#SCADA design Services

Text

Automation Course in Salem. Learn More.

#automation#industrial design#automation training#scada#scad animation#automation and response#automation anywhere#automation platform#automation services#automation software#automation testing#automation tools#plc

0 notes

Text

Revolutionizing Connectivity: A Comprehensive Guide to Remote Terminal Unit Suppliers and Manufacturers

In the rapidly evolving landscape of industrial automation and remote monitoring, Remote Terminal Units (RTUs) stand as pivotal components ensuring seamless data acquisition and transmission. As industries continue to embrace digitization and remote operations, the demand for reliable RTUs has surged, prompting an influx of suppliers and manufacturers striving to meet diverse industrial needs. In this guide, we delve into the world of RTUs, highlighting key suppliers and manufacturers driving innovation in this critical sector.

Understanding Remote Terminal Units (RTUs)

RTUs serve as intermediaries between sensors, equipment, and centralized monitoring and control systems. These compact yet powerful devices collect data from various sensors and instruments deployed in remote locations, process the information, and transmit it to a central control center. Moreover, RTUs can execute commands remotely, enabling operators to control equipment and processes without physical intervention.

Key Features and Considerations

When evaluating RTU suppliers and manufacturers, several factors warrant careful consideration:

Compatibility: RTUs should seamlessly integrate with existing SCADA (Supervisory Control and Data Acquisition) systems and communication protocols prevalent in the industry.

Reliability: In mission-critical applications, reliability is paramount. Look for suppliers offering robust RTUs designed to withstand harsh environmental conditions and ensure uninterrupted operation.

Scalability: As operational requirements evolve, scalability becomes crucial. Opt for suppliers offering scalable RTU solutions capable of accommodating future expansions and upgrades.

Security: With the increasing threat of cyber-attacks, security features such as encryption, authentication, and secure communication protocols are non-negotiable.

Support and Maintenance: Choose suppliers renowned for their exemplary customer support and maintenance services, ensuring prompt assistance and minimal downtime.

Leading RTU Suppliers and Manufacturers

Schneider Electric: With a legacy of excellence in industrial automation, Schneider Electric offers a diverse range of RTU solutions tailored to various industries, emphasizing reliability, scalability, and seamless integration.

Siemens: Renowned for its cutting-edge technologies, Siemens provides innovative RTU solutions characterized by advanced features, robustness, and compatibility with industry standards.

Emerson Electric Co.: Emerson's RTUs combine state-of-the-art technology with unparalleled reliability, offering comprehensive solutions for remote monitoring and control across diverse industrial sectors.

Honeywell International Inc.: Honeywell's RTU portfolio encompasses a wide spectrum of applications, emphasizing security, scalability, and ease of deployment, making it a preferred choice for critical infrastructure projects.

Rockwell Automation: Leveraging its expertise in automation and control systems, Rockwell Automation delivers high-performance RTU solutions optimized for seamless integration, reliability, and efficiency.

Emerging Trends and Future Outlook

As industries continue to embrace Industry 4.0 initiatives and IoT (Internet of Things) technologies, the future of RTUs appears promising. Key trends shaping the future of RTUs include:

Edge Computing: RTUs equipped with edge computing capabilities enable real-time data processing at the edge of the network, reducing latency and enhancing decision-making efficiency.

AI and Machine Learning Integration: Integration of AI (Artificial Intelligence) and machine learning algorithms into RTUs enables predictive maintenance, anomaly detection, and optimization of industrial processes.

Enhanced Cybersecurity Measures: RTU manufacturers are increasingly prioritizing cybersecurity, implementing robust encryption, authentication, and intrusion detection mechanisms to safeguard critical infrastructure from cyber threats.

Remote Asset Management: RTUs equipped with remote asset management features enable proactive monitoring, maintenance, and optimization of distributed assets, enhancing operational efficiency and minimizing downtime.

In conclusion, the realm of RTU suppliers and manufacturers is characterized by innovation, reliability, and a steadfast commitment to addressing the evolving needs of industries worldwide. By partnering with reputable suppliers and leveraging cutting-edge RTU solutions, industries can unlock new levels of efficiency, productivity, and competitiveness in an increasingly interconnected world.

0 notes

Text

FUTURE OF INDUSTRIAL AUTOMATION

What is industrial automation

Automation refers to a wide range of technologies that reduce human interaction in processes, primarily by predetermining decision criteria, subprocess interactions, and related actions and enforcing those predeterminations through machines.

The future of industrial automation is predicted to be defined by rising digitization, industrial internet-of-things, artificial intelligence adopting robotization, and an increasing attention on safety. The future of industrial automation is likely to witness growing integration of digital technology, such as robotics and artificial intelligence, as well as a greater emphasis on safety and flexibility. As these trends continue to change the industry, it is clear that industrial automation will play an important role in increasing efficiency and production across a wide range of sectors.

Automation is the development and application of technologies that enable goods and services to be produced and delivered with minimal or no human interaction. Many previously manual tasks are now more efficient, dependable, and quick due to the development of automation technologies. Automation technologies and processes enable workers to do routine tasks more efficiently and reliably.

Important topics in industrial automation

Electrical drives and controls

Field instrumentation and pneumatic

Programmable logic controllers (PLC)

Supervisory control and acquisition (SCADA)

Distribute control system (DCS)

Human machine interface

Control panel designing

Electrical drives and controls:

An electric drive, also referred to as an electric controller, is a mechanism responsible for regulating the output of a motor, particularly one utilized for producing linear motion. The drive effectively manages the motor's output and promptly responds to a controlling input.

Field instrumentation and pneumatic:

widely used term across various industries to refer to the supervision and regulation of distributed equipment. It is essential for automation engineers to undergo training in Field Instruments and Pneumatics as these are integral components of the controlled system.

Programmable logic controllers (PLC):

A programmable logic controller, also known as a programmable controller, is a ruggedized industrial computer designed to control manufacturing processes such as assembly lines, machines, robotic devices, or any activity that necessitates high reliability, ease of programming, and process fault diagnosis.

Supervisory control and data acquisition (SCADA):

SCADA, also known as supervisory control and data acquisition, refers to a group of software applications used to manage industrial processes. It involves collecting real-time data from remote locations to effectively control equipment and conditions.

Distributed control system:

A distributed control system is a computerized system used to control processes or plants with multiple control loops. It consists of autonomous controllers spread out across the system, without a central operator supervisory control.

Human machine interface:

A distributed control system is a computerized system used to control processes or plants with multiple control loops. It consists of autonomous controllers spread out across the system, without a central operator supervisory control.

Control panel designing:

Control panels consist of electrical components and devices that enable the automation of industrial processes and equipment. To create a personalized control panel, it is crucial to take into account several important factors. These factors ensure that your panel functions effectively, guarantees safety during usage, and maintains its reliability.

Opportunities in industrial automation

Automation engineer

Engineering

Computer programming

Automation product manager

Electrical engineering

SCDA developer

Control system (PLC, HMLI, SCADA)

Benefits of industrial automation

Increase productivity

Improve quality control

Increase workplace safety

Reduce cost

Efficiency

Customer statisfaction

Increase productivity

automation enables businesses to deliver high-quality services more quickly, with improved consistency and precision.

Improve quality control

Industrial automation enhances quality control and boosts customer satisfaction.

Increase workplace safety

Automation helps businesses minimize the chances of accidents and injuries at work.

Reduce cost

Although the initial investment in automation may be costly, the long-term benefits of higher productivity and lower labour costs can result in significant savings over time.

Efficiency

RPA (Robotic process automation) can handle a significantly higher number of processes compared to humans, allowing you to process transactions at a much faster pace.

Customer satisfaction

One of the most exciting aspects of robotic process automation is the positive impact it may have on your consumers.

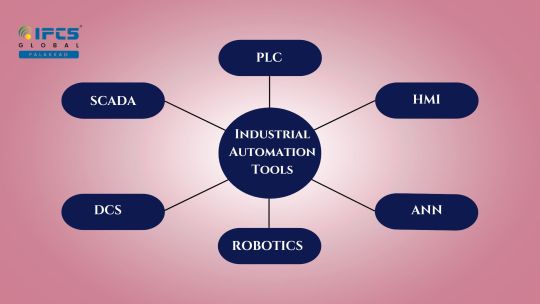

Industrial automation tools

HMI design

Distributed control system

Factory system

SCADA

Robotics

Artificial Neural Network

Programmable logic controller

HMI design

A Human-Machine Interface (HMI) is a user interface or dashboard that allows a person to interact with a machine, system, or device. While the term can theoretically refer to any screen that allows a user to interact with a device, HMI is most usually associated with industrial processes.

HMI can be used to

Visually display data

Track production time, trends, and tags

Oversee KPIs

Monitor machine inputs and outputs

Distributed control system

A Distributed Control System (DCS) is a modern computerized system that automates industrial equipment utilized in both continuous and batch processes. By doing so, it effectively minimizes risks to both individuals and the environment.

Factory system

Factory automation involves the utilization of technology and systems to mechanize a production process, aiming to enhance efficiency and minimize expenses.

SCADA

SCADA stands for Supervisory Control and Data Acquisition. It is a computerized system used to collect and analyse real-time data in order to oversee and manage equipment handling important and time-sensitive materials or events.

Robotics

Industrial automation and robotics employ computers, control systems, and information technology to manage industrial processes and machinery, substituting manual labour and enhancing efficiency, speed, quality, and performance.

Artificial Neural Network

Artificial Neural Networks (ANN) are algorithms that simulate brain activity and are used to model complex patterns and foresee problems. The Artificial Neural Network (ANN) is a deep learning system based on the biological neural networks seen in the human brain.

Programmable logic controller

A programmable logic controller is an advanced computer control system used in industries. It constantly keeps an eye on the input devices and takes actions based on a customized program to manage the output devices.

Why is industrial automation important

Furthermore, industrial automation is focused on enhancing efficiency, speed, and effectiveness. In general, automation can be defined as a technology that performs a process using programmed orders and automatic feedback control to verify that the instructions are carried out correctly. The resulting system is capable of functioning without human assistance.

Conclusion

The field of Industrial automation encompasses a wide array of technologies that aim to minimize human involvement. As we look towards the future, we can expect to see an increased integration of digital advancements like robotics and artificial intelligence, along with a stronger focus on safety and adaptability. There are numerous crucial topics covered within this field, including enhancing safety measures and reducing costs while improving efficiency. Presently, there are abundant opportunities in industrial automation, and IPCS Global in Kerala stands out as one of the top institutes offering courses in this area.

#industrial automation#digital marketing#python fullstack#datascience#ipcsglobal#ipcsglobal palakkad

1 note

·

View note

Text

Rudraja Engineers & Consultants: Your PLC Automation Experts

At Rudraja Engineers & Consultants, we specialize in PLC automation services, focusing on marine and defense engineering. Our goal is to provide comprehensive PLC automation designs based on your basic concepts, enabling the creation of necessary production documentation. We meticulously examine working procedures and shipbuilding practices to deliver diverse results tailored to your needs.

Our team of skilled draughtsmen and design engineers is proficient in 3D design programs such as AutoCAD and other advanced software. With the necessary infrastructure in place, our certified engineers utilize Tekla Software for architectural planning and 3D modeling projects.

Our PLC Automation Services include:

Systems utilizing PLCs

SCADA and HMI operating systems

PC-based automation systems

Motion management options

Panel design, engineering, and provision of customized products for motor control centers

We offer a range of services, including planning and executing automation projects, troubleshooting drives and PLC automation, renovations, panel construction, and industrial automation consulting. Our expertise extends to electrical and automation system design and supply, energy-saving consulting, and maintenance services for automation equipment.

Additionally, we provide training for industrial engineers on PLCs, drives, HMIs, SCADAs, and DCS systems. Our services also include advice on the purchase, testing, and inspection of automation and electrical systems’ equipment, as well as sales of replacement parts.

Our Human Resources boast skilled and knowledgeable engineering draftsmen proficient in programs like SolidWorks, UG NX, Cadmatic, PDMS, and Catia. Our engineers are adept in Aspen, Pro II, Hysis, while our Electrical team excels in SPE tools and Mechanical Designers/Draughtsmen specialize in PV Elite HVAC Pipeline Packages. Our instrumentation processes cover both electrical and mechanical piping, utilizing tools such as PDS/PDIVIS/SP3D, SPP & ID SPI (Intools), Autocad, Microstation, and Cadwork.

We hope this information provides insight into our services at Rudraja Engineers & Consultants. If you're interested in our PLC automation service, don't hesitate to reach out to us. We're here to meet your automation needs with precision and expertise.

Original Source URL : https://www.rudrajaengineers.com/services/plc-automation/

Tags: Rudraja Engineers, Smartplant instrumentation training, Design instrumentation Training ,Intools Training, PLC automation, Electrical and instrumentation works, NABL calibration

#Smartplant instrumentation training#Design instrumentation Training#Intools training#PLC automation#Electrical and instrumentation works#NABL calibration

0 notes

Text

The Heartbeat of Industrial Operations: Exploring Our Instrumentation Solutions

In the dynamic landscape of industrial operations, where precision and efficiency are paramount, instrumentation plays a crucial role as the heartbeat of every process. At Power Tech Electric, we take pride in offering comprehensive instrumentation solutions that power industries across the globe, ensuring smooth operations and optimal performance.

Precision Engineering

Our instrumentation solutions are the result of precision engineering at its finest. Designed by a team of seasoned experts, our instruments are engineered to deliver unparalleled accuracy, reliability, and durability, even in the most demanding industrial environments. From pressure transmitters to temperature sensors, each component is meticulously crafted to meet the highest standards of quality and performance.

Diverse Applications

Our instrumentation solutions find applications across a wide range of industries, including manufacturing, oil and gas, petrochemicals, pharmaceuticals, and more. Whether it's monitoring pressure in a hydraulic system, measuring temperature in a chemical reactor, or controlling flow in a production line, our instruments provide the critical data and control necessary for efficient and safe operations.

Customization Options

We understand that every industrial process is unique, and one-size-fits-all solutions often fall short of meeting specific requirements. That's why we offer customization options to tailor our instrumentation solutions to the precise needs of our customers. Whether it's custom calibration ranges, specialized materials, or unique form factors, we work closely with our clients to deliver solutions that address their unique challenges.

Seamless Integration

Integration is key to maximizing the value of instrumentation in industrial operations. Our solutions are designed with seamless integration in mind, ensuring compatibility with existing systems and workflows. Whether it's integrating with PLCs, SCADA systems, or other control platforms, our instruments offer plug-and-play functionality that minimizes downtime and maximizes productivity.

Reliability and Durability

In industrial environments where uptime is critical, reliability is non-negotiable. That's why our instrumentation solutions are built to withstand the rigors of industrial operations, including extreme temperatures, harsh chemicals, and heavy vibrations. With rugged construction and robust design, our instruments deliver reliable performance day in and day out, keeping operations running smoothly without interruption.

Comprehensive Support

At Power Tech Electric, our commitment to customer satisfaction extends beyond the sale of our products. We offer comprehensive support services to ensure that our customers get the most out of their instrumentation solutions. From installation and commissioning to ongoing maintenance and calibration, our team of experts is dedicated to providing prompt, professional support whenever and wherever it's needed.

Powering Industrial Operations

From monitoring critical parameters to controlling essential processes, instrumentation is the backbone of modern industrial operations. At Power Tech Electric, we're proud to be at the forefront of instrumentation technology, delivering solutions that empower industries to operate with precision, efficiency, and confidence. Join us in exploring the possibilities of our instrumentation solutions and experience the difference they can make in your operations.

0 notes

Text

Power SCADA Market rowth Opportunities and Competitive Landscape Report to 2033

Market Definition

The Power SCADA (Supervisory Control and Data Acquisition) market is witnessing substantial growth driven by the increasing demand for efficient monitoring, control, and management of power generation, transmission, and distribution systems. This market involves the deployment of SCADA systems specifically designed for power utilities, enabling real-time data acquisition, remote monitoring, and control of power grids and substations.

To Know More: https://www.globalinsightservices.com/reports/power-scada-market

Market Outlook

The market outlook for the Power SCADA (Supervisory Control and Data Acquisition) sector remains optimistic and poised for continued expansion in the forthcoming years. Factors such as the increasing need for efficient power grid management, coupled with the rising adoption of smart grid technologies, are driving the demand for Power SCADA solutions. These systems enable real-time monitoring, control, and automation of power grids, enhancing reliability, reducing outage durations, and improving the overall efficiency of power distribution networks. Moreover, the integration of Power SCADA systems with advanced technologies such as IoT (Internet of Things), big data analytics, and AI (Artificial Intelligence) is revolutionizing grid operations, offering predictive insights, and facilitating proactive maintenance, thereby ensuring uninterrupted power supply and enhancing grid resilience. Additionally, the continuous advancements in SCADA technology, including cloud-based solutions, enhanced cybersecurity, and scalability, are expected to further drive market growth, providing utilities with robust tools to manage and optimize complex power systems.

Request Sample: https://www.globalinsightservices.com/request-sample/GIS20893

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization: https://www.globalinsightservices.com/request-customization/GIS20893

Market Segmentation

The segmentation of the industrial power supply market encompasses several key facets, including component type, power rating, end-use industry, and geography. Component types within this market involve transformers, switchgear, UPS (Uninterruptible Power Supply) systems, power converters, and others, each serving distinct functions in regulating and delivering power within industrial settings. Power rating categorization includes various power ranges tailored to different industrial needs, from low-power (below 5 kW) to high-power (above 2500 kW) systems, providing solutions for diverse scale operations. Segmentation by end-use industry covers manufacturing, energy, utilities, oil and gas, and others, each with specific power requirements and operational demands, thereby influencing the type of power supply solutions needed. Geographically, the market spans regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, where factors like infrastructure development, industrialization, energy demand, and regulatory norms influence the demand and growth of industrial power supply solutions within these areas.

Major Players

The key players in the Global Power SCADA Market are ABB, Siemens, Emerson, Schneider Electric, Mitsubishi Electric, Honeywell, Yokogawa Electric Corporation, Rockwell Automation, PSI AG, Motorola Solutions

Request Discounted Pricing: https://www.globalinsightservices.com/request-special-pricing/GIS20893

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS20893

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Iranian Ultrasonic Level Sensor

Title: Iranian Ultrasonic Level Sensor

Introduction:

Iranian ultrasonic level sensors represent a significant advancement in non-contact level measurement technology, catering to the specific needs of various industries in Iran. Developed and manufactured domestically, these sensors leverage ultrasonic waves to accurately determine the distance from the sensor to the liquid, solid, or slurry surface, providing reliable level measurements. Understanding the features, capabilities, and advantages of Iranian ultrasonic level sensors is essential for industries seeking precise and efficient level monitoring solutions tailored to Iranian conditions.

Key Features of Iranian Ultrasonic Level Sensors:

Advanced Technology: Iranian ultrasonic level sensors incorporate cutting-edge ultrasonic technology, combined with advanced signal processing algorithms, to deliver accurate and reliable level measurements. These sensors are designed to operate effectively in challenging industrial environments, ensuring optimal performance and durability.

Customized Solutions: Iranian ultrasonic level sensors are tailored to meet the specific requirements of Iranian industries and applications. They are engineered to withstand harsh environmental conditions prevalent in Iran, including temperature extremes, dust, and humidity, ensuring reliable operation in diverse industrial settings.

Adaptability to Iranian Industries: Iranian ultrasonic level sensors are versatile and suitable for a wide range of industries prevalent in Iran, including oil and gas, petrochemicals, water and wastewater treatment, mining, and agriculture. They can accurately measure levels of liquids, solids, and slurry materials in various types of vessels and tanks.

Robust Construction: Iranian ultrasonic level sensors feature robust construction using high-quality materials, ensuring longevity and reliability in demanding industrial environments. They are designed to withstand mechanical shocks, vibration, and exposure to corrosive substances commonly encountered in Iranian industries.

Easy Installation and Integration: Iranian ultrasonic level sensors are designed for easy installation and integration into existing control systems. They offer flexibility in mounting options and support various communication protocols, allowing for seamless integration with PLCs, SCADA systems, and other automation platforms.

Local Support and Service: Iranian ultrasonic level sensor manufacturers provide comprehensive local support and service to their customers, including technical assistance, training, and maintenance services. This local support ensures prompt response to customer inquiries and efficient resolution of any issues that may arise during sensor operation.

Applications of Iranian Ultrasonic Level Sensors:

Iranian ultrasonic level sensors find applications across a wide range of industries and processes, including:

Oil and gas production and refining

Petrochemical and chemical processing

Water and wastewater treatment

Mining and mineral processing

Agriculture and irrigation

Manufacturing and industrial automation

Conclusion:

Iranian ultrasonic level sensors offer reliable, accurate, and customized solutions for non-contact level measurement in Iranian industries. With their advanced technology, robust construction, adaptability to local conditions, and comprehensive local support, these sensors are well-suited to meet the specific needs of Iranian industries and applications. Integrating Iranian ultrasonic level sensors into level monitoring and control systems enhances efficiency, safety, and productivity, contributing to the growth and success of Iranian industries.

0 notes

Text

PLC System Integrator

On the planet of automation, PLC system integrators play a vital function in making, executing, and preserving control systems for various markets. PLC, which stands for Programmable Reasoning Controller, is a digital computer utilized for automation of normally commercial electromechanical procedures. PLC system integrators are professionals in incorporating software and hardware to develop effective and reliable automatic systems.

The PLC Integrators experts work with a broad series of tasks, from making plants and production line to power centers and water treatment plants. They collaborate with designers, service technicians, and customers to understand the demands of a system, layout the control logic, choose the proper equipment, program the PLC, and test the system to ensure it operates appropriately.

Among the essential responsibilities of a PLC system integrator is to make sure that the control system satisfies the specific requirements of the client while adhering to sector standards and security policies. They should have a deep understanding of PLC programs languages, such as ladder reasoning and feature obstruct diagrams, in addition to expertise of networking, HMI (Human Machine Interface), and SCADA (Supervisory Control and Information Acquisition) systems.

Being a PLC system integrator calls for a mix of technological abilities, problem-solving capacities, and communication skills. Integrators have to be able to fix complex issues, job properly in a group setting, and interact technological information to non-technical stakeholders. Furthermore, staying updated on the latest modern technologies and trends in automation is important to offer cutting-edge services to clients.

Finally, a PLC Programming Company play a crucial role in the area of automation deliberately and executing control systems that improve effectiveness, dependability, and safety in numerous industries. Their experience in PLC programming, hardware choice, and system testing ensures that automated systems fulfill the requirements of clients and abide by sector requirements. As innovation remains to development, the duty of PLC system integrators will certainly end up being a lot more critical in driving the automation transformation ahead.

Visit this site to know more about the above topic: https://www.britannica.com/technology/control-system.

0 notes

Text

How Siemens SICAM Q200 Instrument Optimizes Power Quality Monitoring for Industries

In today's industrial landscape, the reliability and efficiency of power systems are paramount. As industries evolve and demand more from their power networks, ensuring optimal power quality becomes increasingly critical. Siemens' SICAM Q200 instrument stands at the forefront of this challenge, offering advanced solutions for power quality monitoring tailored specifically for industrial applications. With its cutting-edge technology and robust features, the SICAM Q200 enables industries to analyze, diagnose, and optimize their power systems with unprecedented precision and effectiveness.

In this blog, we delve into the functionalities and benefits of the Siemens SICAM Q200 instrument, exploring how it empowers industries to enhance power quality monitoring. From its ability to detect and analyze power disturbances to its intuitive interface and comprehensive reporting capabilities, the SICAM Q200 emerges as a game-changer in the realm of power management. Join us as we unravel the intricacies of this innovative instrument and discover how it revolutionizes power quality monitoring for industries across the globe.

Overview of Siemens SICAM Q200 instrument

The Siemens SICAM Q200 instrument is a state-of-the-art solution designed specifically for power quality monitoring in industrial settings. It is equipped with advanced sensors and analytics capabilities to accurately measure various parameters related to power quality. The SICAM Q200 offers real-time monitoring, data logging, and analysis features, providing industries with valuable insights into the performance of their electrical systems.

The SICAM Q200 is an advanced network analyzer designed for the precise acquisition and assessment of power quality in electrical power supply systems. Equipped with sophisticated algorithms and functions, it serves as a powerful tool for energy management applications. By supporting continuous acquisition and analysis of all relevant parameters, the device enables users to identify and implement quality improvement programs, thus ensuring superior supply quality. This not only prolongs the service life of equipment but also minimizes downtimes.

Classified as a PQ device Class A according to standards such as IEC 62586-1/2 and IEC 61000-4-30 Ed. 3, the SICAM Q200 surpasses Class A requirements, delivering unparalleled accuracy and reliability. It captures, visualizes, analyzes, and transmits various alternating current characteristics including current, voltage, frequency, power, and harmonics. The measured variables can be seamlessly transferred to a PC, energy automation/SCADA system, or displayed on the device's interface via communication interfaces. Moreover, the SICAM Q200 offers a combined recording and analysis function for measured values directly within the device, enhancing convenience and efficiency. Long-term data and events can be transmitted to the SICAM PQS/PQ Analyzer System via IEC 61850, facilitating flexible analyses and report generation, including compliance with standards such as EN 50160.

Features and Functionality of Siemens SICAM Q200

Real-time monitoring capabilities: The Siemens SICAM Q200 offers real-time monitoring capabilities, providing users with instant insights into the performance of their power supply systems. With its high-definition acquisition capabilities, the device continuously monitors key parameters such as voltage, current, frequency, and power quality indicators, ensuring prompt detection of any abnormalities or deviations.

Detection and analysis of power disturbances: SICAM Q200 excels in detecting and analyzing power disturbances, including voltage sags, swells, interruptions, and harmonic distortions. Its advanced algorithms and analytics functions enable precise identification and characterization of power quality issues, allowing users to take proactive measures to mitigate their impact on equipment and operations.

Comprehensive data logging and reporting: The device features comprehensive data logging capabilities, capturing a wide range of power quality parameters over extended periods. This data can be utilized to generate detailed reports, providing valuable insights into the historical performance of the power system and facilitating trend analysis and compliance monitoring.

Integration with existing power systems: SICAM Q200 seamlessly integrates with existing power systems, enabling easy deployment and interoperability with other monitoring and control devices. It supports various communication protocols and interfaces, ensuring compatibility with different hardware and software platforms commonly used in industrial settings.

User-friendly interface and intuitive operation: The SICAM Q200 is designed with a user-friendly interface and intuitive operation, making it accessible to both experienced professionals and novice users. Its graphical display and intuitive navigation allow users to access critical information and perform tasks efficiently, enhancing productivity and ease of use in demanding industrial environments.

Benefits of Using Siemens SICAM Q200

Enhanced reliability and efficiency of power systems: By providing real-time monitoring and analysis of power quality parameters, the SICAM Q200 helps identify potential issues before they escalate, thereby enhancing the overall reliability of power systems. With its ability to detect and mitigate power disturbances promptly, the device contributes to improved system stability and efficiency, minimizing the risk of unplanned outages and disruptions.

Reduction in downtime and maintenance costs: The proactive monitoring capabilities of the SICAM Q200 enable industries to address power quality issues in a timely manner, reducing the likelihood of equipment failures and downtime. By preventing costly production interruptions and minimizing the need for reactive maintenance, the device helps organizations save on repair and replacement costs, ultimately improving their bottom line.

Improved productivity and profitability for industries: With reliable and stable power supply ensured by the SICAM Q200, industries can operate their equipment and processes at optimal levels, maximizing productivity and throughput. The reduction in downtime and maintenance costs translates to increased operational efficiency and profitability, allowing organizations to allocate resources more effectively and focus on core business activities.

Compliance with regulatory standards and requirements: The SICAM Q200 helps industries maintain compliance with regulatory standards and requirements related to power quality and reliability. By capturing and analyzing data in accordance with established standards such as EN 50160, the device ensures that organizations meet legal obligations and industry guidelines, avoiding potential penalties or sanctions.

Applications

Continuous Monitoring of Supply Quality: Insufficient quality of supplied electrical energy stands out as one of the leading culprits behind unplanned downtimes and device failures. It underscores the importance of acquiring and documenting parameters pertinent to supply quality. This process serves as a crucial step in pinpointing potential weak points and instigating necessary measures to rectify them, thereby mitigating the risk of disruptions and equipment failures.

Q200 Power Quality Instrument Application: The SICAM Q200 is employed in single-phase systems, as well as in three-wire and four-wire systems that include a neutral conductor. Its usage spans across various sectors including power utilities, industries, data centers, and commercial applications.

Measured Characteristics and Power Quality

True RMS of voltage and current with 8192 sampled values / 10 sampling cycles (sampling rate 40 kHz @50 Hz), voltage transients with a sampling rate of 1 MHz

Measurement, visualization, recording in PQDIF of frequencies in the range of 2 kHz to 9 kHz (IEC 61000-4-7) and 9 kHz to 150 kHz (IEC610000-4-30- 2015)

Rapid voltage changes

Measurement compliant with IEC 61000-4-30 Class A Ed. 3, reporting and analyses compliant with EN 50160 (CBEMA)

Phase angles

Power of harmonics for harmonic direction detection

Active, reactive and apparent power and energy

Harmonics up to the 63rd harmonic

Conclusion

In conclusion, the Siemens SICAM Q200 instrument stands as a beacon of innovation in the field of power quality monitoring for industries. With its advanced features, intuitive interface, and comprehensive capabilities, the SICAM Q200 empowers industries to achieve unparalleled levels of reliability and efficiency in their power systems. By providing real-time insights, precise analysis, and proactive measures to mitigate disturbances, the SICAM Q200 enables industries to optimize their operations and minimize downtime, ultimately driving productivity and profitability.

As industries continue to evolve and demand more from their power networks, the importance of effective power quality monitoring cannot be overstated. The Siemens SICAM Q200 instrument not only meets but exceeds these demands, offering a holistic solution that addresses the complexities of modern industrial environments. With its proven track record and continuous innovation, the SICAM Q200 remains at the forefront of power quality monitoring, poised to support industries in their quest for excellence and sustainability.

For the best deals on Siemens SICAM Q200 Power Quality Instrument, look no further than Reliserv Solution. As an Authorized Platinum Channel Partner of Siemens, we specialize in Numerical Relays, Automation Products, Power Quality Meters & Instruments, MV Switchgear Spares, and PSS SINCAL Software. Based in Mumbai, Maharashtra, we provide top-notch solutions trusted for quality and reliability. Serving various industries and panel builders, you can reach us at +917506112097 or email [email protected] with your requirements. Explore our range of Siemens Power Quality Measurement for premium-quality products. Click here to learn more.

#siemens#powerquality#energymanagement#industry4_0#smartgrid#powermonitoring#energyefficiency#industrialautomation#electricalengineering#sustainability#gridmonitoring#powersystems#digitaltransformation#energysavings#assetmanagement#reliability

0 notes

Text

industrial automation companies | Industrial automation companies in Dubai UAE

Introduction:

In the thriving landscape of industrial automation in the United Arab Emirates (UAE), Syscom Automation stands as a beacon of innovation and efficiency. This overview explores the pivotal role played by Syscom Automation among industrial automation companies in the UAE, spotlighting their commitment to delivering cutting-edge solutions that elevate industrial processes.

1. Pioneering Industrial Automation Solutions:

Syscom Automation is at the forefront of industrial automation companies in the UAE, pioneering solutions that redefine the manufacturing and operational landscape. With a focus on technological advancements, the company is instrumental in driving the UAE's industrial sector towards unprecedented levels of efficiency and productivity.

2. Comprehensive Automation Offerings:

Syscom Automation provides a comprehensive suite of automation solutions tailored for diverse industrial applications. From process automation to factory automation and control systems, their expertise spans the entire spectrum, ensuring that clients receive end-to-end solutions that optimize operations and enhance overall output.

3. Industry-Specific Expertise:

Recognizing the diverse nature of industries in the UAE, Syscom Automation excels in offering industry-specific automation solutions. Whether it's manufacturing, oil and gas, utilities, or infrastructure, the company's expertise ensures that automation systems are finely tuned to meet the unique challenges and requirements of each sector.

4. Cutting-Edge Technologies:

Syscom Automation embraces cutting-edge technologies, playing a crucial role in ushering in the era of Industry 4.0 in the UAE. Their automation solutions incorporate smart technologies, data analytics, and connectivity, providing clients with intelligent systems that facilitate real-time monitoring, predictive maintenance, and data-driven decision-making.

5. PLC, SCADA, and DCS Mastery:

Specializing in core automation technologies, Syscom Automation excels in Programmable Logic Controller (PLC), Supervisory Control and Data Acquisition (SCADA), and Distributed Control System (DCS) implementations. This mastery ensures the deployment of robust and reliable automation systems that form the backbone of modern industrial processes.

6. Integration for Seamless Operations:

Syscom Automation places a strong emphasis on system integration, fostering seamless operations within industrial facilities. Their solutions are designed to interconnect various automation components, optimizing workflow, enhancing communication, and ultimately contributing to the overall efficiency and effectiveness of industrial processes.

7. Training and Support Infrastructure:

Syscom Automation goes beyond mere implementation by providing comprehensive training and support services. This commitment ensures that clients and their workforce are adept at utilizing and maintaining the implemented automation systems, fostering self-sufficiency and long-term success.

8. Sustainability-driven Automation:

Aligned with the UAE's commitment to sustainability, Syscom Automation integrates eco-friendly practices into their automation solutions. By optimizing energy consumption, reducing waste, and enhancing resource efficiency, the company contributes to the nation's vision of building environmentally conscious and sustainable industrial practices.

Conclusion:

Syscom Automation's leadership among industrial automation companies in Dubai UAE is synonymous with a commitment to excellence, innovation, and efficiency. As the UAE continues its industrial evolution, Syscom Automation remains a trailblazer, providing sophisticated and forward-looking automation solutions that empower industries to thrive in a competitive and sustainable future.

#industrial automation companies#Industrial automation companies in Dubai#Industrial automation companies in UAE#industrial automation

0 notes

Text

Unlocking Efficiency and Reliability with Eternergy

In today's rapidly evolving energy landscape, ensuring the reliability, efficiency, and security of energy infrastructure is paramount. Eternergy emerges as a leading solution provider, offering a suite of cutting-edge testing services designed to meet the demands of modern energy systems. From end to end testing to specialized evaluations like partial discharge and SCADA security testing, Eternergy delivers comprehensive solutions for the challenges facing the energy industry.

Visit here- https://theomnibuzz.com/unlocking-efficiency-and-reliability-with-eternergy/

0 notes

Text

Revolutionizing Connectivity: A Comprehensive Guide to Remote Terminal Unit Suppliers and Manufacturers

In the rapidly evolving landscape of industrial automation and remote monitoring, Remote Terminal Units (RTUs) stand as pivotal components ensuring seamless data acquisition and transmission. As industries continue to embrace digitization and remote operations, the demand for reliable RTUs has surged, prompting an influx of suppliers and manufacturers striving to meet diverse industrial needs. In this guide, we delve into the world of RTUs, highlighting key suppliers and manufacturers driving innovation in this critical sector.

Understanding Remote Terminal Units (RTUs)

RTUs serve as intermediaries between sensors, equipment, and centralized monitoring and control systems. These compact yet powerful devices collect data from various sensors and instruments deployed in remote locations, process the information, and transmit it to a central control center. Moreover, RTUs can execute commands remotely, enabling operators to control equipment and processes without physical intervention.

Key Features and Considerations

When evaluating RTU suppliers and manufacturers, several factors warrant careful consideration:

Compatibility: RTUs should seamlessly integrate with existing SCADA (Supervisory Control and Data Acquisition) systems and communication protocols prevalent in the industry.

Reliability: In mission-critical applications, reliability is paramount. Look for suppliers offering robust RTUs designed to withstand harsh environmental conditions and ensure uninterrupted operation.

Scalability: As operational requirements evolve, scalability becomes crucial. Opt for suppliers offering scalable RTU solutions capable of accommodating future expansions and upgrades.

Security: With the increasing threat of cyber-attacks, security features such as encryption, authentication, and secure communication protocols are non-negotiable.

Support and Maintenance: Choose suppliers renowned for their exemplary customer support and maintenance services, ensuring prompt assistance and minimal downtime.

Leading RTU Suppliers and Manufacturers

Schneider Electric: With a legacy of excellence in industrial automation, Schneider Electric offers a diverse range of RTU solutions tailored to various industries, emphasizing reliability, scalability, and seamless integration.

Siemens: Renowned for its cutting-edge technologies, Siemens provides innovative RTU solutions characterized by advanced features, robustness, and compatibility with industry standards.

Emerson Electric Co.: Emerson's RTUs combine state-of-the-art technology with unparalleled reliability, offering comprehensive solutions for remote monitoring and control across diverse industrial sectors.

Honeywell International Inc.: Honeywell's RTU portfolio encompasses a wide spectrum of applications, emphasizing security, scalability, and ease of deployment, making it a preferred choice for critical infrastructure projects.

Rockwell Automation: Leveraging its expertise in automation and control systems, Rockwell Automation delivers high-performance RTU solutions optimized for seamless integration, reliability, and efficiency.

Emerging Trends and Future Outlook

As industries continue to embrace Industry 4.0 initiatives and IoT (Internet of Things) technologies, the future of RTUs appears promising. Key trends shaping the future of RTUs include:

Edge Computing: RTUs equipped with edge computing capabilities enable real-time data processing at the edge of the network, reducing latency and enhancing decision-making efficiency.

AI and Machine Learning Integration: Integration of AI (Artificial Intelligence) and machine learning algorithms into RTUs enables predictive maintenance, anomaly detection, and optimization of industrial processes.

Enhanced Cybersecurity Measures: RTU manufacturers are increasingly prioritizing cybersecurity, implementing robust encryption, authentication, and intrusion detection mechanisms to safeguard critical infrastructure from cyber threats.

Remote Asset Management: RTUs equipped with remote asset management features enable proactive monitoring, maintenance, and optimization of distributed assets, enhancing operational efficiency and minimizing downtime.

In conclusion, the realm of RTU suppliers and manufacturers is characterized by innovation, reliability, and a steadfast commitment to addressing the evolving needs of industries worldwide. By partnering with reputable suppliers and leveraging cutting-edge RTU solutions, industries can unlock new levels of efficiency, productivity, and competitiveness in an increasingly interconnected world.

0 notes

Text

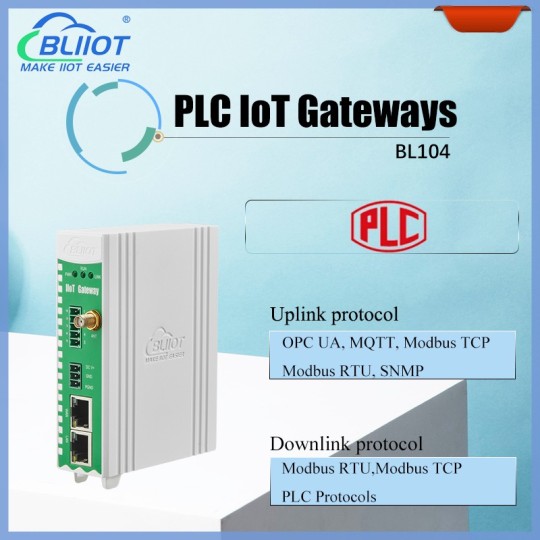

BLIIoT | New Multi-Protocol PLC Gateway BL104 Converts PLC to Cloud/Server for Remote Monitoring

Introduction

With the rapid development of Industry 4.0, it is deeply recognised that real-time, reliable and secure data transmission is crucial in industrial production and life. In this context, high-performance industrial automation PLC data transmission solutions - protocol conversion gateway came into being, widely used in industrial automation systems, PLC remote monitoring and IoT application environment.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT industrial PLC protocol gateways, which not only have excellent stability and anti-interference ability, but also explore the application of industry segments, aiming to bring users a new experience of industrial automation data acquisition and conversion.

Product Description

PLC Gateway BL104 is a specially developed for PLC connect MQTT and OPC UA system and remote PLC program uploading and downloading debugging.

The downlink protocol supports PLC protocols such as Mitsubishi, Siemens, Omron, Delta, Schneider, etc. and Modbus protocol.

The uplink protocol supports Modbus RTU, Modbus TCP, MQTT and OPC UA, access to Cloud, Server, SCADA, MES, ERP and other systems.

PLC Gateway BL104 hardware interfaces include 2 or 6 RS485/RS232 serial ports, 2 network ports and 1 WiFi wireless transmission interface, which realises seamless communication between PLC and OPC UA system.

The PLC gateway BL104 has an industrial-grade design to ensure reliability in harsh environments. BL104 is suitable for industrial automation systems, PLC remote monitoring and IoT applications.The PLC gateway BL104 connects to the future of the industry and provides users with a trusted, low-cost, stable and reliable PLC to Modbus, MQTT and OPC UA solution.

By using its own patented rail-clip technology, the installation process is simplified and the utility of the gateway is ensured.

Product features

Supported protocols: Downlink protocol: Modbus RTU, Modbus TCP, Mitsubishi, Siemens, Omron, Delta, Schneider and other mainstream PLC protocols.Uplink protocol: Modbus RTU, Modbus TCP, MQTT, SNMP and OPC UA.

Hardware interface: 6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.1*4G or WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need

Data security:Support data TSL/SSL, X.509 certificate, SNMPV1/V2, key encryption and other security gateway functions.

Remote Configuration Support: Support remote PLC programming and program uploading and downloading, saving travelling costs and improving service response speed. Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

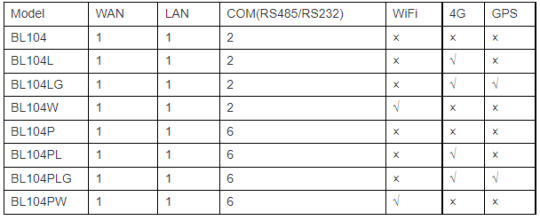

Model List

Application scenarios

Meet the needs of PLC protocol to Modbus MQTT OPC UA in industrial automation and industrial IoT scenarios.

More information about BLIIoT New PLC to Modbus MQTT OPC UA Gateway BL104: https://www.bliiot.com/industrial-iot-gateway-p00415p1.html

#PLC Gateway#Industrial Automation#IoT#Modbus#MQTT#OPC UA#SNMP#Siemens#Omron#Schneider#Delta#mitsubishi

0 notes

Text

IPCS Global [ kollam]

IPCS Global is a research-oriented and progressive approach that offers perfect automation solutions to a vast array of industries which include but are not confined to software, marine and construction engineering. Our Expertise is in Process Automation, Factory Automation, Machine Automation, CNC solutions, Building Management Systems, Energy Management, the Internet Of Things, Robotics, Industrial Calibration and testing, We have been providing industries with services ranging from proposing and installing to absolute commissioning of automated systems, completely adhering to industry standards. IPCS provides its customers with a plethora of products- HMI systems, Programmable Logic Controllers (PLCs), DCS systems, Supervisory Control and Data Acquisition (SCADA), drives, sensors, DCS systems and much more. Apart from all these, we conduct numerous training programs in corporate companies and also for professionals in the areas of PLC, SCADA, DCS, HMI, Drives, Panel Designing, Process Control, Electric Controls, Embedded, Robotics, Industrial Networking, Internet of Things, IT and Digital Marketing Industrial Networking.

1 note

·

View note

Text

Power SCADA Market Is Expected To See Huge Growth Globally By 2033

Market Definition

The Power SCADA (Supervisory Control and Data Acquisition) market is witnessing substantial growth driven by the increasing demand for efficient monitoring, control, and management of power generation, transmission, and distribution systems. This market involves the deployment of SCADA systems specifically designed for power utilities, enabling real-time data acquisition, remote monitoring, and control of power grids and substations.

To Know More: https://www.globalinsightservices.com/reports/power-scada-market

Market Outlook

The market outlook for the Power SCADA (Supervisory Control and Data Acquisition) sector remains optimistic and poised for continued expansion in the forthcoming years. Factors such as the increasing need for efficient power grid management, coupled with the rising adoption of smart grid technologies, are driving the demand for Power SCADA solutions. These systems enable real-time monitoring, control, and automation of power grids, enhancing reliability, reducing outage durations, and improving the overall efficiency of power distribution networks. Moreover, the integration of Power SCADA systems with advanced technologies such as IoT (Internet of Things), big data analytics, and AI (Artificial Intelligence) is revolutionizing grid operations, offering predictive insights, and facilitating proactive maintenance, thereby ensuring uninterrupted power supply and enhancing grid resilience. Additionally, the continuous advancements in SCADA technology, including cloud-based solutions, enhanced cybersecurity, and scalability, are expected to further drive market growth, providing utilities with robust tools to manage and optimize complex power systems.

Request Sample: https://www.globalinsightservices.com/request-sample/GIS20893

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization: https://www.globalinsightservices.com/request-customization/GIS20893

Market Segmentation

The segmentation of the industrial power supply market encompasses several key facets, including component type, power rating, end-use industry, and geography. Component types within this market involve transformers, switchgear, UPS (Uninterruptible Power Supply) systems, power converters, and others, each serving distinct functions in regulating and delivering power within industrial settings. Power rating categorization includes various power ranges tailored to different industrial needs, from low-power (below 5 kW) to high-power (above 2500 kW) systems, providing solutions for diverse scale operations. Segmentation by end-use industry covers manufacturing, energy, utilities, oil and gas, and others, each with specific power requirements and operational demands, thereby influencing the type of power supply solutions needed. Geographically, the market spans regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, where factors like infrastructure development, industrialization, energy demand, and regulatory norms influence the demand and growth of industrial power supply solutions within these areas.

Request Discounted Pricing: https://www.globalinsightservices.com/request-special-pricing/GIS20893

Major Players

The key players in the Global Power SCADA Market are ABB, Siemens, Emerson, Schneider Electric, Mitsubishi Electric, Honeywell, Yokogawa Electric Corporation, Rockwell Automation, PSI AG, Motorola Solutions

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS20893

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Digital marketing courses

IPCS Global Kollam

About our Company

IPCS Global is a modern and research-focused organization that provides ideal automation solutions to a wide range of industries, including but not limited to construction, software, and marine engineering. We have been offering industries services ranging from proposing and installing to absolute commissioning of automated systems, completely adhering to industry standards. Our expertise is in Process Automation, Factory Automation, Machine Automation, CNC solutions, Building Management Systems, Energy Management, the Internet of Things, Robotics, Industrial Calibration and Testing. HMI systems, DCS systems, Supervisory Control and Data Acquisition (SCADA), drives, sensors, PLCs, and many other devices are among the many offerings that IPCS offers to its clients.In addition to all of the above, we also provide a number of training courses for professionals in the fields of PLC, SCADA, DCS, HMI, Drives, Panel Designing, Process Control, Electric Controls, Embedded, Robotics, Industrial Networking, Internet of Things, IT, and Digital Marketing in corporate settings. Business Networking

IPCS began operations in 2008 in Kochi, the ancient port city of Kerala, India. It commenced off as a tiny business executing industrial automation projects for significant customers. Driven by the commitment we make to nurturing the youth and perceiving the need for trained individuals working in the automation industry.

Our Courses

DIGITAL MARKETING

Currently, Experts in digital marketing are constantly in great demand, and businesses continuously search for competent people to expand their businesses through the internet. The entire framework of this sophisticated digital advertising education program hinges on live sessions and project implementation in real time. The main selling point of this diploma program is that enrollment doesn't require a higher degree; all that's needed is a desire and interest in learning about the cutting edge of the digital world. Delivering a comprehensive three-month program in digital marketing has demonstrated its ability to develop exceptionally skilled candidates in this field. The benefit of individualized lesson plans and content will facilitate easy learning. One will differentiate themselves from the competition in the field of digital marketing by obtaining additional technical qualifications.

INDUSTRIAL AUTOMATION

The company IPCS Global is well-known for its proficiency in providing services and training pertaining to industrial automation. Recent technological innovations and patterns needed to compete in the exceedingly competitive fields of PLC, SCADA, DCS, HMI, VFD, Panel Design, and Electrical Controls are covered in our training programs. Our training programs are designed to be practically oriented, with an aim of training individuals and newcomers equally to allow them to surpass standards set by the industry. The list of programs that are specifically designed for professionals, industry experts, or beginners is provided below.

BUILDING MANAGEMENT SYSTEM

Due to the introduction of sophisticated automation technologies, the world is growing greener and wiser these days. Building management systems result in highly secure access, more efficient resource management, and ease of use from any location. The current generation of BMS systems is web enabled and built on open communication protocols, which enable global access and system integration from many system providers. With simply a click, a smart world controlled by large technology firms will be created through the internet of things. The incorrect design and implementation are caused by a shortage of skilled BMS technicians. The BMS industry is in need of proficient professionals who can fulfill all the necessary requirements.

CCTV & SECURITY SYSTEMS

Using its extensive industry expertise in the automation field, IPCS offers a range of training programs designed specifically for professionals, corporations, and educational institutions. IPCS offers a calm and engaging learning atmosphere that supports students' growth as leaders, professionals, and thinkers. In the fiercely competitive fields of automation and embedded technologies, our training programs offer the finest practices for the newest innovations, trends, and problems. Security system and CCTV training, security system and CCTV courses, and security system and CCTV institute.

CONTACT INFORMATION

Address: 1ST FLOOR,K&S TOWER,

Kadappakkada,

Kollam, Kerala - 691008.

Email: [email protected]

Phone: 7736661118

#digital marketing courses#Automation courses#CCTV courses in kochi#building management cousrses in kochi

0 notes