Text

How Can Cement Be Tested Out for the Best Quality?

The Foundation of any kind of building will depend on the raw materials used by the people and it will comprise the basic structure of the building. One such inseparable part of the construction is the cement and it will be finding out the impeccable application in different kinds of construction activities and works. It will not say whether the individuals are constructing a building or a bridge but cement is something that will be making the foundation very much sturdy as well as strong. Hence, undertaking the implementation of cement soundness test apparatus is very much important for the organisations to ensure that everything will be undertaken very professionally and effectively.

Following are some of the most important testing procedures and instruments to be carried out on the segment to check out the quality very professionally:

Implementation of the cement fineness test apparatus is very much important in this particular case so that everybody will be having a clear idea about the initial sample testing of the overall picture of the cement quality. In this particular system, the people will be collecting the semen sample from the packaging cement bags and will be utilising different kinds of equipment to be undertaken in the whole process.

Depending on the utilisation of cement tensile testing machine is another very important thing to be taken into consideration by the organisations throughout the process so that everybody will be able to lead towards a better construction procedure without any kind of doubt. Determining the particle nature of the cement is very important in this particular case so that overall goals are very easily achieved without any kind of doubt.

It is very much vital for the organisations to have a clear idea about the basic implementation of the cement consistency test apparatus so that there is no chance of any kind of doubt and everybody will be on the right track of implementing the things very professionally. In this particular case, the accurate surface area of the same particles have to be checked out so that there is no chance of any kind of hassle throughout the process.

The instruments will be perfectly working on the specific principle where the dry air with constant velocity will be dealing with the things and airflow has to be checked out in the whole process to enjoy accurate procedures.

The utilisation of the concrete testing equipment for sale like the Vicat instrument is a good idea because in this particular case the consistency of the cement paste has to be checked out very easily. Ultimately it will find perfect use throughout the whole process so that there is no chance of any kind of doubt element in the whole process.

Hence, testing cement for different kinds of components like moisture-holding capacity and air permeability is very much important so that there is no chance of any kind of doubt and everybody will be able to indulge in the better quality and durable building foundations.

#cement testing equipment#cement testing machine#cement soundness test apparatus#cement fineness test apparatus

0 notes

Text

Why Utilisation Of The Shock Absorber Testing Machine Is A Good Idea?

Depending upon the utilisation of the shock absorber testing machines is a very good idea on the behalf of people and organisations to ensure that efficiency will be easily present throughout the process and everybody will be able to enjoy the smooth touching of the tires to the pavement of the road. Fortunately, this is considered to be the best possible way of ensuring that every concerned individual will be very much capable of dealing with the things and there will be no chance of any kind of problem throughout the process. The shock absorber bounce test is the best possible approach of making sure that effort systems will be significantly reduced and everybody will be able to enjoy the top-notch functionality.

Following are some of the basic points highlighting the importance of the shock absorber testing machines equipment:

This system is very much capable of bringing a higher level of safety to the car users and further making sure that the suspension system will be easily paid attention to throughout the process.

The utilisation of the shock absorber suspension testing system is the best possible approach of ensuring that steering stability will be easily made available and everybody will be able to enjoy the complete safety of the vehicles of the process.

This particular aspect will always help in making sure that the capability of controlling the cars will be easily protected and there will be no chance of any kind of issue in the whole system.

Another very important benefit of depending on this particular system is that it will help in bringing a higher level of stability in the whole process so that overall friction can be significantly increased and the stability of the car on the road will be significantly improved.

Depending upon the utilisation of the shock absorber testing machines equipment is the best possible approach of ensuring that exerting of the pressure on wheels will be capable of dealing with things and there will be no chance of any kind of problem throughout the process.

This particular system is very much capable of bringing a higher level of comfort element in the whole process and making sure that overall goals will be easily achieved without any kind of problem.

The utilisation of the shock absorber testing apparatus will always help in making sure that the overall balance will be significantly checked out and depending upon the result every technician will be able to replace the required part in the whole process without any kind of problem. In this particular manner, the overall goals will be significantly achieved and diagnosing the problem will become very much easier throughout the process.

Hence, it has been ideally suggested that dealing with things is the best possible approach of ensuring that everything will be dealt with very easily and every organisation will be able to enjoy the best possible ability to drive and have good control over the car. In this particular matter, everything will be renewed and checked very successfully so that there is no chance of any kind of problem.

#shock absorber testing machines#shock absorber testing machines equipment#shock absorber testing apparatus

0 notes

Text

Importance Of Damper Testing Instrument

In the present time, no matter what type of professional you area, you cannot take a chance with the material you use, the procedures you perform and the actions you take. There are many incidents that take place because o the negligence of the professionals. Of course, even if you pick a wrong machine for a specific procedure, you may end up inviting trouble.

Now, there are advanced damper testing machines that you can choose for your space. Of course, you can use them to ensure that nothing goes wrong. But what is the point if the machine itself is not right? Now if you do not know what really these fire dampers are, these are simply the passive fire protection products and items that get used in heating, ventilation, and even that of air conditioning (havoc) ducts to avert any sort of the spread of fire inside the ductwork via fire-resistance rated walls as well as floors.

You know fire/smoke dampers are somewhat similar to that of fire dampers in fire resistance rating, and even avert the spread of smoke within the ducts. When a growth in temperature occurs, the fire damper shuts, usually activated by a thermal element that actually melts at temperatures higher than overall ambient but sufficiently low to highlight the presence of a fire, permitting springs to close the damper blades.

Fire dampers even can also close different receipt of an electrical signal from a specific fire alarm system making use of detectors remote from the damper, showing the sensing of heat or even that of smoke in the building occupied spaces or even that of in the havoc duct system.

But are the fire dampers effective?

Of course, the effectivity of the fire dampers would rely on their effectivity. What is the point if the dampers themselves are not effectively, qualitative and productive? Such a thing would not result in something or anything good. Here, if there is proper damper testing machine, you can be sure that you use it for testing the damper. Of course, these machines are specifically designed to ensure that the dampers are effective, productive and efficient. What is the point if the dampers do not act efficiently at the time of urgency? Here, things would go messy right? So, having a machine is a must to test the effectivity and working of the dampers.

Working of these dampers

Well, as an example, mechanical dampers are the ones that shut the cross-sectional zone of a duct in the time of a fire either by means of turning a fire-resistant board, or by simply simply means of steel shutters, similar to that of blinds on a window (in north America). In the European designs, you would find the turning mechanism is completely contained, allowing the dampers (subject to type approval) to get grouted in place, that allows a heat sink effect to carry out heat from an accidental building fire, that imposes upon a duct and damper, to get conducted into surrounding structures.

Conclusion

So, you should check out the overall damper testing instrument to ensure that the dampers get checked properly before they get used in any space.

0 notes

Text

What Are the Different Types of Cone Penetrometer Equipment Available in the Industry?

It is very much vital for the organizations to be clear about different kinds of penetration testing available in the industry so that everything can be carried out as per the right kind of bearing capacity without any kind of problem. It is very much important for the people to implement that particular type of system which is capable of meeting the essential requirements of international standards: 4968 along with several other kinds of specifications in the form of diameter and several other kinds of related things. The people need to be clear about the connections with the sounding rods so that there is no problem in assembly of the sounding rod with the mantle tube can be carried out by successfully and there will be no chance of any kind of problem in the whole process.

Basically, the implementation of the testing procedure will be consisting of the pushing of the cone so that there is no problem at any point in time in the whole process. In this particular manner, the readings will be carried out very successfully and there will be no chance of any kind of problem in the whole system.

Following are some of the very basic bifurcations of the Cone penetrometer equipment to be implemented in the whole industry:

Hand operated 30 KN unit: This particular get will be consisting of the two-speed gear drive assembly which will help in providing the people with two handles for ease of operation. It can be perfectly supplied with the screw-type anchors along with the implementation of the pressure gauge so that overall purposes are easily fulfilled and everybody has proper access to the sectors of the unit.

100 KN capacity which will be engine driven: It is very much crucial for the people to be clear about this particular type of system so that greater depth and smooth penetration can be easily ensured by the organisations and everybody will be able to fulfil the overall process of the driving mechanism in the whole process. The people need to be clear about this particular system so the toolkit for the machine 1 set along with a tarpaulin cover will be made available to the people.

200 KN machine: This particular machine will be the latest available development in this particular industry and will help in providing the people with the complete opportunity of being very much light in terms of weight. It is capable of fulfilling different kinds of purpose is very successful even further make sure that they will be several kinds of provisions of the whole process without any kind of problem.

Apart from all the above-mentioned points the dedicated manufacturers in this particular industry also help in providing the people with a data acquisition system and sampler so that overall goals are very easily achieved and there is no chance of any kind of problem in the whole process. Hence, having a clear idea about the right kind of machines in the form of Cone penetrometer equipment is important for organisations to become successful in the long run.

0 notes

Text

Why the equipment of soil testing is beneficial?

The Earth's landscape has been divided into two categories from ancient times: water and soil. Soil is an essential component of the Earth's landscape, and it may be found practically anywhere. The soil's usefulness can equally vary from anywhere to everyplace. In early Indian communities, soil was utilized as a main building material. In many nations, urbanization has led to the construction of taller concrete buildings. Despite the fact that the multi-story is built with modern materials such as stones and cement, soil still performs a significant role. The soil on the site where the multi-story building will be built must be capable of supporting such large constructions. When it relates to soil assessment, this is where it serves its purpose. Soil examination equipment directly correlates with it as well.

Is the Soil's Function Fixed?

The soil's function is confined to constructions. Soil also plays an important role in crop production. Many nations, such as India, still rely on farming as their primary source of income. In such circumstances, technological advancement must go synonymously with agricultural advancement. The condition of the soil determines a lot of farming activities. If a farmer wishes to plant rice this season, he should first determine if the soil in his area is appropriate for rice production with the help of a cone penetration test. In this case, agricultural soil monitoring equipment may be useful.

Soil Quality Maintenance Tools in Farming:

1. An in-depth investigation of numerous soil granules and elements is essential of the soil testing process. Soil assessment equipment for agricultural production is used to determine the soil's productivity. These methods can also be used to detect infections in the soil, such as bacteria and viral infections. Strong metals like mercury, as well as other impurities, leave the soil unsuitable for farming use. When utilizing such soil for farming, it is essential to determine the extent of contaminants.

2. Particle size is also determined using certain equipment depending on its diameter. When any architectural activity begins, the physical qualities of the soil granules must be thoroughly investigated. The chemical qualities of the soil are sometimes determined using soil testing instruments. These technologies will also reveal the existence of toxic metals such as arsenic and cadmium. There are specialized instruments for determining the acidity of the soil. This detail about soil health is useful for a variety of purposes.

3. Soil specimens could be examined through the cone penetration test procedure in laboratories with adequate equipment. In these soil testing facilities, the essential equipment for integrative soil analysis must be accessible. Mineral and chemical testing will be performed as part of the soil investigations. Radiological and microbiological investigations will also be performed.

Zoning is a specialized tool that can be used. This strategy aids in the identification of troubled regions in a specific area. These are the situations under which a soil investigation is required. In the relevant locations, this tool allows for a variety of soil testing procedures. These are the regions where farming activity is required. To preserve agricultural integrity, the projected region must be evaluated with soil screening's sophisticated techniques.

0 notes

Text

Why the equipment of soil testing is beneficial?

The Earth's landscape has been divided into two categories from ancient times: water and soil. Soil is an essential component of the Earth's landscape, and it may be found practically anywhere. The soil's usefulness can equally vary from anywhere to everyplace. In early Indian communities, soil was utilized as a main building material. In many nations, urbanization has led to the construction of taller concrete buildings. Despite the fact that the multi-story is built with modern materials such as stones and cement, soil still performs a significant role. The soil on the site where the multi-story building will be built must be capable of supporting such large constructions. When it relates to soil assessment, this is where it serves its purpose. Soil examination equipment directly correlates with it as well.

Is the Soil's Function Fixed?

The soil's function is confined to constructions. Soil also plays an important role in crop production. Many nations, such as India, still rely on farming as their primary source of income. In such circumstances, technological advancement must go synonymously with agricultural advancement. The condition of the soil determines a lot of farming activities. If a farmer wishes to plant rice this season, he should first determine if the soil in his area is appropriate for rice production with the help of a cone penetration test. In this case, agricultural soil monitoring equipment may be useful.

Soil Quality Maintenance Tools in Farming:

1. An in-depth investigation of numerous soil granules and elements is essential of the soil testing process. Soil assessment equipment for agricultural production is used to determine the soil's productivity. These methods can also be used to detect infections in the soil, such as bacteria and viral infections. Strong metals like mercury, as well as other impurities, leave the soil unsuitable for farming use. When utilizing such soil for farming, it is essential to determine the extent of contaminants.

2. Particle size is also determined using certain equipment depending on its diameter. When any architectural activity begins, the physical qualities of the soil granules must be thoroughly investigated. The chemical qualities of the soil are sometimes determined using soil testing instruments. These technologies will also reveal the existence of toxic metals such as arsenic and cadmium. There are specialized instruments for determining the acidity of the soil. This detail about soil health is useful for a variety of purposes.

3. Soil specimens could be examined through the cone penetration test procedure in laboratories with adequate equipment. In these soil testing facilities, the essential equipment for integrative soil analysis must be accessible. Mineral and chemical testing will be performed as part of the soil investigations. Radiological and microbiological investigations will also be performed.

Zoning is a specialized tool that can be used. This strategy aids in the identification of troubled regions in a specific area. These are the situations under which a soil investigation is required. In the relevant locations, this tool allows for a variety of soil testing procedures. These are the regions where farming activity is required. To preserve agricultural integrity, the projected region must be evaluated with soil screening's sophisticated techniques.

0 notes

Text

Why concrete testing is significant nowadays

When it comes to the building industry, it is critical to evaluate the materials that are being utilized. Natural materials can have a variety of characteristics that affect their longevity, sturdiness, and uniformity. The technicians recognize the significance of evaluating materials with various techniques, apparatus, and methodologies. Every technique is distinct and has its own set of advantages and disadvantages. These methods assist researchers in determining the material's grade criteria and determining whether or not to proceed.

Concrete testing is performed to guarantee that the required quality is employed throughout the project, which could be a dam, tunnel, bridge, or other structure. A batch is inspected and tested, which aids in guaranteeing the overall excellence of the product. In addition, there are numerous ways for determining concrete's compressive strengths. As a consequence, it's essential for professionals to consider that each technique will have its basic set of characteristics and outcomes. Rebound hammer, penetration resistance testing, ultrasonic pulse velocity, pull-out experiment, and many other procedures are used to determine the compression strengths of concrete. The compression strength of a concrete specimen is determined by arranging it in a cylindrical form and then pressing it to determine its bearing capacity with the help of a flexural strength machine. It is critical to understand the concrete's quality levels in order to take the best decision. Also, there are numerous methods for testing both fresh and solidified concrete.

The foregoing are a few of the reasons why concrete testing is so important.

1. Measurement of air content

It's crucial to understand how much air is within freshly concrete. The concrete air measurements will facilitate in the technique's on-site producing of quick and accurate findings. By incorporating a few stages to the procedure, it would also be possible to learn regarding the unit weight details.

2. Accurate Quality

It is critical that the concrete solution be of the same composition to provide reliability and dependability. The grade of the entire quantity can be assessed by evaluating a small sample. It will aid in determining the excellence and effectiveness of all work conducted.

3.Examine the difference with time.

The concrete slump assessment will reveal the concrete's periodic fluctuation. A rise in slump indicates a significant moisture levels in the combination. If the concrete is excessively high or extremely low, it will indicate that it is no longer acceptable.

4. Industrial and international requirements are fulfilled.

It assists in the balancing of concrete materials and ensures that they meet industrial and international norms. It will support in the reduction of errors and make the entire process run smoothly.

5. On the construction site

The majority of these procedures may be performed on-site, eliminating the requirement to ship specimens to a research lab. This is definitely a cost-effective piece of technology.

Some of the advantages of concrete analysis are listed above. Make certain you purchase the automatic flexure testing lab equipment with the most advanced features feasible. For catalogs, you can also contact companies via the internet.

0 notes

Text

What Are the Most Important Aspects to Be Taken into Consideration by the People at the Time of Selecting the Universal Testing Machine?

The universal testing machine is very much popular because this particular machine can be perfectly utilised in terms of undertaking different kinds of tests on different types of materials. But before indulging in the purchasing process of such machines people need to consider different kinds of factors in the whole process. The right selection of the machine will always help in determining the accuracy of the various testing systems being conducted by it and further, this particular concept will be based upon the right kind of systems in the whole process.

Following are some of the most important things to be taken into consideration by the people at the time of purchasing the right machines from the house of universal testing machine manufacturer:

It is very much important for people to be clear about the type of test to be undertaken in the whole process so that regards type of testing for example compression testing, fatigue testing and several other kinds of things can be taken very easily. Depending upon the UTS machine which comes from the best manufacturers is vital because it will be compliant with ISO rating and several standards of the industry.

Outlining the calculations in the whole process is another very important thing to be taken into consideration because one must always go with that particular machine that comes with the right controller. Outlining the calculations required in the whole process is vital so that determination of the right system can be undertaken without any kind of problem.

The choice of the universal testing machine will always be based upon the maximum load of the material which the people are considering for testing systems. This particular concept can only be understood when the maximum load will be required for testing will be sure and the right machine will always help in fulfilling the basic requirements in the whole process.

Specification of the drive and actuator is another very important thing to be taken into consideration so that everything can be taken good care of and this particular factor will help in determining whether to go for a static test or dynamic test in the whole process.

Checking out the selection of a group is another very important criterion to be paid attention to because it can either make or break the final results. The decision of the type of machine will always depend upon the material which has to be used in the testing world. People need to be clear about grips and fixtures in the whole process.

Considering the future possibilities of the right universal testing machine is another very important thing to be considered because it will help in ensuring that current requirements will be dealt with very easily and people will be able to undertake the testing systems perfectly without any kind of problem.

Hence, all the above-mentioned aspects must be taken into consideration by the people so that they end up choosing the perfect UTS machine.

0 notes

Text

The entire portfolio of the soil testing laboratory equipment from the house of experts of the industry

Carrying out the soil testing procedures is a very much important aspect to be undertaken by the organisations because this is directly linked with implementing and checking out the condition of the soil and studying the behaviour of soil under different conditions. The load-bearing capacity of the location will help in enabling the idea about weight across the cross-sectional unit area which a particular soil can support. Different kinds of soil testing systems have to be carried out by the organisations in some of the most commonly used soil testing laboratory equipment has been explained as follows:

Beakers: It will help in ensuring that soil testing procedures will be perfectly undertaken and it is available into different kinds of capacity throughout the process without any kind of problem.

Penetration test: This particular type of equipment will always be very much useful as well as economical and will help in ensuring that other standard testing systems will be perfectly undertaken. This particular concept is very much important especially when the soil samples are undisturbed and high moisture content has been perfectly undertaken in the whole process without any kind of problem.

Water still: This particular piece of equipment is considered to be a very important one in modern material testing laboratories and the operation will be perfectly carried out by heating the water gently and converting it to steam by boiling it at a slower rate. The steam will be further condensing into inbuilt contention and can be perfectly collected into the receiver. It will be free from all kinds of impurities and gases and the best part is that it can be perfectly utilised for the operation on 220 V and 50 Hz single-phase supply without any kind of problem. It can also be perfectly utilised in proper combination with the vacuum pump and air compressor throughout the process without any kind of hassle.

Site investigation and sampling equipment: The utilisation of this particular equipment is considered to be a prerequisite to making sure that designing of any kind of structure has been undertaken with a good amount of economical aspect and safety in the whole process. The necessary information regarding the soil conditions will be carried out very easily so that performance under the proposed structure and loads will be undertaken without any kind of problem. It can be perfectly useful for shallow subsoil exploration and will help in ensuring that will be able to achieve the prolonged use of all types of soil without any kind of hassle. It is available in different kinds of models depending upon the diameter of the whole measurement and dimensions.

Relative density: This particular equipment is primarily meant for the determination of the ratio of cohesionless the free trading soils into the densest states depending upon the international standards: 2720. It will also include of vibrating table, cylindrical unit, sub-charge base plate, surcharge weight, handle for a surcharge and several other kinds of related things.

Hence, depending upon the soil density testing equipment is very much vital on behalf of organisations to ensure that testing procedure can be carried out with a higher level of comfort and ease and everything is compliant as per the latest available standards of the industry.

0 notes

Text

What are the basic points which the organisations should know about the static cone penetration testing systems?

The static cone penetration test is an internationally recognised standard in the field test so that collection of data can be perfectly undertaken and organisations have a clear-cut idea about the frictional resistance of the soil. This particular equipment always needs to meet the requirements of the international standard 4968 so that they have a clear-cut idea about the overall base diameter equal and to the area of 10 cm Square. The cone will be connected with the sounding rods which will further be protected with the help of tubes and the readings will also be taken for every 20 cm of penetration so that continuous data is always there and frictional resistance can be perfectly recorded.

Following are some of the very basic types of equipment that have been used in the whole process:

Static cone penetrometer which is hand operated: This particular equipment will incorporate to speed gear drive assembly and will further be provided by two handles for the ease of operation. The important features of the frame will include mounting on a two-column structure System that will further include the set of tools for unit set one and automatic device for the pressure gauge number one. It will also include the screw-type ankles for the reaction complete with the fixtures.

Static Cone penetrometer which is engine driven: This particular unit will help in facilitating the exploration to the greater depth and will ensure that smooth penetration will be perfectly undertaken at a fairly constant penetration rate. The machine will be driven by the 4.8 hp diesel engine which is very much suitable for loading up to a hundred kN and further it will be mounted on the pneumatic area. It includes the driving frame which will further consist of the engine driving pumping unit and it will also include the automatic cut without pressure gauge number one. It will further include the screw anchors and the sounding cone with fiction jacket throughout the process so that people can implement the toolkit for the machine perfectly without any kind of problem. It also comes with a tarpaulin cover.

200KN static cone penetration machine: This particular machine is considered to be the latest development in the industry and has been powered by a 12.5 hp air cooled diesel engine. The frame has very light in weight and further is very much strong to resist the stress which has been developed because of the penetration and withdrawal of the sounding tubes. This particular drive will include too long double-acting hydraulic RAM which has been supported by The to guide columns and further the pressure will be exerted on the tubes very easily. The automatic pressure cut value will be provided that will help in fulfilling the overall purpose is very well and will ensure that provision will be perfectly undertaken throughout the process.

Apart from all the above-mentioned equipment different systems like that acquisition system and the split spoon simpler is also utilised in the whole process to ensure accuracy. Hence, the entire cone penetration test procedure has been explained above.

0 notes

Text

The Use of Reliable Concrete Compression Equipment For Testing High Quality Concrete

Structures would be good depending upon the quality of materials involved. So as to ensure that the buildings are robust and safe you have to put the best materials in them. For any modern day construction concrete is the bread and butter as for the marvels you need only high quality concrete. Just by applying brick strength testing machine you ensure quality bricks are produced same is the case with concrete and it has to be outstanding quality.

Coming to structure safety, the concrete that is used has to comply with industry standards. As far as concrete testing evolves a majority of the civil engineers are of the opinion that compression strength would be the most important factor influencing the buying decision. The use of compression testing machines equipment ensures that the concrete complies with the required standards. But the choice of the right type of machine is essential to undertake the test. Here is an overview to help you in the choice of a right machine.

- The frame capacity of the load along with strength: a concrete compression machine would be testing concrete specimens where they subject them to extreme compression loads. The structure of the machine has to be strong enough to be dealing with such heavy loads. A machine frame load works out to be most important factor to consider when you are about to purchase a compression machine. According to ACI 363 standard it is of the opinion that the machine specimens that you may plan to test

- Take into consideration the same properties and the specific needs: the choice of a machine has to align with sample specification. Even the machine has to support the entire range of sample strength. An explosive failure might turn out to be dangerous. The machine has to be compatible with the range of your sample. A decision is to be made on whether you would choose to be testing only cylinders or it can be prims or cores. The machine that you choose needs to be able to handle the size of the specimen. On the other hand the machine daylight opening should be suited for the specific test in question. The hydraulic module of the machine has to be strong as it may prevent the load from over extending.

- Data handling: if you are doing only a few tests then manual data analysis might be the right step. But in most of the cases it is better to opt for a machine with a good control system. They have to collect large data and link it to the computer system for full testing analysis.

- A quality accessory test: if the collection of accessories is good it may make the machine versatile. An accessory can enable a same machine to be testing samples of various sizes, strengths in an effective way.

To sum it up the use of a concrete compression machine provides complete peace of mind by developing superior structures.

0 notes

Text

Everything Which The Organisations Should Know About The Cube Moulds Testing Machines

The moulding equipment has been perfectly listed under different kinds of international standards and has been utilised for casting by compaction and capping of cement concrete testing specimens to carry out different kinds of compressive strength tests. The cube moulds are utilised for casting cement and concrete specimens for carrying out different kinds of compressive strength testing systems as per the international standard: 516. The cube moulds testing machines are widely manufactured as per the international specifications and the faces of the machine flat with the help of plus -0.02 mm tolerance and the inside dimensions are also very much accurate within the plus -0.2 mm tolerances. Every mould is perfectly supplied with a base plate and is also provided with ISI marks.

Following are some of the basic models provided by the companies in this particular area:

- 50 MM: This is the very basic model that can be based upon cast iron and is utilised for mild steel.

- 70.6 MM: These are the cube moulds which are made up of steel and the tolerance between faces will be maintained at plus -0.1 mm and planes will be maintained at plus -0.03 mm. everything will be provided with an ISI mark.

- 100 MM: This will be made up of cast iron and will have an internal size of 100 MM with the tolerance of plus -0.2 and the best part is that everything is ISI marked.

- 150 MM: This particular cube mould will be made up of cast iron with an internal size of 150 MM along with the tolerance of plus -0.2 and it is also ISI marked.

- 200 MM: In this particular model the cube moulds will be made up of the cast iron.

- 300 MM: This particular model is also similar to the above mentioned once but it will be based upon a good capacity.

- 450 MM: The cube moulds mentioned above will be similar to this one and the cube mould will be made up of the cast iron.

All the above-mentioned sizes will be the standard sizes provided by different kinds of companies to the consumers but on the other hand, some special companies help in making sure the specific size can even be made at the request of the consumers without any kind of problem throughout the process so that overall goals are easily and efficiently achieved. Depending on such companies is considered to be a very good idea so that organisations also have proper access to the cube moulds testing apparatus so that there is no hassle throughout the process and everything has been perfectly achieved.

This concept will further help in making sure that organisations will be able to enjoy a good amount of consistency and accuracy throughout the process without any kind of a hassle because everything will be based upon the right kind of equipment to be used throughout the process along with right kind of systems without any kind of problem. Hence, being clear about all the above-mentioned model is considered to be the key to success in this particular area so that organisations are successful in the long run.

0 notes

Text

Things To Consider When Choosing A Universal Testing Machine

There are different types of issues that may crop up during the selection of a specific materials testing machine, especially one that gets used for multiple tests. Regardless of if a brand-new machine is being acquired or an upgrade is required from past selections, there are manifold crucial steps to consider before you purchase a universal testing machine.

Of course, if you have made up your mind to buy a machine, you should talk to Universal testing machine manufacturer in india and ensure that you have the best experience stored for you. Of course, there are a few things that you would need to keep in mind for the best results.

- Decide the ASTM or ISO national standard of testing to complete Every material that needs to be sold to the public or private sectors should definitely undergo rigorous testing according to national recommendations. The foremost step to take is to find out the kind of test a material should undergo (compression, torsion, tension, bend, peel, fatigue and so on. Of course, you need to ensure this factor or you may regret later on.

- Outline the calculations essential to test the specimen and what systems possess such capabilities. Of course, one of the most vital parts of picking a universal testing machine is choosing the controller to go along with it. You can check out choice between options like the standalone ep2 Digital Controller and the PC-based MTESTQuattro software, which has a huge library of calculations. The point is there are options and you must compare before you decide.

- Pick the utmost load essential for testing your material. Depending on the utmost load required to conduct a test, the kind of universal testing machine can be determined. Qualities such as table-top vs. Floorstanding, dual vs. Single column, and even that of electromechanical vs. Hydraulic can all be understood once the utmost load is chosen. The force capacity eventually determines the size of a system. You can check out various series of load cells to fit your needs.

- Decide the maximum speed essential to conduct the test. The speed that a material testing system carries out at can specify the motor, actuator, and even drive essential to equip the machine with. This is even an important factor to consider for static tests versus that of dynamic fatigue tests.

- Choose the grips or fixtures required to complete your test. Depending on the kind of specimen being tested, the grips purchased might be beneficial or hurt overall results. For instance, rope and thread grips should not be used on medical devices or that of metals. Manual vise grips or even that of pneumatic grips are assistive in testing such products.

Conclusion

So, you can check out universal testing machine india and ensure that you have the best machines on your side to help you carry out your tasks in the most effective and productive manner. After all, once you have the right tools on your side, you can make the most of every task you perform.

0 notes

Text

All That You Need To Know About The Cube Mould Testing Machine Equipment

The equipment that has been listed under the 42 series has been perfectly utilised for casting purposes with the help of compaction and capping of cement concrete testing specimen. Such equipment has been perfectly utilised for carrying out compressive and transverse strength testing following different kinds of IS specifications and standards so that accuracy and reliability are always present in the whole process.

The cube moulds are specifically utilised for casting the cement concrete testing specimens for carrying out compressive strength test as per the IS: 516. This particular type of mould has been manufactured as per the IS specifications and the faces of the machine will be flat with plus -0.02 mm tolerance. Every mould is supplied with a base plate and the following is the complete bifurcation of the cube moulds testing machines equipment:

1. 50 MM: This particular equipment is made up of cast iron and mild steel and is based upon IS 10086-1982. It includes HC 42.05 and 42.051.

2. 70.6 MM with ISI mark: These kinds of cube moulds are made up of steel and the tolerance between faces is maintained at plus -0.1 MM and the planes will be plus -0.0 3MM. Every cube mold in this particular area will carry the ISI mark.

3. 100 MM: The cube mould which is made up of cast iron and has an internal size of a hundred MM with a tolerance of plus -0.2 is the product included in this particular area and every mould will be ISI marked.

4. 100 MM BS 1881: These kinds of cube moulds always make this region requirement of all the above standard and will help in meeting the requirement of both dimensions as well as weight wise systems and the best part is that it is capable of fulfilling the specific requirements of the organisations very easily.

5. 150 MM with ISI mark: This particular type of cube mould will be made up of cast iron and has an internal size of 150 MM with a tolerance of plus -0.2 and plainness plus -0.03. Every cube mould manufactured under this is ISI marked.

6. 200 MM: All the cube moulds manufactured under this particular category are made up of cast iron and are as per the IS: 10086 and are also based upon HC42.35.

7. 300 MM: The cube moulds manufactured under this particular category are made up of cast iron and or as per the IS: 10086 along with HC42.40.

8. 450 MM: The cube moulds manufactured under this particular category will be made up of cast iron and will also be based upon IS: 10086 along with HC42.41.

All the above-mentioned cube mould sizes are very standard cube mould sizes but on the other hand, several kinds of manufacturers can even come up with customised options depending upon the overall requirements of the consumers. Hence, depending upon the cube moulds testing laboratory equipment suppliers is a great idea so that organisations are always able to make the right kind of decisions associated with the whole process.

0 notes

Text

Top 4 Advantages and Points Highlighting The Importance of Soil Testing Equipment

For ages, the geography of the earth has been classified into soil and water and soil is one of the most integral components of geography which is present almost everywhere. The utility of soil can range from anywhere to everywhere and it has been used as a major building component in the villages of India. Due to the advancements in technology, urbanisation has resulted in the formation of concrete of high-rise buildings into different nations but still, soil plays a very important role. The soil on the land where the multi-storey building has to be constructed is capable of holding such massive structures and because of this soil testing comes into play. Hence, the organisations are always under the diehard need of implementing the soil testing laboratory equipment throughout the process so that they can conduct testing and can ensure that overall goals are efficiently achieved with the help of a higher level of reliability and accuracy.

The role of soil is not only limited to the world of construction and another major role is in the agricultural sector. There are different kinds of countries which are dependent upon agriculture as the chief economic and in all such conditions the development of technologies should go in hand-in-hand with agriculture development. Several agricultural activities are dependent upon the quality of soil and if the farmers grow several things they also need to indulge in proper testing of the soil.

Following are the most important points associated with the importance of soil testing equipment:

1. Testing of the soil will include in-depth analysis of various particles and components and the fertility feature of the soil has to be tested with the help of soil testing equipment for agriculture. These kinds of tools are also very much useful in terms of analysing the presence of pathogens in the soil so that bacteria and virus can be studied accordingly.

2. The presence of heavy materials like mercury and other contaminants will make sure that soil is fit for purposes or not. So, to measure the level of contamination it is important to use soil testing equipment for the whole process.

3. Specific kinds of tools are also utilised in analysing the particle size of the soil depending upon the diameter and physical properties of the soil also need to be analysed thoroughly before any kind of construction activity. Such tools are also utilised in terms of settling the chemical properties of the soil so that people have a proper idea of the exact pH measure of the soil. Having information about the quality of soil is another very important thing to be taken into consideration.

4. These kinds of soil testing samples are tested in two laboratories that have sufficient instruments for the holistic testing of the sound. Chemical analysis has to be carried out along with microbial analysis so that the right kinds of decisions are always made.

Hence, the utilisation of soil test engineering test equipment is very much important so that field health can be maintained and the right kind of activities can be carried out very accurately.

0 notes

Text

Things To Consider While Selecting The Universal Testing Machine

The universal testing machine is one of the most popular testing machines across the globe as it can undertake the test of a different material. This machine has taken over the forced testing machines that were earlier popularly used. UTM helps in providing valuable information to the user. But finding the right universal testing machine suppliers in India must not be taken for granted. Various things are to be looked into in ensuring that you come across the quality universal testing machine. Some of these things are mentioned below:

- Type of Test: Different material undergoes a different type of test such as torsion test, compression test, fatigue, etc. One must know what type of test is required for material and thereby choose the UTM efficient in conducting such test. Choose the UTM with ATSM or ISO rating as it provides the surety of quality.

- Outline the Calculation: One must outline the calculations that are required to test the material as it will help in determining the right system and controller. One can choose between standalone digital controllers or PC-based software that provides a comprehensive library of calculations.

- Maximum Load: Before selecting the right system, one must always consider the maximum load of material that is required for testing. This is because there are several options to choose from such as single column, hydraulic vs. electromechanical, etc. All these choices can be overwhelming when one is not sure about the maximum load. Choose the system which best fits one requirement.

- Speed: The next important to take into consideration while selecting the system is the speed as it helps the individual to specify the drive and actuator need in the machine. This factor is of paramount importance, especially in static vs. dynamic tests.

- Grips: The grips must be purchased only after taking into consideration the specimen being used for testing. One must remember that not all grips and fixtures work for all material. There are various grips and fixtures to choose from but a wrong decision can haul the process.

- The choice between deflectometer and extensometer: One must make an important decision of whether to choose between deflectometer and extensometer based on which will be beneficial to the testing material. Extensometer is used for accurately determining the specimen extension during the test whereas a deflectometer is used for calculating the deformation that occurs during the test. Choose the device as per your material testing requirement.

- Future Possibilities: One must choose the universal testing machine that is not apt for your current testing needs but also has the capabilities in meeting future needs. This is because one might need one or maybe 2 tests today but in the future the demand might expand so it is recommended to choose the system with multiple testing capabilities.

- Customer Support: Customer support is integral when it comes to selecting the right system as with time the machine undergoes stress. Thereby the system with good customer support is the safest bet.

Hence these are some of the factors that one must look into before selecting the universal material testing machine

0 notes

Text

Different types of bitumen quality tests used in the road work

Construction of anything that can be road or any building involves a lot of planning behind it. To ensure that the construction work done of it will provide the best result, some tests are conducted to evaluate the consistency, temperature, gradation, and safety of the bitumen. For this different types of tests are conducted using different types of equipment like the penetration test of bitumen apparatus.

Some of the tests are stated below that evaluates the characteristics of the bituminous rocks.

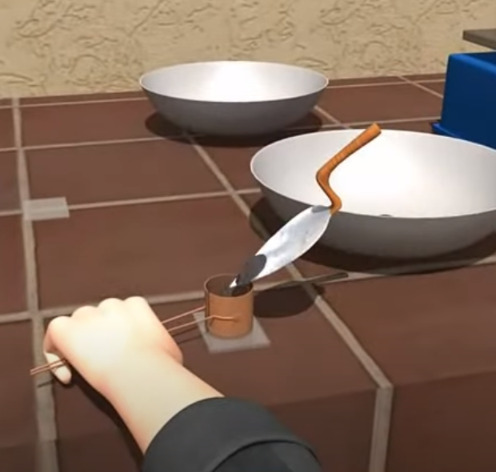

Softening point test: The softening point is when the bitumen is kept under certain temperature conditions so that it can become very soft. For conducting these tests, there is the requirement of ring and ball apparatus. The ring keeps the bitumen sample in the glycerine and the ball is used to put the sample into heat. In this, the temperature is recorded when the bitumen reaches the point of being soft.

Flash and Fire point test: It is very important to check the volatility of the bitumen that is released at high temperatures. So it is very important to make sure that the bitumen should not be overheated so that it catches fire. The flashpoint test will help in evaluating the highest temperature the bitumen can withstand without getting into adverse conditions.

Viscosity test: It is the liquid characteristics of bituminous. This test measures the resistance to flow and measures at what temperature the concrete mix can provide the best results. So every time the concrete mixing is done for the construction purpose the viscosity is observed to get the most stable values.

Ductility test: It is the characteristic of the bitumen that helps in undergoing deformation. The ductility is measured in cm and to evaluate the standard sample of the bitumen will be deformed without breaking it. To conduct these tests, the bitumen sample is heated to a great extent and further, it is poured into the mold and after this, the molds are kept in the cool air. Even after this, the molds are given a water bath for cooling them down. The value of the ductility can be influenced by the temperature at the test and the rate of pulling.

Penetration test: This is one of the tests that is conducted to check the hardness or the softness of the bitumen. The standard bitumen extraction test apparatus is used to conduct the test. The penetrometer is made up of a needle that will weigh around 100 g. The bitumen is decreased to the pouring consistency so that it can be emptied into the containers as per the requirement. The penetration value can get affected if any error in the pouring or the test temperature is done.

All these tests are done according to the need of the construction site. But it is for sure, it is very important to conduct them to have all the in-depth details that will help in taking the best decisions. These decisions can help in getting the best and the most desired results.

0 notes