#Non woven bag printing machine

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

youtube

Fully Automatic Non Woven Paper bag Making Machine-Laxmi Enterprises

Fully Automatic Non Woven Carry bag Making Machine - International Traders Channel - #LaxmiEnterprises #Fully Automatic Non Woven Fully #Automatic Non Woven Carry bag Making Machine Non Woven Carry bag #Making #Machine Fully Automatic Non Woven #NonWoven #Youtube

#non woven machinery#non woven machine operator#non woven machine spare parts#non woven machine manufacturers in china#non woven machinery germany#non woven machine parts hs code#non fabric machine#non woven bags machine#non woven printing machine#non woven cutting machine#non woven bags machine price in delhi#non woven sealing machine#non woven bag machine manufacturer in ahmedabad#non woven bag machine price in kolkata#non woven stitching machine#non woven machine price#non woven fabric machine price in india#non woven printing machine 16x22#non woven carry bag machine price#non woven bag machine price in india#second hand non woven bag making machine#second hand non woven bag making machine in india#non woven fabric manufacturing machine price#non woven bag printing machine 4 colour#non woven bag machine for sale#used non woven machine for sale#non woven sealing machine for sale#non woven types#non woven methods#non woven uses

0 notes

Text

0 notes

Text

Non Woven Bag Making Machine in Patna: Arya Industries

Arya Industries is one of the leading provider of non woven bag making machine in Patna. Non-woven bag making machines have become an essential part of the packaging industry, thanks to their eco-friendly nature and cost-effectiveness. These machines are used to manufacture non-woven bags, which are made from spunbond non-woven fabric. Unlike traditional plastic bags, non-woven bags are biodegradable, reusable, and durable, making them an ideal choice for businesses and consumers who are conscious of environmental issues.

Non woven bag making machine in Patna operate on a relatively simple principle. They use a process called thermal bonding to fuse synthetic fibers together. The key components of a non-woven bag making machine include:

1. Raw Material Feeding Mechanism: This part of the machine is responsible for feeding the raw non-woven fabric into the machine. The fabric is typically supplied in rolls.

2. Printing Unit (Optional): Some non-woven bag making machines come equipped with a printing unit that allows businesses to print their logos or designs directly onto the bags.

3. Ultrasonic Sealing Unit: This unit employs ultrasonic technology to bond the edges of the fabric together, creating a strong seam.

4. Cutting Mechanism: Once the bags are sealed, they are cut into the desired shape and size by a cutting mechanism.

5. Handle Fixing Unit (Optional): In some machines, a handle-fixing unit is included to attach handles to the bags.

6. Collection Unit: Finally, the finished bags are collected and stacked for packaging and distribution.

Non-woven bag making machine in Patna offer a range of benefits that have contributed to their popularity:

1. Eco-Friendly: Non-woven bags are biodegradable and do not contribute to plastic pollution.

2. Cost-Effective: The production cost of non-woven bags is relatively low, making them an economical choice for businesses.

3. Durable: Non-woven bags are sturdy and can be reused multiple times, reducing the need for constant replacements.

4. Customizability: These machines can produce bags in various sizes and designs, making them suitable for a wide range of businesses.

5. High Production Capacity: Non-woven bag making machines are capable of producing a large number of bags in a relatively short period.

There are several types of non-woven bag making machines available in the market, catering to different production needs and budget constraints. The most common types include:

Automatic non woven bag making machine in Patna are highly efficient and require minimal human intervention. They can produce a large number of bags in a short time, making them suitable for businesses with high production demands. These machines often come with features like automatic tension control, computerized touch-screen operation, and integrated printing units for added convenience.

Semi-automatic machines offer a balance between automation and manual operation. While they require some manual input, such as feeding the fabric and removing the finished bags, they are still faster and more efficient than purely manual machines. They are often chosen by smaller businesses looking to scale up their production.

Manual non-woven bag making machine in Patna, as the name suggests, require full manual operation. They are suitable for businesses with limited production requirements or those just starting in the non-woven bag manufacturing industry. These machines are cost-effective and straightforward to operate.

Patna, the capital city of Bihar, has witnessed a significant increase in the use of non-woven bags in recent years. This shift is attributed to growing environmental awareness and regulations against single-use plastics. Businesses in Patna are adopting non woven bag making machine in Patna to produce eco-friendly bags that align with the changing consumer preferences.

Arya Industries, a prominent player in the manufacturing industry in Patna, has made remarkable strides in the field of non-woven bag making machines. Established with a commitment to environmental sustainability, Arya Industries has been at the forefront of providing high-quality non-woven bag making machines in Patna and beyond.

One of the notable offerings from Arya Industries in Patna is the manual non woven bag making machine in Patna. This machine is designed to cater to the needs of small to medium-sized businesses that are venturing into non-woven bag production. Here are some key features of Arya Industries' manual non-woven bag machine :

Affordability: The manual non woven bag machine in Patna by Arya Industries is budget-friendly, making it accessible to startups and smaller businesses.

Ease of Operation: This machine is designed for ease of use, with a user-friendly interface that requires minimal training.

Reliability: Arya Industries' machines are known for their durability and long service life, ensuring a stable production process.

Flexibility: The manual machine can produce a variety of bag sizes and designs, allowing businesses to cater to different customer preferences.

Support and Training: Arya Industries provides comprehensive support and training to its customers, ensuring they can operate the machine efficiently and troubleshoot any issues that may arise.

The use of non woven bag in Patna has had a positive impact on the environment. By reducing the consumption of traditional plastic bags, Patna has contributed to the following environmental benefits:

Non-woven bags are biodegradable and do not pose a threat to the environment when discarded. They do not clog waterways, harm wildlife, or create unsightly litter, which is a common problem associated with traditional plastic bags.

The production of non woven bag in Patna consumes fewer resources compared to plastic bags. These bags are made from synthetic fibers, and the manufacturing process is less resource-intensive, reducing the strain on natural resources.

Visit: https://www.aryaindustries.co/

0 notes

Text

Non woven fabric carry bag making machine price in india

Non-woven fabric carry bag making machines are essential equipment for manufacturing eco-friendly bags that are increasingly replacing traditional plastic bags. These machines enable the production of bags made from non-woven polypropylene fabric, which is durable, reusable, and recyclable.

Several factors influence the price of these machines in India:

Machine Capacity: The production capacity of the machine, measured in bags per minute or hour, significantly affects its price. Higher capacity machines capable of producing more bags per unit time usually come with a higher price tag.

Features and Specifications: Different models of bag making machines offer various features and specifications. Advanced features such as automatic feeding, cutting, and stitching mechanisms, as well as options for printing and customization, can increase the cost of the machine.

Brand and Manufacturer: Reputable brands with a track record of reliability and quality tend to offer machines at higher prices compared to lesser-known or generic brands. However, investing in a well-established brand can ensure better performance, durability, and after-sales support.

Technology and Innovation: Machines equipped with the latest technology and innovative features may command a premium price due to their enhanced efficiency, productivity, and ease of operation. These machines often offer improved energy efficiency and reduced downtime, resulting in long-term cost savings.

Supplier and Distribution Channels: Prices can vary between different suppliers and distributors based on factors such as overhead costs, profit margins, and geographical location. It's advisable to compare prices from multiple sources to ensure a competitive deal.

Additional Costs: Buyers should consider additional costs such as shipping, installation, training, and warranty when budgeting for a non-woven fabric carry bag making machine. These costs can significantly impact the overall investment required.

To obtain accurate pricing information, potential buyers should directly contact manufacturers, distributors, or suppliers of non-woven fabric carry bag making machines in India. They can request detailed quotations based on their specific requirements, including desired capacity, features, and customization options. Additionally, online research and comparison of prices on industrial machinery platforms and marketplaces can provide insights into prevailing market rates and available options. It's essential to factor in not just the initial purchase price but also the overall value, including maintenance, support, and the potential return on investment over the machine's lifespan.

Factory Address:

Gata No. 34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected]

Contact : 8800775462

0 notes

Text

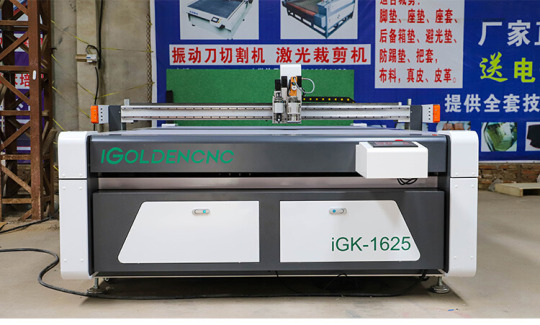

CNC Leather & Fabric Oscillating Knife Cutting Machine

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

An oscillating knife cutting machine, also known as a CNC oscillating knife cutter, is a specialized cutting tool used in various industries for precision cutting of a wide range of materials. It operates by rapidly moving a knife blade back and forth in an oscillating motion to cut through materials with high precision and minimal material waste. These machines are highly versatile and are used for cutting materials like fabrics, leather, foam, rubber, paper, cardboard, composites, and more.

A vibrating knife option is an important tool for companies that need to process flexible materials. These flexible materials include packaging foam, foam core, blender foam, corrugated plastic, or cardboard. These materials all pose challenges to traditional router planning or cutting tools, but the “saw action” of the oscillating knife makes it easy to cut these materials, providing a clean cutting edge without fraying.

Oscillating Knife Cutting Machine Advantages

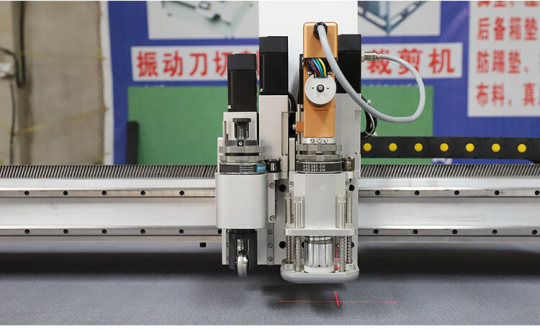

Knife Options: These machines can be equipped with various knife types, including straight blades, serrated blades, V-shaped blades, and more, depending on the specific material and cutting requirements.

Precision: Oscillating knife cutters offer high precision and can cut intricate shapes, patterns, and curves with sharp corners. This makes them well-suited for industries that require intricate or custom designs.

Software and Design: Design your cutting patterns using computer-aided design (CAD) or computer-aided manufacturing (CAM) software. The machine’s software then translates these designs into cutting paths.

Tool Control: Many oscillating knife cutters come with multiple toolheads, allowing for different tools to be used in one machine. For instance, you can use a knife for cutting, a creasing tool for scoring, or a pen for marking.

Depth and Speed Control: Adjust the cutting depth and cutting speed to match the material you’re working with. Different materials may require different settings for optimal results.

Material Hold-Down: These machines often use vacuum tables, conveyor systems, or other methods to hold down the material during cutting, ensuring precision and preventing material shift.

Applicable materials of oscillating knife cutting machine:

Oscillating knife machine is suitable for cutting various thin flexible materials. The digital cutting machine is designed for small batch production, which can save costs while maintaining speed and accuracy. This digital cutting machine is used in various industries such as packaging, printing, advertising display, leather processing, architectural modeling, composite materials, and tool modeling.

Leather,sticker,cardboard,Plastic box,corrugated cardboard,film,foam board,acrylic board,rebound rubber,rubber cloth,gasket material,garment cloth,footwear material,bags materials,non-woven fabrics,carpets,sponge,PU,EVA,XPE,PVC,PP,PE,PTFE,ETFE,and composites,whose thickness of above materials is below 22 mm.

Oscillating knife cutting machines are valuable tools for industries that require precision cutting of soft and semi-rigid materials. They offer efficiency, speed, and accuracy, making them suitable for both mass production and custom manufacturing. When used correctly, these machines can improve productivity and the quality of the final products.

CNC Knife Cutting Machines

Complementing other areas within our cutting machine range, the CNC knife cutting tables bring even greater versatility to the cutting process. These beautifully made, sophisticated machines are produced by one of the largest, specialized manufacturers of CNC cutting tables in the world. This total focus on innovative machines with very elegant software has culminated in a sophisticated range of CNC knife cutting machines which will cut an ever increasing range of materials at maximum speed with minimum waste.

This very wide range of flatbed cutting machines includes models with fixed beds and moving conveyors so that any material format – sheet, roll or a combination of both, can be processed. Ideal for short run, fast response working, these systems are also eminently suitable for full scale production as well as prototyping.

Add to this the large range of cutting tools that can be carried on the multi-tool cutting head – fixed blade, pizza wheel [rotary blade], electric or pneumatic oscillating blade, milling and routing, kiss cut, ultrasonic and pen – and the sheer versatility is clear.

Processing advantages

Automatic feeding system with intelligent correction function

This product uses a full-automatic feeding platform, which realizes the automatic work of feeding and cutting, saving labor costs. With the automatic deviation-feeding system, it can overcome the deformation problem of flexible materials in the printing or embroidery process, intelligently handle the deformation matching, and realize the automatic search Edge cutting.

Cutting tool without pollution

Compared with laser cutting, the cutting speed of the cutter is faster, no odor, and the cutting edge will not be carbonized. It is especially suitable for cutting intimate apparel such as swimwear and cycling clothes. Customers can also configure different types of tools according to the cutting material to meet the processing of different materials.

Automatic edge-finding and precise cutting

This product applies the industry’s advanced precise visual recognition algorithm and fine numerical control cutting technology. It searches and locates the graphic position through the vision system, controls the precise movement of the cutting head to the corresponding position, and automatically aligns and cuts along the edge with an error of less than 0.5MM.

Automatic operation saves costs

Fully-automatic feeding platform, continuous cutting, no special care required, easy operation; this product supports multiple layout methods, can achieve seamless stitching and cutting of the same graphic, reduce waste consumption; integrate its various high-quality functions, achieve faster speed, save material More and better performance. So as to reduce production costs and improve production efficiency.

0 notes

Text

Non-woven bag making machines are industrial machines used in the manufacturing of eco-friendly, durable, and reusable non-woven polypropylene (PP) bags. These machines are designed to produce bags without the use of weaving or knitting processes, making them cost-effective and environmentally friendly.

Features of a non-woven bag making machine:

Feeding Mechanism: These machines have a feeding system that takes the non-woven fabric rolls as input material. The fabric is typically made of spunbond non-woven polypropylene, a material known for its strength, durability, and recyclability.

Printing Unit (Optional): Some machines have an integrated printing unit that allows customization of the bags with logos, designs, or information as per customer requirements.

Ultrasonic Sealing/Cutting: Non-woven bag making machines use ultrasonic technology for sealing and cutting the fabric. This process ensures strong, neat seals without the need for thread or glue.

Handle Attachment: Some machines are equipped with systems to attach handles to the bags, whether through ultrasonic welding, punching, or other mechanisms.

Automatic Counting and Stacking: These machines often come with automatic counting and stacking systems to facilitate easy packaging and handling of the produced bags.

Speed and Efficiency: Non-woven bag making machines can produce bags at high speeds, ensuring efficient production to meet commercial demands.

For more details,

▪ Visit:- https://www.indiantradebird.com/

▪ Call:- +91 8511142701

0 notes

Text

Revolutionizing Eco-Friendly Packaging: The Non-Woven Bags Machine

In today's world, environmental consciousness has become a significant driver of consumer choices. People are increasingly aware of the impact of plastic on the environment, and this awareness has led to a surge in demand for eco-friendly packaging solutions. Non-woven bags have emerged as a sustainable alternative to traditional plastic bags, and the non-woven bag machine plays a pivotal role in their production.

The Non-Woven Bags Machine – A Technological Marvel

The production of non-woven bags requires advanced technology, and the non-woven bags machine is at the heart of this process. These machines are designed to efficiently manufacture non-woven bags at scale, making them a crucial tool for businesses looking to embrace sustainable packaging.

How the Non-Woven Bags Machine Works

The non-woven bags machine operates through a multi-step process that transforms raw materials into finished bags. The key steps include:

Material Feeding: The machine starts by feeding rolls of non-woven polypropylene fabric into the system. This material forms the basis of the bags and is available in various colors and thicknesses.

Printing: Some non-woven bags machines are equipped with printing units, allowing businesses to customize their bags with logos, branding, or other designs. This personalization adds value to the product and helps with brand recognition.

Ultrasonic Bonding: One of the critical processes in non-woven bag production is ultrasonic bonding. This technique fuses the layers of non-woven fabric together, creating a sturdy and durable bag without the need for traditional sewing or adhesives. Most non-woven bags machines use state-of-the-art techniques to work with efficiency.

Cutting and Shaping: Once the material is bonded, the machine cuts and shapes it into the desired bag size and style. Non-woven bags come in various shapes, such as tote bags, grocery bags, and promotional bags, and the machine can be configured accordingly.

Handle Attachment: If the design includes handles, the machine can attach them seamlessly. Handles can be made from the same non-woven material or added separately, depending on the design and strength requirements.

The Environmental Benefits of Non-Woven Bags

Non-woven bags are celebrated for their eco-friendly attributes. These bags are reusable, reducing the need for single-use plastic bags that often end up polluting oceans and landfills. They are also recyclable, which means that when they eventually reach the end of their life cycle, they can be repurposed into new non-woven products.

The non-woven bags machine represents a significant leap in sustainable packaging technology. It enables businesses to produce eco-friendly, customizable, and durable bags that not only meet the demands of environmentally conscious consumers but also provide economic advantages. As the world moves towards greener practices, the non-woven bags machine is a pivotal tool for businesses seeking to reduce their environmental impact while meeting the needs of their customers. Non-woven bags are more than just a packaging solution; they are a symbol of a commitment to a cleaner and more sustainable future.

0 notes

Text

Textile Machinery - Different Products For Various Textile Processes

Textile machinery is utilized in the processing of textiles, fabrics and all forms of woven and non-woven textile items. A list of these machines is used in many parts of textile manufacturing from spinning and weaving to dyeing and warping. There are also tools used in order to extrude plastic and synthetic fiber. Some natural fibers that go well with any of this equipment are wool, cotton and silk while artificial fibers like nylon, polypropylene and polyester benefit from these machines too.

Textile machinery is offered in the market as brand new items but there are also used ones that manufacturers may consider purchasing. These are available through Internet venues and other local equipment providers within a certain locale. Some of the most popular traders or dealers of these industrial products belong to associations like the Association of Machinery and Equipment Appraisers and American Textile Machinery Association.

In other countries, there are yet other organizations where these traders are linked to. Generally, no broderie textile matter what name the dealers are associated with, the following products are included in their product catalogue.

Machinery for sewing, garment and embroidery

Among a list of names in the textile equipment department, those in the sewing and embroidery processes are always sought after by textile industries. Popular machine names are sewing machines, garment cutting machines, embroidery machines, hemming machines and overlock machines. There are also very specific products like flat ironers, denim sewing machines and needle detector machines. There are those that deal with heavy fabrics, trimmings and button holes. In this department, all items gear to aspects of sewing, embroidery and garment manufacture.

Weaving machines

Weaving is also another important process in the textile industry that is why some of the best textile machinery is made for this particular endeavor. A company may choose from rapier looms, warping machines, water jet looms, carpet making machines and jacquards machine. Some other items in the brochure are beaming machines, sizing machines and needle looms. With each product name, one will be able to learn about its real function.

Other forms of machines for textile manufacturing

Dyeing is also catered to by a list of textile machinery. The continuous dyeing machine is included as well as the centrifugal hydro-extractors machine. Padders, jiggers and dosing machines are highly recommended for this part of the process. There are also items particularly made for knitting, spinning, laundry, printing and finishing. Some traders provide textile machines for footwear, bags and others for leather manufacture.

0 notes

Text

plastic carry bag manufacturers in vadodara

Koshambh specializes manufactures high-quality, fancy and eco-friendly plastic bags in large quantities. We offer different kinds of plastic carry bags and bags for packaging different agricultural foods and products in various colors, sizes, shapes, materials and prints as per your requirements. Equipped with innovative modern technology and infrastructure, we produce the best quality of carrying bags in bulks for every and any day usage at affordable prices. Also, our plastic products ate 100% Export Oriented Units.

We manufacture plastic bags using the best raw materials as per the type of polyethylene bags in the market. It includes High-density polyethylene (HDPE) Polypropylene (PP) Craftpaper and Non-Woven materials. Located in Halol and Manjusar, Vadodara, Gujarat, we produce 6050 metric tons of plastic bags a month. Our powerful extrusion machines and processes perfectly mix all the raw materials. Once the plastic strips are ready, we cut it in different sizes as per the customer’s requirements. The plastic bags are then strongly stitched to make sure it’s durable. The final part is printing, where we add colours and emboss branding and prints. We make sure we only give you the best quality bags so that one can carry everything and anything desire

Koshmabh understands that with a great manufacturing process comes greater responsibility. Plastic and plastic waste management is something that the world is fighting together to make our mother earth a better place for our future generations. As a leading exporter and manufacturer of the country, we also manufacture biodegradable and eco-friendly plastic bags that decompose easily and do not harm our environment.

Contact Us

For more detail - inquire us at +91 265 2334401

Mail to: [email protected]

Address

301-302, Gamthi Complex,

Opp. Productivity Council Productivity Road,

Alkapuri,

Vadodara - 390007

Gujarat

India

Inquire us your requirement

0 notes

Text

All about Woven Bag Printing

Woven bag printing is the process of printing custom designs, logos, or text onto woven polypropylene bags. These bags are commonly used for packaging and transporting goods such as grains, flour, fertilizer, and other bulk materials. Non Woven Bag

The printing process typically involves the use of specialized machines that can print high-quality images onto the bags. The bags are first prepared by being cut to the desired size and shape. Then, the bags are loaded onto the printing machine, where the design is applied using ink or dye.

There are several types of printing techniques that can be used for woven bag printing, including flexographic printing, gravure printing, and digital printing. Flexographic printing is the most commonly used technique for woven bag printing, as it is cost-effective and produces high-quality results. Non Woven Bag Printing

When designing a woven bag for printing, it is important to consider the bag's size, shape, and material. The design should be carefully planned to ensure that it is legible and visually appealing, while also providing any necessary information about the product being packaged.

Overall, woven bag printing is an effective way to customize packaging and promote brand awareness for a wide range of products.

View More - Non Woven Bag Supply

0 notes

Text

Non woven bags supplier in India

Tulip Fabrics Private Limited is the best non woven bags supplier in India. Tulip is the supplier of all types of non woven bags like D cut, W cut, U cut non woven bags, printed non woven bags, non woven shopping bags, promotional non woven bags, non woven advertising bags, customised printed non woven bags etc.

Tulip Fabrics Private Limited is one of the most premium Non Woven Fabrics Manufacturers in India. Tulip manufactures the best quality non woven fabrics with the help of efficient machines. These non woven fabrics are manufactured and supplied to the clients at a very reasonable and affordable price.

Tulip Fabrics Private Limited is also the most premium non woven rolls manufacturer in India. These non woven rolls require an enhanced mechanical strength. Non woven rolls of different hardness, porosity and elasticity are designed in Tulip. These non woven rolls have high applications in steel, aluminium, automotive and textile industries.

Tulip Fabrics Private Limited is the best non woven fabrics supplier in India. Tulip is supplying the best and the most premium quality non woven fabrics with the help of an efficient and effective labour base and productive machinery. Tulip has reached the highest level of customer satisfaction by being the best non woven bags manufacturer in India.

Tulip Fabrics Private Limited has proved to be the best non woven fabrics exporter in India. Tulip is exporting non woven fabrics of the best quality to different countries of the world. Tulip is the most successful in establishing itself in the global market. Tulip has exported a variety of non woven fabrics around the globe and has established as a renowned name worldwide.

#nonwovenbagsmanufacturerinindia#nonwovenbagssupplierinindia#nonwovenfabricsmanufacturerinindia#nonwovenrollsmanufacturer

0 notes

Text

Exploring the Latest Punching Machine Prices in India: A Comprehensive Guide for Buyers

Punching machines are an essential piece of equipment in many industries, including manufacturing, fabrication, and construction. These Non woven bag printing machine are used to punch holes, cut shapes, and create patterns in various materials, including metal, paper, and plastic. Punching machines come in various types, and each type has its unique features and benefits. In this article, we will explore the latest punching machine prices in India and provide a comprehensive guide for buyers.

Types of Punching Machines

There are different types of punching machines available in the Indian market, including:

Hydraulic Punching Machine: This type of machine uses hydraulic pressure to punch holes or cut shapes in materials. Hydraulic punching machines are ideal for heavy-duty punching tasks and can work with different types of materials.

Mechanical Punching Machine: This type of machine uses mechanical pressure to punch holes or cut shapes in materials. Mechanical punching machines are ideal for light to medium-duty punching tasks and are more affordable than hydraulic punching machines.

CNC Punching Machine: This type of machine uses computer numerical control (CNC) technology to punch holes or cut shapes in materials. CNC punching machines are ideal for high-precision punching tasks and can work with different types of materials.

Features and Benefits of Punching Machines

Punching machines come with various features and benefits, including:

Speed: Punching machines are designed to work fast and efficiently, making them ideal for mass production tasks.

Precision: Punching machines are designed to produce accurate and precise cuts and holes, ensuring the quality of the final product.

Versatility: Punching machines can work with different types of materials, including metal, paper, and plastic.

Safety: Punching machines are designed with safety features that protect the operator from accidents and injuries.

Punching Machine Prices in India

The prices of punching machines in India vary depending on the type, features, and specifications of the machine. The prices of hydraulic punching machines range from INR 3,50,000 to INR 10,00,000, while the prices of mechanical punching machines range from INR 1,50,000 to INR 4,00,000. The prices of CNC punching machines range from INR 10,00,000 to INR 30,00,000.

Factors to Consider When Buying a Punching Machine

When buying a punching machine, there are several factors to consider, including:

Type of Machine: The type of punching machine you choose should be based on your specific needs and the nature of the task you intend to perform.

Size and Capacity: The size and capacity of the punching machine should be suitable for your workspace and the materials you intend to work with.

Features and Specifications: The features and specifications of the punching machine should meet your requirements and match your budget.

Brand and Reputation: The brand and reputation of the manufacturer should be considered to ensure the quality and reliability of the punching machine.

Conclusion

Punching machines are essential equipment for various industries and come in different types and specifications. The prices of punching machines in India vary depending on the type and features of the machine. When buying a non woven bag printing machine manufacturer , buyers should consider the type of machine, size and capacity, features and specifications, brand and reputation, and budget. By following these guidelines, buyers can make informed decisions and choose the right punching machine for their specific needs.

0 notes

Text

Canada Hospitals and Clinics Market Pointing to Capture Largest Growth - 2030

https://theprose.com/post/714346/usa-industry-consulting-service-market-2023-latest-trending-industry-is-booming-globallyhttps://theprose.com/post/714348/europe-roads-and-highways-consulting-service-market-outlook-2023-size-players-cost-structureshttps://theprose.com/post/714351/usa-heating-coil-for-heat-treatment-market-report-pointing-to-capture-growth-2029https://theprose.com/post/714354/europe-metal-pallet-pooling-marketstatistics-industry-planning-structurehttps://theprose.com/post/714356/usa-transaction-monitoring-for-financial-services-market-2023-size-share-trends-growthhttps://theprose.com/post/714359/europe-transaction-monitoring-for-healthcare-market-future-scope-demands-2029https://theprose.com/post/714362/usa-non-woven-adhesives-for-adult-incontinence-market-to-witness-huge-growth-by-2029https://theprose.com/post/714364/usa-underground-brine-iodine-market-2029-growing-rapidly-with-latest-trendhttps://theprose.com/post/714367/europe-communication-networks-market-2023-demand-future-scopehttps://theprose.com/post/714370/usa-kiosk-printer-supplies-market-advancing-the-growth-globally-by-trendshttps://theprose.com/post/714380/europe-sliding-door-market-2023-overview-forecast-study-2029https://theprose.com/post/714375/europe-inkjet-coding-equipment-market-segmented-by-type-application-end-userhttps://theprose.com/post/714383/europe-carbon-steel-hole-saws-market-challenges-opportunities-size-sharehttps://theprose.com/post/714385/europe-hygienic-butterfly-valves-market-2023-booming-across-globe-by-segmentshttps://theprose.com/post/714386/usa-coreless-holding-furnaces-market-analysis-by-leading-manufacturers-2023-2029https://theprose.com/post/714387/europe-carbon-fiber-laminates-market-2023-2029-explained-effective-movementshttps://theprose.com/post/714390/usa-3d-printed-nanomaterials-market-hitting-new-heights-between-2023-2029https://theprose.com/post/714392/europe-dsl-tester-market-outlines-the-growth-factors-2029https://theprose.com/post/714393/usa-digital-resistivity-meters-market-2023-latest-trending-industry-is-booming-globallyhttps://theprose.com/post/714395/europe-ceramic-antennas-in-electronic-devices-market-outlook-2023-size-players-cost-structureshttps://theprose.com/post/714396/usa-automatic-liquid-filling-machines-market-report-pointing-to-capture-growth-2029https://theprose.com/post/714398/europe-fpc-antennas-marketstatistics-industry-planning-structurehttps://theprose.com/post/714400/usa-rugged-embedded-solutions-market-2023-size-share-trends-growthhttps://theprose.com/post/714402/europe-rugged-computer-systems-market-future-scope-demands-2029https://theprose.com/post/714404/usa-robotic-process-automation-in-finance-market-to-witness-huge-growth-by-2029https://theprose.com/post/714405/usa-semi-automatic-bagging-machines-market-2029-growing-rapidly-with-latest-trendhttps://theprose.com/post/714406/europe-inflatable-stand-up-paddle-board-market-2023-demand-future-scopehttps://theprose.com/post/714407/usa-electric-center-console-boats-market-advancing-the-growth-globally-by-trendshttps://theprose.com/post/714408/europe-airboats-market-2023-overview-forecast-study-2029https://theprose.com/post/714409/europe-electric-pontoon-boats-market-segmented-by-type-application-end-user

0 notes

Text

Non Woven Bag Making Machines in Patna: Arya Industries

Arya Industries has emerged as a leading provider of Non Woven Bag Making Machines in Patna, offering a diverse range of machinery solutions to support the growing demand for eco-friendly bags. With a relentless commitment to quality and innovation, Arya Industries has set new standards in the field of non-woven bag manufacturing equipment, making it a pioneer in Patna's industrial landscape.

The world is becoming increasingly aware of the detrimental effects of plastic pollution on the environment. Non-woven bags, made from spunbond or meltblown fabric, have emerged as a sustainable alternative. These bags are durable, reusable, and most importantly, biodegradable. Their eco-friendly nature has led to a surge in demand for non-woven bags, and businesses are looking for efficient and reliable machinery to produce them. Arya Industries has recognized this demand and has become a key player in providing Non Woven Bag Making Machines in Patna.

Arya Industries, headquartered in Patna, has carved a niche for itself in the manufacturing and supply of non-woven bag making machines. The company's mission is to revolutionize the way non-woven bags are produced, emphasizing innovation, quality, and sustainability. With a dedicated team of engineers, designers, and technicians, Arya Industries has consistently pushed the boundaries of technology to offer state-of-the-art machinery.

Arya Industries' flagship product is the Non Woven Bag Making Machine, designed to cater to the specific requirements of businesses in Patna and beyond. This machine is versatile and capable of producing a wide range of non-woven bags, from standard shopping bags to customized designs. Some of its key features include:

High Production Capacity: The machine is engineered for high-speed production, ensuring that businesses can meet their production targets efficiently.

Precision and Consistency: Arya Industries' machines are known for their precision in cutting, stitching, and printing, resulting in a consistent and professional final product.

User-Friendly: The machines are designed with user-friendliness in mind, making it easier for operators to work with them without extensive training.

Low Maintenance: Regular maintenance is minimal, reducing downtime and ensuring optimal performance over an extended period.

While automated machines have their advantages, Arya Industries also recognizes the need for more affordable and manual alternatives. The Manual Non-Woven Bag Machine in Patna offered by the company is an ideal choice for small-scale businesses or those looking for cost-effective options. This machine is designed to be simple, easy to operate, and highly durable.

Quality is a cornerstone of Arya Industries' philosophy. They understand that the success of their clients largely depends on the quality of the non-woven bags they produce. Therefore, they consistently invest in research and development to improve their machinery and stay ahead in the industry.

Quality Materials: Arya Industries uses high-grade materials to manufacture their machines, ensuring durability and reliability.

Stringent Testing: Every machine undergoes rigorous testing and quality checks to ensure it meets industry standards.

Customer Support: The company provides excellent after-sales support, assisting clients in case of any technical issues or inquiries.

Arya Industries is leading the way in the manufacturing of non woven bags in Patna. Their commitment to quality, sustainability, and customer success has earned them a prominent place in the industry. As the demand for eco-friendly alternatives to plastic bags continues to grow, Arya Industries remains dedicated to providing innovative and efficient solutions, revolutionizing the way non-woven bags are made in Patna and beyond.

Visit: https://www.aryaindustries.co/non-woven-bag-making-machine.php

0 notes

Text

THE STORY OF THE PLASTIC BAG

THE STORY OF THE PLASTIC BAG

We have examined the process of plastic bags in detail, from production to the end user, subsequently to the nature at the end. Plastic bags play an important role in our lives, with a good or bad grace. But these bags aren't as innocent as they look! In good old times we used to use paper bags, cloth bags or nets instead of plastic bags. Thus, people could stay healthier with what they ate and drank, so incidence of cancer cases was very low. But today, this has changed dramatically. Plastics, used in all areas of our lives, has entered our life by means of packaging and nylon bags. While plastic bags begin the production process at the factory, they first pass through the plastic raw material mixing machine. The raw material mixed in this machine is processed in a plastic film machine and becomes a film roll. Therefore, it is necessary to have a good film machine. However, many factories do not prefer the best quality film machine because they care about low costs. A printing press is required to print on the bag from the machine. The next step for the plastic bag coming out of the printing press is the cutting machine. Since a recycling machine is not used during these production stages, unnecessary and harmful substances may be added to the production process making the product both hard to dissolve in the nature and harmful for the individuals who use it in the long term.Get more news about oem laminated non woven bag,you can vist our website!

Perhaps it is not taken seriously, but plastic bags cause irreversible damage on the human body. Plastic bags, which can be manufactured very cheaply and can cause damage directly to the environment and nutrients compared to the price-quality balance, are exactly as harmful as what we think. In addition, a nylon plastic bag dissolves in 400 years in the sea and in 800 years on the land. Nylon bags are in use all over the world since the 80s, whereas it has become widespread in Turkey at the end of the 80s. Back then, it was preferred because it was so cheap, moreover it was considered as an indicator of civilization. On the other hand, some countries that put emphasis on nature and human health impose bans or apply taxes to minimize the use of plastic bags. For instance, in Mexico, India, Delhi, Mumbai and Vasco, the use of plastic bags is prohibited. On the other hand, some environmentalist municipalities in Bangladesh, Rwanda and Australia have banned the use of plastic bags in cities. In developed countries such as Switzerland, Sweden, Norway, Germany and the Netherlands, they are sold in cash. The nylon bags thrown into the sea are eaten by sea creatures, and this causes the death of their digestive system immediately. At the same time, nylon bags that are transparent absorb heat like a greenhouse and cause fires in forests. Black plastic bags do not only damage the soil but also give harm to people directly through vegetables and fruits. Nylon bags leave harmful chemicals in the environment when they start to become deformed in nature after years, and these substances contaminate the soil, water and our food chain. For this reason, plastic bags should not be used unless it is obliged to do so. It will be healthy for your health to use cloth bags, wheeled market bags, nets or baskets instead of plastic bags. By re-using the bowls used in shopping, you also save money. Apartment managers can also put recycling bins into apartment buildings and separate plastic wastes from other materials, thus preventing them from mixing with nature; they can even generate a small amount of financial income.

0 notes