Text

Engineering is One of the Leading Manufacture and Supplier of Stainless Steel Nuts.

#Stainless Steel Stud Bolt Manufacturers In India#Stainless Steel 304 Stud Bolts#SS Stud Bolts#304 SS Stud Bolts#Stainless Steel Stud Bolts#Stud Bolts For Stainless Steel Flanges#Stainless Steel Stud bolts and nuts#SS Bolts

0 notes

Text

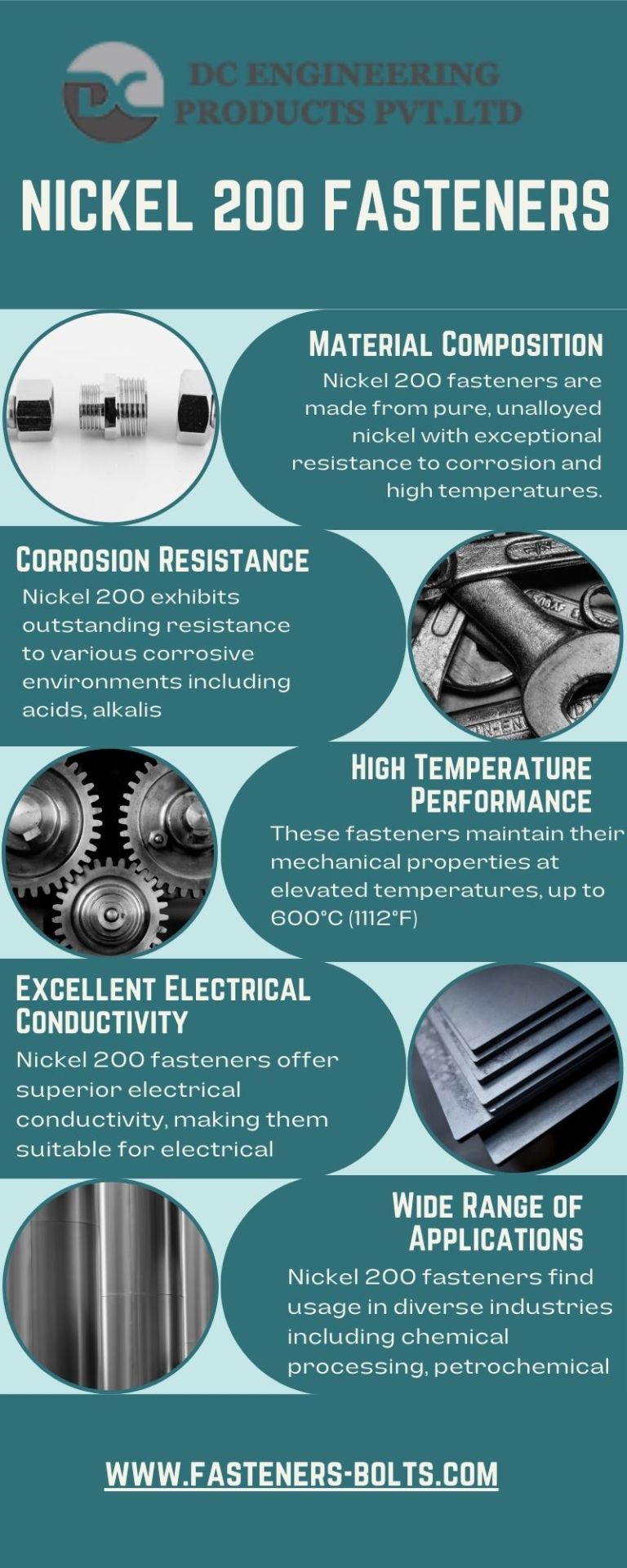

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

STAINLESS STEEL NUTS

Stainless Steel Nuts

In the world of fasteners, where every bolt, screw, and nut plays a crucial role in holding structures together, stainless steel nuts stand out as unsung heroes. Often overlooked compared to their flashier counterparts, stainless steel nuts play a vital role in various industries, offering durability, corrosion resistance, and reliability. Among the companies championing the excellence of stainless steel nuts, DC Engineering shines brightly, providing top-quality solutions that stand the test of time.

The Superiority of Stainless Steel Nuts

Stainless steel nuts are the backbone of countless structures, from towering skyscrapers to intricate machinery. What sets them apart is their composition of iron alloyed with chromium, which forms a protective layer on the surface, preventing corrosion and rusting, even in the harshest environments. This innate corrosion resistance makes Stainless steel nuts ideal for outdoor applications, marine environments, and industries where sanitation is paramount, such as food processing and pharmaceuticals.

Furthermore, stainless steel nuts offer exceptional strength and durability, ensuring that joints remain securely fastened under heavy loads and extreme conditions. This reliability is indispensable in critical infrastructure and safety-critical applications, where the failure of a single fastener could have catastrophic consequences.

DC Engineering: Elevating Stainless Steel Nuts to New Heights

Among the leading providers of Stainless steel nuts, DC Engineering stands out for its commitment to excellence and innovation. With a reputation built on quality craftsmanship and unparalleled expertise, DC Engineering has become synonymous with reliability and customer satisfaction.

DC Engineering's stainless steel nuts are engineered to meet the highest standards of performance and durability. Utilizing premium-grade stainless steel alloys and state-of-the-art manufacturing processes, each nut is precision-crafted to exacting specifications, ensuring a perfect fit and maximum holding power.

But DC Engineering's dedication to excellence goes beyond just the product. Their team of skilled engineers and technicians works tirelessly to understand the unique needs of their customers and provide tailored solutions that exceed expectations. Whether it's custom sizing, special coatings, or innovative designs, DC Engineering goes the extra mile to ensure that every client receives the perfect fastening solution for their specific application.

The Versatility of Stainless Steel Nuts

One of the most remarkable qualities of Stainless steel nuts is their versatility. From industrial machinery to household appliances, automotive components to aerospace technology, stainless steel nuts find application in virtually every sector imaginable. This versatility is a testament to their reliability, adaptability, and enduring performance.

Whether it's holding together a suspension bridge, securing a satellite in orbit, or simply keeping a kitchen cabinet door closed, stainless steel nuts play an indispensable role in our daily lives, often without us even realizing it. And behind many of these vital connections, you'll find the craftsmanship and expertise of DC Engineering, ensuring that the world stays securely fastened together.

Conclusion

In a world where strength, durability, and reliability are paramount, Stainless steel nuts stand as beacons of excellence. And leading the charge in providing top-quality stainless steel nuts is DC Engineering, a company dedicated to pushing the boundaries of innovation and craftsmanship. With their unwavering commitment to quality and customer satisfaction, DC Engineering continues to elevate stainless steel nuts to new heights, ensuring that the structures and technologies of tomorrow remain securely fastened together.

0 notes

Text

STAINLESS STEEL 310/310S STUD BOLTS

Introduction:

In the realm of industrial materials, few substances match the versatility, durability, and reliability of stainless steel. Among the plethora of stainless steel grades available, Stainless Steel 310 stands out as a formidable choice for various applications across industries. Recognizing its significance, DC Engineering is proud to shed light on the exceptional qualities and applications of Stainless Steel 310.

Stainless Steel 310: The Unyielding Alloy:

Stainless Steel 310 is a high chromium-nickel alloy renowned for its exceptional resistance to high-temperature environments. Composed primarily of iron, chromium, and nickel, with additions of manganese and silicon, SS 310 exhibits superior oxidation resistance even under cyclic conditions.

Key Attributes of Stainless Steel 310:

High Temperature Resistance: One of the most prominent features of Stainless Steel 310 is its ability to withstand elevated temperatures. It retains strength and oxidation resistance at temperatures up to 2100°F (1149°C), making it ideal for applications in heat treatment furnaces, radiant tubes, and other high-temperature environments.

Corrosion Resistance: SS 310 offers excellent resistance to oxidation and corrosion in various atmospheric environments. Its chromium and nickel content form a protective oxide layer, enhancing its durability and longevity in corrosive settings, including chemical processing plants and marine environments.

Superior Mechanical Properties: With its combination of high chromium and nickel content,Stainless Steel 310 boasts excellent mechanical properties, including high tensile strength, toughness, and ductility. This makes it suitable for structural components, piping systems, and pressure vessels subjected to high stress and temperature fluctuations.

Applications of Stainless Steel 310:

Heat Treatment Furnaces: Due to its exceptional high-temperature resistance, SS 310 is commonly used in the construction of heat treatment furnaces, where it ensures prolonged service life and reliable performance under extreme thermal conditions.

Chemical Processing Equipment: In chemical processing industries,Stainless Steel 310 finds extensive use in reactors, heat exchangers, and piping systems handling corrosive chemicals and high-temperature fluids, where its resistance to oxidation and corrosion is paramount.

Aerospace and Power Generation: The aerospace and power generation sectors rely on SS 310 for components exposed to extreme temperatures and demanding operating conditions. Its high-temperature strength and oxidation resistance make it indispensable for gas turbine engine components, exhaust systems, and aerospace structures.

Petrochemical Industry: Stainless Steel 310 plays a vital role in the petrochemical industry, where it is utilized in refinery equipment, distillation columns, and piping systems for its ability to withstand aggressive environments and high-temperature processes.

DC Engineering: Your Trusted Partner for Stainless Steel Solutions:

At DC Engineering, we pride ourselves on delivering premium-grade stainless steel products tailored to meet the diverse needs of our clients. With a commitment to quality, innovation, and customer satisfaction, we offer a comprehensive range of Stainless Steel 310 products engineered to excel in the most demanding applications.

From customized fabrications to off-the-shelf components, our experienced team employs state-of-the-art manufacturing processes and stringent quality controls to ensure the highest standards of excellence. Whether you require heat-resistant furnace components, corrosion-resistant piping systems, or precision-engineered structural components, DC Engineering is your trusted partner for superior stainless steel solutions.

Conclusion:

Stainless Steel 310 stands as a testament to the ingenuity and resilience of modern metallurgy, offering unparalleled performance in high-temperature and corrosive environments. With its remarkable attributes and diverse applications, SS 310 continues to be a cornerstone material across industries, driving innovation and progress.

0 notes

Text

Super Duplex Steel 32750 Fasteners

Super Duplex Steel 32750 Fasteners

Introduction:

In the realm of industrial engineering, the choice of materials for fasteners plays a pivotal role in ensuring structural integrity, corrosion resistance, and longevity of assemblies. Super Duplex Steel 32750 emerges as a frontrunner in this domain, offering a remarkable blend of strength, durability, and resistance to harsh environments. Among the champions of innovation in this field is DC Engineering, a leading company that recognizes the unparalleled advantages of Super Duplex Steel 32750 fasteners.

Understanding Super Duplex Steel 32750:

Super Duplex Steel 32750 is a high-alloy material characterized by its exceptional corrosion resistance and mechanical properties. Composed of a balanced mixture of austenite and ferrite phases, this steel exhibits superior strength, making it ideal for demanding applications in industries such as oil and gas, marine, chemical processing, and more. The addition of elements like chromium, molybdenum, and nitrogen enhances its resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking, thereby extending its service life even in aggressive environments.

Advantages of Super Duplex Steel 32750 Fasteners:

Corrosion Resistance: One of the most notable features of SuperDuplex Steel 32750 fasteners is their exceptional resistance to corrosion. This property makes them well-suited for offshore and marine applications where exposure to saltwater and harsh chemicals is common.

High Strength: With higher tensile and yield strengths compared to conventional stainless steel fasteners, Super Duplex Steel 32750 fasteners offer enhanced reliability and load-bearing capacity, ensuring structural integrity in critical assemblies.

Durability: The inherent robustness of Super Duplex Steel 32750 translates into excellent durability, allowing fasteners to withstand extreme temperatures, pressure fluctuations, and mechanical stresses without compromising performance.

Cost Efficiency: While Super Duplex Steel 32750 fasteners may have a higher initial cost than standard materials, their extended service life and reduced maintenance requirements contribute to long-term cost savings, making them a sound investment for industrial applications.

DC Engineering: Pioneering Excellence in Fastening Solutions:

DC Engineering stands at the forefront of engineering innovation, offering a comprehensive range of high-quality fastening solutions tailored to meet the diverse needs of modern industries. With a steadfast commitment to excellence, DC Engineering leverages cutting-edge technologies and industry expertise to deliver products that exceed customer expectations.

The inclusion of Super Duplex Steel 32750 fasteners inDC Engineering's product portfolio underscores the company's dedication to providing superior solutions that prioritize performance, reliability, and longevity. By harnessing the unique properties of this advanced material, DC Engineering empowers businesses to optimize their operations, enhance safety, and achieve sustainable growth.

Conclusion:

In the dynamic landscape of industrial engineering, the selection of appropriate fastening materials is paramount to the success and longevity of critical infrastructure. Super Duplex Steel 32750 fasteners emerge as a standout choice, offering unparalleled corrosion resistance, strength, and durability. With DC Engineering leading the charge in delivering innovative fastening solutions, industries can harness the full potential of Super Duplex Steel 32750 to overcome challenges, elevate performance, and drive progress in a competitive global market.

0 notes

Text

Duplex Steel UNS S32205 Bolts

Duplex Steel UNS S32205 Bolts

In the realm of engineering and construction, the significance of quality fasteners cannot be overstated. Bolts, in particular, serve as the backbone of structural integrity, holding together critical components with steadfast reliability. Among the myriad materials available for bolt manufacturing, Duplex Steel UNS S32205 emerges as a beacon of excellence, embodying the fusion of strength, corrosion resistance, and durability. In this article, we delve into the remarkable attributes of Duplex Steel UNS S32205 bolts, unraveling their unparalleled superiority in various applications.

Understanding Duplex Steel UNS S32205:

Duplex stainless steels represent a class of materials renowned for their exceptional combination of properties. UNS S32205, in particular, stands out due to its dual-phase microstructure, comprising austenite and ferrite phases in roughly equal proportions. This unique composition imparts remarkable mechanical and corrosion-resistant properties, making it ideal for demanding environments where conventional materials falter.

Strength and Durability:

At the core of its allure lies the formidable strength of Duplex Steel UNS S32205. Bolts crafted from this material exhibit superior tensile and yield strengths compared to traditional stainless steels. This robustness enables them to withstand high mechanical loads, ensuring structural integrity even under challenging conditions. Whether it's in offshore rigs, chemical processing plants, or marine structures, the resilience of UNS S32205 bolts remains unmatched, providing a reliable foundation for critical installations.

Corrosion Resistance:

One of the most distinguishing features of Duplex Steel UNS S32205 is its exceptional corrosion resistance. The alloy's dual-phase structure acts as a barrier against corrosive agents, including chloride ions, acidic solutions, and harsh chemicals. This inherent resistance to pitting, crevice corrosion, and stress corrosion cracking makes it a preferred choice for applications exposed to corrosive environments. In industries such as oil and gas, desalination, and pulp and paper, where corrosion poses a significant threat to equipment longevity, the deployment of UNS S32205 bolts ensures prolonged service life and minimal maintenance requirements.

DC Engineering: Pioneering Excellence in Fastening Solutions

In the realm of engineering solutions, DC Engineering stands at the forefront, epitomizing innovation, quality, and reliability. With a commitment to excellence ingrained in its ethos, DC Engineering has established itself as a trusted provider of cutting-edge fastening solutions tailored to meet the diverse needs of industries worldwide.

Through meticulous research and development, DC Engineering has harnessed the unparalleled properties of Duplex Steel UNS S32205 to engineer a range of high-performance bolts that exceed industry standards. Leveraging advanced manufacturing techniques and stringent quality control measures, DC Engineering ensures that each bolt bearing its insignia delivers unmatched performance and durability.

Conclusion:

In the intricate tapestry of modern engineering, the significance of high-quality fasteners cannot be overstated. Duplex Steel UNS S32205 bolts, with their unparalleled strength, corrosion resistance, and durability, emerge as a testament to ingenuity and precision engineering. As industries continue to push the boundaries of performance and reliability, the collaboration between innovative materials like UNS S32205 and pioneering companies like DC Engineering paves the way for a future built on a foundation of excellence and resilience.

0 notes

Text

ASTM A193 B6 Stud Bolts

In the realm of engineering, precision and reliability are paramount. Industries ranging from construction to manufacturing rely heavily on the integrity of fasteners to ensure the structural integrity and safety of their projects. In this pursuit, ASTM A193 B6 Stud Bolts emerge as stalwarts, offering a blend of durability, corrosion resistance, and strength. In this article, we delve into the characteristics and advantages of ASTM A193 B6 Stud Bolts, shedding light on their significance in various applications. Additionally, we explore how DC Engineering, a leading player in the engineering domain, harnesses these qualities to deliver unparalleled solutions to its clients.

Understanding ASTM A193 B6 Stud Bolts:

ASTM A193 B6 Stud Bolts are a type of fastener engineered to withstand high levels of tensile stress and extreme environmental conditions. These bolts are manufactured from austenitic stainless steel, specifically grade B6, which contains chromium, nickel, and molybdenum. This composition renders ASTM A193 B6 Stud Bolts resistant to corrosion, oxidation, and various forms of chemical attack, making them ideal for use in harsh environments such as marine applications, chemical processing plants, and offshore structures.

Moreover, ASTM A193 B6 Stud Bolts undergo rigorous testing and quality control measures to ensure compliance with ASTM International standards. These standards guarantee uniformity in material composition, mechanical properties, and dimensional accuracy, thereby enhancing the reliability and performance of the fasteners.

Advantages of ASTM A193 B6 Stud Bolts:

Corrosion Resistance: One of the primary advantages of ASTM A193 B6 Stud Bolts is their exceptional corrosion resistance. The presence of chromium and nickel in the stainless steel alloy forms a passive oxide layer on the surface, protecting the bolts from corrosive agents such as saltwater, acids, and alkalis. This property extends the service life of the fasteners, reducing maintenance costs and downtime.

High Strength: ASTM A193 B6 Stud Bolts exhibit high tensile strength, allowing them to withstand heavy loads and extreme tension without deformation or failure. This strength is crucial in applications where structural integrity is paramount, such as in construction, power generation, and petrochemical industries.

Temperature Stability: The molybdenum content in ASTM A193 B6 Stud Bolts enhances their resistance to high temperatures and thermal cycling. This feature makes them suitable for use in elevated temperature environments where conventional fasteners might degrade or lose their mechanical properties.

Versatility: Due to their superior mechanical properties and corrosion resistance, ASTM A193 B6 Stud Bolts find application across a wide range of industries and environments. Whether it's securing flanges in pipelines, anchoring structural components, or fastening equipment in corrosive environments, these bolts offer versatile solutions to diverse engineering challenges.

DC Engineering: Pioneering Excellence in Fastening Solutions

At the forefront of engineering innovation stands DC Engineering, a renowned provider of precision-engineered solutions to industries worldwide. Leveraging decades of experience and a commitment to excellence, DC Engineering specializes in the design, manufacturing, and supply of high-performance fasteners, including ASTM A193 B6 Stud Bolts.

With a focus on quality and reliability, DC Engineering ensures that every fastener meets the most stringent industry standards, exceeding the expectations of its clients. The company's state-of-the-art manufacturing facilities, coupled with a team of skilled engineers and technicians, enable it to deliver customized solutions tailored to specific project requirements.

DC Engineering's dedication to innovation extends beyond product excellence to encompass comprehensive support services, including technical consultation, material selection guidance, and onsite assistance. By forging collaborative partnerships with its clients, DC Engineering strives to anticipate challenges and deliver cost-effective, sustainable solutions that drive success.

conclusion

ASTM A193 B6 Stud Bolts epitomize the pinnacle of fastening technology, offering unparalleled strength, corrosion resistance, and reliability. As industries continue to evolve and demand higher performance from their engineering components, these fasteners remain indispensable assets in ensuring the integrity and longevity of critical infrastructure. With DC Engineering leading the charge in innovation and quality, the future of fastening solutions looks promising, underpinned by a steadfast commitment to excellence and customer satisfaction.

#ASTM A193 Grade B6 Bolts#ASTM A193 B6 Bolts#ASTM A193 B6 Stud Bolts#ASTM A193 B6 Stainless Steel Bolts

0 notes

Text

Duplex Steel UNS S32205 Bolts

In the realm of engineering and construction, selecting the right materials is paramount. From bridges to skyscrapers, every structure relies on the strength and reliability of its components. When it comes to fasteners like bolts, the choice of material can make a significant difference in the integrity and longevity of a project. One material that stands out in this regard is Duplex Steel UNS S32205, a versatile alloy known for its exceptional properties. In this article, we delve into the world of Duplex Steel UNS S32205 bolts, exploring their characteristics, applications, and why they're a preferred choice for many industries.

Understanding Duplex Steel UNS S32205:

Duplex Steel UNS S32205 is a duplex stainless steel that combines the desirable properties of both austenitic and ferritic stainless steels. It offers excellent corrosion resistance, high strength, and good weldability, making it suitable for a wide range of applications. This alloy typically consists of approximately 22% chromium, 5-6% nickel, 3% molybdenum, and a balance of iron, along with small amounts of other elements such as nitrogen and manganese.

Key Properties of Duplex Steel UNS S32205 Bolts:

Corrosion Resistance: One of the most significant advantages of Duplex Steel UNS S32205 bolts is their superior corrosion resistance. They exhibit excellent resistance to chloride stress corrosion cracking, making them ideal for use in marine environments, chemical processing plants, and offshore oil and gas platforms.

High Strength: Duplex Steel UNS S32205 bolts offer high strength, allowing them to withstand heavy loads and extreme conditions. This property makes them suitable for structural applications where strength and reliability are crucial.

Good Weldability: Unlike some other high-strength alloys, Duplex Steel UNS S32205 maintains good weldability. This means that it can be easily welded using common techniques, allowing for efficient assembly and construction processes.

Temperature Resistance: Duplex Steel UNS S32205 retains its mechanical properties at both high and low temperatures, providing stability and performance across a wide range of operating conditions.

Applications of Duplex Steel UNS S32205 Bolts:

Due to their exceptional properties, Duplex Steel UNS S32205 bolts find applications in various industries, including:

Oil and Gas: Bolts used in offshore platforms, subsea equipment, and oil refineries require resistance to corrosion from seawater and harsh chemicals. Duplex Steel UNS S32205 bolts are well-suited for such demanding environments.

Chemical Processing: Equipment and structures in chemical processing plants are exposed to corrosive substances and high temperatures. Duplex Steel UNS S32205 bolts offer the necessary corrosion resistance and strength to ensure reliable performance in these conditions.

Construction: In construction projects, especially in coastal areas or regions with high humidity, Duplex Steel UNS S32205 bolts are favored for their resistance to corrosion and durability.

Pulp and Paper Industry: Duplex Steel UNS S32205 bolts are used in the pulp and paper industry for their ability to withstand the corrosive effects of various chemicals used in the manufacturing process.

Introducing DC Engineering:

At the forefront of providing high-quality engineering solutions is DC Engineering, a leading manufacturer and supplier of industrial fasteners. With a commitment to innovation and excellence, DC Engineering offers a comprehensive range of Duplex Steel UNS S32205 bolts tailored to meet the diverse needs of clients across industries. Backed by extensive research and development, DC Engineering ensures that its products adhere to the highest standards of quality and performance.

Conclusion:

Duplex Steel UNS S32205 bolts represent a pinnacle in engineering materials, combining corrosion resistance, high strength, and versatility. With their wide-ranging applications across industries, these bolts are indispensable components in critical structures and equipment. As industries continue to demand solutions that can withstand harsh environments and heavy loads, the significance of materials like Duplex Steel UNS S32205 only continues to grow. Partnering with a reputable manufacturer like DC Engineering ensures access to top-quality bolts that meet the most stringent requirements, ensuring the success and longevity of engineering projects.

0 notes

Text

0 notes

Text

Duplex Steel UNS S32205 Bolts

Introduction:

In the realm of industrial engineering, the choice of materials holds paramount importance, especially when it comes to fasteners like bolts. In this context, Duplex Steel UNS S32205 bolts emerge as a shining example of durability, corrosion resistance, and overall performance. Among the array of companies specializing in engineering solutions, DC Engineering stands out for its expertise in providing top-notch Duplex Steel UNS S32205 bolts, ensuring reliability and excellence in every application.

Understanding Duplex Steel UNS S32205 Bolts:

Duplex Steel UNS S32205, also known as Duplex 2205, is a nitrogen-enhanced duplex stainless steel that exhibits a balanced combination of high strength, corrosion resistance, and good weldability. It comprises roughly equal proportions of ferrite and austenite phases, contributing to its exceptional properties.

Duplex Steel UNS S32205 bolts manufactured by DC Engineering are specifically designed to meet the demanding requirements of various industries, including offshore, chemical processing, petrochemical, and marine applications. These bolts offer numerous advantages over conventional materials, making them an ideal choice for critical structural connections.

Key Features and Benefits:

Superior Corrosion Resistance:Duplex Steel UNS S32205 bolts are highly resistant to corrosion, especially in environments containing chlorides, acids, and alkaline solutions. This characteristic ensures longevity and reliability in harsh operating conditions, reducing the need for frequent maintenance and replacement.

High Strength and Toughness: With significantly higher strength compared to standard austenitic stainless steels, Duplex Steel UNS S32205 bolts offer enhanced load-bearing capacity and resistance to mechanical wear and tear. This attribute makes them suitable for heavy-duty applications where structural integrity is paramount.

Excellent Weldability: DC Engineering's Duplex Steel UNS S32205 bolts can be easily welded using common techniques, allowing for seamless integration into complex assemblies without compromising performance. This facilitates efficient installation and maintenance procedures, reducing downtime and associated costs.

Cost-effectiveness: While offering superior properties, Duplex Steel UNS S32205 bolts remain cost-effective compared to other high-performance materials. Their extended service life and minimal maintenance requirements translate to long-term savings for industries relying on durable fastening solutions.

DC Engineering: A Trusted Partner for Engineering Excellence:

DC Engineering has established itself as a leading provider ofDuplex Steel UNS S32205 bolts, catering to diverse industrial needs with precision-engineered solutions. With a relentless commitment to quality, innovation, and customer satisfaction, the company continues to set new benchmarks in the field of engineering.

AtDC Engineering, every bolt undergoes stringent quality control measures to ensure compliance with industry standards and customer specifications. The company's state-of-the-art manufacturing facilities, coupled with a team of skilled professionals, enable the production of Duplex Steel UNS S32205 bolts that exceed expectations in terms of performance and reliability.

Conclusion:

In conclusion,Duplex Steel UNS S32205 bolts offered by DC Engineering represent the pinnacle of engineering excellence, combining unmatched strength, corrosion resistance, and versatility. As industries worldwide strive for enhanced efficiency and sustainability, these bolts

0 notes

Text

http://www.jfeindia.com/tap-end-stud-fastener.html

#Tap End Stud ASTM 182 SS 304L Manufacturer#Tap End Stud SS 317#Tap End Stud SS 317L#Carbon Steel ASTM 193 B7 Tap End Stud#Carbon Steel ASTM 193 B7M Tap End Stud#Duplex Steel S32205 Tap End Stud#Duplex Steel S31803 Tap End Stud#Incoloy 800 Tap End Stud#Incoloy 800H Tap End Stud#Monel 400 Tap End Stud manufacturer#Hastelloy B2 Tap End Stud#Hastelloy B3 Tap End Stud#Hastelloy C22 Tap End Stud

0 notes

Text

http://www.jfeindia.com/threaded-rod.html

#ASTM A193 Stainless steel 304 Threaded Rod Manufacturer#ASTM A193 SS347 Threaded Rod#Stainless Steel ASTM 193 316H Threaded Rod Stud#Stainless Steel ASTM 193 316Ti Threaded Rod Stud#Carbon Steel ASTM 193 B7 Threaded Rod Stud#Hastelloy B3 Threaded Rod Stud#Hastelloy C22 Threaded Rod Stud

0 notes

Text

http://www.jfeindia.com/heavy-hex-bolts.html

#SS ASTM 182 317 Heavy Hex Bolt fastener#ASTM 182 SS 317L Heavy Hex Bolt fastener#SS ASTM 182 321H Heavy Hex Bolt Fastener#Carbon Steel ASTM 193 B6 Heavy Hex bolt fastener#Carbon Steel ASTM 193 B7 Heavy Hex bolt fastener#Alloy Steel ASTM 320 L7A Heavy Hex Bolt Fastener#Brass C270000 heavy Hex Bolt Fastener#Naval Brass C46200 Heavy Hex Bolt#Hastelloy B2 heavy Hex bolt#Monel 400 Heavy Hex Bolt Fastener

0 notes

Text

http://www.jfeindia.com/double-end-stud.html

#Double End Stud ASTM 182 SS 304/304L#Stainless Steel ASTM 193 316L/316H/316Ti Double End Stud#Double End Stud SS 317/317L#Carbon Steel ASTM 193 B7/B7M Double End Stud#Duplex Steel S31803/S32205 Double End Stud#Incoloy 800/800H/800HT Double End Stud#Inconel 600/601 Double End Stud#Monel 400/K500 Double End Stud manufacturer#Hastelloy B2/B3/C22 Double End Stud

0 notes

Text

0 notes

Text

0 notes