Text

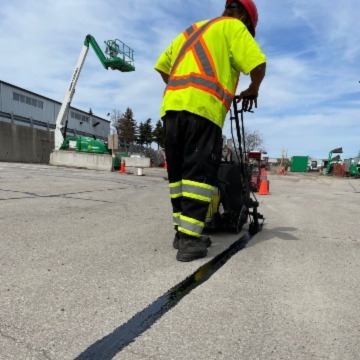

Pavement crack sealing Grimsby

The procedure of treating existing cracks on an asphalt surface is called crack sealing. One of the worst mistakes you can make in terms of extending the life of asphalt is to ignore cracks. Water and dirt can seep through asphalt cracks, which leads to the expansion of fractures and eventual breaking of the asphalt.

0 notes

Text

Driveway-Sealing Cambridge

Your driveway is losing the liquid component that holds the aggregates together as its once deep black

color begins to fade to a drab gray. This is the point at which your driveway is vulnerable to more

degradation, heaving, and cracking.

0 notes

Text

Patch repair Hamilton

With time, all asphalt surfaces are susceptible to degradation. Factors such as excessive traffic volume, chemical spills, severe weather, water intrusion, and ultraviolet radiation exposure can cause asphalt to deteriorate prematurely, necessitating repair.

0 notes

Text

Paving your driveway can make your house look more inviting and better from the outside. It is a wise move to pave your driveway since it enhances the functionality and market worth of your house in addition to its aesthetic appeal. Your driveway is not just a practical place to park your car; it's also a significant feature of the entry to your house. If you drive to strike a balance between design and utility, it could have a significant impact each time you return home.

0 notes

Text

Advantages and the steps involved in sealing an asphalt parking lot

Parking lot seal coating is one economical and practical solution to safeguard and increase the life of your asphalt pavement. This post will discuss the advantages of seal coating as well as the steps required to provide this worthwhile Parking lot seal coating service in Oakville.

Parking Lot Seal Coating's Advantages

For your asphalt parking lot, seal coating has several advantages that make it an investment well worth making:

1. Protection from the Elements: Sealcoating serves as a barrier to keep out harmful UV rays, rain, snow, and chemicals. It also protects the asphalt from damaging UV rays and stops water from penetrating the surface, which can cause cracks and potholes.

2. Increased Lifespan: An asphalt parking lot's lifespan can be considerably increased with regular seal coating. You can stop deterioration and the need for pricey repairs or resurfacing by sealing the surface.

3. Improved Appearance: A parking lot with new seal coating appears smooth, clean, and well-kept. It improves your property's overall curb appeal and leaves a favorable impression on guests, tenants, and buyers.

4. Cost savings: Compared to the costs involved in replacing or repairing a parking lot made of asphalt, seal coating is a more affordable option. In the long term, it helps you avoid making needless purchases.

5. Enhanced Safety: Sealcoating produces a level and smooth surface by filling in small cracks and flaws. This lessens the possibility of trip hazards and improves vehicle traction, reducing the likelihood of collisions and associated liabilities.

The Procedure for Sealcoating Asphalt

After learning about the advantages, let us examine the seal coating procedure:

Cleaning and Preparation: The parking lot surface must be completely cleaned to get rid of all dirt, debris, and plants. This guarantees that the seal coat will adhere properly.

Crack Filling: Before sealing coating, any existing cracks or potholes should be fixed. This entails using a premium crack filler to seal the cracks and stop additional water damage and penetration.

Application of Sealcoating: Using sophisticated equipment, our experienced seal coating firm will apply a thin layer of sealant to the surface after it has been cleaned and repaired. This guarantees uniform and even covering.

Curing and Drying: Depending on the weather, the seal coat needs 24 to 48 hours to cure and dry. Limiting foot and car traffic currently is essential to promoting healthy bonding. Furthermore, the temperature should be maintained for a few days after the application at least 55 degrees.

Striping and Marking: Lastly, the parking lot is designated and striped to meet your unique needs. Parking spots, directional indicators, handicap insignia, and any additional stencils that may be required should all be painted.

It is crucial to remember that seal coating should only be done by qualified experts who are familiar with the nuances of the procedure. To guarantee a superior and long-lasting outcome, it is imperative to work with a trustworthy Oakville seal coating service provider.

0 notes

Text

Protective boards and specialty painter's tape are used to keep the perimeters safe. Many of our Burlington clients have lovely border put around their asphalt driveway, and they have every reason to want to be sure they are safe. We make sure that all borders are covered with our specialty painter's tape before we start sealing the driveway. We also utilize edge boards as a backup precaution to make sure that no product ever touches anything other than asphalt.

0 notes

Text

Crack sealing is the process of addressing the current cracks on an asphalt surface. Leaving cracks unattended is one of the most detrimental mistakes when it comes to prolonging the lifespan of the asphalt. Cracks in the asphalt allow for water and dirt

to penetrate the surface, causing the cracks to expand and the asphalt to break. The pavement cracks must be cleaned of any loose debris and vegetation before applying the crack sealer. This ensures that enough sealant is applied to create an air-tight seal between the pavement. If the crack is not properly cleaned beforehand, the hot rubberized sealant will not bond to the asphalt.

0 notes

Text

Protective boards and specialty painter's tape are used to keep the perimeters safe. Many of our Burlington clients have lovely border put around their asphalt driveway, and they have every reason to want to be sure they are safe. We make sure that all borders are covered with our specialty painter's tape before we start sealing the driveway. We also utilize edge boards as a backup precaution to make sure that no product ever touches anything other than asphalt.

0 notes

Text

Seal Coating for Parking Lots

A spotless and well-kept parking lot sets the stage for a positive first impression. Seal coating an asphalt parking lot every three to five years is a necessary part of lot maintenance. Primarily composed of rock, stone, and gravel, asphalt pavement is bound together by an asphalt cement binder. Prolonging the asphalt's breakdown process requires maintaining the binder, which is derived from crude oils. The binder will be weakened by chemicals, rain, and UV light, which is why seal coating is crucial for preserving asphalt.

An outer layer of protection against the elements is offered by seal coating. You may save money and increase the life of your asphalt with a routine seal coating program!

Several factors help us determine if we can seal the coat or not.

Age

The binder is probably broken if a parking lot has not had seal coating for more than ten years. Should this be the case, seal coating the lot will not do much to keep the asphalt safe. The sealant finds it difficult to adhere in cracks and crevices where layers of dirt, grease, and debris have accumulated. This is why preserving a gorgeous jet-black appearance requires adhering to a correct seal coating regimen. Right now, the only way out is to apply a fresh asphalt topping over the existing one.

State of the Asphalt

The age of asphalt does not necessarily indicate its state. A parking lot that is eight years old may be in better condition than one that is four years old, depending on factors including traffic, asphalt mixture ratios, exposure to chemicals, and ultraviolet radiation. When assessing a parking lot, we look for significant cracks and repairs in the asphalt as well as the strength of the bond between the asphalt stone and binder.

Price/Value

Seal coating is not a substitute for appropriately addressing structural and safety issues. We advise conserving your money to pay for parking lot repairs or installation rather than sealing off a major crack or ignoring a pothole. Applying seal coating to a lot of deteriorated surfaces will merely cover up the issue. You will be revisiting seal coating in about a year. It would be more cost-effective for you to fix your lot and/or resurface it with new pavement.

Patching and Routing Fissures

Cracks in your driveway or lot should be channeled and fixed before sealing it. The procedure of grinding a channel that is ¾" wide and ½" deep while following the random crack line is known as crack routing. This gives the sealer a homogeneous, clean reservoir. The purpose of crack sealing is to stop water seeping into the subgrade, which eventually causes alligator cracks and potholes.

A 40% higher possibility of sealant success and clean surfaces for sealant application are obtained by routing cracks before installation.

0 notes

Text

THINGS TO AVOID WHEN PAINTING PARKING LOT AREAS

The significance of making a good first impression on customers regarding your company or commercial space cannot be overstated. To put it simply, those who see the outside of your building will be affected in a lasting way. First impressions are greatly influenced by architecture, landscaping, and general neatness, yet parking lots are frequently disregarded. The parking lot may put customers in a busy or stressful position depending on your business and location, but frequent maintenance on your end can significantly improve that. While routine cleaning is usually sufficient, there are times when repainting or resurfacing your parking lot is necessary. Here are some tips for painting parking lot areas from Line striping company Oakville, the people who know it best.

PAINT TYPES

Paint comes in what seems like an infinite variety, each with a unique purpose, on the market. It is crucial that you make informed decisions when picking up paint for line painting or parking lot resurfacing. In the end, traffic paint is the best option if you want some variance in the surface's structure. However, compared to other options, asphalt and concrete paints are made to adhere to pavement and have a far longer lifespan. One can further categorize the field of asphalt and concrete paint into solvent-based and water-based products. While solvent-based paint typically contains volatile organic chemicals, water-based paint is typically more environmentally benign. Although solvent-based paints are more common for high traffic areas, water-based paints are less long-lasting despite being better for the environment.

The ideal paint for a parking lot's surface is asphalt or concrete paint, but you will need different kinds for line painting, curbs, poles, and other details. For several of these parking lot features, thermoplastic or chlorinated rubber paint are common choices. They resist chips and are robust.

An essential component of giving your parking lot a fresh look is line painting. First, decide on a specialty line paint. Think about how you want to use it after that. Professional line striper suggests a line striper that works with the paint cans or buckets you decide on for bigger projects. In addition to straight lines, you should think about the best approach to stencil specialty things like hand cap stalls, no parking zones, fire lanes, and arrows into your parking lot using the same type of paint. When painting your lines, think about incorporating some grit to reduce the potential for these lines to become slippery and unique glass beads to increase the reflection and visibility of your markings.

Make careful to review your local laws and regulations regarding parking lot paint and line painting to determine which materials are permitted or prohibited for use in such projects.

ESSENTIAL STEPS

The same fundamental processes are included in every parking lot paint project, and each one is crucial to consider. The asphalt surface must be well-cleaned before applying brushes. Large material should be blown off the lot as a good place to start, and power washing will help thoroughly clean the area. The cleanliness of the parking lot pavement increases the visibility of each fracture. After filling any necessary cracks, take care of any concerns with seal coating. Make sure you have all the tools necessary to finish your line painting and parking lot resurfacing project as soon as possible once the surface has been cleaned and all cracks have been filled. Your business may suffer greatly from an unusable parking lot, so you should take care to get it right the first time. Work quickly and methodically to complete the task with the least amount of lost time.

Though it may seem unusual, your parking lot may reveal a lot about your company or commercial space. First impressions matter a lot. Giving your parking lot the same care and attention as you give your business will ensure that your customers and

staff are much happier and will come back time and time again. Get more advice from the experts in parking lot painting by getting in touch with line striping company Oakville right now.

0 notes

Text

Sealcoating Your Driveway Before Winter Arrives: Four Reasons

If you own a home with an asphalt driveway, you may not be aware that seal coating is necessary or believe that fall is too late to get it done. While applying seal coating in the fall presents certain difficulties, it is still far superior than doing asphalt repair or replacing paving in the future. Here are four solid excuses to seal coat your driveway before winter arrives, in case you are still on the fence:

1: Economical

Seal coating your driveway might save you money in the long run by averting expensive repairs. Untreated asphalt paving will require complete repair far more frequently, which can be quite expensive and inconvenient. Sealing will ultimately save you money and take a lot less time.

2: Offers defense against chilly weather

What is the main justification for sealing your driveway? It forms a shield that keeps the cold out. Winter's regular patterns of freeze-thaw can be disastrous for driveways that are not covered. Because of the expansion and contraction cycle, asphalt paving is prone to cracking; however, seal coating can stop these cracks from developing. Additionally, it will prevent water from getting into any existing cracks, which can prevent more damage from happening.

3: Increases pavement longevity

Seal coating extends the lifespan of your driveway by preventing weather-related issues including extreme cold and UV ray damage. A smoother, crack-free driveway is made possible by seal coating, and since smoother pavements can last up to 25% longer than uneven ones, replacement or repairs will not need to be considered for a much longer time. Any opportunity to prolong the life of a significant home feature is advantageous for homeowners, regardless of whether they intend to remain in their home for the foreseeable future or decide to put it up for sale. Additionally, a lovely, smooth driveway will raise the value of your house.

4: The ideal season

Because the weather is usually more temperate in the fall and spring, these are the ideal seasons to seal your driveway. It must be warmer outside than fifty degrees Fahrenheit to apply seal coating. Furthermore, there must be no significant rain for a full day. Early fall is the best time to seal coat your driveway because the leaves are still changing on the trees. Additionally, sealing in the fall offers you the best defense against severe winter weather.

0 notes

Text

Sealcoating Your Driveway Before Winter Arrives: Four Reasons

If you own a home with an asphalt driveway, you may not be aware that seal coating is necessary or believe that fall is too late to get it done. While applying seal coating in the fall presents certain difficulties, it is still far superior than doing asphalt repair or replacing paving in the future. Here are four solid excuses to seal coat your driveway before winter arrives, in case you are still on the fence:

1: Economical

Seal coating your driveway might save you money in the long run by averting expensive repairs. Untreated asphalt paving will require complete repair far more frequently, which can be quite expensive and inconvenient. Sealing will ultimately save you money and take a lot less time.

2: Offers defense against chilly weather

What is the main justification for sealing your driveway? It forms a shield that keeps the cold out. Winter's regular patterns of freeze-thaw can be disastrous for driveways that are not covered. Because of the expansion and contraction cycle, asphalt paving is prone to cracking; however, seal coating can stop these cracks from developing. Additionally, it will prevent water from getting into any existing cracks, which can prevent more damage from happening.

3: Increases pavement longevity

Seal coating extends the lifespan of your driveway by preventing weather-related issues including extreme cold and UV ray damage. A smoother, crack-free driveway is made possible by seal coating, and since smoother pavements can last up to 25% longer than uneven ones, replacement or repairs will not need to be considered for a much longer time. Any opportunity to prolong the life of a significant home feature is advantageous for homeowners, regardless of whether they intend to remain in their home for the foreseeable future or decide to put it up for sale. Additionally, a lovely, smooth driveway will raise the value of your house.

4: The ideal season

Because the weather is usually more temperate in the fall and spring, these are the ideal seasons to seal your driveway. It must be warmer outside than fifty degrees Fahrenheit to apply seal coating. Furthermore, there must be no significant rain for a full day. Early fall is the best time to seal coat your driveway because the leaves are still changing on the trees. Additionally, sealing in the fall offers you the best defense against severe winter weather.

0 notes

Text

Which Surface Treatment Option Is Most Appropriate for Your Needs in Pavement Maintenance?

Remember this when it comes to the pavement beneath your feet:

conserve now, or pay later. The proactive preservation of pre-existing pavements might be characterized as pavement preservation. When it comes to choosing a maintenance plan for your pavement, there are numerous options available. Not every solution is appropriate for every repair, so you need assess each circumstance individually to decide which course of action is best.

Here is a summary of some of the most widely used surface treatment solutions available, along with recommendations for when to use each technique. The goal of pavement engineers is to find the ideal solution on the ideal pavement at the ideal moment. Whatever your favorite method of preservation, we can all agree that keeping pavement preserved today is preferable to allowing it to deteriorate irreversibly.

Sealing and filling cracks:

What: Crack filling and sealing is often carried out with emulsions, cutbacks, or liquid asphalt and is only thought to be a temporary solution. Cracks are sealed against moisture and debris by this method.

Where: As long as the pavement is structurally sound and stays steady, crack sealing will keep the crack tightly sealed. It can be necessary to reseal every year in regions with severe temperatures when expansion and contraction happen often. Only dry surfaces and temperatures over 40°F should be used for sealing and filling, as cold temperatures cause the pavement to shrink and crack open. Until the sealant has dried, no vehicles should be permitted on the sealed fissures.

Why: One somewhat frequent and inevitable kind of damage to asphalt pavement is cracking. According to the Asphalt Institute, filling and sealing cracks is the most crucial pavement care task. Cracks should be sealed as soon as possible to help stop water seeping in, which can hasten pavement deterioration and cause potholes and base failures.

What is chip sealing?

The pavement surface is sprayed with a binder, and aggregate is then immediately layered on top of it. In between the aggregate and the binder, the surface is rolled, and curing takes place. After that, any loose aggregate is removed by sweeping the surface.

Where: On pavement that is structurally sound and has only minor surface flaws.

Why: Aged, damaged, and raveled surfaces are addressed using chip seals. They shield pavements from snow, rain, and sunlight. They prolong pavement life, prevent raveling, lessen water penetration, and enhance the frictional properties of pavements that bleed slightly.

Slurry sealing:

What: These treatments are applied to pavements that have little deterioration; they are thin, emulsion-based sealants. Good pavements are shielded, their lifespan extended, and minor surface imperfections are rectified by the black surface.

Where: Aging asphalt pavements in good structural condition with only minimal raveling or cracks and where skid resistance has not decreased are good candidates for slurry sealing.

Why: For a relatively modest cost, this treatment fills in small fractures, waterproofs the surface, and restores its visual appeal.

0 notes

Text

The Significance of Parking Lot Striping for Commercial Establishments

A business property requires a lot of labor to maintain. Parking lot striping is one of those maintenance chores that is easy to put off because of the financial consequences. However, improper parking lot striping might have negative consequences.

The Advantages of Skilled Parking Lot Marking for Business Establishments

Not all owners of commercial real estate must deal with parking lot maintenance. After all, parking lots are not often included in commercial buildings. However, those who do will soon discover that parking lots need maintenance to remain in good shape. One of these jobs is stripping parking lots.

Parking lot striping may seem simple, but it requires some preparation and effort. Taking a do-it-yourself method is not a good idea, particularly if you have never done it before. Below are some advantages of hiring a pro to strip parking lots.

Attractive to the Eyes

A parking lot that is completely empty and devoid of any lines is not visually appealing. It will not even resemble a parking lot without parking painted lines. Rather, it will merely seem like a sizable piece of asphalt or concrete.

Bright paint, on the other hand, appears neat and attractive on a black surface. A well-kept parking lot conveys to clients and onlookers your concern for your organization and commercial real estate. For many businesses, the parking lot is what customers see when they arrive. Make a favorable impression on them right away by spending money on parking lot striping.

Safety for People on Foot

Having your parking lot painted with bright, clear lines can help to guarantee pedestrian safety. The routes that customers and staff should travel will be known to them. It reduces the possibility of accidents occurring when people walk or stand in places meant for cars. Owners of business properties are also aware that on-site injuries can have disastrous legal consequences.

Avoids Mishaps

To elaborate on the last point, accidents can be avoided with the use of clear parking lot stripes. Because drivers cannot see faded arrows for pathways, entries, and exits well, there is an increased risk of vehicular accidents in parking lots. They ultimately must make a snap decision about which way to go, occasionally crashing into an incoming vehicle or person.

Enhances The Flow of Traffic

Parking spaces and slots are not the only things that benefit from parking lot striping. They serve as a guide for drivers as well. Traffic can flow more easily when entrances, exits, and directional arrows are all properly marked. Of course, having a parking lot layout that facilitates the easy flow of traffic also helps.

Makes the Most of Parking Spaces

Customers like parking lots to be handy. In fact, the presence of a parking place increases the likelihood that customers will visit a business. Nobody wants to deal with the hassle of finding parking to buy takeout, after all. Thus, it makes sense that you would want to accommodate as many cars as you can in your parking lot as a proprietor of a commercial building.

Assistance with Layout

Even on a small lot, choosing a layout might be difficult. Making the most of the parking lot requires careful measurement of every aspect. Professionals can assist you in this by designing a parking lot layout that meets your needs.

Availability of Tools and Materials

In a way, striping is an artistic medium. For visitors and employees to see the lines properly, they must be bright and straight. If you do not have the proper supplies and equipment, finishing the project will not take days or even weeks—especially if you have a wide workspace.

Additionally, expert striping businesses can assist with this. These businesses are equipped with parking lot striping equipment and are aware of the best parking lot striping paint to utilize and they provide the best parking lot striping service in your Waterdown area.

Services You Require

Painting parking lots is not limited to recently constructed parking lots. The weather can cause paint to fade with time, and partially faded stripes are just as terrible as having no stripes at all. Thankfully, businesses usually provide a wide range of services, some of which include both new and re-striped parking lots.

0 notes

Text

10 Most Common Questions About Asphalt Sealing

The only way professionals can tell you about the importance of driveway and asphalt maintenance is to listen to your query. They have compiled a list of your top ten most frequently asked questions concerning asphalt sealing, and we have the answers.

Why Is Asphalt Sealing Important?

Getting your asphalt treated might boost your home's value. Common elements that might damage your driveway and pavement include harsh winters with heavy snow and ice, as well as oil and paint spills from automobiles and do-it-yourself tasks. Sealing your asphalt not only restores the natural color of your driveway but also preserves the fragile ground underneath. Water and moisture can pile up beneath the earth, softening it. The soft and moist underside puts your driveway at risk of sinking every time you drive your car.

Ten of Your Most Common Questions About Asphalt Sealing

Is it shiny?

When tar is sprayed, it shines. As it dries, it produces a gorgeous matte finish that adds smoothness to your asphalt and makes your vehicle stand out.

How long does the seal last?

A seal should last 3-4 years; however, the more frequently you use your driveway, the faster it will wear down. We recommend sealing your driveway and other asphalt areas every 1-2 years to protect the delicate underbelly.

Will it fill cracks?

No. The sealant is applied as a thin layer to the surfaces. Does this imply you will have cracks and holes indefinitely? Absolutely not. To fill the gaps and holes, they use a mixture of rubber and tar. Then we spray the rubber along with the rest of the driveway, and you can see the hole disappear right before your eyes.

Is it safe for my lawn?

Tar does what it does. It is not ideal for your lawn, but professionals receive enough training, which includes proper driveway prep and tape-off procedures. Professionals are currently following the greatest customer satisfaction standards, so they understand what to tape and what not to spray. However, they are also human, and they can occasionally make mistakes. They have the tools to do it correctly every time.

How do you get it off the concrete sidewalk?

As previously stated, technicians are also human, and the spray occasionally gets away from them. Professionals are prepared with some wax solution that will remove tar from any concrete sidewalk.

Can you put a new seal on an old one?

If you just installed a seal on your driveway, another seal or a different type of seal may not dry properly. Depending on what is combined with the tar, some goods do not mix well. This combination could produce lines and runoff. The entire appearance will be harmed, and you will have to pay extra money to correct it. Whether it has been a year or a few years, the general color is a good indicator.

I just had my driveway cemented, but now I see lines. What happened?

It is normal to observe lines on your driveway once it's been cemented. There is no reason to worry, depending on how new your driveway is and what was left on it. If you have oil or paint stains, the tar will absorb at varying rates. If lines develop, it indicates that there is a coating of material preventing it from settling evenly. These lines are not permanent either. Sometimes, it takes a day.

What can I do to ensure the seal lasts longer?

There are a few minor things you can do throughout the year to help the seal live longer. During the winter, try not to apply too much salt when deicing. The salt will break down the seal and cause the color to fade more quickly.

You could also check that your eavestroughs are draining properly. Clogged gutters and downspouts may cause water to pool around the edges and seep underneath any open areas.

What kind of weather is suitable for asphalt sealing?

Sealing your driveway in late spring and summer. For the seal to be fully absorbed, the asphalt must be dry and free of any prospective rain.

How can I have my driveway sealed?

Okay, this question is simple. You can contact driveway-sealing asphalt experts in Hamilton and they will take care of your asphalt. They have an excellent customer service team who can answer all your questions and provide a free, no-obligation quote that is valid for a full calendar year.

0 notes

Text

How to fix and restore a broken driveway made of asphalt

The inevitable duty of clearing up the mess caused by winter weather has arrived, just like it does every summer. Now is the best time to fix a cracked tarmac driveway and fix potholes, unless you want to ignore the issue or hire a professional contractor in Hamilton.

Should you accept this task, it will examine affordable methods for filling in depressed spots on the asphalt, repairing potholes, removing stains from oil and chemical spills, and revitalizing old or damaged driveways and parking lots.

Although driveways may evoke images of opulent country estates and majestic castles, any property with a garage or parking area is probably going to have some sort of driveway.

The proverb that states "first impressions matter" is especially true when it comes to driveways of properties up for sale. Before they have even entered the front door, the driver may make or break the decision for the people seeing the home if it appears pitted or has numerous minor potholes and cracks.

However, it is not only about potential buyers; broken driveways detract from the appearance of your house to friends, family, and neighbors. Now is the moment to identify the issue and consider a solution if the asphalt appears to be in poor condition or if there are potholes.

cracks in the driveway

Driveway cracks are a common occurrence, particularly in high-traffic locations (such as tiny family homes with little to no car usage) or in areas where the asphalt is subjected to high levels of sunlight, precipitation, snow, ice, and other seasonal element cycles. Although the harm cannot be stopped, there are ways to anticipate it and stay one step ahead. Read this post about fixing cracks in garage floors and concrete if you need to deal with them.

To shield the tarmac from the elements, moss, algae, and weeds, now is the time to act and seal any small cracks in addition to resealing the entire surface.

However, tree roots can cause heavier-duty cracks by separating the concrete or asphalt. This may be a prevalent issue in neighborhoods and council estates. Due to potential harm, a tree may need to be chopped down or have its roots "removed" as much as feasible. This is obviously extensive remodeling work, maybe involving tearing up the entire driveway and resurfacing or laying new flooring.

Indentations in the asphalt

Although it is the responsibility of a driveway, it is only right that any depressions be filled as soon as possible, before that little dimple in the drive turns into a pothole. Nobody enjoys being walked all over.

Little low spots in the surface called depressions and divots can form when water collects, as in the case of puddles or fuel spills. Isolated settlement of the underlying foundation layer can also result in depressions. They are possibly the most prevalent and unnoticed driveway damage.

Blemishes: damage from abrasive, chemical, or oil substances

Vehicles do damage tarmac surfaces by leaking, whether they are in a driveway, parking lot, minor in-road, or main highway. This is particularly frequent from parked autos, as chemical or abrasive substance damage can develop greatly in short- or long-term parking places.

The one word that councils dread the most is potholes. Tarmac driveways and parking lot surfaces are particularly susceptible to them. They are a big annoyance to any asphalt stretch and dangerous to run over quickly.

Repairing the damage: Detailed instructions

Clean, dry surfaces are the ideal conditions for performing any driveway repair work:

1. Use a pressure washer to thoroughly clean the surface.

2. Use a brush with firm bristles to clean the surface.

3. To get rid of any weeds, algae, or moss that is tenacious, use a surface cleaning.

4. To repair any petroleum damage, use an oil-spot primer.

5. Use an ice scraper or a flat spade to trim the margins of any grass or turf that is above the pavement.

6. Remove any leaves, dust, and debris that may have gathered in any corners and been blown onto the wet, drying tarmac.

7. Never trample over a mess to make it easier for postal workers or pedestrians to reach a building.

8. Apply a mask to the driveway's margins where it touches walls, fences, buildings, or foundations.

patching up cracks in the driveway

The best course of action is to get the damaged area ready:

1. Clean out any dirt or loose material from the fracture using a screwdriver.

2. Remove any tiny dirt completely using a brush or vacuum cleaner.

Make sure the crack is dry and free of moisture by using a bitumen-based filler to fill the spaces.

0 notes

Text

How to Choose the Best Line Striping Contractor

Important Takeaways:

During your project, an expert line striping professional can provide accuracy and the capacity to manage unforeseen difficulties.

Timeless, accurate, and aesthetically pleasing line striping is a result of using high-quality tools and materials.

Cost is important, but you need strike a balance between price and quality to get value without sacrificing the outcome.

Demand thorough, itemized quotations that provide you peace of mind about the quality of the work being done.

The visual representation of a professional's abilities and the happiness of their former clientele is provided by past work examples and referrals.

As a property owner, you are aware of how critical it is to preserve the appearance and functionality of your home. Whether it is a driveway for a home, a sports court, or your place of business, line striping is an element that frequently gets overlooked but is vital to both comfort and safety. Markings and symbols applied correctly direct traffic and pedestrians while enhancing the appearance of your property. As a result, the outcome of your project can be greatly impacted by selecting the appropriate specialist. We will present you advice, factors to think about, and insights to help you make an informed choice.

And our paving specialists are available to assist you if you are prepared to improve your property with accuracy and excellence.

Choosing the Ideal Line Professionals in Striping Evaluate Their Experience

Experience is crucial when it comes to line striping. An expert in line striping has probably worked on a variety of projects, from parking lots to roadways, and is familiar with the specifications needed for each. Their wealth of experience and understanding can guarantee the timely and successful completion of your project. Seek out experts who have completed successful projects that are comparable to your requirements in the past. Request case studies or references to evaluate their qualifications and experience. An expert in line striping can provide insightful advice, make recommendations for upgrades to make your property safer and more functional, and deal with any unforeseen problems that may come up while the project is underway.

Examine Their Tools and Supplies

The tools and materials used have a big impact on the quality of line striping. Find out what kind of paint and stripping machinery they use. The lifetime of your project can be ensured by using more durable and accurate markings made possible by well-maintained, modern equipment. Ask about the paint and thermoplastic materials they use as well. Superior materials guarantee that your lines endure bad weather and heavy traffic for a long time.

An appropriate professional should be open and honest about the tools and supplies they use, and they should be prepared to justify their approach to your project. This openness shows you how dedicated they are to excellence and clarifies the value they offer.

Examine Their Prices

When choosing a line striping expert in Burlington, price is important even though you desire high-quality work. Get estimates from several experts to get an idea of how much your project will typically cost. Extremely cheap quotes should be avoided since they could suggest hurried or inferior work, which could affect the caliber of your marks.

However, expensive costs could put a strain on your budget while not ensuring superior quality. Strive for a balance between cost and quality, and keep in mind that a fair price indicates a fair value for the task, guaranteeing that you get high-quality outcomes without going over budget.

Demand Detailed Estimates

Make sure the estimates you receive from possible line striping contractors are comprehensive and itemized. This guarantees that all the expenses, including labor, supplies, and any other fees, are clearly broken down for you. You can adequately compare different providers by using itemized quotations. Make sure everything is in written and keep an eye out for any unexpected or hidden costs. A trustworthy line striping specialist would be happy to provide you a thorough price that considers the requirements of your project. This degree of openness shows professionalism and enables you to see where your money is going, which instills trust in the worth of the services rendered.

Assess responsiveness and professionalism

The line striping expert's response and professionalism may be a good indicator of how your project will be handled. Examine their ability to communicate, their timeliness, and their readiness to answer your queries and concerns. The entire procedure can run more smoothly and enjoyably if the professional is receptive and takes the time to understand your preferences. Additionally, their dedication to prompt and transparent communication can result in a fruitful collaboration, guaranteeing that your project moves forward without needless hiccups or miscommunications.

Ask to See Samples of Prior Work

One of the best methods to judge the skill of a line striping specialist is to look through their prior work. Ask to see samples of their completed projects, particularly ones that are comparable to yours. This provides you with an illustration of their skill and attention to detail. Examine the work for neat, clean lines, well-applied markings, and the degree to which any issues about your project have been resolved. To learn more about previous customers' experiences with the professional and to assess the overall level of happiness and service quality, you can also ask for references from previous clients.

Ask About Safety and Compliance

For line striping projects, especially those involving roads and public areas, compliance and safety are crucial. Make sure the line striping expert understands and complies with any applicable local laws, such as those about the use of certain colors, symbols, or ADA accessibility. Additionally, they ought to put safety first by making sure the work environment is secure throughout the job and by utilizing the proper signage. A professional who prioritizes safety and compliance shows a dedication to meeting or exceeding industry standards in results delivery, ensuring the functionality and security of your property.

0 notes