Text

These readers are used for advanced automation and management system such as Automatic Time Attendance for Schools, Personnel Tracking in Manufacturing Plants, Library Security, Access Control, Toll Plaza Automation, Parking Automation, Hospital Management, Laundry Automation, Event Management, Logistics Management, and other customized Automation Processes and Solutions.

The Advantage of using RFID Readers is it saves a lot of time, for access and identification, they are accurate, more reliable, and can be used in demanding environments, even in crowded areas, there is no need to flash the card. These RFID readers have an inbuilt motion detector to allow only persons with a valid RFID Tag/Card to access the premises. These readers are with LF, HF, and UHF frequency, with a reading distance of up to 15 m depending on the RFID Tag and external factors.

#rfid solutions#rfid technology#rfid reader#handheld scanner#inventory management#retail solutions#rfid scanner

0 notes

Text

RFID Readers vs. Barcode Scanners: A Comparative Analysis

The debate between RFID (Radio Frequency Identification) and barcode technology revolves around their respective capabilities, limitations, and suitability for various applications in inventory management and tracking. While both technologies serve the common purpose of capturing data, they differ significantly in their operating principles, performance, and cost considerations. This debate has intensified as businesses seek to optimize their operations and leverage advancements in tracking and logistics technology.

RFID vs. Barcode: A Concise Comparison

Aspect -

Operating Principle

Data Capture Speed

Range and Flexibility

Durability

Cost Considerations

RFID Readers -

It uses radio waves to communicate with RFID tags.

High-speed data capture; reads multiple tags quickly.

Greater range and flexibility; reads tags remotely.

RFID tags are durable; RFID readers have fewer moving parts.

Higher upfront costs; ongoing expenses for tags.

Barcode Scanners -

It relies on optical scanning to read barcodes.

Slower data capture; reads one barcode at a time.

Limited range; requires direct line-of-sight.

Barcode labels can be damaged; scanners may require maintenance.

Lower initial investment: maintenance costs may accrue over time.

Higher upfront costs; ongoing expenses for tags.

Lower initial investment: maintenance costs may accrue over time.

Will RFID Replace Barcode?

The question of whether RFID will eventually replace barcode technology has puzzled experts and businesses alike. While RFID offers several advantages over traditional barcode scanners, like faster data capture, greater automation, and improved efficiency in inventory management, making RFID the go-to choice comes with its own set of challenges.

Cost is a big concern. RFID demands a hefty upfront investment in readers, tags, and infrastructure. For smaller businesses, these costs can be a barrier to adoption.

Compatibility is another issue. Many businesses have already heavily invested in barcode technology, with established systems and processes centered around barcode scanning. Shifting to RFID would mean significant changes to how things operate, which might not be practical or cost-effective in the short term.

The future might not be about choosing one over the other but finding ways for RFID and barcode tech to work together. Hybrid systems that blend both technologies can offer the best of both worlds, letting businesses enjoy the perks of RFID while still relying on the trusty barcode when needed.

While RFID technology offers compelling advantages over traditional barcode systems, including faster data capture, greater automation, and improved efficiency, the widespread replacement of barcodes with RFID is unlikely to occur soon. Instead, businesses are likely to adopt a pragmatic approach, integrating RFID where it provides clear benefits while continuing to utilize barcode technology where it remains effective and cost-efficient. The future of tracking and logistics technology may thus be characterized by a hybrid approach that combines the strengths of RFID and barcode systems to meet the diverse needs of businesses across various industries.

#rfid solutions#rfid technology#rfid reader#rfid scanner#handheld scanner#inventory management#retail solutions#rfid garments tag#barcode scanner

0 notes

Text

Efficient inventory management is crucial for any business, and RFID scanners play a significant role in streamlining this process. With many options available, choosing the right scanner can be daunting. This guide will help you navigate the key considerations and select the perfect RFID scanner for your inventory management needs.

#rfid scanner#rfid solutions#rfid technology#rfid tags#rfid reader#active rfid tags#Handheld Scanner#inventory management#warehouse management#retail solutions

0 notes

Text

How to Choose the Right RFID Scanner for Your Inventory Management

Efficient inventory management is crucial for any business, and RFID scanners play a significant role in streamlining this process. With many options available, choosing the right scanner can be daunting. This guide will help you navigate the key considerations and select the perfect RFID scanner for your inventory management needs.

Understanding RFID Technology

Before diving into the selection process, it's essential to understand how RFID (Radio Frequency Identification) technology works. RFID systems comprise tags, readers, and software. The RFID scanner (reader) uses radio waves to communicate with RFID tags attached to items in your inventory. This technology allows for quick and accurate data collection, significantly improving inventory tracking and management.

Key Factors to Consider

When choosing an RFID scanner, consider the following factors to ensure it meets your inventory management requirements:

1. Range and Frequency

RFID scanners operate at different frequencies (low, high, and ultra-high frequency). The frequency affects the range and speed of data transmission.

Low Frequency (LF): Suitable for short-range applications (up to 10 cm), such as animal tracking.

High Frequency (HF): Ideal for medium-range applications (up to 1 meter), including access control and ticketing.

Ultra-High Frequency (UHF): Best for long-range applications (up to 12 meters), making it perfect for inventory management in warehouses.

2. Environment and Durability

Consider the environment where the RFID scanner will be used. If your inventory is managed in harsh conditions (e.g., extreme temperatures, dust, moisture), opt for a rugged and durable scanner. Look for devices with an IP (Ingress Protection) rating that indicates their resistance to environmental factors.

3. Portability and Ergonomics

Depending on your operational needs, you may require handheld or fixed RFID scanners.

Handheld Scanners: Provide mobility and flexibility, allowing staff to move freely while scanning items.

Fixed Scanners: Ideal for static installations, such as conveyor belts or entry/exit points, where continuous scanning is required.

Ergonomics is also crucial for handheld scanners to ensure they are comfortable for prolonged use.

4. Read Speed and Accuracy

Efficient inventory management depends on the speed and accuracy of the RFID scanner. Look for devices that offer high read rates and accuracy, especially if you handle large volumes of inventory. This ensures quick data capture and minimizes errors.

5. Integration and Compatibility

Ensure that the RFID scanner integrates seamlessly with your existing inventory management system. Compatibility with your software and hardware infrastructure is vital for smooth operations. Check if the scanner supports common communication protocols and can easily connect to your database.

6. Battery Life

For handheld RFID scanners, battery life is a critical consideration. Choose scanners with long-lasting batteries to avoid frequent recharges and interruptions during inventory processes. Some models also offer replaceable batteries for extended use.

7. Cost and Budget

It's important to consider your budget when making a decision, although cost shouldn't be the only determining factor. Evaluate the total cost of ownership, including initial purchase price, maintenance, and potential upgrades. Investing in a high-quality RFID scanner may have a higher upfront cost but can save money in the long run by improving efficiency and reducing errors.

Popular RFID Scanner Models for Inventory Management

Here are a few popular RFID scanner models that are well-suited for inventory management:

IDT RHC72: IDT RHC72 is an android-based rugged portable scanner specially designed for hassle-free scanning of items. This device is packed with features and offers best-in-class ease of use and integration tools, combined with a powerful RFID engine. It delivers exceptional performance in demanding scanning environments such as logistics, warehouse management, manufacturing, retail solutions, and asset tracking. Additionally, it can be equipped with either an E710 or R2000 linearly or circularly polarized antenna, enabling it to read tags in bulk from long distances.

IDT RH160IDT: RH160 is a versatile UHF scanner that supports UHF RFID as well as 1D/2D scanning. It is integrated with a self-developed Impinj E310 chip-based UHF module that provides outstanding tag reading performance with a maximum reading range of 30 cm. Experience high-performance barcode scanning with our advanced scanner, capable of reading various 1D and 2D barcodes. This versatile device is suitable for a wide range of applications, including retail, inventory, warehouse, logistics, and manufacturing. With its powerful capabilities, the IDT RH160 is an excellent choice for businesses that require reliable and efficient scanning technology.

The IDT RHC4050 is an extremely durable and rugged RFID reader that operates on the Android platform. This device is specifically designed to deliver exceptional RFID performance with a read range of over 10 meters, making it the ideal choice for bulk reading operations.This versatile RFID reader is an excellent choice for a wide range of industries, including Logistics, Retail, Warehousing, Energy, Industrial Management, Livestock Management, and more. With its seamless integration capabilities, the IDT RHC4050 is a powerful asset for any business, delivering top-tier performance and durability in even the most demanding environments.

Conclusion

Choosing the right RFID scanner for your inventory management involves evaluating your specific needs and considering factors such as range, durability, portability, read speed, integration, battery life, and cost. By understanding these elements, you can make an informed decision that enhances your inventory processes, improves accuracy, and boosts overall efficiency.

For more insights on inventory management and the latest in RFID technology, follow our blog and stay updated with industry trends.

For any Inquiry Call Us On - 9910885043

#RFID Scanner#rfid solutions#rfid technology#rfid reader#rfid tags#Handheld Scanner#warehouse management#inventory management#Retail Solutions

0 notes

Text

An RFID tag is composed of two fundamental components: an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) that stores the tag's ID and other relevant information.

RFID tags use radio waves to transmit data about an item to the antenna/reader combination. These tags typically do not have a battery, unless specified as Active or BAP tags. "They" refers to passive RFID tags, which do not have their own power source. Instead, they receive the energy required to operate from the radio waves generated by the RFID reader. When the tag receives the transmission from the antenna/reader, the energy flows through the internal antenna to the tag’s chip. This energy activates the chip, which then modulates the energy with the desired information and transmits a signal back to the antenna/reader.

#rfid tags#rfid solutions#rfid tags manufacturers#rfid technology#active rfid tags#rfid reader#rfid manufacturing company

0 notes

Text

Choosing the Right RFID Tag: A Breakdown of Different Types and Their Uses

Introduction to RFID Tags and Their Functionality

An RFID tag is composed of two fundamental components: an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) that stores the tag's ID and other relevant information.

RFID tags use radio waves to transmit data about an item to the antenna/reader combination. These tags typically do not have a battery, unless specified as Active or BAP tags. "They" refers to passive RFID tags, which do not have their own power source. Instead, they receive the energy required to operate from the radio waves generated by the RFID reader. When the tag receives the transmission from the antenna/reader, the energy flows through the internal antenna to the tag’s chip. This energy activates the chip, which then modulates the energy with the desired information and transmits a signal back to the antenna/reader.

On each chip, there are four memory banks – EPC, TID, User, and Reserved. Each of these memory banks contains information about the item that is tagged or the tag itself, depending on the bank and its specifications. Two of the memory banks, EPC and User, can store unique identifying information. The TID bank cannot be updated because it contains information about the tag itself and the unique tag identifier. The tag’s Reserved memory bank is used for special tag operations, such as locking the tag or expanding its available EPC memory. Different types of tags exist, including read-only tags that allow reading of stored data but not changing it, read/write tags that allow alteration or rewriting of stored data, and a combination of both, where some data is permanently stored while the remaining memory is left accessible for future encoding and updates.

RFID Tag Types and Operational Modes

Hundreds of different RFID tags are available in various shapes and sizes, each with features and options specific to certain environments, surface materials, and applications. Choosing the ideal tag for a specific application, environment, and item material is crucial for optimal tag performance.

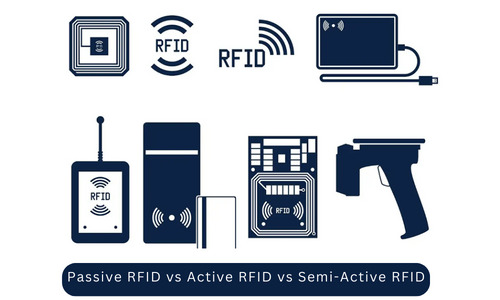

An RFID Tag can be categorized into passive, semi-passive, or active.

Passive tags, the more common variant, do not require direct line-of-sight to a reader, making them versatile but with a shorter read range. They are compact and lightweight, activated by the energy from an RFID reader. This tag has a limited range of 0-15 meters, which makes it suitable for short-range applications only. The reading range is constrained by the power required to activate the chip. Given their size and cost, passive tags are the most common and can be inlaid like labels or take the form of hard tags made from materials such as plastic or metal. Ideal for applications requiring close-range identification, such as inventory management, access control, and retail item tracking.

Active RFID tags, featuring a battery that requires replacement every 3-5 years, excel in live tracking applications, offering an extended read range compared to passive tags. They have a higher reading range (up to 100 meters) than passive tags. These tags are more expensive due to the cost of their battery and transmitter. Despite the higher cost, they are suited for real-time tracking of high-value assets, vehicle tracking, and monitoring large-scale operations like shipping and logistics.

Semi-Passive Tags, very rarely used, function somewhere between active and passive tags. These tags are battery-powered, helping extend the communication range. Find applications in environments where a longer communication range is needed but where the continuous transmission of active tags may not be necessary, such as environmental monitoring and equipment maintenance tracking.

To Get More Information Visit our Website: https://www.idsolutionsindia.com/product/rfid-tags/

#RFID tags#RFID readers#RFID solutions#RFID technology#RFID tags cost#Active RFID tags#RFID tags manufacturers#RFID clothing tags#RFID laundry tags#Inventory Management System#Animal warehouse management

0 notes

Text

In India, the pervasive influence of RFID technology is causing a profound shift in industries and everyday routines. Its wireless capabilities find diverse applications, from optimizing inventory management in retail to streamlining healthcare record-keeping. As India progresses in its digital transformation, RFID adoption is surging across sectors, delivering unmatched efficiency, precision, and ease.

In this RFID-driven landscape, ID Tech emerges as a leading RFID solution provider, playing a pivotal role in India’s technological advancement. With a diverse range of applications, ID Tech has provided solutions for wagon tracking, file tracking, library automation, e-seals, container tracking, and more. As India embraces the era of digital transformation, ID Tech stands at the forefront, providing unmatched expertise and innovative RFID solutions that drive efficiency, precision, and ease across sectors.

#RFID solutions#rfid technology#rfid reader#rfid tags#rfid scanner#RFID tags manufacturers#rfid manufacturing company#rfid manufactures

1 note

·

View note