Text

Top Hydraulic Bucket Grab Models You Need to Know

Hydraulic bucket grabs are essential attachments for various industries, including construction, agriculture, forestry, and waste management. These grabs are used for material handling, loading, and sorting tasks. Here are some top hydraulic bucket grab models you should know about:

Kinshofer Clamshell Bucket Grab: Kinshofer offers a range of clamshell bucket grabs designed for excavators, cranes, and material handlers. These grabs feature hydraulic cylinders for precise control and can be equipped with various shell configurations for different applications, such as digging, dredging, or bulk material handling.

Rotobec Power Attachment Clamshell Bucket Grab: Rotobec manufactures high-quality clamshell bucket grabs suitable for excavators, loaders, and material handlers. These grabs feature heavy-duty construction, robust hydraulic systems, and interchangeable shells for versatility in handling different materials, including logs, scrap, and debris.

LaBounty Hydraulic Grapple Bucket: LaBounty produces hydraulic grapple buckets for excavators and material handlers. These grabs feature rugged construction, large-capacity jaws, and powerful hydraulic cylinders for efficient material handling and loading. They are commonly used in demolition, recycling, and waste handling applications.

CAT® Hydraulic Multi-Grapple Bucket: Caterpillar offers a range of hydraulic multi-grapple buckets designed for Cat excavators and backhoe loaders. These grabs feature durable construction, replaceable wear components, and advanced hydraulic systems for precise control and high productivity in material handling tasks, such as sorting, loading, and demolition.

Liebherr Hydraulic Timber Grab: Liebherr manufactures hydraulic timber grabs for forestry and construction applications. These grabs feature heavy-duty construction, large-capacity jaws, and optimized hydraulic systems for handling timber logs, branches, and tree trunks with precision and efficiency.

These are just a few examples of top hydraulic bucket grab models available in the market. When selecting a hydraulic bucket grab for your equipment, consider factors such as the application, material type, machine compatibility, capacity, and hydraulic system requirements to ensure optimal performance and productivity.

0 notes

Text

Step-by-Step Guide to Installing a Magnetic Filter in Your Home

Installing a magnetic filter in your home heating system can help improve efficiency and protect your boiler or furnace from damage caused by sludge, debris, and magnetic particles in the water.

Here's a step-by-step guide to installing a magnetic filter:

Step 1: Choose Installation LocationChoose a suitable location for the magnetic filter along the flow pipe of your heating system, ideally close to the boiler or furnace.

Ensure there is enough space for installation and future maintenance.

Step 2: Prepare PipesShut off the power to your heating system.

Turn off the water supply to the boiler or furnace.

Drain the heating system to relieve pressure.

Cut the pipe where you intend to install the magnetic filter, using a pipe cutter or hacksaw. Make sure the cut is clean and straight.

Step 3: Install Isolation ValvesIf isolation valves are not already installed on the pipe, add them now. These valves will allow you to shut off the water flow to the magnetic filter for maintenance without affecting the rest of the heating system.

Install the isolation valves on both sides of the cut pipe according to the manufacturer's instructions.

Step 4: Mount the Magnetic FilterMount the magnetic filter onto the pipe, ensuring that the flow direction arrow on the filter matches the direction of water flow in the pipe.

Secure the filter in place using the provided brackets or straps.

Step 5: Connect PipesConnect the inlet and outlet pipes of the magnetic filter to the corresponding pipes using compression fittings or threaded connections.

Apply pipe sealant or PTFE tape to the threads of the fittings to ensure a watertight seal.

Tighten the fittings securely using an adjustable wrench or spanner.

Step 6: Monitor and MaintainMonitor the magnetic filter periodically to ensure it is functioning correctly.

Follow the manufacturer's recommendations for maintenance, which may include cleaning or flushing the filter at regular intervals.

By following these steps, you can successfully install a magnetic filter in your home heating system to help improve efficiency and protect your boiler or furnace from damage. If you're unsure about any step of the installation process, consider consulting a professional plumber or heating engineer for assistance.

0 notes

Text

Maximizing Efficiency: How Magnetic Filters Can Improve Your System Performance

Magnetic filters are valuable tools in optimizing system performance, especially in systems that involve fluid flow, such as HVAC systems, hydraulic systems, and industrial machinery. Here's how magnetic filters can enhance efficiency:

Removing Contaminants: Magnetic filters are designed to capture ferrous contaminants present in the fluid flow, such as iron particles and steel debris. By removing these contaminants, the filter helps prevent damage to sensitive components like pumps, valves, and seals, thereby improving the overall efficiency and lifespan of the system.

Reducing Downtime: Contaminants can cause blockages and malfunctions, leading to costly downtime for maintenance and repairs. Magnetic filters help reduce the frequency of downtime by preventing these issues, ensuring that your system operates smoothly and efficiently.

Improving Energy Efficiency: A clean system operates more efficiently, reducing energy consumption. By keeping the fluid clean and free of contaminants, magnetic filters can help improve the energy efficiency of your system, saving you money on operating costs.

Enhancing System Performance: Clean fluid flow is essential for optimal system performance. Magnetic filters ensure that the fluid remains clean, which helps maintain consistent performance and prevents issues such as overheating or pressure drops.

Extending Equipment Life: By protecting components from damage caused by contaminants, magnetic filters can extend the life of your equipment. This means fewer replacements and repairs, saving you money in the long run.

Overall, magnetic filters are a cost-effective solution for improving system efficiency and performance. By investing in magnetic filters, you can maximize the efficiency of your system, reduce downtime, and extend the lifespan of your equipment.

0 notes

Text

Demolition Pulverizers: How to Safely and Effectively Operate Them

Operating demolition pulverizers requires adherence to safety protocols and a clear understanding of the equipment. Here are some guidelines for safe and effective operation:

Safety Precautions:

Training: Operators must undergo proper training on how to operate the specific model of demolition pulverizer they'll be using.

Read the Manual: Familiarize yourself with the manufacturer's manual for the pulverizer. It contains crucial information on operation, maintenance, and safety guidelines.

Safety Gear: Always wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, gloves, steel-toed boots, and hearing protection.

Inspect the Equipment: Before operation, thoroughly inspect the pulverizer for any damage or faults. Ensure all components are in good working condition.

Clear Work Area: Remove debris, bystanders, and unnecessary personnel from the work area to prevent accidents.

Communication: Establish clear communication channels between the operator and any ground workers or spotters.

Operation:

Positioning: Place the pulverizer in the correct position for the task, ensuring stability and proper alignment with the target material.

Hydraulic Connections: Connect the pulverizer securely to the excavator or machinery using appropriate hydraulic connections.

Start-Up: Engage the pulverizer according to the manufacturer's instructions, slowly increasing power to avoid sudden jerks or unexpected movements.

Control Movements: Operate the pulverizer with precision, controlling movements to avoid unnecessary stress on the equipment and the structure being demolished.

Monitoring: Continuously monitor the equipment and surrounding area for any signs of malfunction or hazards.

Material Handling: Be cautious while handling debris, ensuring it's safely removed or processed to avoid accidents or injury.

Maintenance:

Regular Checks: Conduct routine maintenance checks on the pulverizer, including hydraulic systems, structural integrity, and moving parts.

Lubrication: Ensure all moving parts are adequately lubricated as per the manufacturer's recommendations.

Repairs: Address any faults or damages immediately by following manufacturer guidelines or involving trained technicians.

Shutdown:

Proper Shutdown: After completing the work, properly shut down the pulverizer according to the manufacturer's instructions.

Disconnect Hydraulics: Disconnect hydraulic lines carefully to prevent leaks or unexpected movements.

Secure Storage: Store the pulverizer securely and safely when not in use, protecting it from environmental elements.

Always prioritize safety and compliance with operating guidelines when using demolition pulverizers. If you're unsure about any aspect of operation or maintenance, consult the manufacturer's manual or seek guidance from qualified professionals.

0 notes

Text

A hydraulic sieve bucket is an attachment used with hydraulic excavators, and it is designed for sifting and separating materials during excavation and construction activities.

0 notes

Text

A hydraulic hammer, also known as a hydraulic breaker or demolition hammer, is a powerful attachment designed to break through or demolish various materials using a hydraulic mechanism. Hydraulic hammers are commonly used in construction, mining, quarrying, and demolition applications.

0 notes

Text

Essential Tips for Operating a Telescopic Boom Safely

Operating a telescopic boom, such as a telehandler or a telescopic forklift, can be a challenging task that requires proper training and safety precautions to prevent accidents and ensure the safety of both the operator and those around them.

Here are some essential tips for operating a telescopic boom safely:

Training and Certification : Ensure that operators are properly trained and certified to operate telescopic booms. They should be familiar with the specific machine they will be using and its controls.

Pre-Operation Inspection : Conduct a thorough pre-operation inspection of the telescopic boom, checking for any visible damage, loose components, hydraulic leaks, and tire conditions.

Stability : Be aware of the machine's stability. Ensure it's set up on a firm and level surface. Use outriggers or stabilizers as required to prevent tip-overs.

Load Capacity : Know and adhere to the machine's load capacity limits. Do not exceed the maximum weight capacity specified by the manufacturer.

Load Securement : Safely secure all loads before lifting or moving them. Use appropriate rigging equipment, such as slings and hooks, and make sure the load is balanced and properly attached.

Proper Positioning : Always position the telescopic boom directly above the load to maintain stability and avoid tipping.

Clear Communication : Establish clear communication with ground personnel, spotters, and other operators. Use hand signals or two-way radios when necessary.

Watch for Overhead Obstructions : Be aware of overhead obstacles, such as power lines, trees, and structures. Maintain a safe clearance distance from these hazards.

Travel Safely : When moving the telescopic boom, do so at a controlled speed, especially when the boom is extended. Keep the load low to the ground to maintain stability.

Avoid Rapid Movements : Avoid sudden or jerky movements of the boom or the load, as this can cause instability and lead to accidents.

Use Seat Belts : Always wear the provided seat belt while operating the telescopic boom to prevent ejection in the event of a sudden stop or tip-over.

Stay Clear of the Load : Do not stand or pass under the load or the boom. Keep a safe distance from the equipment and loads at all times.

Use Proper PPE : Wear the appropriate personal protective equipment (PPE), including a hard hat, high-visibility vest, and safety shoes.

Emergency Procedures : Familiarize yourself with the machine's emergency shutdown procedures and know how to respond in the event of a malfunction or emergency.

Maintenance and Inspections : Regularly inspect and maintain the telescopic boom according to the manufacturer's guidelines. Address any issues promptly to ensure safe operation.

Stay Informed : Stay up-to-date with the latest safety regulations and best practices for operating telescopic booms.

Remember that safety is a shared responsibility, and everyone working around the telescopic boom should be aware of these safety practices to prevent accidents and create a secure work environment. Always follow the manufacturer's guidelines and any specific safety regulations in your region.

0 notes

Text

A mechanical grapple, often simply referred to as a grapple, is a type of attachment or tool used in various industries, including construction, forestry, agriculture, and material handling. It is designed to grasp, lift, and manipulate objects, typically heavy or bulky ones, with ease and precision. Grapples come in various shapes and sizes, and their specific design depends on their intended application.

0 notes

Text

A sieve bucket, also known as a screening bucket or sieve shaker bucket, is a specialized attachment used in construction and excavation equipment, such as excavators and loaders. It is designed for sifting and separating materials, typically soil, sand, gravel, and other debris, in various applications.

0 notes

Text

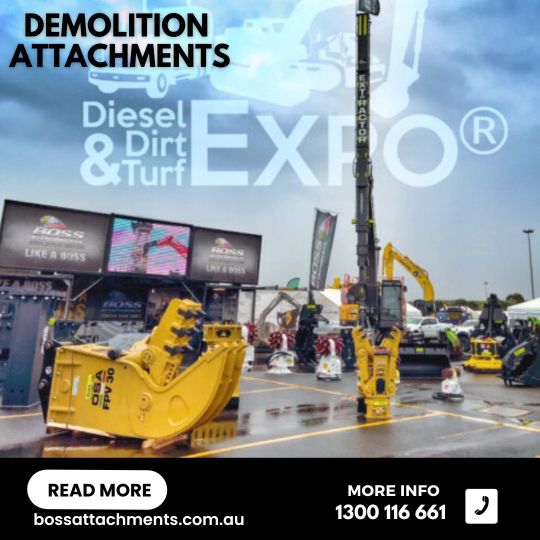

Construction & Demolition Attachment - Boss Attachments

Demolition attachments are specialized tools and equipment used in the construction and demolition industry to break down and remove structures, concrete, and other materials. These attachments are typically used with heavy machinery like excavators and demolition robots to efficiently dismantle buildings, concrete structures, and other materials.

When using demolition attachments, it's crucial to prioritize safety and follow proper demolition procedures to ensure the safety of operators and nearby workers. Additionally, compliance with local regulations and environmental considerations are essential when handling demolition waste and debris.

0 notes

Text

"Fortress Equipment" does not refer to a specific company or product as of my last knowledge update in September 2021. It's possible that a company or product with this name has been established or become more well-known since then. To get the most up-to-date information on "Fortress Equipment," I recommend conducting an internet search or visiting their official website if they exist.

0 notes

Text

Demolition attachments are specialized tools and accessories designed to be used with heavy machinery, such as excavators, backhoes, and skid-steer loaders, to assist in the process of breaking down and removing structures, debris, and materials during demolition projects.

0 notes

Text

Dust control solutions refer to various methods and techniques employed to minimize or manage the generation and dispersion of dust particles in different environments. Dust can be a significant issue in various industries, construction sites, mining operations, agricultural activities, and even residential areas, as it can pose health risks, degrade air quality, and impact overall cleanliness.

0 notes

Text

How to use a mechanical grapple

A mechanical grapple is a type of gripping device that uses mechanical means, such as levers, gears, or linkages, to close and secure its jaws around an object. It is often used for grabbing and lifting various materials in industrial, construction, forestry, and other applications. Unlike hydraulic or powered grapples, which rely on fluid pressure to operate, mechanical grapples are manually operated and do not require external power sources.

0 notes

Text

An excavator grab, also known as a grapple or grab bucket, is an attachment used with excavators and other heavy machinery to handle various materials, such as rocks, debris, logs, and other bulky items. It consists of two or more hinged arms with claw-like structures at the end that can close and grip objects securely.

0 notes

Text

A jaw crusher bucket, also known as a jaw crusher attachment, is an excavator attachment that is specifically designed to process and crush materials directly on-site, eliminating the need to transport large pieces of material to a crushing plant. It utilizes a jaw crusher mechanism that applies pressure to compress and break down the material into smaller pieces.

0 notes

Text

A mechanical grapple is a type of tool or device used to grab, hold, and lift objects. It is commonly used in various industries, including construction, forestry, agriculture, and material handling.

0 notes