolutionises this process, significantly mitigating its environmental impact.

a. Energy Efficiency: Concrete pumps represent a paradigm shift in efficiency, requiring substantially less energy than traditional methods, such as manual labour or crane-based placements. This elevated efficiency directly translates into lower carbon emissions during concrete placement, aligning with the global push for reduced energy consumption and emissions.

b. Minimised Vehicle Use: One of the most profound environmental benefits of concrete pumping is the substantial reduction in vehicle emissions. By eliminating the need for numerous concrete delivery trucks and additional equipment, construction sites become less congested and emissions are significantly curtailed, bolstering air quality and mitigating environmental harm.

Precise Placement and Waste Reduction

Concrete pumps excel in their ability to ensure precise placement of concrete. This precision significantly reduces the likelihood of over-pouring or spillage, thus minimising waste and ensuring that only the necessary amount of concrete is used for each project. Consequently, fewer raw materials are required, leading to a dramatic reduction in the environmental footprint associated with concrete production.

Reduced Noise Pollution

Construction sites, notorious for their noise levels, often disrupt the surrounding environment and impact the quality of life for nearby communities. Concrete pumping emerges as a quieter alternative to traditional methods, helping to ameliorate noise pollution and enhance the overall environmental quality in the vicinity of construction sites.

Enhanced Site Management

Concrete pumping requires fewer personnel and equipment on-site in comparison to conventional concrete placement methods. This streamlined approach to construction operations not only reduces the physical footprint of construction sites but also enhances the management of environmental impacts. Factors such as soil compaction and disruption of natural habitats are minimised, contributing to a more sustainable and eco-friendly construction process.

Minimised Material Transportation

Transporting substantial quantities of concrete to elevated or remote locations can be a logistical and environmental challenge. Concrete pumping addresses this issue adeptly by reducing the need for extensive material transportation, particularly in hard-to-reach areas. Consequently, wear and tear on access roads is minimised, and emissions from concrete delivery vehicles are substantially curtailed.

Extended Concrete Lifespan

Precisely placed concrete exhibits a longer lifespan due to reduced defects and better consolidation. This extended lifespan translates into fewer replacements and repairs, conserving valuable resources and reducing the environmental impact associated with both concrete production and disposal.

Use of Sustainable Materials

Concrete pumping is perfectly compatible with the utilisation of sustainable and recycled materials, such as fly ash, slag, or recycled aggregates. These materials can partially replace traditional cement and aggregates, further reducing the environmental footprint of concrete production. This aligns with the growing emphasis on sustainable construction practices, which prioritise the use of environmentally friendly materials.

Concrete pumping transcends its role as a mere construction technique; it embodies a revolutionary approach to sustainability within the construction industry. By mitigating carbon emissions, minimising waste, reducing noise pollution, and streamlining the overall environmental impact of construction projects, concrete pumping is unequivocally pivotal in forging a greener and more eco-friendly future for the construction sector. The adoption of this technology not only brings us closer to achieving global climate goals but also fosters a sense of responsibility in construction practices that prioritises environmental preservation. Embracing concrete pumping is not just a step forward; it's a leap toward a more sustainable and environmentally conscious construction industry.

0 notes

Text

8 Tips for Finding a Reliable Concrete Supplier

Construction projects are always crucial. They need to be inspected thoroughly, even in the smallest detail, to ensure everything is correct and in line with the plans. And when it comes to this topic, one thing that needs attention is the reliability and professionalism of concrete suppliers. They have an impact on the success of the project, considering it will be incomplete without them. With this, here are some tips for finding a concrete Hunter Valley supplier:

Research Local Suppliers

The first thing you need to do is look for local suppliers. One search on the internet, and you will see many of them. Search for one near the area to lessen the cost of delivery, and they are near the location. You will also not have problems contacting them because you can go to their office anytime needed.

Ask for Recommendations

If researching for local concreters online will not work, another tip is to ask for recommendations. You can get them from family, friends, colleagues, and other concrete professionals. They might know someone who has enough experience in the industry. But if these people cannot suggest anyone, builders and contractors can also lend some help. They surely have direct contact with concrete suppliers before, so you can ask if they have contact. They can provide valuable insights because their experiences are a good foundation.

Check Credentials

Once you have multiple concrete supplier options, check their credentials and see if they are the ones you need. Check if they have a licence and insurance because those can affect the trust you will give them. You will see these details on the website of the company, but it is better if you ask questions. A reputable and responsible supplier will provide the information you need to guarantee that they are the one you are looking for and you can trust your project with them.

Evaluate Experience

The experience of concrete suppliers is also a major factor before hiring them. If they do not have enough experience in the industry, how can you be sure that they are worth the trust? Choose a supplier that can show a consistent positive track record, especially on projects that are similar to yours. You will also see here if they are familiar with the project and the issues they face.

Visit the Facility

Aside from checking their credentials and experiences, you also need to be aware of the condition of their facility. Visit them to see if they have the correct equipment and tools to do the job. Their storage and batching processes are also factors you should never overlook. Having a well-maintained facility is a good sign that they are someone you can trust with your project. Doing this before hiring them can give you an idea about what to expect from these professionals. However, if you see the opposite, do not hesitate to look for another supplier to contact.

Delivery Capacity

Delivery is a crucial part of looking for a concrete supplier because they need to supply the required quantity needed for your project. If they do not have the capacity, then it is a sign to look for another one to trust. But aside from their capacity, you must also consider checking if they meet delivery schedules. Guaranteeing this can give you peace of mind because you know that they will not cause delays to the project.

Customer Ratings and Reviews

Every purchase you make must include reading customer ratings and reviews. They are available to be viewed on the internet for a reason, and it is to give future clients an idea about what others experience with the supplier and if they have the correct products. A mix of positive and negative reviews is what you will notice, so take time to read them and see if they are the correct people to partner with.

Emergency Services

Emergencies can happen anytime, even in construction projects. To ensure that the concrete you will purchase will get the attention it needs, search for a supplier that is open during emergencies. Having 24/7 availability is a huge factor in businesses, so choose one that will not give you a headache.

Other tips include:

Quality Control

Contract Terms

Long-Term Relationship

Product Range

Pricing Transparency

Payment Terms

Selecting the wrong concrete supplier can negatively affect the overall project. But you can prevent that from happening by ensuring that they are worth your trust. These tips can be your foundation looking for one, so do not forget to check and add more to the list if needed. All the best!

0 notes

Text

10 Tips For Pressure Washing Your Concrete Surface Properly

Pressure washing a solid surface requires meticulous attention to detail and a keen understanding of how the process impacts the material. Cleaning these hard surfaces with the assistance of concrete Hunter Valley experts enhances the aesthetic appeal of your space and also prevents the proliferation of mould, mildew, and other unwanted substances.

Embracing the method of pressure washing speaks to a dedication to maintaining and preserving the quality of solid surfaces under our care. This practice is more than just the mechanical act of deploying water under pressure; it is an exercise that demands an astute understanding of the method, technology, and the material being cleansed. Engaging in periodic pressure washing isn’t solely about restoring the original visual appeal of a space, but it also plays a pivotal role in mitigating wear and tear, thereby enhancing the longevity of the surface.

This guide provides some helpful, professional tips to pressure wash your concrete surface effectively and safely.

Understand Your Surface

Every solid surface is unique and understanding its characteristics, such as porosity and texture, is vital. Appreciate its structural composition and absorbency level as this will guide you in selecting the appropriate pressure washing techniques and cleaning solutions to achieve optimal results.

Choose the Right Equipment

Selecting the appropriate pressure washer and accessories is crucial. A washer with a power range of 2000 to 3000 PSI (pounds per square inch) is generally suitable for most residential solid surfaces. Ensure to also select the right nozzle for a precise spray pattern, considering both width and intensity, to effectively clean without causing damage.

Safety First

Prioritise your safety and that of your surroundings. Wear protective gear such as goggles, gloves, and non-slip footwear to protect against high-pressure water and flying debris. Also, ensure that the washing area is cordoned off to prevent accidental injury to passersby.

Test a Small Area First

Before beginning the cleaning process, it's prudent to test a small, inconspicuous area with the pressure washer. This preliminary step will help identify the right pressure, nozzle, and detergent to use while ensuring that no damage occurs to the surface.

Pre-Soak the Surface

Begin by pre-soaking the surface with water or a suitable cleaning solution. Allowing it to seep in for a few minutes will loosen the embedded dirt, making it easier to wash away when pressure is applied.

Adequate Detergent Use

Choosing and applying the right detergent enhances the cleaning power of your pressure washer. Ensure the cleaning solution is suitable for solid surfaces, and use it as per the manufacturer’s guidelines to effectively break down grime without damaging the substrate.

Utilise a Consistent Technique

Employ a consistent and systematic washing technique. Typically, start from the top (for vertical surfaces) or one edge (for horizontal surfaces), gradually working your way down or across. Ensure to maintain a steady distance and angle between the nozzle and the surface to prevent streaking or uneven cleaning.

Mind the Weather

Consider the weather conditions on the day of your pressure washing. Ideal conditions would be a calm, overcast day to prevent quick drying of the cleaning solution under direct sunlight and to avoid battling against the wind.

Post-Cleaning Care

After pressure washing, inspect the surface for any remaining stains or residues. Additionally, consider applying a suitable sealant to protect the freshly cleaned surface from future stains and weathering, thereby prolonging its pristine appearance.

Maintenance and Timely Repeats

Implement a regular maintenance schedule and conduct timely pressure washing to prevent the accumulation of tough stains and ensure the longevity of the surface. Proactive management will simplify future cleaning endeavours and uphold the aesthetic and structural integrity of the solid surface.

Pressure washing your solid surface is not merely a task but an art that combines the right equipment, techniques, and safety measures. This ten-step guide underscores a comprehensive approach to effectively and safely navigate the process, guaranteeing a spotless, well-maintained surface that stands the test of time.

Adherence to the insightful tips above will make sure that the cleanliness and durability of your solid surfaces lasts, while also protecting and enhancing the overall aesthetic value of your commercial or residential space.

0 notes

Text

7 Types Of Concrete Used On Hobart Roads

Roads are marvels of engineering, intricately designed pathways that connect people, places, and possibilities. As vital arteries of our cities, they cater to our daily commutes, and leisurely drives, and facilitate commerce and trade. They are silent witnesses to countless stories, from first-time drivers nervously navigating their routes to the routine of daily commuters and the roar of heavy vehicles. Yet, how often do we stop to consider what lies beneath our tyres, or the myriad decisions that concrete Hunter Valley experts go into creating these stretches we so often take for granted?

The science of road-making has evolved tremendously over the years, incorporating advancements in material science, environmental considerations, and urban planning principles. Roads are no longer just about getting from point A to B; they're about doing so safely, efficiently, and sustainably. An essential aspect of this evolution has been the selection of the right materials, which are tailored to specific needs, locations, and traffic patterns.

Let’s embark on this fascinating journey beneath our tyres with the following list!

Plain Cement Pavements

This type of pavement is perhaps the simplest, made up of one key ingredient - cement. Its resilience is drawn from the strength of the cement itself. Used in many urban areas, plain cement pavements can withstand heavy loads, making them suitable for main thoroughfares and busy intersections.

Reinforced Pavements

While similar in appearance to the previous type, reinforced pavements incorporate steel reinforcements within. These steel bars or meshes provide an added layer of durability, making the material especially resilient to tensions that might cause cracks. This enhancement ensures longer road life and is particularly suitable for areas with extreme weather changes or heavy vehicular traffic.

Pervious Pavements

Environmental consciousness is a driving force behind the rising popularity of this material. Pervious pavements are designed to allow water to pass through them, reducing water runoff during heavy rainfall and thus helping in groundwater recharge. Besides being eco-friendly, this type reduces the risk of water-logging and flooding on roadways.

Composite Pavements

As the name suggests, composite pavements are a combination of materials. Typically, an asphalt layer is superimposed over a cement pavement. This dual layering harnesses the benefits of both materials, ensuring flexibility, durability, and better load distribution. It also provides an effective solution for upgrading existing roads that have started showing signs of wear and tear.

High-Performance Mixes

In the quest for even greater resilience and longevity, high-performance mixes have been developed. These are engineered to exhibit certain enhanced properties, like greater resistance to heavy loads, better flexibility, or higher skid resistance. Such materials might incorporate polymers, fibres, or special additives that lend these specialised traits. Ideal for high-traffic zones or in conditions where there's a high wear-and-tear expectancy, these materials are a testament to the advancements in road construction technology.

Segmented Block Pavements

Rather than a continuous spread, this type involves individual blocks, usually interlocking, laid out to form the road surface. Not only does this design provide visual appeal, but it also allows for better water drainage and ease of repair. If a certain section becomes damaged, only the affected blocks need to be replaced, ensuring quicker and more cost-effective maintenance.

Recycled Material-Based Pavements

A recent trend, driven by sustainability goals, is the use of recycled materials in road construction. Old tyres, glass, and even certain plastics can be processed and incorporated into road materials. These recycled-content pavements are not just eco-friendly but also demonstrate good performance, making them a win-win solution for modern roadways.

The road beneath our feet is more than just a path; it's a testament to engineering genius, environmental considerations, and the drive to always improve and innovate. With multiple types of materials available for use, local authorities and engineers make informed choices, always keeping in mind the safety and comfort of commuters, the longevity of the road, environmental implications, and cost-effectiveness.

From simple cement pavements to high-tech, high-performance mixes, every type of material has its unique advantages and ideal use cases. The next time you find yourself cruising down a local road, take a moment to appreciate the science and decisions that went into its creation. Safe travels!

1 note

·

View note