Text

Types and application of carbon refractory raw materials

Carbonaceous materials have many advantages and are widely used in steel, non-ferrous metals, and other industries. Carbon has stable chemical properties, high thermal conductivity, good electrical conductivity, low linear expansion coefficient, strong thermal shock resistance, is not wetted by most molten metals, and has good wear resistance and corrosion resistance. It is used for refractory materials with high strength but easy oxidation. Carbon-containing refractories are typical neutral refractories, which can be made into fired carbon bricks, self-fired carbon bricks, silicon carbide bricks, and amorphous carbon ramming materials.

Carbon materials in refractory materials include common graphite, carbon materials, silicon carbide, etc.

1. Graphite

Graphite is the main raw material and an important component of graphite products (such as graphite clay products, and graphite silicon carbide products). China has the largest natural graphite reserves in the world. According to the crystalline form of graphite, it can be divided into flake graphite, block graphite, and unformed graphite.

2. Carbon materials

Carbon accouterments used in refractories include coke, anthracite, etc. Carbon materials are widely used in steelmaking, steelmaking, and non-ferrous smelting.

(1) Coke

Coke is an amorphous carbon. In industrial production, use bituminous coal or some substances with high carbon content (such as petroleum pitch, residual oil, coal tar pitch, etc.) to heat the air adiabatically to make it coke. The product of coal coking is metallurgical coke, the product of petroleum pitch or residual oil painting pitch is petroleum coke, and the product of coal navigator pitch coking is pitch coke. Metallurgical coke is mainly used as blast furnace fuel and reducing agent for steelmaking, and can also be used to produce various carbon blocks and carbon electrodes; the other two cokes are used relatively less.

(2) Anthracite

Anthracite is an important raw material for the production of carbon bricks, silicon carbide, carbon electrodes, electrode pastes, and bottom pastes.

3. Silicon carbide

Silicon carbide is also a very common refractory material with a wide range of applications. It can be used for refractory bricks and amorphous materials, effectively improving product quality and service life.

That's all, welcome to communicate with us.

Our company produces Recarburizer, Graphite Electrodes, and Premelting-Refining Slag, Please contact us if necessary, Whatsapp:+8618032200119, email:

11 notes

·

View notes

Text

Precautions for Using Graphite Electrodes

Graphite electrodes do have many advantages, but how to use them? How to improve efficiency, reduce costs and increase profits. Therefore, in the application of graphite materials, the following problems should be solved first:

First, dust. Because graphite has a fine particle structure, old dust will be generated during the production process, which has a great impact on the factory and the surrounding environment. The most important thing is the impact of dust on the equipment, because the conductivity of graphite is very good, if it enters the power box, it will easily cause short circuit failure. There are two solutions to this: one is post-oil processing, and the purchased graphite is soaked in spark oil for some time before processing. Graphite powder will not fly. The other is the upgrade of the machining center: the so-called upgrade is mainly to add a vacuum cleaner to the ordinary machining center.

Secondly, because graphite is relatively brittle, if graphite is processed by the method of processing copper electrodes (graphite is more brittle than copper), it is easy to cause electrical damage, especially when processing thin electrodes. In these processes, choosing tools and graphite with appropriate hardness can reduce tool wear and electrode damage. It is recommended to use the milling process to process graphite, and choose diamond tools or diamond-coated tools as much as possible.

Thirdly, the discharge treatment of the discharge gap: is different from copper, because the graphite electrode discharges faster, and more processing slag is corroded per unit of time, how to effectively discharge the slag becomes a problem. Therefore, the discharge gap is larger than that of copper. Generally speaking, when setting the discharge gap, the discharge gap of graphite is larger than that of copper.

Finally, get its drawbacks in perspective: Beyond dust, graphite leaves a few things to be desired. For example, in the processing of mirror molds, compared with copper electrodes, graphite electrodes are not easy to achieve the desired effect. To achieve a better surface effect, it is necessary to choose the finest graphite particles, and the cost of this graphite is often several times higher than that of ordinary graphite.

That's all, welcome to communicate with us.

Our company produces Recarburizer, Graphite Electrodes, and Premelting-Refining Slag, Please contact us if necessary, via Whatsapp:+8618032200119, email: [email protected]

2 notes

·

View notes

Text

Definition and characteristics of graphite electrode

Definition: Graphite electrodes are mainly made of petroleum coke and needle coke, coal tar pitch is used as a binder, and are made by calcination, batching, kneading, pressing, roasting, graphitization, and machining. The conductor that releases electric energy to heat and melts the charge can be divided into ordinary power graphite electrode, high power graphite electrode, and ultra-high power graphite electrode according to its quality index.

In general, carbon is created by carbonizing mixed coke substances with a binding pitch at 1,000°C in a baking furnace. When this carbon is graphitized in an electric furnace at 3,000°C, the formless carbon body takes on the structure of crystalline graphite. This is called graphite. Carbon materials are generally pitch saturate and re-baked to enhance electrical and mechanical properties before graphitization.

Graphite electrode characteristics:

• High-temperature resistance.

• Good thermal and electrical conductivity.

• Low thermal expansion.

• Good machinability.

• Good chemical resistance.

• Corrosion resistant, longer life than most metal electrodes.

•Compared with the traditional 50hz ground electrode, the resistivity is small and very suitable for high-frequency current.

These days Graphite Electrodes can be used in many ways in our daily life. Graphite Electrode is a very significant object that is employed in the electric curve heater for steel making, for its luminous electrical conductivity and extraordinary anti-thermal shock capability. As a conductor, graphite electrodes are mainly used in electric arc furnaces to release electric energy in the form of arcs to heat and melt the charge. These features make Graphite Electrodes the most appropriate material to melt scraps, DRI, etc. by arc energy.

That's all, welcome to communicate with us.

Our company produces Recarburizer , Graphite Electrode , Premelting-Refining Slag ,Please contact us if necessary ,Whatsapp:+8618032200119, e-mail : [email protected]

0 notes

Text

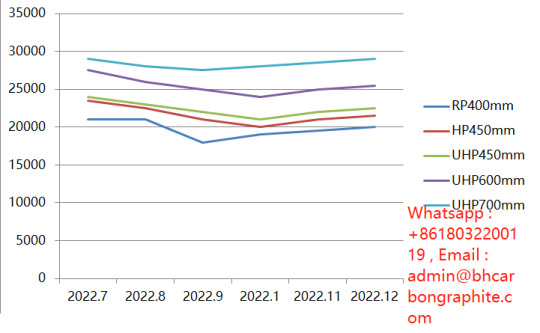

Affected by supply and demand, the price of graphite electrodes continues to rise

At present, the price of graphite electrodes continues to rise, mainly due to high costs and low profits. Graphite electrode companies are highly motivated to increase prices. In addition, the supply side of the current graphite electrode market is shrinking, and some companies are still reducing production and controlling production. Therefore, driven by supply and cost, graphite electrode companies have increased their prices.

Graphite Electrode price trend

Recently, the price of graphite electrodes in China has increased by 1000/ton. As of December 2022, the mainstream price of graphite electrodes in China (diameter 300mm-600mm): RP 21500-23500 yuan/ton; HP 22000-24500 yuan/ton; UHP 23500-28000 yuan/ton; UHP 700mm is 30500-31500 yuan/ton. However, due to poor demand from steel mills, no transactions have been made after the price adjustment. The specific analysis is as follows:

1. With the price of graphite electrodes currently low and profits insufficient, businesses hope prices will rise.

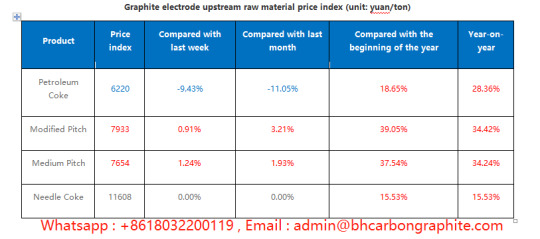

At present, the raw material price of graphite electrodes is 6230 yuan/ton, down 9.42% from last week. However, The graphite electrode industry has a long production cycle and price declines tend not to have an immediate impact. The production cost for a graphite electrode is about 20,000-21,000 yuan/ton. Graphite electrode prices are not high enough currently, the market is on a rebound and graphite electrode companies haven't been able to reverse their losses.

2. Graphite electrodes have low productivity. The industry has priced them higher than normal due to the lack of supply.

It is understood that the overall operating rate of the graphite electrode market is still insufficient. At the end of December, the overall operating rate was less than 40%. On the one hand, due to the impact of the epidemic in some areas, there is a shortage of labor force, increasing labor costs; on the other hand, as the end of the year approaches, the production of some enterprises is also restricted. Affected by environmental protection supervision, the production of graphite electrodes in Handan, Hebei is limited.

Recommend a high-quality manufacturer of graphite electrodes:https://www.bhcarbongraphite.com/

3. Demand is reduced, and graphite electrode companies are under greater pressure.

Export: According to foreign trade salesmen, compared with last year, the export orders of graphite electrodes have decreased significantly this year, and there is pessimism about the market.

In terms of steelmaking plants: Electric furnace steelmaking plants are losing money, operating less, and the demand for graphite electrodes is relatively small. Long-process steel mills mainly purchase on demand. The rise in the price of graphite electrodes may stimulate steel mills to replenish their stocks, thereby easing the pressure on graphite electrode companies.

2023 Market Forecast

At present, the operating rate of graphite electrode enterprises is insufficient, the cost is high, and the demand in the downstream market is weak. Therefore, graphite electrode enterprises want to push up prices and reverse losses. However, due to the impact of downstream demand, there is still no significant improvement. After the price rises, there is no order volume.

Therefore, I predict that after the Lunar New Year, all walks of life will resume work and production one after another, the demand and supply will increase significantly, and the price of graphite electrodes will develop steadily and positively.

That's all, welcome to communicate with us.

2 notes

·

View notes