#gas-flow-meter

Text

Why Is The Actual Mass Flow Rate Important In Gas Flow Measurement?

Measurement of gas mass flow under process circumstances is never easy. To do it, there aren't many flow methods available, such thermal mass calorimetry and coriolis flow.Gas mass stays constant but gas volume changes in response to changes in temperature and pressure, according to Charles & Boyle's law. This is the primary justification for why it's crucial to determine actual mass flow rate during procedures.

First, let's examine the distinction between Standard and Actual Flow Rates.

STANDARD FLOW RATES:

Standard flow rate is a flow rate of gas at specific pressure and temperature conditions. It is dependent on pressure and temperature conditions. It is termed as Standard volumetric

(Sm3/hr or SCFM) or Standard Mass flow rate (Kg/hr at specific standard conditions).

There are different standards conditions used internationally such as :

ISO2533 (1.01325bara @ 15°C );

DIN 1343 ( 1.01325bar @ 0°C);

Standard (1.01325bar @ 20°C) etc.

(above with 0% relative humidity conditions generally or sometime varying conditions )

ACTUAL FLOW RATES

Actual Flow rate is a flow rate of gas at different pressure and temperature conditions, It is independent of pressure and temperature conditions. It is termed as Actual Volumetric ( Am3/hr or ACFM ) or Actual Mass Flow Rate (Kg/hr at actual process conditions)

IMPORTANCE OF ACTUAL MASS FLOW RATE MEASUREMENT

As per Charles Law states that at constant pressure ideal gas volume increases with increase in temperature or gasses expands when heated.

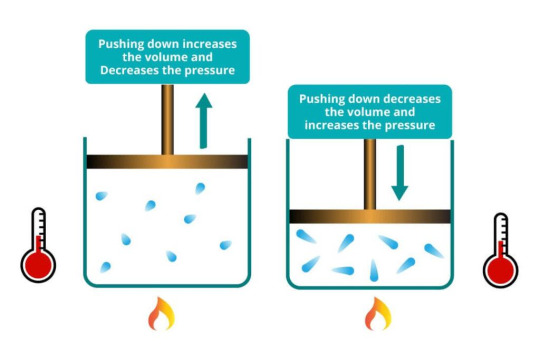

And Bolye’s Law asserts that at a fixed temperature ideal gas volume is inversely proportional to pressure imposed on the gas. It suggests at constant temperature volume increases when pressure falls and gas volume decreases when pressure increases.

According to the aforementioned laws, measuring the volumetric gas flow rate results in a significant measurement inaccuracy because the volume of the gas changes as temperature and pressure do.

In order to accurately monitor and regulate the process conditions, we must ascertain the real mass flow rate of gas.

The Leomi 587 Insertion Thermal Mass Flow Meter for Actual Mass / Volume Flow Rate measurement was created with the process industry's actual need for precise and genuine measurement when improving process conditions in mind.

#thermal mass flow meter#compressed air#gas flow meter in india#compressed air flow meter#gas flow meter

0 notes

Text

Unveiling Precision: Nagman Flow's Coriolis Mass Flow Meter

Welcome to Nagman Flow, where precision instrumentation meets cutting-edge technology. In this blog post, we dive into the world of flow measurement with a focus on the Coriolis Mass Flow Meter. We will explore the intricacies of this innovative device, its applications, and how Nagman Flow's expertise ensures unparalleled accuracy in mass flow measurement.

Coriolis Mass Flow Meter: A Breakthrough in Flow Measurement

The Coriolis Mass Flow Meter represents a revolution in flow measurement technology. Operating on the principle of the Coriolis effect, this meter offers unparalleled accuracy in measuring mass flow rates. Nagman Flow's Coriolis Mass Flow Meter is engineered to deliver precise measurements across various fluid mediums, from liquids to gases.

Advantages of Nagman Flow's Coriolis Mass Flow Meter

Precision Measurement: Nagman Flow's Coriolis Mass Flow Meter provides precise measurement of mass flow rates, ensuring accuracy and reliability in critical processes.

Versatility: Whether measuring liquids or gases, Nagman Flow's Coriolis Mass Flow Meter offers unmatched versatility, making it suitable for a wide range of applications.

Low Maintenance: Built with robust construction and advanced technology, Nagman Flow's Coriolis Mass Flow Meter requires minimal maintenance, reducing downtime and operational costs.

Coriolis Gas Flow Measurement: With specialized configurations for gas flow measurement, Nagman Flow's Coriolis Mass Flow Meter excels in accurately measuring gas flow rates, providing valuable insights for various industries.

Applications of Coriolis Mass Flow Meter

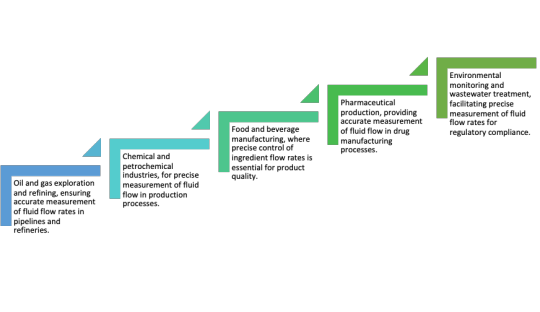

Nagman Flow's Coriolis Mass Flow Meter finds applications across diverse industries, including:

In the realm of flow measurement, Nagman Flow's Coriolis Mass Flow Meter stands as a beacon of precision and reliability. With its advanced technology and unparalleled accuracy, Nagman Flow ensures that industries can rely on precise mass flow measurements for optimal performance and efficiency. Trust Nagman Flow to deliver exceptional solutions for all your flow measurement needs. Contact us today to learn more about Nagman Flow's Coriolis Mass Flow Meter and experience the difference in precision instrumentation.

0 notes

Text

Oxygen gas regulator

NINGBO DSW INDUSTRY CO., LTD established in 2004 year, is a global leader in research & development and manufacturing in the welding fields.

Our major products are oxy-fuel cutting and welding equipment such as oxy-acetylene and oxy-fuel welding and cutting equipment, cutting torches, cutting tips, welding nozzles, heating torches, gas regulators, cutting and welding outfits.

For over 10 Years, DSW has been exported to more than 50 countries,listed as long-term strategic partner due to its reliability and accumulated experience.

The medical oxygen regulator is an essential device that is securely attached to an oxygen cylinder to carefully control and regulate the flow of oxygen to the patient. This device plays a crucial role in ensuring that the pressure of the oxygen coming from the cylinder is adjusted to a safe and appropriate level that meets the specific needs of the patient. By carefully regulating the flow of oxygen, the medical oxygen regulator guarantees that the patient receives the precise amount of oxygen required at the prescribed rate for effective treatment.

In healthcare settings such as hospitals, clinics, and other medical facilities, oxygen regulators are widely used to administer oxygen therapy to patients with various respiratory conditions or other medical needs. The DSW-86 pressure gauge is an integral component of the oxygen regulator, providing a clear indication of the pressure level within the gas cylinder to ensure that the oxygen flow is maintained at the correct level.

0 notes

Text

Choosing Excellence: LPG Gas Meter Providers

Choose excellence in LPG gas measurement with our guide to LPG Gas Meter Providers. Trustworthy sources that prioritize accuracy and reliability.

#lpg gas meter#lpg gas flow meter#lpg gas measurement meter#lpg gas meter suppliers#lpg gas flow meter manufacturers

0 notes

Text

A Guide to Natural Gas Flow Meters

As you reviewed the selection guide, you have likely narrowed your search to a few meters that might be suitable for your project. Now you should weigh the advantages and disadvantages of each so that you can make an educated decision.

Thermo mass flow meters rely on the principle that heat transfer is proportional to the mass flow of gas. They contain a heated element and one or more temperature sensors. In order to determine the flow rate, the temperature difference between the heated element and the gas is measured. For large natural gas pipelines, the flow meter price can be very low for insertion type natural gas flow meters and inline type natural gas flow meters. It has SCFM, kg/h, grams per second, grams per minute, mmscfd, Sm3/h, Nm3/h.

These meters utilize the Coriolis effect, which is the deflection of fluid due to the rotation of the Earth. The gas flows through a vibrating tube in a Coriolis flow meter. The gas motion causes the tube to twist, and the degree of twisting is proportional to the mass flow rate. The Coriolis flow meter is the best natural gas flow meter. It can measure natural gas mass flow directly, and it is the most accurate meter for measuring natural gas flow. Additionally, it can measure natural gas flow rates at high pressures.

A turbine rotor is placed in the gas stream to measure the flow rate. The rate of rotation is proportional to the flow rate as the gas flows through the meter. In order to calculate the flow rate, this rotational motion is converted into an electrical signal.

The Vortex Shedding Flow Meter is based on the principle that vortices or swirling patterns are shed alternately on each side of an obstacle when gas flows past it (such as a bluff body). Flow rate is determined by the frequency of vortex shedding. These vortices are detected and counted.

An orifice plate is a thin plate with a hole (or orifice) in the center. With each flow of gas through the orifice, there is a pressure drop that correlates to the flow rate. Pressure sensors are used to measure this pressure drop before and after the orifice plate.

Technical specifications for natural gas flow meters

A wide range of natural gas flow sensors is available: 3/4", 1/2", 1", 2", 3", 4", NB 100mm, 6", 8", 10", 12" and max 6000mm.

Process connections include wafers or flanges, threads, inline natural gas turbine flow meters, and insertion natural gas flow meters.

A low pressure rating, such as 10 PSI, can be used to detect natural gas leaks and measure low flow rates. It also comes in high pressure ratings, such as 150LB, 300LB, 600LB ,900 class high pressure natural gas flow meters.

Natural gas turbine flow meter with 4-20mA, pulse or relay outputs, real-time data transmission, RS485 or HART interface

Price of natural gas flow meters in the industry

Industrial natural gas flow meters are priced based on a number of factors. Our natural gas flow meter price starts at $500. Customers can choose the right meter for their field application and budget. Contact us at [email protected] to get your price cost for an industrial natural gas flow meter.

Generally, the larger the gas sensor size, the higher the price. For example, a 4" natural gas flowmeter costs more than a 1" flowmeter.

The different measurement principle for natural gas flowmeters results in different prices. In addition to DP flow meters (differential pressure flow meters), we can also provide orifice flow meters for natural gas, Coriolis mass flow meters, thermal gas flow meters for measuring natural gas, and turbine flow meters for measuring natural gas volumetric flow. Unfortunately, SILVER does not offer portable natural gas flow meters or ultrasonic natural gas flow meters.

Our natural gas flowmeters are rated at 232 PSI (normal condition), but if customers require 600LB or 300 Class flowmeters, ANSI or ASME pressure, the price will be higher. To detect leaks from NG pipes, you can purchase our low flow natural gas flow meter for NG gas with typical low flow.

There are several functions of a natural gas flowmeter: electronic natural gas flow meter, totalizer calculation, HART communication, RS 485, lithium battery power supply, and EVC (temperature and pressure correction). These functions affect the price of a natural gas flowmeter. Get more info about compressed air insertion flow meter.

Natural gas flowmeter brand: The natural gas flowmeter of well-known brands is not cheap, such as EMERSON, ROSEMOUNT, ENDRESS, FOXTHERMAL, SIERRA. In contrast, SILVER offers many cheap alternatives, you can buy economical natural gas flow meters from China factories.

What is the best natural gas flow meter?

In order to save money on natural gas flow meters, we all hope to buy the best models. The best natural gas lies in the working conditions and applications that the industrial natural gas flowmeter you choose to meet, the budget to be met, the prompt delivery date, and the timely after-sales service. Choosing the right manufacturer is the best solution for your industrial natural gas flow meter needs.

0 notes

Text

Your Reliable Turbine Flow Meter Supplier: Burak Metering

For accurate flow measurement solutions, rely on Burak Metering as your turbine flow meter manufacturer. We provide premium meters and knowledgeable services.

#turbine flow meter#turbine flow meter manufacturer#turbine meter#turbine gas meter#turbine gas meter manufacturer

0 notes

Text

Precision in Gas Measurement: Exploring High Pressure Flow Meters and Natural Gas Meter Installation

In the realm of energy management, accurate measurement of gas flow is crucial for efficiency and safety. This article delves into two vital components that contribute to precise gas measurement: high pressure flow meters and natural gas meter installation. Join us as we uncover the significance, features, applications, and advantages of these essential elements.

Unveiling High Pressure Flow Meters

High pressure flow meters are specialized instruments designed to accurately measure the flow of gases under high pressure conditions. These meters play a critical role in various industries where precise gas flow measurement is essential for optimal performance.

Key Features of High Pressure Flow Meters

Pressure Resilience: High pressure flow meters are engineered to withstand and accurately measure gas flow under extreme pressure conditions, ensuring reliable data.

Accurate Measurement: These meters provide precise measurements of gas flow rates, contributing to efficient process control and accurate billing.

Diverse Applications: High pressure flow meters find applications in industries such as oil and gas, aerospace, and manufacturing, where high-pressure gas flow measurement is essential.

Exploring Natural Gas Meter Installation

Natural gas meter installation is a critical process that involves the proper setup and calibration of gas meters to ensure accurate measurement of natural gas consumption. Professional installation plays a key role in reliable energy management.

Key Aspects of Natural Gas Meter Installation

Professional Expertise: Natural gas meter installation is performed by trained professionals who follow industry standards and guidelines to ensure accurate and safe installation.

Calibration and Testing: Installed meters are calibrated and tested to verify their accuracy and proper functioning, ensuring precise gas consumption measurement.

Compliance: Installation is carried out in compliance with safety regulations and local codes to guarantee the safety of individuals and properties.

Applications and Benefits

High Pressure Flow Meters:

Oil and Gas Industry: High pressure flow meters are used in the oil and gas sector to measure gas flow rates in pipelines, aiding in efficient transportation and distribution.

Manufacturing Processes: These flow meters contribute to precise gas flow control in manufacturing processes, ensuring consistent product quality.

Natural Gas Meter Installation:

Residential Consumers: Proper installation of natural gas meters ensures accurate billing and fair consumption assessment for residential consumers.

Industrial Facilities: Installation in industrial settings facilitates precise monitoring of gas usage for cost control and process optimization.

Installation and Maintenance for Optimal Performance

Proper installation and maintenance are crucial for optimal performance of high pressure flow meters and natural gas meter installation. Here's an overview of the process for these components:

High Pressure Flow Meters:

Careful Installation: High pressure flow meter should be installed according to manufacturer guidelines, ensuring proper sealing and connections.

Regular Maintenance: Scheduled maintenance visits ensure meters remain accurate and functioning properly under high-pressure conditions.

Natural Gas Meter Installation:

Professional Setup: Trained technicians perform proper installation, ensuring gas meters are correctly connected and calibrated.

Periodic Inspection: Regular inspections and maintenance checks help identify and address any issues that may affect meter accuracy.

Conclusion

High pressure flow meters and natural gas meter installation are pivotal in ensuring accurate and efficient gas flow measurement. By providing precise data, compliance with standards, and professional installation, these components contribute to effective energy management, cost control, and safety.

Investing in premium high pressure flow meters and professional natural gas meter installation is essential for industries and consumers seeking accurate and reliable gas measurement. With their accuracy, pressure resilience, and compliance, these components pave the way for optimized gas usage and sustainable energy practices.

0 notes

Text

100 SCCM to 100 SLPM Low Flow Tactical Flow Meter

100 SCCM to 100 SLPM Low Flow Tactical Flow Meter, Battery Powered for 2 years

$800.00

Find your medical gas flow meter easily amongst the 209 products from the … Oxygen or Air 0 – 15 L/min st&ard flow rate Low flow, 0 – 3.5 & 0 – 5 … PRODUCT DETAILS The TSI Mass Flow Meter 41401 (0.01-20 L/min / Air … a centralized medical gas pipeline system, to the patient with the use of a mask or a cannula.

Low Flow Gas Mass flow meters for methane shipping from stock & configured for you OEM OK

EASY to use Low Flow Mass Flow Meters. Check our stock & prices that beats our competition. Read more..

0 notes

Text

Flameproof CNG Flow Meters for Automobile

CNG engines are thoroughly tested to ensure high efficiency and better performance.

The most important part of this system was the CNG Flow Meter, which accurately measures the mass flow rate of the CNG that is supplied during the engine testing. The flow meter needs to be flame-proof.

Manas, one of the top ten flowmeter manufacturers, maybe the only Indian company with this capability. This flow meter is CMRI-certified and suitable for gas categories IIa and IIb.

https://manasmicro.com/cng-flow-meter/

#manasmicro#flowmeter#flowmeters#flowmetermanufacturers#suppliers#testing#gas#CNGflowmeter#automobileindustry#automobile#flameproof#flameproofcngflowmeter#thermalmassflowmeter#CMRIcertified#M#electromagnetic flow meter#flow meter#process instruments#thermal mass flow meter

0 notes

Text

How does a Add Value Coriolis flow meter work?

Mass and volume flow measurement

As a typical application of Coriolis effect, the Coriolis flow meter allows the measured fluid to pass through a measuring tube in vibration driven by an applied electromagnetic field. However, when mass flows through the measuring tubes, a reaction force does occur which, at a certain moment on the inflow side, is directed opposite to the other side. These forces, referred to as Coriolis force, cause the tubes to sway, out of phase. The phase shift is proportional to the mass flow. Therefore, the mass flow measurement can be realized by measuring the phase shift proportion.

Density measurement

During the measurement, the measuring tubes reach their natural frequency. This is linked to the mass of the measuring tubes, or the mass of the medium in the measuring tubes. Coriolis mass flow meters thus measure the density of the medium.

Temperature measurement

Temperature is a measured variable that is available as an output. Each instrument has a built-in temperature sensor that measures the product temperature.

#flow meter#coriolis flow meter#mass flow measurement#liquid measurement#density measurement#gas measurement

0 notes

Text

BLAST FURNACE GAS FLOW MEASUREMENT IN STEEL PLANT

In steel manufacturing Iron ore is smelted in blast furnaces along with fuel (coke) and flux (limestone), which are continuously delivered from the top of the furnace. Through a network of pipes (tuyeres), hot blast air with oxygen enrichment is forced into the lower part of the furnace. While material is falling downhill in the furnace as a result, chemical processes take place.

MEASUREMENT OF GAS FLOW IN A STEEL PLANT:

Low-calorie flue gas, also known as blast furnace gas, will escape the top of the furnace and is then used in additional low-heating furnaces during subsequent steel-making operations. Typically, the primary components of blast furnace gas are N2 (50–55%), CO (20–25%), CO2 (16–18%), etc. It has some moisture content and has sticky but cleanable carbon particle filth.

In these difficult situations, Leomi offers the Leomi-586 Insertion Thermal Mass flowmeter, which outperforms current Orifice Or Averaging Pitot tube-based DP type flow transmitters.

ADVANTAGE OF THERMAL MASS FLOWMETER INSTALLATION IN THIS APPLICATION:

low velocity of 0.6 m/s or less and no pressure loss is measured

simple installation with quick turnaround for huge pipe diameter

Sensor probe is easily removed for when cleaning is necessary.

A KEY LIMITATION OF CURRENTLY USED DP-TYPE FLOW METRE:

Limits on significant pressure drop measurement of the low flow range

difficult to install, time-consuming, and expensive initially

This application requires a challenging non-removable design.

0 notes

Text

A Closer Look at Flow Meters: Enhancing Accuracy and Efficiency in Fluid Measurement

Introduction:

In industries where fluid flow plays a critical role, accurate measurement is essential for process optimization, quality control, and cost management. Flow meters are the unsung heroes in these operations, providing vital data and insights into fluid dynamics. In this blog post, we will delve into the world of flow meters, exploring their significance, working principles, types, and the benefits they offer in various applications. So, let's dive in and unravel the mysteries of flow meters!

1. The Importance of Flow Meters:

Fluid flow is a fundamental aspect of many industries, including oil and gas, chemical processing, water management, and manufacturing. In this section, we will discuss why flow meters are crucial for these sectors and how they contribute to enhanced productivity, safety, and resource utilization.

2. Understanding Flow Meter Principles:

To comprehend the intricacies of flow meters, we must grasp their underlying principles. In this section, we will explore the four main types of flow meters: differential pressure, positive displacement, velocity, and mass flow meters. We'll explain the working mechanisms of each type and highlight their strengths and limitations.

3. Differential Pressure Flow Meters:

One of the most common types of flow meters is the differential pressure flow meter. In this section, we will take a closer look at orifice plates, venturi tubes, and flow nozzles - three widely used differential pressure flow meter variants. We'll explain their construction, working principles, and discuss their applications and considerations for accurate measurements.

4. Positive Displacement Flow Meters:

Positive displacement flow meters are known for their precise measurements of low flow rates. In this section, we will examine the working principles of gear meters, nutating disc meters, and oval gear meters. We'll explore their advantages, limitations, and typical applications in industries such as food and beverage, pharmaceuticals, and fuel distribution.

5. Velocity Flow Meters:

Velocity flow meters, such as turbine and electromagnetic meters, rely on the fluid's velocity to measure flow rates. In this section, we will delve into their working principles, installation considerations, and applications. We'll also discuss the challenges associated with fluid properties, calibration, and maintenance.

6. Mass Flow Meters:

For applications where mass measurement is crucial, mass flow meters provide accurate results by directly measuring the mass of the flowing fluid. We will explore thermal mass flow meters, Coriolis flow meters, and their working principles, advantages, and limitations. This section will highlight their significance in industries like pharmaceuticals, chemical processing, and HVAC systems.

7. Selecting the Right Flow Meter:

Choosing the appropriate flow meter for your specific application is vital for accurate and reliable measurements. In this section, we will discuss the key factors to consider, such as fluid characteristics, flow range, accuracy requirements, installation constraints, maintenance needs, and cost considerations. By understanding these factors, you can make an informed decision when selecting a flow meter.

8. The Future of Flow Meter Technology:

As technology advances, so does the field of flow meters. In this section, we will explore emerging trends and innovations, including digitalization, Internet of Things (IoT) integration, and advancements in sensor technology. We'll discuss how these developments are shaping the future of flow meter technology and the potential benefits they offer.

9. Conclusion:

Flow meters are indispensable tools for accurate fluid measurement in various industries. By understanding their principles, types, and considerations for selection, you can optimize processes, reduce costs, and ensure safe operations. We hope this blog post has shed light on the world of flow meters and provided you with valuable insights into their significance and applications. Remember, precision in flow measurement leads to efficiency and success!

#flow meters#water meter test bench#gas meter calibration#flow meter#coriolis mass flow meters#flow meter calibration#liquid flow calibration system

0 notes

Text

Kapwell Ltd, a UK based company, offers Mud Gas Separator, Liquid Seal Monitoring, Vacuum Degasser, Choke Control system, Vent Tower for MGS and Flowmeter Skid suitable for offshore,

Landrig and shale gas drilling operations. We guarantee high quality for each and every package.

#Gas Scrubber#Coriolis Mass Flow Meter#Vacuum Degassing#Hydrocyclone Separators#Oil and Gas Separators

0 notes

Text

Industry Standard: Gas Flow Meter Manufacturer

Set the industry standard with the Gas Flow Meter Manufacturer. Discover how our meters redefine precision and reliability in gas flow measurement.

#Gas Flow Meter Types#Gas Flow Meter Manufacturers in Maharashtra#Gas Flow Meter Suppliers#Gas Flow Meter Suppliers in Mumbai#Natural Gas flow Meter#Natural Gas Flow Meter Types

0 notes

Text

Leomi-High quality professional Insertion Thermal Mass Flow Meter Company in India

Leomi-High quality professional Insertion Thermal Mass Flow Meter and Thermal Mass Flow Meter services Provider Company in India, More Information visit our website www.leomi.in

#Insertion Thermal Mass Flow Meter in India#Thermal Mass Flow Meter in India#Calorimetric Flow Meter in India#Insertion Thermal Mass Flow Meter#Compressed Air Flow Meter in India#Thermal Mass Flow Meter#Air Flow Meter in India#Mass Flow meter India#Calorimetric Flow Meter#Compressed Air Flow Meter#Gas Flow Meter in India#Air Flow Meter#Gas flow meter

0 notes