#footwear polyurethane manufacturers

Text

1, 4 Butanediol Market Competitive Landscape2033 2024

Overview and Scope

1,4-Butanediol is a colourless and water-soluble, thick fluid with a high point of boiling (230°C) at room temperature used as a source of gamma-hydroxybutyrate (GHB), a recreational drug with euphoric and sedative effects. It is also utilized in the synthesis of various organic compounds, especially the solvent oxolane (also known as tetrahydrofuran, or THF). It functions as a protic solvent, prodrug, and neurotoxin

Sizing and Forecast

The 1, 4 butanediol market size has grown strongly in recent years. It will grow from $8.84 billion in 2023 to $9.61 billion in 2024 at a compound annual growth rate (CAGR) of 8.8%. The growth in the historic period can be attributed to demand from polybutylene terephthalate (pbt) production, growing textile industry usage, expansion in the automotive sector, increasing demand for tetrahydrofuran (thf), use in pharmaceutical and cosmetic products..

The 1, 4 butanediol market size is expected to see strong growth in the next few years. It will grow to $13.06 billion in 2028 at a compound annual growth rate (CAGR) of 8.0%. The growth in the forecast period can be attributed to growth in bio-based 1,4 butanediol production, expanding end-use applications, rising demand for polyurethane, increased adoption in resin and coating formulations, focus on sustainable chemical production.. Major trends in the forecast period include market expansion in asia-pacific, technological advancements in production, fluctuations in raw material prices, innovation in product applications..

Segmentation & Regional Insights

The 1, 4 butanediol market covered in this report is segmented –

1) By Type: Synthetic, Bio Based

2) By Application: Tetrahydrofuran (THF), Polybutylene Terephthalate (PBT), Gamma Butyrolactone (GBL), Polyurethane (PU), Others

3) By End-Use: Chemical, Sports, Automotive, Electronic, Footwear, Others

Asia-Pacific was the largest region in the 1,4 butanediol market in 2023. The regions covered in the 1, 4 butanediol market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

The increasing automotive sector is expected to propel the growth of the 1,4-butanediol market in the coming future. The automotive sector encompasses businesses involved in the creation, distribution, sale, and upkeep of automobiles. In automotive sector, the manufacture of vehicle’s bumpers, fenders, spoilers, and automobile front and rear end fascia require urethane elastomers made from 1,4-butanediol. Thus, the increasing demand from the automotive sector boosts the expansion of the 1,4-butanediol market. For instance, in March 2022, according to the European Automobile Manufacturers Association, a Belgium-based association that integrates Europe's 14 largest auto, truck, van, and bus manufacturers, over 6.3 million passenger automobiles were produced at US auto facilities in 2021, an increase of 3.1% from the preceding year. Therefore, the increasing automotive sector is driving the 1,4-butanediol market.

Key Industry Players

Major companies operating in the 1, 4 butanediol market report are BioAmber Inc., BASF SE, Ashland Global Holdings Inc., Mitsubishi Chemical Corporation, SK Global Chemical Co Ltd., Dairen Chemical Corporation, LyondellBasell Industries NV, Dow Inc., Genomatica Inc., Xinjiang Tianye Co Ltd., ExxonMobil Corporation, Koch Industries, PTT Global Chemical Public Company Limited, Saudi International Petrochemical Company, Chemtura Corporation, Chongqing Jianfeng Chemical Co Ltd., Royal Dutch Shell PLC, Mitsui & Co Ltd., DCC plc., Nan Ya Plastics Corporation, Sinopec Yizheng Chemical Fibre Company Limited, Shanxi Sanwei Group Co. Ltd., Invista S.à r.l., Nanjing Bluestar Co. Ltd., Oxea GmbH, TCC Group, Formosa Plastics Corporation, International Specialty Products, Huntsman Corporation, Myriant Corporation, Davy Process Technology .

The 1, 4 butanediol market report table of contents includes:

1. Executive Summary

2. 1, 4 Butanediol Market Characteristics

3. 1, 4 Butanediol Market Trends And Strategies

4. 1, 4 Butanediol Market - Macro Economic Scenario

5. Global 1, 4 Butanediol Market Size and Growth

.

.

.

31. Global 1, 4 Butanediol Market Competitive Benchmarking

32. Global 1, 4 Butanediol Market Competitive Dashboard

33. Key Mergers And Acquisitions In The 1, 4 Butanediol Market

34. 1, 4 Butanediol Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

Artificial Leather Market: A Compelling Long-Term Growth Story

The Latest research study released by AMA “Worldwide Artificial Leather Market” with 100+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint and status. Understanding the segments helps in identifying the importance of different factors that aid the market growth. Some of the Major Companies covered in this Research are Alfatex ITALIA (Italy), Mayur Uniquoters Limited (India), Zhejiang Hexin Industry Group (China), Yantai Wanhua Synthetic Leather Group Co. Ltd (China), NAN YA Plastics Industrial Co. Ltd (China), Teijin Limited (Japan), Kuraray (Japan) Kuraray Co. Ltd. (Japan), DuPont (United States), Uniroyal (United States), Asahi Kasei Corporation (Japan), San fang chemical industry co. ltd. (China), Toray Coatex Co. Ltd. (Japan), H.R. Polycoats Pvt. LTD. (Japan).

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/21708-global-artificial-leather-market

Brief Summary of Artificial Leather:

Artificial leather resembles similar to natural one but is less expensive and finds its applications across various domain such as clothing, footwear and automotive sectors among others. Raw materials such as Polyvinyl Chloride (PVC) and Polyurethane are used in the production of artificial leather along with excessive chemical. The use of chemicals leads to an adverse effect on the environment and key manufacturers are finding ways and means to reduce the same as production and consumption of artificial leather grow rapidly.

Market Trends:

Rise in Demand for Low-Cost Versatile Leather Products

Market Drivers:

Growing Demand for Artificial Leather in Footwear Sector

Cost Effectiveness and Advantage over Pure Leather

Market Challenges:

Lack of Durability Limits its Applications

Effect on Trade Activity Owing to Slowdown in Global Economy

Market Opportunities:

Changing Fashion Statement and Increase in Disposable Income in Emerging Countries

Rising Demand for Lightweight Leather in Automotive Industry

The Global Artificial Leather Market segments and Market Data Break Down are illuminated below:

by Type (PVC-leather, PU-leather, Bio-leather), Application (Automotive, Clothing, Foot wear, Bags, purses & wallets, Furnishing, Others), End User Industry (Automotive, Furnishing, Footwear, Clothing, Others)

This research report represents a 360-degree overview of the competitive landscape of the Global Artificial Leather Market. Furthermore, it offers massive data relating to recent trends, technological, advancements, tools, and methodologies. The research report analyzes the Global Artificial Leather Market in a detailed and concise manner for better insights into the businesses.

Regions Covered in the Global Artificial Leather Market:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Enquire for customization in Report @ https://www.advancemarketanalytics.com/enquiry-before-buy/21708-global-artificial-leather-market

The research study has taken the help of graphical presentation techniques such as infographics, charts, tables, and pictures. It provides guidelines for both established players and new entrants in the Global Artificial Leather Market.

The detailed elaboration of the Global Artificial Leather Market has been provided by applying industry analysis techniques such as SWOT and Porter’s five-technique. Collectively, this research report offers a reliable evaluation of the global market to present the overall framework of businesses.

Attractions of the Global Artificial Leather Market Report:

The report provides granular level information about the market size, regional market share, historic market (2018-2023) and forecast (2024-2032)

The report covers in-detail insights about the competitor’s overview, company share analysis, key market developments, and their key strategies

The report outlines drivers, restraints, unmet needs, and trends that are currently affecting the market

The report tracks recent innovations, key developments and start-up’s details that are actively working in the market

The report provides plethora of information about market entry strategies, regulatory framework and reimbursement scenario

Get Up to 10% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/21708-global-artificial-leather-market

Strategic Points Covered in Table of Content of Global Artificial Leather Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Artificial Leather market

Chapter 2: Exclusive Summary – the basic information of the Artificial Leather Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Artificial Leather

Chapter 4: Presenting the Artificial Leather Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2017-2022

Chapter 6: Evaluating the leading manufacturers of the Artificial Leather market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2023-2028)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

finally, Artificial Leather Market is a valuable source of guidance for individuals and companies.

Get More Information @: https://www.advancemarketanalytics.com/reports/21708-global-artificial-leather-market Artificial Leather Market research provides answers to the following key questions:

What is the expected growth rate of the Artificial Leather Market?

What will be the Artificial Leather Market size for the forecast period, 2024 – 2032?

What are the main driving forces responsible for changing the Artificial Leather Market trajectory?

Who are the big suppliers that dominate the Artificial Leather Market across different regions? Which are their wins to stay ahead in the competition?

What are the Artificial Leather Market trends business owners can rely upon in the coming years?

What are the threats and challenges expected to restrict the progress of the Artificial Leather Market across different countries?

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Artificial Leather Market#Artificial Leather Market Demand#Artificial Leather Market Trends#Artificial Leather Market Analysis#Artificial Leather Market Growth#Artificial Leather Market Share#Artificial Leather Market Forecast#Artificial Leather Market Challenges

0 notes

Text

There are several sustainable and eco-friendly alternatives to Skechers that prioritize ethical manufacturing and use of responsibly-sourced materials:

Vessi Cityscape Sneakers

Vessi Cityscape sneakers are a great waterproof and vegan alternative to Skechers walking shoes. They are lightweight, breathable, and suitable for city walks and light hiking[2]. Key features:

100% waterproof knit upper

Cushioned insole for comfort

Minimalist and stylish design

Vegan and Blue Sign certified

Allbirds Tree Runners

Allbirds Tree Runners are made from renewable eucalyptus tree fiber and are a sustainable alternative to Skechers casual sneakers[5]. Highlights:

Lightweight and breathable eucalyptus fiber upper

Carbon-negative green EVA soles

Machine washable

Certified B-Corp meeting high environmental standards

Cariuma OCA Low Sneakers

Cariuma's OCA Low sneakers use premium natural materials like bamboo, organic cotton, and natural rubber[5]. Key points:

Bamboo knit upper with organic cotton lining

Sugarcane-based insoles and natural rubber outsoles

Carbon-neutral manufacturing

Ethical factory conditions certified by GOTS and Fairtrade

Other brands like Veja, Tropicfeel, and Saola offer stylish, eco-friendly sneaker alternatives using recycled plastics, natural rubber, and other sustainable materials[3][5]. Checking ethical brand directories can help find the right sustainable Skechers alternative[4].

Citations:

[1] https://www.ethicalconsumer.org/fashion-clothing/shopping-guide/ethical-trainers

[2] https://vessi.com/blogs/the-forecast/best-alternative-to-skechers-walking-shoes

[3] https://goodonyou.eco/alternatives-skechers/

[4] https://directory.goodonyou.eco/brand/skechers

[5] https://www.thegoodtrade.com/features/sustainable-sneakers/

There are several sustainable and ethical alternatives to Adidas that prioritize environmental responsibility and fair labor practices. Here are some of the best options:

Veja

Veja is a French brand that makes stylish and sustainable sneakers using materials like organic cotton, wild rubber from the Amazon, and recycled plastic bottles[1]. Their V-10 and Esplar models are great alternatives to Adidas classics like Stan Smiths.

Etiko

Etiko is a certified B-Corp that makes vegan sneakers using organic cotton and natural rubber. Their low and high-top sneaker styles have a classic look comparable to Adidas sneakers[1].

Good Guys

Good Guys is a French vegan brand that uses recycled and plant-based materials like pineapple leaf fiber. Their SAMO sneakers have a sleek design reminiscent of Adidas Sambas[2].

Other ethical brands like Loci, Noah, and Flamingos' Life also offer stylish and sustainable sneaker alternatives to Adidas using recycled plastics, natural rubber, and other eco-friendly materials[2][4]. Checking ethical brand directories can help find the right fit for your style and values.

Citations:

[1] https://goodonyou.eco/sustainable-alternatives-adidas/

[2] https://goodonyou.eco/alternatives-to-adidas-samba-sneakers/

[3] https://hypebae.com/2023/4/sustainable-sneakers-earth-day-nike-adidas-new-balance-stella-mccartney

[4] https://www.opumo.com/magazine/best-alternatives-to-adidas-samba/

[5] https://karmawallet.io/blog/2024/05/adidas-sustainability-the-good-the-bad/

Based on the information provided in the search results, here are some recommended sustainable alternatives for work shoes and footwear aimed at the working class:

Recycled and Plant-Based Materials

Snibbs Work Shoes[1] - These slip-resistant work shoes utilize recycled cotton, recycled plastic, plant-based polyurethane, and corn starch for a sustainable and durable design suitable for long shifts.

Rothy's[3] - While not specifically work shoes, Rothy's makes stylish flats and sneakers from recycled plastic bottles and other renewable materials that could work for some workplaces.

Sauvs[5] - This brand blends recycled polyester with natural materials like rubber and cotton to create fashionable yet sustainable sneakers and shoes.

Secondhand and Repairable Options

Thrifting at places like Goodwill[5] - Buying secondhand shoes reduces waste and is a very affordable option for working class budgets.

Shoes with replaceable soles[5] - Opting for quality shoes where you can replace just the worn soles extends the lifespan and reduces the need to buy new shoes frequently.

Repairing existing shoes[2] - Having shoes resoled or repaired by a cobbler is a sustainable way to get more wear out of your current work footwear.

The key factors are looking for durable materials like recycled plastics and plant-based components, as well as prioritizing longevity through secondhand purchases, replaceable soles, and repairing shoes when possible[1][2][3][5]. This allows working class individuals to have sustainable footwear options that are affordable and designed to withstand tough workplace conditions over many years of use.

Citations:

[1] https://snibbs.co/blogs/foot-safety/most-sustainable-materials-for-shoes

[2] https://sustainability.stackexchange.com/questions/12777/are-there-sustainable-footwear-alternatives-to-leather-boots-shoes

[3] https://www.cnn.com/cnn-underscored/fashion/best-sustainable-shoes

[4] https://www.ethicalconsumer.org/fashion-clothing/shopping-guide/ethical-shoes

[5] https://www.reddit.com/r/sustainability/comments/18bl1fp/what_is_the_most_sustainable_vegan_and_nonplastic/

#ethical consumerism#sustainable living#sustainable fashion#sustainable shoes#Rothy's#Snibbs Work Shoes#Sauvs#Etiko#Good Guys#Cariuma#Allbirds#Vessi Cityscape

0 notes

Link

Check out this listing I just added to my Poshmark closet: Madden Girl Boots.

0 notes

Text

BASF at Simac — Endless possibilities of combining design, performance, and sustainability for footwear

Step towards a net-zero emissions with the Reduce, Recycle, Rethink approach

Innovative coating technologies for highly flexible substrates

Additive manufacturing — a game changer for the footwear industry

Infinergy® — more comfort for business shoes

Sustainable PU systems, TPU and E-TPU, 3D printed molds, functional coatings, and the comfort of a sneaker for dress shoes — all these solutions for the footwear industry will be presented by BASF at Simac. The international machinery and technology exhibition for shoes, is being held in Milan from September 22–24. In hall 14, booth G 40, visitors will be given insights into sustainable footwear solutions, high performance materials and coating solutions for shoe soles.

Footwear innovations for circular economy

Future-oriented footwear materials are inconceivable without sustainability. Sustainability is a main pillar of BASF’s strategy and an integral part of all business decisions. That is why BASF invests around 2 billion a year in research and development and drives the development of new products that make a significant contribution to sustainability. BASF’s approach to a circular economy in footwear consists of three fields of action: Reduce, Recycle, Rethink. At the show, BASF experts will give a deep insight into this approach and present sustainable material solutions for polyurethane systems and thermoplastic polyurethanes.

The main goal is to reduce the consumption of fossil resources and thus CO2 emissions. Elastopan® N (PU systems) and Elastollan® N (TPU) contribute to this, as they are partly based on renewable raw materials such as sugar, corn or castor oil. These bio-based plastic solutions are available in various densities and degrees of hardness and are suitable for all applications in the footwear sector.

In addition, BASF’s integrated production system enables the substitution of fossil by renewable feedstock derived from bio-waste. This concept, called the BASF biomass balance approach, can be compared to green electricity: When alternative energy sources (e.g., wind and solar energy) are fed into the power grid, the output of the end product, electricity, remains unchanged. Similarly, at BASF: the biobased or recycled raw materials are fed into the production network at the beginning and then further processed in many steps, e.g., into plastics. This principle offers the advantage that greenhouse gas emissions are reduced, and fossil raw materials are saved, while product quality and properties remain the same. For customers in the footwear industry, this also means that the product design and the processing for shoes do not have to be adapted. This concept can be applied to BASF’s complete range of PU systems, TPU and E-TPU for footwear.

To achieve the ultimate goal of a circular economy, we need to rethink the production and use of footwear in general. This is the task that Italian designer Linda Lipari, together with designer Pierpaolo Righetto and students from Calzaturiero Politecnico (the School of Footwear Design and Technology) dedicated themselves to during the recent design competition, namely “design in the sign of sustainability”. The basis for the students’ various creative interpretations is the designers’ “RE2.0” sole design. RE implies Restart, Rethink, Recreate, Reconquer the world. The students’ unique shoe creations, combinations of design, performance, and sustainability, will be presented at the BASF booth.

Highly elastic soft touch coatings

Furthermore, BASF will present innovative coatings technologies for highly flexible substrates from our Coatings division. These solutions protect, functionalize and color flexible surfaces. They set new standards in design opportunities, individualization and enable BASF’s customers to optimize their processes.

As NovaFlex valureTM, BASF markets reverse-coated substrates which can achieve unique optical and haptic properties by combining paint formulation, texture, and carrier material. NovaCoat-D combines in-mold coating and release coating in a new way. Besides its demold properties, the coating provides protection against sunlight, scratches, and dirt. Thanks to its many years of expertise, BASF can offer a wide range of colors and effects and bring in additional functionalities for e.g., shoe uppers and sole.

3D Printing — from molds and tools to completely printed shoes

From 3D printed molds and tools to completely 3D printed shoes — Additive Manufacturing can be a real game changer for the footwear industry. At Simac 2021, BASF 3D Printing Solutions GmbH with its brand Forward AM presents 3D printed molds and lasts through which development cycles can be shortened tremendously. On top of this, visitors will see completely 3D printed high heels and barefoot shoes as well as midsoles manufactured with latticed designs which enable new ways of cushioning, shock absorption and comfort and which can be tuned to the customer’s specific needs. Lattice designs can be challenging for traditional manufacturing methods but are easy to produce in Additive Manufacturing. So, they perfectly showcase how 3D printing supplements traditional manufacturing methods and how customers benefit from BASF’s cross-technology solutions. This will also be highlighted by a new solution for the shoe industry — presented for the first time at Simac — which combines 3D printing with Infinergy® material.

Infinergy® — the comfort of a sneaker for business shoes

Infinergy®, is the expanded thermoplastic polyurethane (E-TPU) and leading high-performance responsive material by BASF. The closed-cell, elastic particle foam combines the properties of TPU with the advantages of foams, making it as elastic as rubber but lighter. It provides exceptional cushioning. Initially it was designed for the world of sports. Since 2015 Infinergy® is used in the midsole of safety shoes and setting new standards for cushioning and comfort in shoes. These standards are now transferred to business and casual shoes. Professionals who are constantly on the go can now benefit from Infinergy® in particular as it returns the energy in each step, reducing fatigue and dampening shock on joints. Infinergy® offers a natural cushioning effect at the heel and middle part of the foot in the sole. The responsiveness and rebound allows more comfort in movement which is a real relief for professionals battling long-standing hours at work and commute.

More information www.footwear.basf.com

About BASF’s Performance Materials division

BASF’s Performance Materials division encompasses the entire materials’ know-how of BASF regarding innovative, customized plastics under one roof. Globally active in four major industry sectors — transportation, construction, industrial applications and consumer goods — the division has a strong portfolio of products and services combined with deep understanding of application-oriented system solutions. Key drivers of profitability and growth are our close collaboration with customers and a clear focus on solutions. Strong capabilities in R&D provide the basis to develop innovative products and applications. In 2020, the Performance Materials division achieved global sales of €5.63 bn. More information online: www.plastics.basf.com.

About BASF 3D Printing Solutions

BASF 3D Printing Solutions GmbH, headquartered in Heidelberg, Germany, is a 100% subsidiary of BASF New Business GmbH. It focuses on establishing and expanding the business under the Forward AM brand with advanced materials, system solutions, components and services in the field of 3D printing. BASF 3D Printing Solutions is organized into startup-like structures to serve customers in the dynamic 3D printing market. It cooperates closely with the global research platforms and application technologies of various departments at BASF as well as with research institutes, universities, startups and industrial partners. Potential customers are primarily companies that intend to use 3D printing for industrial manufacturing. Typical industries include automotive, aerospace and consumer goods. For further information please visit www.forward-am.com.

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. More than 110,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio is organized into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €59 billion in 2020. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the U.S. Further information at www.basf.com.

Source — https://promotions.basf.com/

0 notes

Text

Enhancing Product Performance: The Power of TPU Film

In the realm of product innovation, every element counts. From durability to flexibility, manufacturers are constantly seeking ways to elevate performance and enhance user experience. One such crucial component making waves in various industries is Thermoplastic Polyurethane (TPU) film. This versatile material has become a cornerstone for enhancing product performance across a spectrum of applications. In this article, we delve into the transformative impact of TPU film, explore its applications, and shed light on the key players in the industry.

Understanding TPU Film:

TPU film, derived from thermoplastic polyurethane, is renowned for its exceptional properties. It combines the advantages of both plastic and rubber, offering high elasticity, transparency, and resistance to abrasion, oil, and grease. This makes it an ideal choice for numerous industries, including automotive, textiles, footwear, and electronics.

Applications Across Industries:

Automotive Industry: In the automotive sector, TPU film finds application in airbags, interior components, and protective films. Its ability to withstand extreme temperatures and provide superior tear strength ensures optimal safety and durability.

Textile Industry: TPU film revolutionizes the textile industry by imparting waterproof and breathable properties to fabrics. From sportswear to outdoor gear, TPU-coated textiles offer unmatched comfort and performance in diverse weather conditions.

Footwear Industry: TPU film is widely used in footwear manufacturing for its flexibility, abrasion resistance, and adhesion properties. It reinforces shoe soles, enhances grip, and prolongs the lifespan of footwear, catering to the demands of athletes and casual wearers alike.

Electronics Industry: TPU film plays a crucial role in the electronics sector, serving as a protective layer for electronic displays, touchscreens, and circuit boards. Its scratch-resistant and anti-static properties safeguard delicate components, ensuring longevity and reliability.

Key Players in India:

In India's burgeoning market for TPU film, key players encompass a spectrum of manufacturers and suppliers catering to diverse industrial needs. TPU manufacturers in India stand at the forefront, leveraging cutting-edge technology and robust manufacturing processes to produce high-quality films tailored to specific requirements. These manufacturers boast extensive expertise in polymer science and engineering, allowing them to innovate and optimize formulations to meet evolving market demands. With state-of-the-art facilities and stringent quality control measures, TPU manufacturers ensure consistency and reliability in their products, earning them a reputation for excellence in the industry.

Complementing the efforts of TPU manufacturers are TPU film suppliers in India, who play a pivotal role in connecting manufacturers with end-users across various sectors. These suppliers serve as intermediaries, offering comprehensive solutions that encompass not only product distribution but also customization services and technical support. With extensive networks and logistics capabilities, TPU film suppliers facilitate seamless transactions, ensuring timely delivery and customer satisfaction. Moreover, they foster strong partnerships with both manufacturers and end-users, serving as trusted advisors and solution providers in navigating the complexities of TPU film applications.

Furthermore, within the realm of TPU film in India, TPU sheet manufacturers emerge as key players catering to specific industrial requirements. These specialized manufacturers focus on producing TPU films in sheet form, catering to applications such as automotive interiors, footwear components, and industrial coatings. By specializing in sheet manufacturing, these players offer expertise and precision in producing films with consistent thickness, surface finish, and mechanical properties. Their dedication to innovation and product development drives advancements in TPU sheet technology, paving the way for enhanced performance and durability in a wide range of applications across industries.

Conclusion:

In conclusion, TPU film emerges as a game-changer in enhancing product performance across diverse industries. Its remarkable properties, coupled with the expertise of TPU manufacturers and suppliers in India, fuel innovation and drive technological advancements. As the demand for high-performance materials continues to rise, TPU film stands out as a versatile solution, offering unparalleled benefits for manufacturers and end-users alike.

Frequently Asked Questions (FAQs):

What are the advantages of TPU film over other materials?

TPU film offers a unique combination of elasticity, transparency, and durability, making it superior to traditional materials like PVC and rubber. It provides excellent resistance to abrasion, chemicals, and weathering, ensuring long-term performance across various applications.

How is TPU film manufactured?

TPU film is produced through a multi-step process involving polymerization, extrusion, and calendaring. First, raw materials are polymerized to form thermoplastic polyurethane pellets. These pellets are then melted and extruded into a thin film using specialized equipment. Finally, the film undergoes calendaring to achieve the desired thickness and surface finish.

What factors should be considered when selecting TPU film suppliers in India?

When choosing TPU film suppliers in India, factors such as product quality, technical support, pricing, and delivery capabilities should be taken into account. It is essential to partner with reputable suppliers who offer consistent quality, responsive customer service, and timely delivery to meet project deadlines and ensure customer satisfaction.

Is TPU film recyclable?

Yes, TPU film is recyclable, making it an environmentally friendly choice for sustainable manufacturing practices. Through proper recycling processes, TPU waste can be reprocessed and reused in various applications, reducing environmental impact and promoting circular economy principles.

0 notes

Text

Polyurethane (PU) Resin Prices, Pricing, Trend, Supply & Demand and Forecast | ChemAnalyst

Polyurethane (PU) resin prices play a pivotal role in various industries, spanning from construction to automotive manufacturing and beyond. As a versatile polymer, PU resin is prized for its durability, flexibility, and wide range of applications. However, understanding the dynamics of PU resin pricing involves delving into a complex interplay of factors.

Market demand stands as a primary driver of PU resin prices. Industries such as construction, automotive, furniture, and footwear rely heavily on PU resin for its diverse properties. Fluctuations in demand within these sectors can significantly impact resin prices. For instance, during periods of economic growth, increased construction activity and consumer spending on durable goods often lead to higher demand for PU resin, consequently driving prices upward.

Raw material costs also exert substantial influence on PU resin pricing. The production of polyurethane involves several chemical components, including isocyanates and polyols. The prices of these raw materials are subject to market volatility, influenced by factors such as crude oil prices, supply chain disruptions, and geopolitical tensions. Any fluctuations in the cost of raw materials can directly impact the overall production costs of PU resin, prompting manufacturers to adjust prices accordingly.

Moreover, technological advancements and innovations within the polyurethane industry can impact resin pricing dynamics. As manufacturers develop more efficient production processes or discover alternative raw materials, production costs may decrease, leading to more competitive pricing for PU resin. Conversely, investments in research and development for eco-friendly or high-performance formulations may lead to higher production costs, thus affecting resin prices.

Get Real Time Prices of Polyurethane (PU) Resin: https://www.chemanalyst.com/Pricing-data/polyurethane-pu-resin-1150

Global market dynamics also play a crucial role in determining PU resin prices. The polyurethane industry is highly interconnected on a global scale, with factors such as international trade policies, currency fluctuations, and geopolitical events influencing supply and demand dynamics. For instance, tariffs imposed on imported raw materials or finished goods can disrupt supply chains and escalate production costs, ultimately affecting resin prices.

Environmental regulations and sustainability initiatives further shape the landscape of PU resin pricing. As governments worldwide prioritize environmental conservation and impose stricter regulations on emissions and chemical usage, manufacturers may incur additional compliance costs. Investments in sustainable practices, such as reducing carbon emissions or transitioning to bio-based raw materials, can impact production costs and, consequently, resin prices.

Additionally, market competition among PU resin manufacturers contributes to pricing variability. As numerous players operate within the polyurethane industry, both domestically and internationally, competitive pressures can lead to price fluctuations. Manufacturers may adjust pricing strategies to maintain market share, capture new opportunities, or respond to actions taken by competitors.

The COVID-19 pandemic serves as a recent example of how external shocks can disrupt PU resin pricing dynamics. The unprecedented global crisis led to supply chain disruptions, reduced industrial activity, and fluctuations in raw material availability, causing volatility in resin prices. While some sectors experienced a temporary downturn in demand, others, such as healthcare and packaging, witnessed increased usage of PU resin for applications like medical equipment and protective packaging.

Looking ahead, several trends may shape the future trajectory of PU resin prices. The growing emphasis on sustainability and circular economy principles is expected to drive investments in recycling technologies and bio-based materials, potentially impacting resin pricing as these innovations mature. Additionally, advancements in digitalization and automation could optimize production processes, leading to cost efficiencies that may influence pricing dynamics.

In conclusion, the pricing of PU resin is influenced by a myriad of factors, including market demand, raw material costs, technological developments, global market dynamics, regulatory frameworks, and competitive pressures. Navigating these complexities requires industry players to stay abreast of market trends, adapt to changing conditions, and innovate to meet evolving customer needs. As the polyurethane industry continues to evolve, understanding the multifaceted nature of resin pricing dynamics remains essential for stakeholders across various sectors.

Get Real Time Prices of Polyurethane (PU) Resin: https://www.chemanalyst.com/Pricing-data/polyurethane-pu-resin-1150

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

PPE: A Crucial Line of Defense for Worker Safety

Personal Protective Equipment Market is projected to achieve a value of USD 80,042.6 Million in 2023, with a linear behavior in the market growth it is forecasted to achieve a value of USD 137,877.6 Million by 2033 with a CAGR of 6.7% during the forecast period 2023-2033. Research analysts use quantitative as well as qualitative analytical techniques to provide users, business owners, and industry professionals with accurate and actionable data.

The report includes an executive summary, global economic outlook, and overview sections which provide a consistent analysis of the Personal Protective Equipment market. Additionally, the report in the Market Overview section outlines PLC analysis and PESTLE analysis to provide a thorough analysis of the market. The overview section details Porter's five forces analysis which helps to reveal a possible scenario of the market by disclosing a competitive scenario with respect to the Personal Protective Equipment Market.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/sample-request/personal-protective-equipment-market/1321

Key companies profiled in this research study are:

Honeywell International Inc.

Lakeland Industries Inc.

DuPont; 3M

Ansell Ltd.

Avon Rubber plc

COFRA S.r.l.

FallTech; Alpha Pro Tech Limited

Mine Safety Appliances (MSA) Company

Lindstrom Group

Mallcom (India) Ltd

Radians, Inc.

Polison Corp.

Delta Plus Group.

Personal Protective Equipment Market Segmentation:

By Product

Head Protection

Eye Protection

Face Protection

Hearing Protection

Protective Clothing

Heat & flame protection

Chemical defending

Clean room clothing

Mechanical protective clothing

Limited general use

Others

Respiratory Protection

Air-purifying respirator

Supplied air respirators

Protective Footwear

Leather

Rubber

PVC

Polyurethane

Others

Fall Protection

Soft Goods

Hard Goods

Others

Hand Protection

Disposable

Durable

Others

By Application

Construction

Manufacturing

Oil & Gas

Chemicals

Food

Pharmaceuticals

Healthcare

Transportation

Mining

Others

Market Concentration & Characteristics:

In order to obtain a competitive edge in the market, the industry focusses on research and development efforts to create innovative technologies for product manufacturing and integration across many value chain stages. The companies typically employ strategies such as product creation, distribution network expansion, and portfolio expansion.

Developing demand in wealthy economies like North America and Western Europe is for PPE to be manufactured under contract, based on distributor specifications. It is anticipated that factors like enhanced technical assistance and growing consumer awareness of product price-performance ratios will increase demand for private labels.

Personal Protective Equipment (PPE) Market Trends:

The industrial head protection market is mounting as a result of the continued trend of employing environmentally friendly materials to preserve environmental safety. In order to produce safety helmets, companies are acquiring environmentally friendly raw resources like fossil fuels and utilizing technology inventions to increase demand for their products.

For example, MSA provides V-Gard GREEN Hard Hat, which is 95% bio-based and USDA Certified Bio-based. Green High-Density Polyethylene (GHDPE), a biopolymer primarily derived from ethanol derived from sugarcane, is used in the production of these helmets. The product has the potential to lower atmospheric CO2 levels and reduce carbon emissions related to the production of GHDPE.

The leading players of the Personal Protective Equipment industry, their market share, product portfolio, company profiles are covered in this report. Key market players are analyzed on the basis of production volume, gross margin, market value, and price structure. The competitive market scenario among Personal Protective Equipment players will help the industry aspirants in planning their strategies. The statistics presented in this report are an accurate and useful guide to shaping your business growth.

Purchase a Copy of this Personal Protective Equipment Market research report at@ https://wemarketresearch.com/purchase/personal-protective-equipment-market/1321?license=single

Finally, Personal Protective Equipment Market report is the believable source for gaining the Market research that will exponentially accelerate your business. The report provides locales, economic conditions, item values, benefits, limits, creations, supplies, requests, market development rates, and numbers, etc. Personal Protective Equipment Industry Report Announces Additional New Task SWOT Examination, Speculation Achievement Investigation and Venture Return Investigation.

Report Customization Service:

We Market Research customizes the report according to your needs. This report can be personalized to suit your requirements. Get in touch with our sales team so you can get a report tailored to your needs.

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry. WE MARKET RESEARCH is a frontrunner in helping numerous companies; both regional and international to successfully achieve their business goals based on our in-depth market analysis. Moreover, we are also capable of devising market strategies that ensure guaranteed customer bases for our clients.

Contact Us:

Mr. Robbin Joseph

Corporate Sales, USA

We Market Research

USA: +1-724-618-3925

Websites: https://wemarketresearch.com/

Email: [email protected]

#personalgrowth#protective#marketingtools#marketingcoach#marketingexperts#personalizedornaments#personalstylists#.#Created by Inflact Hashtags Generator

0 notes

Text

Global Methylene Diphenyl Diisocyanate, Toluene Diisocyanate and Polyurethane Market Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

A Qualitative Research Study accomplished by Data Bridge Market research's database of 350 pages, titled as Global Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market with 100+ market data Tables, Pie Charts, Graphs & Figures spread through Pages and easy to understand detailed analysis. The rapidly revolutionizing market place demands the best market and business solutions to thrive in the market.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market business report can be referred efficiently by both established and new players in the industry for absolute understanding of the market. It covers various parameters that range from latest trends, market segmentation, new market entry, industry forecasting, target market analysis, future directions, opportunity identification, strategic analysis, insights to innovation. In this industry report, industry trends have been described on the macro level which makes it possible outline market landscape and probable future issues. The statistical and numerical data collected to generate this report is mostly denoted with the graphs, tables and charts as required which make this report more user-friendly.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market, By Type (Toluene Diisocyanate (TDI), Methylene Diphenyl Diisocyanate (MDI)), Raw Material (Crude Oil, Natural Gas, Toluene, Benzene, Nitric Acid, Methanol, Chlorine, Others), Application (Polyurethane Foam, Polyurethane Elastomers, Polyurethane Adhesives and Sealants, Polyurethane Coatings, Others), End Use (Footwear, Furniture, Automotive, Building And Construction, Home Appliances, Textile, Healthcare, Electrical and Electronics, Packaging, Industrial Machinery, Others) - Industry Trends and Forecast to 2030.

Access Full 350 Pages PDF Report @

The Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market competitive landscape provides details by the competitors. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, and application dominance.

Major Points Covered in TOC:

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market Overview: It incorporates six sections, research scope, significant makers covered, market fragments by type, Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market portions by application, study goals, and years considered.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market Landscape: Here, the opposition in the Worldwide Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market is dissected, by value, income, deals, and piece of the pie by organization, market rate, cutthroat circumstances Landscape, and most recent patterns, consolidation, development, obtaining, and portions of the overall industry of top organizations.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Profiles of Manufacturers: Here, driving players of the worldwide Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market are considered dependent on deals region, key items, net edge, income, cost, and creation.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market Status and Outlook by Region: In this segment, the report examines about net edge, deals, income, creation, portion of the overall industry, CAGR, and market size by locale. Here, the worldwide Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market is profoundly examined based on areas and nations like North America, Europe, China, India, Japan, and the MEA.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Application or End User: This segment of the exploration study shows how extraordinary end-client/application sections add to the worldwide Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market.

Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market Forecast: Production Side: In this piece of the report, the creators have zeroed in on creation and creation esteem conjecture, key makers gauge, and creation and creation esteem estimate by type.

Keyword: Research Findings and Conclusion: This is one of the last segments of the report where the discoveries of the investigators and the finish of the exploration study are given.

What to Expect from the Report, a 7-Pointer Guide

The Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market report dives into the holistic Strategy and Innovation for this market ecosystem

The Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market report keenly isolates and upholds notable prominent market drivers and barriers

The Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market report sets clarity in identifying technological standardization as well as the regulatory

framework, besides significantly assessing various implementation models besides evaluation of numerous use cases

The Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market report is also a rich repository of crucial information across the industry, highlighting details on novel investments as well as stakeholders and relevant contributors and market participants.

A through market analytical survey and forecast references through the forecast tenure, encapsulating details on historical developments, concurrent events as well as future growth probability.

Some of the major players operating in the global Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane market are:

DuPont (U.S.)

Solvay (Belgium)

DAIKIN (Japan)

DOW (U.S.)

Huntsman International LLC (U.S.)

Bostik (France)

H.B. Fuller Company (U.S.)

Sika AG (Switzerland)

Cardolite Corporation (U.S.)

Kukdo Chemical Co., Ltd., (South Korea)

BASF SE (Germany)

Freudenberg SE (Germany)

Covestro AG (Germany)

LANXESS (Germany)

Mitsui Chemicals Inc. (Japan)

Wanhua (China)

Arkema (France)

Hexion (U.S.)

Woodbridge (Canada)

Browse Trending Reports:

Waste to Energy Market Size, Share, Trends, Growth Opportunities and Competitive Outlook https://www.databridgemarketresearch.com/reports/global-waste-to-energy-market

Green Concrete Market Size, Share, Trends, Growth and Competitive Outlook https://www.databridgemarketresearch.com/reports/global-green-concrete-market

Polylactic Acid (PLA) Market Size, Share, Trends, Global Demand, Growth and Opportunity Analysis https://www.databridgemarketresearch.com/reports/global-polylactic-acid-pla-market

Plastic Compounding Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus https://www.databridgemarketresearch.com/reports/global-plastic-compounding-market

Olefins Market Size, Share, Trends, Industry Growth and Competitive Analysis https://www.databridgemarketresearch.com/reports/global-olefins-market

Polyvinyl Chloride (PVC) Compound Market Size, Share, Trends, Growth Opportunities and Competitive Outlook https://www.databridgemarketresearch.com/reports/global-pvc-compound-market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

#Global Methylene Diphenyl Diisocyanate#Toluene Diisocyanate and Polyurethane Market Market Size#Share#Trends#Growth Opportunities and Competitive Outlook#market research#market analysis#market share#market trends#market size#market report#marketresearch#markettrends

0 notes

Text

Impact of COVID-19 on the Polyurethane Prepolymer Market: Strategies for Resilience

Polyurethane Prepolymers: An Essential Raw Material for Manufacturing Industries

What are Polyurethane Prepolymers?

Polyurethane prepolymers, also known as isocyanate terminated prepolymers, are polyols that have been reacted with diisocyanates but terminated with residual isocyanate groups. They are highly viscous resins synthesized by reacting a polyol such as polyether polyol or polyester polyol with a diisocyanate like MDI or TDI in a 1:1 or 1:2 stoichiometric ratio resulting in an isocyanate functional prepolymer.

Applications of Polyurethane Prepolymers

Polyurethane prepolymers find wide applications due to their versatile chemical and physical properties. Some key applications include:

Coatings - Prepolymers are used as binders, crosslinkers and intermediates in manufacturing coatings for wood, concrete, leather and various industrial applications. Their excellent adhesion, chemical resistance and flexibility makes them ideal for coatings.

Adhesives and Sealants - The film forming and adhesive properties of prepolymers are leveraged to produce structural and high-performance adhesives as well as sealants for construction and automotive applications.

Elastomers - Prepolymers impart flexibility, elasticity and high strength to elastomers used in hoses, gaskets, rollers and various flexible molded articles. They aid in processability and enhance mechanical properties.

Footwear - The mechanical strength and flexibility imparted by prepolymers in polyurethane enables their use in manufacturing shoe soles, heels and sport shoe midsoles providing comfort and durability.

Types of Polyurethane Prepolymers

Based on the polyol/diisocyanate ratio and reactants used, prepolymers can be categorized as:

- MDI based: Formed from reaction of MDI with polyester polyols or polyether polyols. Offer high strength, hardness and chemical resistance. Widely used.

- TDI based: React TDI with polyols. Provide flexibility and high elongation. Used in elastomers, sealants and adhesives.

- Polyester based: Have good hydrolytic stability and strength. Used in coatings.

Manufacturing Process of Polyurethane Prepolymers

The manufacturing process involves the following key steps:

1. Reaction of Polyol and Diisocyanate: Polyether polyol or polyester polyol is charged into the reactor and heated to the required temperature. Diisocyanate like MDI or TDI is added slowly with agitation.

2. Controlled Polyaddition Reaction: The exothermic polyaddition reaction between hydroxyl groups of polyol and isocyanate groups proceeds. Process parameters like temperature, catalysts are controlled.

3. Termination Reaction: Once the pre-set NCO index is reached, the prepolymer is terminated by residual isocyanate groups and deactivated by adding catalyst kill.

4. Filtration and Packaging: The viscous prepolymer solution is filtered to remove impurities and filled in drums, IBCs or bulk tankers.

Applications determine the suitable type of prepolymer and optimization of process parameters like reaction temperature, reaction time and NCO index yields prepolymers with desired physical and chemical qualities. Strict quality control during manufacturing is vital.

Outlook for Polyurethane Prepolymers Market

The global polyurethane prepolymers market is forecast to grow at over 5% CAGR through 2030 driven by increasing usage in coatings, adhesives, sealants, thermoplastic polyurethanes and various consumer and industrial applications. Rapid growth of key end use industries like footwear, construction, automotive, packaging and furniture will boost demand.

Moreover, continuous product innovation to develop new grades catering to changing industry and regulatory trends along with expansion into emerging markets in Asia Pacific and Middle East regions are factors expected to fuel the prepolymer market in the coming years. However, volatility in raw material prices remain a key challenge. Overall, polyurethane prepolymers market outlook looks positive owing to their excellent performance attributes and versatile usage profile.

#Polyurethane Prepolymer Market Growth#Polyurethane Prepolymer Market Trends#Polyurethane Prepolymer Market

0 notes

Text

What's the Best Material for Sneaker Sole?

Sneaker soles, often overlooked, are a critical component of footwear, providing the necessary support, cushioning, and traction for everyday use. They impact not only the shoe's functionality and comfort but also contribute to its overall aesthetic and environmental footprint.

Historical Evolution of Sneaker Soles

The evolution of sneaker soles is a fascinating journey. Initially, soles were made from simple materials like leather and wood. However, with the advent of vulcanized rubber in the 19th century, the sneaker industry underwent a transformation. This innovation led to the creation of more durable and flexible soles, paving the way for modern sneaker designs.

Types of Materials Used in Sneaker Soles

Modern sneaker soles are crafted from a variety of materials, each offering unique benefits. Rubber, polyurethane (PU), ethylene vinyl acetate (EVA), and thermoplastic rubber (TPR) are among the most popular choices.

Rubber Soles

Rubber is the traditional choice for sneaker soles. Its key advantages include excellent traction and high durability, making it ideal for outdoor and athletic footwear. However, rubber soles can be heavy and offer less shock absorption compared to newer materials.

Polyurethane (PU) Soles

PU soles are known for their resilience and resistance to wear and tear. They provide good stability and are often used in work and safety shoes. On the downside, PU soles can be stiff and less comfortable for prolonged wear.

Ethylene Vinyl Acetate (EVA) Soles

EVA is a lightweight and flexible material, popular in running and casual shoes. It provides good cushioning, which helps in reducing impact on the joints. However, EVA soles may wear down faster than rubber or PU, especially under heavy use.

Thermoplastic Rubber (TPR) Soles

TPR is a blend of rubber and plastic, offering a balance between flexibility, comfort, and durability. It's commonly used in various types of footwear, including children's shoes, due to its versatile properties.

Comparison of Materials

When comparing these materials, factors like durability, comfort, cost, and environmental impact must be considered. Rubber and PU are typically more durable, while EVA and TPR offer greater comfort and flexibility. The choice of material often depends on the specific needs of the wearer and the intended use of the sneaker.

The Best Material for Performance Sneakers

For athletes and sports enthusiasts, the sole material must provide excellent grip, flexibility, and durability. Rubber, with its superior traction, is often the preferred choice for outdoor sports shoes, while EVA is favored for its lightweight properties in running shoes.

The Best Material for Casual Sneakers

In casual sneakers, comfort and style take precedence. EVA and TPR are popular choices due to their lightweight and flexible nature, providing comfort for everyday wear.

The Best Material for Eco-Friendly Sneakers

With growing environmental concerns, the demand for eco-friendly sneaker soles has risen. Materials like recycled rubber, organic cotton, and bioplastics are being explored to reduce the carbon footprint of footwear.

The Role of Design in Sneaker Soles

The design of sneaker soles, including the pattern and thickness, also plays a crucial role in the shoe's overall performance. Innovative designs can enhance grip, provide better shock absorption, and improve the shoe's aesthetic appeal.

Consumer Preferences and Trends

Consumer preferences in sneaker soles are influenced by a blend of factors including fashion trends, brand loyalty, and awareness of environmental issues. Manufacturers must stay attuned to these trends to meet the evolving demands of consumers.

Future of Sneaker Sole Materials

The future of sneaker soles lies in the ongoing research and development of new materials and technologies. Advances in material science promise the emergence of more sustainable, durable, and comfortable sole options.

Conclusion

Choosing the best material for a sneaker sole involves considering the shoe’s purpose, wearer's needs, and environmental impact. As technology progresses, we can expect more innovative and sustainable options in sneaker sole materials.

FAQs

What is the most durable material for sneaker soles?

Rubber and PU are generally the most durable options.

Are EVA soles suitable for running shoes?

Yes, EVA is preferred for running shoes due to its lightweight and cushioning properties.

Can sneaker sole materials impact athletic performance?

Definitely, the right sole material can significantly affect traction, comfort, and agility.

Are there eco-friendly sneaker sole options available?

Yes, materials like recycled rubber and bio-based plastics are becoming more common.

Do sneaker sole materials vary based on shoe style?

Yes, performance, casual, and eco-friendly sneakers often use different materials to meet specific requirements.

1 note

·

View note

Text

Will Polyurethane Yellow? Discover the Truth Behind This Common Concern

Yes, polyurethane can yellow over time. Polyurethane can undergo a chemical reaction with sunlight or certain chemicals, causing it to change color and turn yellow.

This yellowing can affect the appearance of the polyurethane finish on surfaces such as wood or plastic. Polyurethane is a popular choice for protecting and enhancing the durability of various surfaces, but one common concern is its tendency to yellow.

Whether it's applied to furniture, flooring, or other finished products, polyurethane can gradually develop a yellow tint. This change in color can be attributed to the chemical reaction between polyurethane and factors such as sunlight or specific chemicals. While this yellowing effect may not be desired or aesthetically pleasing, it is a common occurrence that users should be aware of when considering polyurethane for their projects. We will explore the reasons behind polyurethane yellowing and discuss some preventive measures to maintain the clarity and appearance of polyurethane finishes.

What Is Polyurethane?

Polyurethane is a durable material used in various products. Over time, it may turn yellow due to prolonged exposure to sunlight and heat. It's essential to protect polyurethane items from these elements to maintain their original color and appearance.

Polyurethane is a versatile and highly durable synthetic material that is widely used in various industries. With its exceptional properties, it has become a popular choice for a wide range of applications. Polyurethane is known for its excellent resistance to wear, tear, and abrasion. It is also highly flexible and can be molded into different shapes and forms.

Composition Of Polyurethane

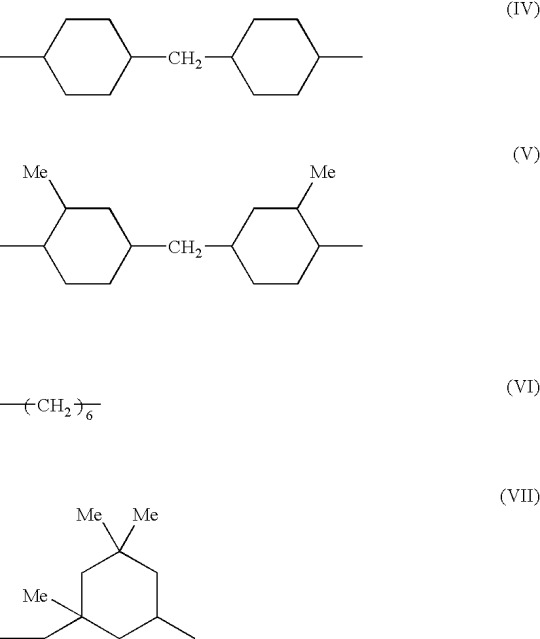

Polyurethane is composed of a combination of two main components: polyols and isocyanates. Polyols are organic compounds that contain multiple hydroxyl (OH) groups, while isocyanates are compounds that contain multiple isocyanate (NCO) groups. When these two components react with each other, a chemical reaction occurs known as polymerization, which forms the solid structure of polyurethane.

In addition to polyols and isocyanates, polyurethane can also contain other additives such as catalysts, blowing agents, and fillers. These additives help to enhance specific properties of polyurethane, such as its elasticity, hardness, and flame resistance.

Common Uses Of Polyurethane

Polyurethane has a wide range of applications due to its versatility and durability. Some common uses of polyurethane include:

- Furniture: Polyurethane foam is commonly used in the manufacturing of furniture, including sofas, chairs, and mattresses. Its high resilience and comfort make it an ideal choice for cushions and padding.

- Coatings: Polyurethane coatings provide excellent protection and resistance against chemicals, abrasion, and UV radiation. They are often used in the automotive industry, construction, and marine applications.

- Insulation: Polyurethane foam insulation is widely used in the construction industry for its excellent thermal insulation properties. It helps to reduce energy consumption and improve heating and cooling efficiency.

- Footwear: Polyurethane is frequently used in the production of footwear, providing cushioning, shock absorption, and durability. It is commonly found in athletic shoes, boots, and sandals.

- Automotive: Polyurethane is used in various automotive parts and components, including bumpers, dashboards, and seating. Its high strength and ability to withstand harsh conditions make it ideal for automotive applications.

Polyurethane's adaptability and performance make it a valuable material across numerous industries. Its ability to withstand wear and tear, as well as its versatility in various forms, contribute to its widespread use in countless applications.

Understanding The Yellowing Process

Understanding the Yellowing Process:

Polyurethane is a commonly used coating for various surfaces due to its durability and protective properties. However, over time, you may notice that polyurethane can develop a yellowish tint. To fully comprehend this yellowing process, it is important to understand the factors contributing to it, as well as the effects of the environment on polyurethane.

Factors Contributing To Yellowing:

- UV radiation exposure

- Aging of the polyurethane

- Presence of certain chemicals

Yellowing of polyurethane is primarily a result of exposure to UV radiation. The sun's ultraviolet rays can accelerate the breakdown of the polyurethane's structure, leading to the development of a yellow hue. Additionally, the aging process of the polyurethane over time can also contribute to its yellowing. As the coating ages, it becomes more vulnerable to environmental factors and can gradually change color. Moreover, certain chemicals present in the surrounding environment, such as formaldehyde or ammonia, can react with the polyurethane and cause it to yellow.

Effects Of Environment On Polyurethane:

The environment in which polyurethane is exposed can significantly impact its yellowing process. Factors such as temperature, humidity, and airflow can all influence the aging and yellowing of the coating. High temperatures can accelerate the breakdown of the polyurethane, while high humidity levels can introduce moisture that can affect its structure. Similarly, inadequate airflow can prevent the coating from properly drying, potentially leading to discoloration. It is important to consider these environmental factors when applying and maintaining polyurethane coatings to minimize yellowing and prolong its lifespan.

Debunking Common Myths

Debunking common myths about polyurethane yellowing is crucial for anyone considering using this type of finish for their projects. There are many misconceptions surrounding polyurethane yellowing that can lead to confusion and misinformed decisions. Let's address these myths and provide clarity on this topic.

Clarifying Misconceptions About Polyurethane Yellowing

Myth 1: Polyurethane will always be yellow over time.

Fact: While some polyurethane products may yellow over time, advancements in technology have led to the development of non-yellowing formulas. Look for products labeled as "non-yellowing" or "water-based" to minimize the risk of yellowing.

Myth 2: All types of wood finishes are susceptible to yellowing.

Fact: Certain wood finishes, especially solvent-based ones, are more prone to yellowing compared to water-based alternatives. Choosing the right type of polyurethane for your project can significantly reduce the risk of yellowing.

Addressing Concerns

- Overexposure to sunlight can accelerate the yellowing process.

- Choosing water-based polyurethane can help prevent yellowing.

By understanding the factors that contribute to polyurethane yellowing and debunking the common myths associated with it, you can make informed decisions when selecting the right finish for your woodworking projects.

Credit: www.amazon.com

Preventing Yellowing Of Polyurethane

Polyurethane can yellow over time, but steps can be taken to prevent this discoloration. Properly storing it away from sunlight and using UV-resistant finishes can help maintain its original color and prevent yellowing.

Best Practices For Application

Polyurethane, a popular finish for wood surfaces, has the tendency to yellow over time due to exposure to sunlight and other environmental factors. However, by following a few best practices during application, you can minimize the chances of yellowing and ensure a long-lasting, clear finish.

- Clean and prepare the surface: Before applying polyurethane, it is important to clean and prepare the surface properly. Remove any dirt, grease, or previous finishes using a mild detergent and sandpaper. This will ensure proper adhesion and reduce the likelihood of yellowing.

- Use a high-quality product: Invest in a high-quality polyurethane product specifically designed for clarity and UV resistance. These formulations are less likely to yellow and offer better protection against discoloration.

- Apply thin coats: When applying polyurethane, it is crucial to avoid thick coats. Thick layers of polyurethane are more prone to yellowing, so it is best to apply multiple thin coats instead. This allows for better curing and minimizes the chances of yellowing.

Proper Maintenance

Even with the best application practices, polyurethane may still experience some yellowing over time. However, proper maintenance can help slow down the yellowing process and keep the finish looking clear and fresh.

- Keep out of direct sunlight: Excessive exposure to sunlight can accelerate the yellowing of polyurethane. To prevent this, consider using blinds, curtains, or UV-protective window films to block out direct sunlight.

- Avoid harsh chemicals: Certain cleaning agents and chemicals can cause discoloration of polyurethane. To maintain its clarity, use only mild, non-abrasive cleaners and avoid harsh chemicals or solvents.

- Regular cleaning and dusting: Routine cleaning and dusting help remove dirt and debris that can contribute to discoloration. Use a soft, lint-free cloth or mop to gently clean the surface without scratching the finish.

- Reapply a protective coat: Over time, the protective layer of polyurethane may wear off. To maintain its clarity and prevent yellowing, consider periodically reapplying a thin coat of polyurethane to the surface.

Conclusion And Recommendations

After delving into the topic of whether polyurethane is yellow over time, we can draw some conclusions and provide recommendations for preserving polyurethane finishes.

Summary Of Key Points

- Exposure to UV light and certain chemicals can cause polyurethane to yellow over time.

- Higher-quality polyurethane products tend to resist yellowing better than lower-quality ones.

- Choosing water-based polyurethane may help reduce the chances of yellowing.

- Yellowing can also be influenced by environmental factors such as temperature and humidity.

- Proper surface preparation and application techniques can help achieve a more durable and long-lasting finish.

Tips For Preserving Polyurethane Finishes

To ensure your polyurethane finishes maintain their clarity and color over time, consider the following recommendations:

- Limit exposure to direct sunlight by using blinds or curtains to protect furniture or surfaces.

- Avoid placing polyurethane-coated items near heat sources, such as radiators or heating vents.

- Regularly dust and clean polyurethane surfaces with a gentle, non-abrasive cleaner.

- Use furniture polish or wax specifically formulated for polyurethane surfaces to enhance their protection.

- Consider applying additional coats of polyurethane every few years to refresh the appearance and protection.

By following these tips and taking proper care of your polyurethane finishes, you can minimize the likelihood of yellowing and enjoy their beauty for years to come.

Frequently Asked Questions On Will Polyurethane Yellow

What Polyurethane Does Not Yellow?

Some types of polyurethane do not yellow over time. These polyurethanes have special additives that prevent discoloration, making them suitable for applications where maintaining a clear and non-yellow finish is important.

How Do You Finish Wood Without Yellowing?

To finish wood without yellowing, use a water-based polyurethane or a UV-resistant finish. Avoid oil-based finishes, which can yellow over time. Make sure to apply thin, even coats and allow for adequate drying time between layers. Regular maintenance and cleaning can also help preserve the wood's natural color.

Will Oil-Based Polyurethane Yellow Over Time?

Yes, oil-based polyurethane can be yellowed over time.

Will Water-Based Polyurethane Yellow Over White Paint?

Water-based polyurethane may yellow over white paint due to its inherent properties. However, using a high-quality, non-yellowing water-based polyurethane, proper application, and regular maintenance can help minimize this effect. Consider conducting a test on a small area before applying to the entire surface.

Conclusion

The potential yellowing of polyurethane is a common concern among users. By understanding the contributing factors and implementing preventative measures, such as choosing the right type of polyurethane and proper application techniques, you can minimize the risk of yellowing and preserve the beauty of your surfaces.

Stay informed and proactive to maintain the longevity and appearance of your polyurethane-coated items.

Read the full article

0 notes

Text

Polyurethane Prepolymer Market Growth Catalysts: A Deep Dive into Market Drivers

Polyurethane prepolymer is a versatile polymer that exhibits characteristics like strength, toughness, durability and flexibility, making it widely applicable in various end-use industries. Polyurethane prepolymer enhances structural integrity and insulation properties in applications such as rigid & flexible foams, thermoplastic elastomers, coatings, adhesives & sealants among others. Rapid industrialization and increasing infrastructure development has driven the global demand for high-performance insulating materials in construction, automotive, packaging and other industrial applications.

The global Polyurethane Prepolymer Market is estimated to be valued at US$ 60 billion in 2023 and is expected to exhibit a CAGR of 6.4% over the forecast period 2023-2031, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

With growing environmental concerns and government regulations promoting energy conservation, demand for green buildings with superior insulation properties has increased significantly. Polyurethane foam products play a vital role in manufacturing highly efficient insulated panels for walls, roofs and other building components. As the construction industry shifts focus towards sustainable design and construction, polyurethane prepolymer market is expected to witness lucrative opportunities owing to its excellent thermal insulation and moisture resistance qualities. Implementation of strict energy efficiency codes in developed economies will further propel the sales of polyurethane foam insulation in residential as well as commercial construction projects over the forecast period.

Porter’s Analysis