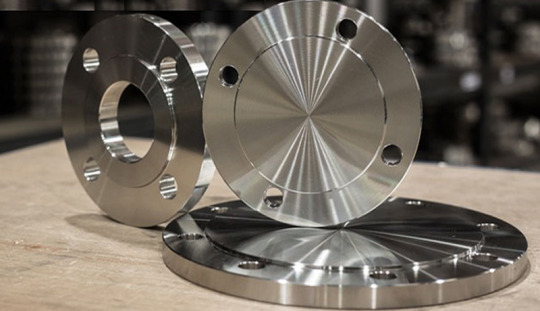

#Stainless Steel Lap Joint Flanges

Text

Flanges Suppliers in AFRICA – Alkun Steel

Flanges are the unsung heroes of industrial piping systems, providing essential connections that keep our infrastructure running smoothly. The right flange ensures safe and efficient operation in oil refineries, chemical plants, or maritime vessels. In Africa, where industries are booming and demand for quality engineering solutions is at its peak, companies like Alkun Steel stand tall as providers of top-notch flange solutions. Alkun Steel is a trusted partner in Africa's industrial landscape with an array of flange types tailored to meet diverse needs. Let's delve into the world of flanges and explore the offerings of Alkun Steel, the go-to carbon steel and stainless steel flange supplier in Africa.

Carbon Steel Flange Supplier in AFRICA

Carbon steel flanges are essential for piping systems to connect pipes, valves, pumps, and other equipment. They are made from carbon steel, a steel alloy primarily composed of iron and carbon, with different elements added to enhance properties like strength, hardness, and durability. Carbon steel flanges are known for their strength, resistance to corrosion, and affordability, making them widely used in various industrial applications.

Several carbon steel flanges are designed for specific purposes and applications. Some of the most common types include:

1. Slip-on Flanges in AFRICA (SO): These flanges have a slightly larger bore diameter than the outside diameter of the pipe. They are slipped over the pipe and then welded at the inner and outer edges, providing a strong and secure connection.

2. Weld Neck Flanges in AFRICA (WN): Weld neck flanges feature a long, tapered hub that provides an ideal pipe connection. They are welded to the pipe and the adjoining pipe, offering excellent strength and stability, particularly in high-pressure and high-temperature applications.

3. Blind Flanges in AFRICA (BL): Blind flanges seal the end of a pipe or vessel. They are typically used in applications where future expansion might be needed or temporarily block off a pipeline.

4. Socket Weld Flanges in AFRICA (SW): Socket weld flanges are designed with smaller-diameter pipes. They are welded directly onto the pipe, creating a smooth bore and a tight seal.

5. Threaded Flanges in AFRICA: These flanges have internal threads that allow them to be screwed onto the pipe. They are commonly used in low-pressure applications and where welding is not feasible.

6. Lap Joint Flanges in AFRICA (LJ): Lap joint flanges are used with stub ends. They allow for easy alignment of bolt holes and are ideal for non-standard connections or systems requiring frequent dismantling.

7. Orifice Flanges in AFRICA: Orifice flanges are specifically designed for flow measurement or restriction applications. They feature a small orifice opening that can be used with an orifice plate to measure flow rates.

8. Ring-Type Joint (RTJ) Flanges in AFRICA: RTJ flanges use a ring joint gasket to create a tight seal in high-pressure and high-temperature applications. They are commonly used in the oil and gas industries.

These are just a few examples of the many carbon steel flanges available, each with unique features and advantages suited to different piping requirements.

Stainless Steel Flange Supplier in AFRICA

Stainless steel flanges are made from stainless steel, a corrosion-resistant alloy known for its durability, strength, and resistance to rust and corrosion. They are widely used in various industries, including chemical processing, oil and gas, food processing, pharmaceuticals, and water treatment, where corrosion resistance and hygiene are essential.

Here are the different types of stainless steel flanges:

1. Slip-on Stainless Steel Flange in AFRICA: These flanges have a bore slightly larger than the outer diameter of the pipe. They are slipped over the pipe and then welded on both sides for a secure connection.

2. Weld Neck Stainless Steel Flange in AFRICA: These flanges have a long tapered hub designed to provide an ideal pipe connection. They are welded inside and outside to ensure strength and stability, especially in high-pressure and high-temperature applications.

3. Blind Stainless Steel Flange in AFRICA: These flanges seal the end of a pipe or vessel. They are commonly used in applications where future expansion may be needed or to temporarily block off a pipeline.

4. Socket Weld Stainless Steel Flange in AFRICA: Designed for smaller diameter pipes, these flanges are welded for a tight seal. They feature a recessed area to insert the pipe, providing a smooth flow path.

5. Threaded Stainless Steel Flange in AFRICA: These flanges have threads machined onto their inner bore, allowing them to be screwed onto the pipe for easy installation and removal.

6. Lap Joint Stainless Steel Flange in AFRICA: These flanges allow for easy alignment of bolt holes. They are often used in non-standard connections or where the alignment of the bolt holes is critical.

7. JIS/Marine Stainless Steel Flange in AFRICA: Designed to Japanese Industrial Standards, these flanges are suitable for marine applications. They come in various pressure ratings, such as 5k, 10k, pn6, and 16k, catering to different requirements in aquatic environments.

Conclusion

Having reliable partners is paramount in the dynamic world of industry and infrastructure. Alkun Steel, with its commitment to quality, innovation, and customer satisfaction, emerges as a beacon in Africa's flange supply landscape. From Slip-on to Weld Neck, Blind to Socket Weld, Alkun Steel offers a comprehensive range of carbon steel and stainless steel flanges to cater to diverse applications across various industries. As Africa continues its industrialization and economic growth journey, companies like Alkun Steel play a vital role in providing the foundational components that keep the wheels of progress turning. With Alkun Steel, customers receive top-quality products and benefit from the expertise and support of a trusted ally in their journey towards success.

0 notes

Text

Platinex Piping is a premier supplier of flanges, including slip on raised face flanges, blind, weld neck, groove &tongue threaded & socket flanges in Mumbai.

0 notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

8 notes

·

View notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes

Text

Supplier of Industrial Flanges in Nagpur

Simplex Steels is a Manufacturer and Supplier of Industrial Flanges in Nagpur, Maharashtra, India.

Simplex Steels specializes in producing a wide range of stainless steel products, including sheets, plates, coils, pipes, tubes, bars, wires, rods, channels, flats, industrial flanges, and more.

Industrial flanges are essential components used to connect pipes, valves, pumps, and other equipment in various industrial systems.

These crucial elements ensure the seamless flow of fluids, gases, and other materials, providing both structural integrity and ease of maintenance.

Our Industrial Flanges offer easier installation compared to weld neck flanges; slip-on flanges slide over the pipe and weld in place. They suit lower-pressure applications and often used in low-stress environments.

Users employ them to close the end of a piping system. Unlike other flanges, blind flanges do not have a bore, making them ideal for sealing off pipelines, and valves.

Designed for small-diameter high-pressure pipes, socket weld flanges have a socket into which the pipe fits. They then weld around the pipe, providing a strong and leak-proof connection.

These flanges find use with lap joint stub ends and suit systems requiring frequent disassembly for inspection or cleaning. They do not weld or fix directly to the pipe, allowing easy removal.

Industrial flanges connect pipes, valves, and equipment in piping systems, ensuring secure, leak-proof joints. They facilitate maintenance, withstand high pressure and temperature, and find use in oil, gas, chemical, and power industries.

Simplex Steels is a Manufacturer and Supplier of Industrial Flanges in Nagpur and locations like Chandrapur, Solapur, Nashik, Kolhapur, Aurangabad, Amravati, Navi Mumbai, Sangli, Jalgaon, Akola, Latur, Ahmednagar, Parbhani, Jalna, Bhiwandi, and Chalkaranji.

Do not hesitate to contact us if you need more information or if you have any questions.

Read the full article

0 notes

Text

Supplier of Stainless Steel Flanges in Madhya Pradesh

Krystal Steel is a Supplier of Stainless Steel Flanges in Madhya Pradesh and We are Manufacturer of SS Flanges in Ahmedabad, Gujarat, India.

Krystal Steel is a Manufacturer, Stockiest, and Exporter of SS Sheets, Plates, Coils, Fasteners, Pipes and Tubes, Bars, Wires, Rods,

Strip Coils, Angles, Channels, Flats, Industrial Valve, SS Flanges, Industrial Fittings, SS Dairy Valves.

We specializes in crafting a wide variety of Stainless Steel Flanges in different shapes and sizes, tailored to meet specific customer

requirements and specifications.

We proudly serve a global clientele, meeting the substantial demand for our products worldwide.

Our flanges division is equipped with an integrated forge shop capable of producing a comprehensive range of pipe fittings, including flanges

and butt welding fittings.

We adhere to international standards such as ASME, ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, and UNI.

Our flanges are renowned for their exceptional quality and reliability, earning a solid global reputation.

We offers a comprehensive range of flanges, encompassing various grades of metallic materials and styles.

Types of Flanges:

Blind Flange

Weld Neck Flange

Slip On Flange

Socket Weld Flange

Threaded Flange

Lap Joint Flange

Orifice Flange

Why Choose Our Products?

Manufactured from high quality materials

Durable

Efficient performance

Dimensional accuracy

Faster Delivery

Competitive Price

In-house Testing Facility

Packaging and stock facility

Qualified Technicians

Quality controllers

Krystal Steel is a Supplier of Stainless Steel Flanges in Madhya Pradesh Including locations like Indore, Bhopal, Jabalpur, Gwalior, Dewas,

Ujjain, Satna, Rewa, Ratlam, Singrauli, Pithampur, Mandideep, Neemuch, Bhind, Chhindwara, Damoh, Mandsaur, Morena, Khandwa,

Hoshangabad.

Feel free to contact us for more information and inquiries.

Read the full article

0 notes

Text

Stainless Steel SS Flanges Manufacturer

‘C-Way Engineering Exports’ is the leading manufacturer of ASME/ANSI/IS/DIN/BS/JIS stainless steel SS flanges manufacturer in India. Standard sizes of carbon steel flanges and stainless steel flanges are available readily in the stock to deliver immediately. C-Way Flanges are designed and manufactured in accordance with international quality standards including ANSI/ASME B16.5, ANSI/ASME B16.47 Series A and Series B, and API standards flanges. The size of flanges ranges from ½ inches to 48 inches. We produce Weld Neck Flanges, Blind Flange, Slip On Flanges, Socket Weld Flanges, Threaded Flange, Lap Joint Flanges, Spectacle Flanges in 150 #, 300#, 600#, 900#, 1500# and 2500# class.

We excel as a stainless steel (SS) Flanges Manufacturer In India. We manufacture Flanges using a variety of materials, including carbon steel, stainless steel, alloy steel, and exotic materials such as Duplex, Super Duplex, Nickel Alloys, Hastelloy, Inconel. We cater to the huge global demand of our customers who are spread across 6 continents and around 110 countries. Our products are reputed and well known across the globe for their reliability and quality.

All Flanges with standard sizes and materials are readily available in stock for immediate delivery. "Looking for large diameter Flanges ? Contact us today for Customized Flanges.

0 notes

Text

Best Flanges Manufacturers | Arcellor Controls

Arcellor Controls is the best Flanges manufacturing that uses premium quality raw materials and advanced technology in the process of manufacturing. Our Flanges are available in various specifications and designs. We offer various categories of Flanges like Stainless Steel Threaded Flanges, Weld Neck Flange, Slip-on Flange, Socket Weld, Flange, Lap Joint Flange, and much more. We have a record of serving multiple clients with our quality products and services.

0 notes

Text

SS Flanges Supplier in Maharashtra

SS Flanges Supplier in Maharashtra:

Company Overview:

Rahul Steel India is an approved Manufacturer and Supplier of SS Flanges in Maharashtra, India.

SS flanges are typically made from stainless steel, a corrosion-resistant alloy composed primarily of iron, chromium, nickel, and other alloying elements.

The composition of stainless steel provides excellent resistance to corrosion, making it suitable for use in various environments, including corrosive and high-temperature applications.

Types:

SS flanges come in various types, each serving specific purposes in piping systems, including:

Weld Neck Flanges

Slip-On Flanges

Socket Weld Flanges

Lap Joint Flanges

Threaded Flanges

Blind Flanges

Orifice Flanges

Spectacle Blind Flanges

Expander Flanges

Reducing Flanges

Companion Flanges

Features:

SS flanges offer excellent corrosion resistance, high strength, and versatility for various applications.

They are easy to install and maintain, ensuring long-lasting performance and minimizing downtime.

Designed for harsh environments like chemical plants, offshore rigs, and marine settings.

Available in different sizes, pressure ratings, and configurations to meet piping system requirements.

Applications:

Oil and Gas

Petrochemical

Chemical Processing

Power Generation

Water Treatment

Food and Beverage

Pharmaceutical

HVAC (Heating, Ventilation, and Air Conditioning)

Shipbuilding

Construction

Rahul Steel India are SS Flanges Supplier in Maharashtra Including Ahmednagar, Akola, Amravati, Aurangabad, Beed, Bhusawal, Bhandara, Buldhana, Chandrapur, Daulatabad, Dhule, Gadchiroli, Gondia, Hingoli, Jalgaon, Jalna, Kolhapur, Latur, Mumbai City, Mumbai Subarban, Nagpur, Nanded, Nandurbar, Nashik, Osmanabad, Palghar, Parbhani, Pune, Raigad Ratnagiri, Sangli, Satara, Sindhudurg, Solapur, Thane, Wardha, Washim, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Osmanabad, Pandharpur, Sangli, Satara, Sevagram, Solapur, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

For further inquiries or to discuss customization options, please feel free to contact us.

Read the full article

#Ahmednagar#Akola#Amravati#Aurangabad#Beed#Bhandara#Bhusawal#Buldhana#Chandrapur#Daulatabad#Dhule#Exporter#Gadchiroli#Gondia#Hingoli#India#Jalgaon#Jalna#Kalyan#Karli#Kolhapur#Latur#Mahabaleshwar#Maharashtra#Malegaon#Manufacturer#Matheran#MumbaiCity#MumbaiSubarban#Nagpur

0 notes

Text

Wide Array of Stainless Steel Flange Options

Stainless steel flanges are widely used in various industries due to their durability, strength, and corrosion resistance. These flanges are designed to connect pipes, valves, and other equipment in a piping system, providing a secure and leak-proof connection. With a wide array of stainless steel flange options available in the market, it is important to understand the different types and their applications.

Weld neck flanges are one of the most common types of flanges used in piping systems. These flanges have a long tapered hub that provides an easy transition from the flange to the pipe. They are welded to the pipe, providing a strong connection and reducing stress concentration. Weld neck flanges are commonly used in high-pressure and high-temperature applications, such as oil and gas, petrochemical, and power plant industries.

Slip-on flanges are easy to install and have a low initial cost, making them popular in industries where frequent assembly and disassembly are required. These flanges slip over the end of a pipe and are then welded in place. Slip-on flanges are mainly used in low-pressure applications and are commonly used in water treatment and general plumbing.

Socket weld flanges are similar to slip-on flanges in terms of installation, but they provide a better flow capacity due to a smooth bore and a better sealing surface. These flanges are welded to the pipe and have a socket-like design that allows for a smooth flow of fluid. Socket weld flanges are commonly used in industries such as chemical, pharmaceutical, and food processing.

Lap joint flanges are designed to be easily aligned and bolted together with a stub end or lap joint ring. These flanges are commonly used in systems that require frequent dismantling and cleaning. Lap joint flanges are commonly used in industries such as pulp and paper, marine, and wastewater treatment.

Threaded flanges have internal threads that allow them to be screwed onto the pipe. These flanges are used in low-pressure applications and are commonly found in plumbing systems and small diameter piping.

Blind flanges are used to close off or seal the end of a piping system. These flanges do not have a center hole and are commonly used to provide access to the pipeline for inspection, cleaning, or maintenance. Blind flanges are commonly used in industries such as chemical processing, oil and gas, and water treatment.

When choosing a stainless steel flange, it is important to consider factors such as pressure rating, temperature range, and the compatibility of the flange material with the fluid being transported. Stainless steel flanges are available in various grades, including 304, 316, and 321, each offering different levels of corrosion resistance and mechanical properties.

0 notes

Text

Top Supplier of Industrial Flanges in Rajasthan

Company Overview:

Meghmani Metal is an ISO 9001:2015 certified Manufacturer and Supplier of Industrial Flanges in Rajasthan, India, renowned for its quality products and services.

They specialize in providing a diverse range of industrial flanges crucial for connecting pipes, valves, pumps, and equipment across various industries.

Meghmani Metal offers various types of flanges including weld neck, slip-on, blind, socket weld, lap joint, and threaded flanges, each tailored for specific applications with unique features.

Flanges are typically constructed from materials such as carbon steel, stainless steel, alloy steel, PVC, CPVC, and fiberglass, selected based on operating conditions, pressure, temperature, and corrosion resistance requirements.

Flanges play a critical role in establishing a secure seal between pipes or equipment components, preventing leaks and ensuring the integrity of piping systems. They also facilitate easy installation, inspection, and maintenance.

Available in various sizes, from small diameter flanges used in residential plumbing to large diameter flanges utilized in industrial settings like oil refineries and power plants.

Flanges can be connected to pipes or equipment using methods such as welding, bolting, or threading, chosen based on the type of flange and application requirements.

Manufactured in compliance with international standards such as ANSI/ASME, ASTM, DIN, BS, and JIS, ensuring compatibility and high performance.

Applications:

Oil and Gas

Petrochemical

Chemical Processing

Power Generation

Water treatment

Pharmaceuticals, and manufacturing.

Supplier Coverage:

Meghmani Metal serves as a Top Supplier of Industrial Flanges in Rajasthan Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Exporter#Ganganagar#GangapurCity#Hanumangarh#India#IndustrialFlanges#IndustrialFlangesinRajasthan#Jaipur#Jaisalmer#Jalore

0 notes

Text

Flanges Suppliers in UGANDA – Alkun Steel

Flanges are the unsung heroes of industrial piping systems, quietly ensuring seamless connections and optimal performance. In Uganda, the quest for reliable flange solutions is answered in Alkun Steel. With a commitment to quality, precision, and versatility, Alkun Steel is a beacon of excellence in supplying various flange types tailored to meet diverse industrial needs. From carbon steel to stainless steel, Alkun Steel delivers a comprehensive range of flanges, each meticulously crafted to uphold the highest standards of reliability and durability. Join us as we delve into the world of flanges supplied by Alkun Steel, exploring their types, applications, and the unmatched value they bring to Uganda's industrial landscape.

Different Types of Flange & Their Uses

Slip-on Flange Supplier in UGANDA

Slips onto the pipe and then welded for a secure connection.

Weld Neck Flange Supplier in UGANDA

This flange has a long tapered hub for welded connections, which is ideal for high-pressure applications.

Blind Flange Supplier in UGANDA

This flange seals the end of a pipe or vessel and is used for temporary blockage or future expansion.

Socket Weld Flange Supplier in UGANDA

Designed for smaller diameter pipes, welded for a tight seal.

Orifice Flange Supplier in UGANDA

Used for flow measurement or restriction in pipelines.

RTJ Flange Supplier in UGANDA

Uses a ring joint gasket for high-pressure applications.

Threaded Flange Supplier in UGANDA

Features threads for easy installation and removal.

Lap Joint Flange Supplier in UGANDA

It allows for easy alignment of bolt holes and is ideal for non-standard connections.

Spectacle Blind Flange Supplier in UGANDA

This flange combines the functionality of a blind flange and a spacer to isolate sections of the piping system.

Grooved Flange Supplier in UGANDA

Uses grooves and gaskets for easy assembly and disassembly.

Square Flange Supplier in UGANDA

Typically used in square tubing or structures.

Marine Flange Supplier in UGANDA

This flange is designed to meet Japanese industrial standards and is suitable for marine applications.

Carbon Steel Flange Supplier in UGANDA

Carbon steel flanges are essential for piping systems to connect pipes, valves, pumps, and other equipment. They are made from carbon steel, a steel alloy primarily composed of iron and carbon, with different elements added to enhance properties like strength, hardness, and durability. Carbon steel flanges are known for their strength, resistance to corrosion, and affordability, making them widely used in various industrial applications.

Several carbon steel flanges are designed for specific purposes and applications. Some of the most common types include:

1. Slip-on Flanges in UGANDA (SO): These flanges have a slightly larger bore diameter than the outside diameter of the pipe. They are slipped over the pipe and then welded at the inner and outer edges, providing a strong and secure connection.

2. Weld Neck Flanges in UGANDA (WN): Weld neck flanges feature a long, tapered hub that provides an ideal pipe connection. They are welded to the pipe and the adjoining pipe, offering excellent strength and stability, particularly in high-pressure and high-temperature applications.

3. Blind Flanges in UGANDA (BL): Blind flanges seal the end of a pipe or vessel. They are typically used in applications where future expansion might be needed or temporarily block off a pipeline.

4. Socket Weld Flanges in UGANDA (SW): Socket weld flanges are designed with smaller-diameter pipes. They are welded directly onto the pipe, creating a smooth bore and a tight seal.

5. Threaded Flanges in UGANDA: These flanges have internal threads that allow them to be screwed onto the pipe. They are commonly used in low-pressure applications and where welding is not feasible.

6. Lap Joint Flanges in UGANDA (LJ): Lap joint flanges are used with stub ends. They allow for easy alignment of bolt holes and are ideal for non-standard connections or systems requiring frequent dismantling.

7. Orifice Flanges in UGANDA: Orifice flanges are specifically designed for flow measurement or restriction applications. They feature a small orifice opening that can be used with an orifice plate to measure flow rates.

8. Ring-Type Joint (RTJ) Flanges in UGANDA: RTJ flanges use a ring joint gasket to create a tight seal in high-pressure and high-temperature applications. They are commonly used in the oil and gas industries.

These are just a few examples of the many carbon steel flanges available, each with unique features and advantages suited to different piping requirements.

Conclusion

In a world where precision and reliability are paramount, Alkun Steel emerges as the trusted partner for all flange needs in Uganda. Through their unwavering commitment to quality, Alkun Steel ensures that nationwide industries can confidently operate, knowing that their piping systems are fortified with the finest flange solutions. Whether carbon steel, stainless steel, or specialized marine flanges, Alkun Steel's comprehensive offerings cater to diverse applications, promising unmatched performance and longevity. As Uganda's industrial sector continues to evolve, Alkun Steel remains steadfast in its mission to provide cutting-edge flange solutions that propel businesses forward, one connection at a time.

0 notes

Text

Why buttweld fittings are important and what are their uses

The most common types of pipe fittings are threaded fittings, socket welded fittings, and buttweld fittings, of which the threaded fittings are the most popular. There are several advantages to both of these types of fittings. However, this blog will focus on the advantages of buttweld fittings and their application in particular.

It is necessary to use pipe fittings in pipelines in order to allow the following to take place:

Changing the direction in which liquid flows through pipes.

Liquid flows in two directions through the branching of the pipe.

The diameter of the pipe is reduced.

Auxiliary equipment is attached.

The pipeline has reached its end.

Special Piping Materials offers buttweld fittings that are designed and constructed in accordance with the ASME standards for buttweld fittings. Many different materials are available for the manufacture of these fasteners, for example, super duplex, nickel alloys, stainless steels, duplexes, 6% molybdenum alloys, as well as 5% molybdenum alloys.

Buttweld fittings

Manufacturing:

Hot or cold forming is the process of manufacturing a buttweld fitting by bending and moulding it into the desired shape. Heat treatment is also used to remove any residual stresses and to achieve specific mechanical properties, as well as to remove residual stresses.

Buttweld fittings have to have the ends of their end caps bevelled, and the exact shape of the bevel depends largely on the wall thickness of the pipe to which the fitting is being attached. There is a wide range of exotic materials that can be used for buttweld fittings, such as super duplex material, nickel alloy material, and even 6% molybdenum material. There is a good chance that the material of the fitting will be the same as the pipe system that it will be attached to, in the majority of cases.

There are several types of buttweld fittings defined in the ASME B16.9 standards, including corrosion-resistant buttweld fittings that conform to MSS SP43 specifications that are designed to be light-weight.

Pipelines are altered using ‘elbows’.

Pipe bore sizes can be reduced or increased by using ‘reducers’.

Multiple ways are available for splitting the flow in the pipe with ‘Tees’ or ‘Crosses’.

When pipelines need to be closed, ‘caps’ are used.

Types of ButtWeld Pipe Fittings

Pipe Elbows – Pipe elbows allow a change in direction between two lengths of pipe or tube, usually done with carbon steel elbows with connection ends.

Pipe Bending – Materials used for pipe bends include carbon steel, alloy steel, stainless steel, low-temperature steel, and high-performance steel.

Pipe Tees – Our seamless tube tees and welding tube tees, as well as straight tees and reducing tees, can be supplied. The inlet and outlet sizes of pipe tees are usually the same.

Pipe Cross – Fitting with four openings exactly opposite one another, on the same side. In pipe fittings, a pipe cross is used. A four-pipe junction requires it. One inlet can be connected to three outlets, or three inlets can be connected to one outlet.

End Caps – Plastic End Caps, Stainless Steel End Caps, ASTM, DIN, ANSI, ISO, JIS and ISO Standards, 1/2 to 56 Inches. Different types of pipe caps are available, such as carbon steel caps, stainless steel caps, and alloy steel caps.

Pipe Reducer – Pipe reducers provide flexibility in connecting fractional tubes in a wide variety of applications by providing a tight connection.

Stub End – A Stub End is a fitting used to replace welded flanges in applications requiring rotating backup flanges. Lap Joints and Vanstone Flared Laps are also called lap joints. Stub End back surfaces are seated against a rotating backup flange.

Coupling Fittings – Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter that can be used to connect or disconnect the tubes without disturbing it.

Applications:

Many industries use buttweld fittings for altering, dividing, and terminating fluid flow. The following types of processes are used in these facilities: waste treatment, chemical processing, breweries, petrochemical plants, cryogenic plants, paper production, gas processing, and even nuclear power plants. It is clear from this wide variety of applications how robust a buttweld fitting is and how highly regarded it is. Read More About This Article On Our Website For More information: https://thesteelexporter.com/why-buttweld-fittings-are-important-and-what-are-their-uses/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes

Text

Supplier of Industrial Flanges in Chennai

Simplex Steel is a Manufacturer and Supplier of Industrial Flanges in Chennai, Tamil Nadu, India.

Established in 2012, Simplex Steel is headquartered in Ahmedabad, Gujarat, India. Holding ISO 9001:2015 certification, the company showcases its commitment to maintaining high standards of quality and excellence.

Our specialty lies in the fabrication of a wide range of stainless steel products, encompassing sheets, plates, coils, pipes, tubes, bars, wires, rods, channels, flats, industrial flanges, and various other items.

Industrial flanges play a crucial role in connecting pipes, valves, pumps, and other equipment in various industrial settings.

These components are meticulously designed to provide a secure and leak-proof connection, ensuring the seamless flow of fluids or gases within a system.

Our industrial flanges are available in a wide range of sizes, pressure ratings, and configurations, industrial flanges can be customized to meet specific project requirements.

Common types include weld neck flanges, slip-on flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges, each serving unique purposes depending on the application and operating conditions.

Our industrial flanges also contribute to the overall safety and efficiency of industrial operations. Properly installed flange connections help prevent leaks, minimize downtime, and ensure the integrity of the system, ultimately enhancing productivity.

Industrial flanges undergo stringent quality testing and adhere to industry standards and certifications, such as ANSI, ASME, ASTM, and DIN, to guarantee performance and reliability.

Simplex Steel is a Manufacturer and Supplier of Industrial Flanges in Chennai and locations like Advadi, Kanagam, Ennore, Chetpet, Minjur, Kolathur, Mylapore, Ennore, Adyar, MRC Nagar, Pallikaranai, Egattur, Nesapakkam, Perungalathur, Kottivakkam, Kazhipattur.

For detailed information or inquiries, please feel free to contact us.

0 notes

Text

Supplier of Stainless Steel Flanges in Madhya Pradesh

Krystal Steel is a Supplier of Stainless Steel Flanges in Madhya Pradesh and We are Manufacturer of SS Flanges in Ahmedabad, Gujarat, India.

Krystal Steel is a Manufacturer, Stockiest, and Exporter of SS Sheets, Plates, Coils, Fasteners, Pipes and Tubes, Bars, Wires, Rods,

Strip Coils, Angles, Channels, Flats, Industrial Valve, SS Flanges, Industrial Fittings, SS Dairy Valves.

We specializes in crafting a wide variety of Stainless Steel Flanges in different shapes and sizes, tailored to meet specific customer

requirements and specifications.

We proudly serve a global clientele, meeting the substantial demand for our products worldwide.

Our flanges division is equipped with an integrated forge shop capable of producing a comprehensive range of pipe fittings, including flanges

and butt welding fittings.

We adhere to international standards such as ASME, ANSI, EN, DIN, AFNOR, AWWA, GOST, BS, JIS, AS, MSS, SA, and UNI.

Our flanges are renowned for their exceptional quality and reliability, earning a solid global reputation.

We offers a comprehensive range of flanges, encompassing various grades of metallic materials and styles.

Types of Flanges:

Blind Flange

Weld Neck Flange

Slip On Flange

Socket Weld Flange

Threaded Flange

Lap Joint Flange

Orifice Flange

Why Choose Our Products?

Manufactured from high quality materials

Durable

Efficient performance

Dimensional accuracy

Faster Delivery

Competitive Price

In-house Testing Facility

Packaging and stock facility

Qualified Technicians

Quality controllers

Krystal Steel is a Supplier of Stainless Steel Flanges in Madhya Pradesh Including locations like Indore, Bhopal, Jabalpur, Gwalior, Dewas,

Ujjain, Satna, Rewa, Ratlam, Singrauli, Pithampur, Mandideep, Neemuch, Bhind, Chhindwara, Damoh, Mandsaur, Morena, Khandwa,

Hoshangabad.

Feel free to contact us for more information and inquiries.

Read the full article

0 notes

Text

MS Flange Manufacturer in Mumbai

SK Steel Corporation is the Best MS Flange Manufacturers and Suppliers in Mumbai | MS Flange Manufacturer in Mumbai

SK Steel Corporation is the most trusted name in Best Quality Industrial Mild Steel Flange Manufacturer in Mumbai, India. We are one of all type of industrial MS Flange Manufacturers and Suppliers in Mumbai with Wide Range of Product which is highly precision forging pipe flanges, Forge fitting, Metal rings customized machining parts and forging part with consistent quality. Our product are widely used for different Industrial such as Plastic Molding, Packaging Machine, Pharmaceuticals etc. We are known for our Premium Quality Mild Steel Flanges with Excellent Durability and Performance as well as simple Installation.

This complete guide looks into the MS flange production and supply industry in Mumbai, showing major companies, their products, and useful data to help you make decisions.

The Importance of MS Flange: MS Flange Manufacturers and Suppliers in Mumbai

MS flanges are widely used in a variety of sectors because they combine the following:

Strength and durability: These flanges, which are made of premium mild steel, provide excellent durability to pressure and wear, guaranteeing long-lasting performance.

Versatility: Available in various sizes, shapes, and pressure ratings, MS flanges readily adapt to diverse application requirements.

Cost-effectiveness: Compared to other flange materials like stainless steel or alloy steel, MS flanges offer a more economical option, making them ideal for cost-sensitive projects.

Easy fabrication and installation: MS flanges are readily weldable and can be easily installed using standard tools and equipment.

Types of MS Flanges

MS flange come in various types, each suited for specific applications. Here are some commonly used types:

Weld Neck: Ideal for high-pressure and high-temperature applications due to their superior strength and rigidity.

Slip-On: Offers a cost-effective solution for low-pressure and low-temperature applications.

Lap Joint: Provides a flexible connection for piping with misalignment or thermal expansion concerns.

Blind: Used to close off the end of a pipe or create a pressure barrier.

Socket Weld: Designed for small-diameter pipes and offers ease of installation.

Threaded: Employs threads for connection, eliminating the need for welding.

Best MS Flange Suppliers and Manufacturers in Mumbai

Mumbai is home to numerous MS flange manufacturers and suppliers, each offering unique strengths and expertise. Here are a few prominent players to consider:

SK Steel Corporation: With years of experience and a commitment to quality, SK Steel Corporation has established itself as a Best MS Flange Manufacturer in Mumbai. They offer a comprehensive range of flanges, including weld neck, slip-on, lap joint, and blind flanges, in various sizes and pressure ratings. SK Steel Corporation also provides custom flange solutions to meet specific project requirements.

M.S. Flange Manufacturing Co.: Renowned for their high-quality flanges and prompt service, M.S. Flange Manufacturing Co. is a leading manufacturer in Mumbai. They offer a wide variety of flanges, catering to various industrial applications.

Flanges Manufacturer India M.K.Industries: This company specializes in the manufacture and supply of custom-made MS flanges. They work closely with clients to understand their specific needs and provide tailored solutions.

Jagdish Metals & Alloys: This leading supplier offers a comprehensive selection of MS flanges, along with other metal products and services. They cater to a wide range of industries and are known for their customer-centric approach.

1 note

·

View note