Text

How to Improve The Finish of Auto Parts Machined by CNC

CNC machining center is widely used in the current machining market and the future development trend is also very good. It can be said that most of the parts are related to cnc machining. Especially in the auto parts industry, the vast majority of products are machined by cnc. For example, such as bumpers, dashboards, door swivels, drive shafts, gears, gearboxes, wheels, brake drums, etc., are first machined in small pieces by cnc and then glued into shape.

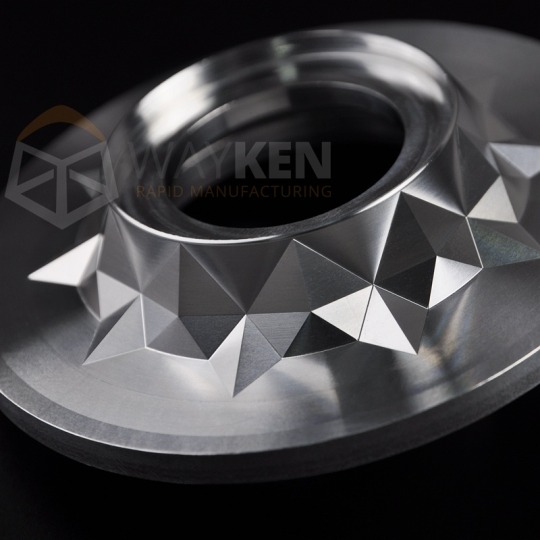

At present, large cnc machining has become an important processing method indispensable in the processing of auto parts, in large auto parts cnc machining perhaps you will encounter a variety of problems, such as processing the workpiece has a pattern finish is not high, then what causes auto parts cnc machining finish is not high? Today for you to introduce in detail to improve the finish of automotive parts especially functional prototype machined by CNC.

If the cnc machining center is not placed in a flat position will produce vibration, will affect the workpiece processing finish, so to ensure the stability of the cnc machining center, in order to better improve the finish of automotive parts cnc machining.

In the cnc machining project, try to avoid the spindle high-speed operation jitter, because to eat processing jitter will largely affect the workpiece finish.

Auto parts cnc machining try to choose high-quality coolant and sharp wear-resistant tools.

CNC machining chip slot to open well, try to avoid poor chip lead to workpiece scratch, affecting the workpiece finish.

Before cnc machining, be sure to match the spindle speed of the lathe and tool feed speed.

0 notes

Text

The Rise in Market Demand for CNC Parts

Globally, the demand for Computer Numerical Controls (CNC) machines and products is at an all-time high. According to research, the CNC machine tools market will get to $117.65 billion by 2027. The Asian region takes up a more significant market share due to the rising demand for CNC machines from India, China, and Japan.

WayKen is one of the players in this market at the forefront of innovation in their product development. As one of the most specialized manufacturers for high-end prototypes in China, Wayken offers customized and high-quality CNC machining options for both metal and plastic parts.

According to WayKen CEO, “With the advance in technology and the demand for automation in almost all industries and sectors, precise CNC machining is necessary. The pre-programmed software in the CNC parts is very reliable and accurate.”

Industries such as aviation, aerospace, and automobile are susceptible and require high levels of precision. Small errors can result in loss of lives and cash as well. Therefore, they rely on CNC machines to eliminate any discrepancies and errors in the operations.

The healthcare industry needs specialized products for its patients for different health conditions and complications. These include orthotic devices and implants, which need to be accurate and error-free for them to work.

Cars and automobiles are some of the top users of CNC parts. The companies in these sectors require durable parts for their car models. Critical components such as brakes, valves, rims, and engine parts are customized using this technology.

The aerospace industry is one of the most critical when it comes to accuracy. Turbines, bushings, landing, and flight controls need to be without error at all times. The use of CNC machining is critical in keeping every component of the airplane running smoothly.

Laptops, smartphones, and home electric appliances are held together by these key CNC technologies. The CNC parts are prototyped for each device for seamless operations.

CNC parts that are metallic can be either made from zinc alloy, brass, aluminum, stainless steel, or copper. The various grades of these metals can be designed into different specifications. Some of the critical machined metal parts created using CNC machining include fittings, suspension arms, ball joints, brackets, and rollers.

WayKen provides CNC machining, which involves turning, milling, drilling, and tapping various metal materials. Customized plastic CNC machining requires more specialized equipment and efficient programming.

WayKen CEO says, “The company utilizes CNC machining advanced techniques to produce high-quality products. By developing a versatile range of inspection processes on all steps, the fabricated parts have superior accuracy. “

In most industries, there is a growing need for machines with superior competencies. With limited floorspaces, companies are looking more into smaller devices that are efficient. CNC parts make up the prototype of most of these machines.

CNC machining has existed for several years now. However, the advance in computerized machinery to run operations has sparked increased commercial interest among companies.

The durability of CNC parts is unmatchable. With the strong material composition of these parts and machines have superior strength even under high temperatures. This hardiness reduces the costs needed to replace parts.

2 notes

·

View notes