Photo

Rotary lobe pumps are designed for low, medium and high-viscosity media and offer gentle pumping action and reliable performance. Our portfolio includes three ranges: SX, SRU and OptiLobe . With its robust construction, each pump is developed for a different type of demand and meets high standards of quality and reliability. Collectively, they provide operating economy and high flexibility of use.

https://www.alfalaval.in/products/fluid-handling/pumps/rotary-lobe-pumps/

0 notes

Link

Alfa Laval is committed to providing a safe, healthy and attractive working environment. Here we highlight the health and safety progress in Alfa Laval’s operations in India.

0 notes

Link

Alfa Laval offers enormous possibilities for production related purchasing. Our dedicated global service network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into a Performance Agreement for predictable and worry-free operations. To restore equipment and optimize performance, a range of cleaning services for heat transfer, and separation equipment are available to you.

0 notes

Link

Alfa Laval copper-brazed plate heat exchangers are a compact, efficient and maintenance-free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability. This enables the longest possible service life – even under conditions with extremely high design pressures.

Brazed plate heat exchangers have no headers, tie bars or sealing gaskets because the plates are furnace brazed at temperatures of 1100°C. During the assembly phase, a sheet of brazing material (generally copper but also nickel) is placed between the plates, the pack is pressed and subsequently baked for some hours.

#brazed plate heat exchanger#brazed heat exchanger#brazed heat exchanger manufacturers#brazed plate heat exchanger manufacturers

0 notes

Link

Alfa Laval Oceania won the tender for this project, covering the delivery, installation and commissioning of seven Alfa Laval AS-H 300 Belt Thickener units, which separate liquid from solids by gravity drainage through a 3-metre-wide porous filter belt. The new thickeners were configured to process waste activated sludge (WAS) and Three-Phase Separator (TPS) sludge.

0 notes

Link

The Alfa Laval AS-H Belt Thickener is considered the industry standard for removal of liquid from a solid-liquid suspension/sludge. The Alfa Laval AS-H Belt Thickener uses basic gravity to thicken dilute sludge and slurries. It is suitable for all municipal sludge types as well as industrial sludges that flocculate – particularly those from biological and activated sludge processes.

0 notes

Link

Alfa Laval doesn’t do average. Whether it is our multi-purpose Industrial range; the Semi-welded industrial range for refrigeration and exacting processes; the Hygienic range for food, beverage and pharma applications; or the Specialized range for condensation, evaporation and fibrous media – you buy into reduced cost of ownership and increased efficiency and safety.

0 notes

Link

Alfa Laval’s broad portfolio of thermal and separation technologies are ideal solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen.

0 notes

Photo

Alfa Laval decanter centrifuges help you separate solids from liquids within one single continuous process. Stand out from the competition with high performance separation that results in extracted / clarified products of excellent quality and higher commercial value. Make a difference as you recover valuable raw materials, reduce energy consumption and lower footprint and waste management costs with our industrial decanter centrifuge machines and services. https://www.alfalaval.in/products/separation/centrifugal-separators/decanters/

0 notes

Photo

The Alfa Laval Olmi range of customized heat exchangers is designed and built for the toughest applications in chemical processing industries, oil & gas production and power stations. These units maximize plant sustainability through low service requirements and exceptional reliability, resulting in competitive total cost of ownership and trouble-free operation. https://www.alfalaval.in/products/heat-transfer/tubular-heat-exchangers/process-shell-and-tube-heat-exchangers/

0 notes

Photo

Alfa Laval’s broad portfolio of thermal and separation technologies are ideal solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen. https://www.alfalaval.in/industries/energy-and-utilities/sustainablesolutions/sustainable-solutions/clean-energy/green-hydrogen/

0 notes

Link

A centralised sampling system allows for placing the sample valve at the optimal point for sampling: on the middle of the cylindrical part of the vessel, independent of whether there is easy access to this point or not.

0 notes

Link

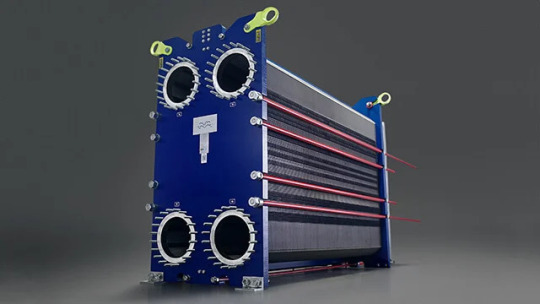

With Alfa Laval gasketed plate heat exchanger, heat cuts through the surface and separates the hot medium from the cold. Thus, heating and cooling fluids and gases use minimal energy levels. The theory of heat transfer between mediums and fluids happens when Heat is always transferred from a hot medium to a cold medium. In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the fluids into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates.

Plate heat exchangers are extremely energy efficient, because the energy required usually already exists within the system and can then be easily transferred to another system or process instead of just being allowed to cool down or be pumped out and wasted. Plate exchanger is the most efficient due to turbulent flow on both sides. High heat-transfer coefficient and high turbulence due to even flow distribution are important. However, a plate heat exchanger regenerator is restricted to low viscosities.

0 notes

Link

The i-Series centrifugal pumps are ideal for most standard duties, securing effective yet gentle liquid transfer. Building on decades of pump design expertise, they offer easy cleaning, simplified maintenance and low cost of ownership in the long term. They are EHEDG-compliant and come with FDA-approved elastomer's.

0 notes

Link

Fully welded plate heat exchanger is a plate heat exchanger made of a series of corrugated metal plates welded by laser or argon arc welding. The plate group and the plate group are connected by welding with molding strips. Because there is no gasket seal, it has higher temperature and pressure resistance.

The Alfa Laval Compabloc range provides compact, efficient and reliable heat transfer for a wide range of process duties. Full and easy cleanability on both circuits make them the most service-friendly welded heat exchangers on the market. It’s easy to see why together, Compabloc, Compabloc+ and Compabloc Free Flow have become the undisputed champions of heat exchange in some of the most demanding applications.

#welded plate heat exchanger#fully welded plate heat exchanger#welded plate and frame heat exchanger

0 notes

Photo

With Alfa Laval gasketed plate heat exchanger, heat cuts through the surface and separates the hot medium from the cold. Thus, heating and cooling fluids and gases use minimal energy levels. The theory of heat transfer between mediums and fluids happens when Heat is always transferred from a hot medium to a cold medium. In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the fluids into alternate channels. The plate pack is assembled between a frame plate and a pressure plate, and compressed by tightening bolts fitted between these plates.

0 notes

Link

Alfa Laval offers enormous possibilities for production related purchasing. Our dedicated global service network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into a Performance Agreement for predictable and worry-free operations. To restore equipment and optimize performance, a range of cleaning services for heat transfer, and separation equipment are available to you.

0 notes