#packaging industry

Text

Read About 9 Trendy Printing Techniques of Packaging Industry

#Business#Custom Boxes#Custom CBD Boxes#Custom Printed CBD Boxes#Packaging#Packaging Industry#Printing Techniques

4 notes

·

View notes

Text

Our high-quality boxes are the perfect way to make your cosmetic brand stand out on the shelf and leave a lasting impression. ✨

Plus, for a limited time, get 20% off your entire order of cosmetic boxes! Don't miss out on this chance to take your brand to the next level.

🌐 Place Your Order: https://rb.gy/ia3jry

☎️ Call Us Now: +1 (424) 478-6786

#packaging#designs#packaging solutions#print247us#print#packaging design#packaging industry#custom boxes#custom box printing#packagingideas

2 notes

·

View notes

Text

Unlocking the Potential: A Comprehensive Overview of the Printing Ink Market

Introduction:

The printing ink market is a crucial component of the printing industry, supporting various sectors such as packaging, publishing, commercial printing, and more. As technology continues to evolve and environmental concerns gain prominence, the printing ink market is experiencing significant shifts. This comprehensive overview delves into the key aspects shaping the printing ink market landscape.

Market Analysis:

The printing ink market is witnessing steady growth, driven by advancements in printing technology and the increasing demand for printed materials across industries. With the rise of digital printing, there is a growing need for high-quality, versatile printing inks compatible with diverse printing processes.

Industry Trends:

Several trends are influencing the printing ink market, including:

Shift Towards Digital Printing: Digital printing technologies are gaining traction due to their efficiency, customization capabilities, and reduced setup times. This trend is driving the demand for digital inks tailored for various substrates.

Sustainability: Environmental concerns are driving the development of eco-friendly printing inks formulated with renewable resources and fewer volatile organic compounds (VOCs). Manufacturers are focusing on sustainable ink formulations to meet regulatory requirements and consumer preferences.

Innovation: Continuous innovation in ink formulations is enhancing print quality, durability, and compatibility with different substrates. Nano-based inks, UV-curable inks, and specialty inks are among the innovations driving market growth.

Emerging Markets: Emerging economies are witnessing rapid industrialization and urbanization, leading to increased demand for printed materials across sectors such as packaging, textiles, and advertising. This presents lucrative opportunities for ink manufacturers to expand their presence in these regions.

Ink Types:

Printing inks are categorized based on their formulation and application, including:

Lithographic Inks: Used in offset printing for high-quality commercial printing applications such as magazines, catalogs, and brochures.

Flexographic Inks: Ideal for packaging printing due to their ability to adhere to various substrates and withstand the rigors of packaging processes.

Gravure Inks: Commonly used in high-speed printing processes for packaging materials, labels, and flexible packaging.

Digital Inks: Specifically designed for digital printing technologies such as inkjet and electrophotography, offering quick drying times and vibrant colors.

Market Size and Regional Analysis:

The printing ink market is geographically diverse, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific dominates the market due to the presence of major manufacturing hubs and the growing demand for printed packaging in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and sustainability initiatives.

Growth Drivers:

Key factors driving the growth of the printing ink market include:

Rise in Packaging Industry: The booming packaging industry, driven by e-commerce, food & beverage, and consumer goods sectors, is fueling the demand for high-quality printing inks for packaging applications.

Technological Advancements: Continuous innovation in printing technology, including digital printing and inkjet technology, is expanding the scope of applications for printing inks and driving market growth.

Increasing Demand for Customization: Consumers are increasingly seeking personalized and customized products, driving the need for printing solutions that offer flexibility and customization capabilities.

Conclusion:

The printing ink market is undergoing a transformation, driven by technological advancements, sustainability initiatives, and evolving consumer preferences. As the industry embraces digitalization and environmental consciousness, ink manufacturers are innovating to meet the demands of a dynamic market landscape. By staying abreast of industry trends and investing in research and development, stakeholders can unlock the full potential of the printing ink market.

#Printing Ink#Market Analysis#Industry Trends#Printing Technology#Ink Types#Growth Drivers#Market Size#Regional Analysis#Sustainability#Digital Printing#Packaging Industry#Environmental Regulations#Innovation#Emerging Markets

0 notes

Text

Discover how TeroTAM's CMMS system is boosting productivity in the Packaging Industry through strategic asset management and maintenance.

0 notes

Text

Polypropylene (pp) strapping rolls are preferred for strapping on fully automated packaging lines. They are a good substitute for steel straps and come in different sizes and thicknesses.

0 notes

Text

Unveiling the Importance of Corrugated Packaging Boxes

Explore the essential role of corrugated packaging boxes in safeguarding products and boosting brand credibility. Discover their numerous benefits now!

0 notes

Text

Lyka Global: Top quality RPET Sheets manufacturer & supplier in India

When it comes to sustainable packaging solutions, Lyka Global stands out as a premier manufacturer and supplier of top-quality RPET (Recycled Polyethylene Terephthalate) sheets in India. With a strong commitment to environmental responsibility and product excellence, Lyka Global offers a range of RPET sheets that meet the highest standards of quality, performance, and sustainability.

As a leading RPET sheets manufacturer, Lyka Global utilizes state-of-the-art manufacturing processes and cutting-edge technology to produce sheets that are not only eco-friendly but also durable and versatile. Made from recycled PET materials, Lyka Global's RPET sheets are a testament to the company's dedication to reducing plastic waste and promoting a circular economy.

Whether you're in the packaging, printing, or manufacturing industry, Lyka Global's RPET sheets offer a sustainable solution for a wide range of applications. From food packaging and consumer goods to signage and displays, these sheets provide the strength, clarity, and versatility you need to enhance your products and brands while minimizing your environmental footprint.

In addition to their exceptional quality, Lyka Global's RPET sheets are backed by a commitment to customer satisfaction and support. With a team of experts ready to assist you every step of the way, from product selection to customization and delivery, Lyka Global ensures a seamless experience for all your packaging and printing needs.

Choose Lyka Global as your trusted partner for high-quality RPET sheets in India and join the movement towards a more sustainable future. Together, we can make a positive impact on the environment while delivering superior products and solutions to meet the needs of today's consumers and businesses.

#rpet sheet#fruit packaging#high quality packaging#Packaging industry#PET sheets#Pharma & Medical Devices Packaging#Sustainable Packaging#sustainable solutions

1 note

·

View note

Text

Revolutionize your Label Printing : The Superiority of Narrow Web Flexographic Printing and WEBTECH'S Cutting-Edge Solution!

In the ever-evolving landscape of label printing, choosing the right technology is paramount for ensuring not just efficiency but also excellence in your end products. Today, we unravel the distinctive advantages of Narrow Web Flexographic Printing Machines over Offset and Gravure alternatives, and how Webtech's latest generation Flexo Label Press stands as a game-changer in this domain.

### 1. Precision in Flexibility : Narrow Web Flexo Printing Machines offer unmatched flexibility when it comes to substrate selection. Whether you're dealing with paper, film, or other specialty materials, the precision in handling diverse substrates provides label printers with a competitive edge. Webtech's Flexo Label Press takes this flexibility to the next level, accommodating a wide range of materials, ensuring you have the versatility needed for your varied label applications.

### 2. Cost-Effective Advantage : In the realm of label printing, cost-effectiveness is a critical factor. The setup costs of Narrow Web Flexo Printing are notably lower compared to Offset and Gravure alternatives, making it a financially savvy choice, especially for short to medium print runs. Webtech's latest Flexo Label Press optimizes this advantage, offering a seamless and cost-effective setup process for enhanced operational efficiency.

### 3. Speed, Productivity, and Precision : Webtech's advanced Flexo Label Press brings speed, productivity, and precision together. The press is engineered for high-speed label production, ensuring not only rapid turnaround times but also maintaining precision in every print. This competitive advantage over Offset and Gravure printing is a game-changer in meeting tight deadlines and delivering labels of superior quality.

### 4. Sustainable Printing Practices : The latest generation of Narrow Web Flexo Printing is aligned with growing environmental concerns. Webtech's Flexo Label Press integrates eco-friendly features, minimizing resource usage and waste generation. This commitment to sustainability resonates with the increasing demand for environmentally responsible printing practices.

### 5. Unparalleled Print Quality and Customization : Webtech's Flexo Label Press leverages cutting-edge technology to deliver unparalleled print quality. The servo-driven presses, advanced drying systems, and precise registration mechanisms ensure sharp and vibrant labels. This level of print quality, coupled with the press's capability for intricate customization, surpasses the limitations often encountered in Gravure and Offset printing.

### 6. Technological Innovation with Webtech's Flexo Label Press : Webtech's latest generation Flexo Label Press introduces innovative features that redefine label printing standards. From enhanced automation for streamlined workflows to intuitive controls for user-friendly operation, this press is designed to elevate your label printing experience. The incorporation of the latest technology ensures that you stay ahead in the competitive landscape of label manufacturing.

In conclusion, the decision to embrace Narrow Web Flexographic Printing, particularly with Webtech's cutting-edge Flexo Label Press, is a strategic move toward operational efficiency, cost-effectiveness, sustainability, and superior print quality. Stay ahead in the label printing game with technology that evolves with your needs.

Thank you for entrusting us with your time and attention and for joining us on this exploration of the world of label printing technology. Stay tuned for more insights and innovations in the dynamic field of printing machinery.

For further inquiries or a closer look at Webtech's Flexo Label Press, please feel free to contact our dedicated team.

Best Regards,

WEBTECH GROUP

www.webtechengg.com

#label printing#flexo innovation#packaging industry#PrintCraft Chronicles by Webtech#Packaging Labels

0 notes

Text

Packaging with Purpose: Insights into the Corrugated Packaging Market

People always want to have their goods delivered to them safely and rather quickly, whether they are brought from an online store or a brick and mortar one. It is very important to ensure that the goods are delivered, without any damage or spoilage. This is done with the help of corrugated packaging

Corrugated boxes are a more and more popular form of CPG packaging. It’s a tough, lucrative, and…

View On WordPress

#Cardboard Packaging#Corrugated Packaging#Customized Boxes#Eco-Friendly Containers#Market Insights#Market Players#market trends#Packaging Industry#packaging innovations#Packaging Solutions#Supply Chain Packaging#sustainable packaging

0 notes

Text

AUTOMATION IN DIWALI PACKAGING

कैसे करें दिवाली पैकेजिंग में ऑटोमेशन का उपयोग: समय और लेबर की बचत का तरीका"

"Harnessing Automation in Diwali Packaging: A Way to Save Time and Labor"

1. Diwali Packing for Automatic Machines

2. Saving Time

3. Labor Efficiency:

4. Smart Pack Diwali Packaging Machines

5. Improved Design and Branding Control:

6. Business Expansion Opportunities:

7. Ensuring Safety and Hygiene:

8. Reduced Environmental Impact:

9. Quality Control:

10. Financial Benefits:

Explain the benefits of automation in Diwali packaging processes for industries, including cost and time savings

Diwali, one of India's most celebrated festivals, is a time when people exchange gifts and share sweets with their loved ones. It's a time when the packaging industry experiences a flow in demand, but it also poses a significant challenge as it requires both time and labor-intensive efforts.

In this article, we will explore the advantages of incorporating automation into the Diwali packaging processes, highlighting how it can lead to substantial cost and time savings.

1. Diwali Packing for Automatic Machines:

One of the most efficient ways to streamline Diwali packaging is by utilizing automatic packaging machines. These machines, often referred to as "Diwali packing machines" or "Diwali sweet packing machines," are designed to package items such as sweets, gifts, and other Diwali essentials with speed and precision. Once set up, these machines can work autonomously, packaging a large volume of items quickly, thus saving both time and labor.

2. Saving Time:

Automation in Diwali packaging translates into significant time savings. When done manually, packaging each item requires careful counting and packaging, which can take hours. Automated machines can accomplish the same task in a matter of minutes, enabling you to prepare more packages in less time.

**3. Labor Efficiency:**

Utilizing Diwali packaging machines can lead to substantial labor savings. Manual packaging processes often require a large workforce to meet the high demand during the festive season. Automation reduces the need for human intervention, thus minimizing labor costs.

**4. Smart Pack Diwali Packaging Machines:**

Some advanced machines now fall under the category of "smart packaging machines." These machines incorporate sensors and IoT (Internet of Things) technology to enhance their functionality. By using data, you can manage your production process efficiently and make better use of your resources, ultimately aiding your packaging process in meeting its requirements more effectively.

**5. Improved Design and Branding Control:**

Automation allows for better control over the design and branding of your packaging. These machines can consistently produce packages with a professional and attractive appearance. This not only saves time but also ensures that your products are presented in the best possible way to attract customers.

**6. Business Expansion Opportunities:**

By automating your Diwali packaging process, you free up resources that can be redirected toward expanding your business. You can focus on aspects like distribution and marketing because the packaging workload is significantly reduced due to automation.

**7. Ensuring Safety and Hygiene:**

Safety and hygiene are of utmost importance during Diwali packaging, especially when handling food items like sweets. Automated machines can ensure high levels of hygiene and safety in the packaging process, instilling trust in your customers and maintaining the quality of your products.

Read More

#packaging machines sealing machines#packaging industry#packaging machinery#packaging machines#packaging#sealing machines

0 notes

Text

#oil proof paper#synthetic paper market#waterproof paper#synthetic paper#lamination for packaging#Packaging industry

0 notes

Text

We offer Upto 20% special discount if you require printing of various designs for product labels. make this in different way

Love it? Design your dream labels! DM or link in bio.

#packaging#designs#packaging solutions#print#print247us#packagingideas#packaging design#packaging industry#custom labels#my labels

0 notes

Text

Exploring the Polyvinyl Alcohol Films Market: Innovations, Trends, and Growth Opportunities

Introduction to Polyvinyl Alcohol Films

Polyvinyl alcohol (PVA) films have garnered significant attention in various industries owing to their versatile properties and eco-friendly nature. These films, derived from synthetic polymer polyvinyl alcohol, offer exceptional barrier properties, biodegradability, and flexibility, making them ideal for a wide range of applications. In this article, we delve into the dynamic landscape of the polyvinyl alcohol films market, exploring its trends, innovations, and growth prospects.

Growing Demand for Sustainable Packaging Solutions

The increasing awareness regarding environmental sustainability has fueled the demand for eco-friendly packaging materials. Polyvinyl alcohol films have emerged as a preferred choice for sustainable packaging solutions due to their biodegradability and compostability. With stringent regulations on single-use plastics and growing consumer preference for green packaging alternatives, the polyvinyl alcohol films market is witnessing substantial growth.

Expanding Applications in Food Packaging

One of the key applications of polyvinyl alcohol films is in food packaging. These films provide excellent barrier properties against moisture, oxygen, and aroma, thereby extending the shelf life of packaged food products. Moreover, their transparent nature enhances product visibility, making them ideal for packaging perishable goods such as fruits, vegetables, and meat. As food safety regulations become more stringent, the demand for high-quality packaging materials like PVA films is expected to rise further.

Innovations Driving Market Growth

The polyvinyl alcohol films market is characterized by continuous innovation aimed at enhancing product performance and expanding application scope. Manufacturers are investing in research and development activities to develop advanced PVA formulations with improved mechanical strength, heat resistance, and barrier properties. Furthermore, the incorporation of nanotechnology has opened up new possibilities in enhancing the functionality of polyvinyl alcohol films, such as antimicrobial properties and enhanced barrier performance.

Rising Demand in Pharmaceutical Packaging

In the pharmaceutical industry, polyvinyl alcohol films are gaining traction for packaging sensitive drugs and medical devices. These films offer excellent chemical resistance and compatibility with a wide range of pharmaceutical formulations, ensuring the integrity and stability of packaged products. Additionally, their non-toxic nature makes them suitable for direct contact with pharmaceuticals, complying with stringent regulatory requirements.

Download Sample Copy: https://shorturl.at/bwUZ1

Market Challenges and Opportunities

While the polyvinyl alcohol films market presents lucrative opportunities, it is not without its challenges. The high production costs associated with PVA films compared to conventional plastic films pose a barrier to market growth. Moreover, the availability of alternative biodegradable packaging materials adds to the competitive landscape. However, the increasing focus on sustainable development and the implementation of innovative manufacturing technologies present avenues for market players to overcome these challenges and capitalize on emerging opportunities.

#Polyvinyl Alcohol Films#Sustainable Packaging#Biodegradable Films#Food Packaging#Pharmaceutical Packaging#Environmental Sustainability#Innovation#Market Trends#Nanotechnology#Packaging Industry

0 notes

Text

Mailer Packaging: Market Dynamics, Innovations, and Future Potential

The global mailer packaging market size is expected to reach USD 76.48 billion by 2030. The increasing use of e-commerce for buying and selling products as the players operating in the industry offer easy transportation and home delivery services which save time and money for the end users are driving the market growth.

Gain deeper insights on the market and receive your free copy with TOC now @: Mailer Packaging Market Report

The growing demand for mailer packaging across the e-commerce industry for the packaging of varied products including apparel, jewelry, and books & stationery among others across the globe is driving the market growth. Furthermore, a continuously increasing number of online sellers as well as shoppers across the globe is fueling the demand for packaging mailers. The rapidly increasing marketing and advertisement expenditure of the e-commerce players such as Walmart, Amazon, eBay, and Shopsy among others is further supporting the market growth.

Non-cushioned mailers are leading the market and are also projected to maintain their dominance during the forecast timeframe from 2022 to 2030. The wider application portfolio of non-cushioned mailers as they are used for packaging apparel and textiles among others is contributing to the segmental dominance. Non-cushioned mailers are mostly made up of plastic materials as the material provides leakage-free and liquid-resistant transportation at a cheaper cost compared to paper mailers.

The increasing concerns associated with plastic usage in the packaging industry and its harmful impact on the environment are projected to limit the growth of plastic mailers during the forecast period. Additionally, the rising awareness about the sustainable alternatives of plastic mailers including paper mailers is further projected to restrict the growth of plastic mailers.

#Mailer Packaging#EcoFriendly Packaging#Sustainable Shipping#Packaging Solutions#Packaging Innovation#Ecommerce Packaging#Packaging Trends#Shipping Supplies#Logistics Solutions#Minimalist Packaging#Corrugated Packaging#Protective Packaging#Custom Packaging#Packaging Industry#Brand Packaging#Mailer Boxes#Shipping Sustainability#Packaging Efficiency#EcoPackaging

0 notes

Text

The Global Packaging Design Services Market Is Estimated to Witness High Growth Owing To a Shift towards Sustainable Packaging

The global packaging design services market is projected to be valued at US$ 24.63 billion in 2023 and is expected to exhibit a CAGR of 4% over the forecast period, according to a new report published by Coherent Market Insights. A) Market Overview: Packaging design services refer to the process of designing packaging materials and concepts that are visually appealing, functional, and meet the requirements of the product. These services play a crucial role in the marketing and branding strategies of companies, as attractive packaging can enhance product visibility and customer engagement. With a rising emphasis on product differentiation and branding, the demand for packaging design services is expected to grow significantly. Additionally, packaging design services help in improving product protection, convenience, and ensuring regulatory compliance. These factors are driving the adoption of packaging design services across various industries, including food and beverage, healthcare, beauty and personal care, and consumer goods. B) Market Key Trends: One key trend in the Packaging Design Services market is the shift towards sustainable packaging. With increasing consumer awareness about environmental issues, there is a growing demand for eco-friendly packaging solutions. Packaging design services are playing a vital role in developing sustainable packaging options that reduce waste and minimize the use of harmful materials. For example, companies are adopting reusable or biodegradable packaging materials, such as paper-based packaging, compostable plastics, and plant-based materials. These materials not only reduce the environmental impact but also enhance brand image and customer loyalty. Moreover, sustainable packaging designs are aesthetically appealing and can create a positive impression among consumers. C) PEST Analysis: - Political: Governments worldwide are implementing regulations to reduce plastic waste and promote sustainable packaging. This is driving companies to adopt eco-friendly packaging solutions. - Economic: The growing e-commerce industry is boosting the demand for innovative packaging designs that ensure product safety during shipping and handling. - Social: Consumers are becoming more conscious of sustainability and eco-friendly practices, leading to a higher demand for products packaged in environmentally friendly materials. - Technological: Advancements in technology, such as 3D printing and digital printing, are enabling packaging design services to offer more creative and customizable packaging solutions. D) Key Takeaways: - The global packaging design services market is expected to witness high growth, exhibiting a CAGR of 4% over the forecast period, due to increasing demand for visually appealing and sustainable packaging solutions. - North America is expected to dominate the market, driven by the presence of key players and the rising adoption of innovative packaging designs in the region. - Key players operating in the global packaging design services market include Schawk Inc. (SGK Inc.), Interbrand Corporation, Packaging Corporation of America (PCA), Tetra Pak International S.A., Amcor plc, Rieke Packaging Systems, Landaal Packaging Systems, Gerresheimer AG, TricorBraun Inc., Design Packaging Inc., Crown Holdings Inc., Berlin Packaging LLC, Kush Bottles Inc. (KushCo Holdings Inc.), PaperWorks Industries Inc., and The Freelance Portfolio. In conclusion, the global packaging design services market is experiencing significant growth due to the increasing demand for visually appealing and sustainable packaging solutions. The shift towards sustainable packaging is a key trend that is driving the market's growth. Governments' regulations, the growth of the e-commerce industry, changing consumer preferences, and technological advancements are shaping the market landscape. With North America leading the market, key players are focusing on innovative designs and materials to meet the evolving needs of the industry.

#coherent market insights#Packaging Industry#Packaging Design Services Market#Graphic Design#Branding

0 notes

Text

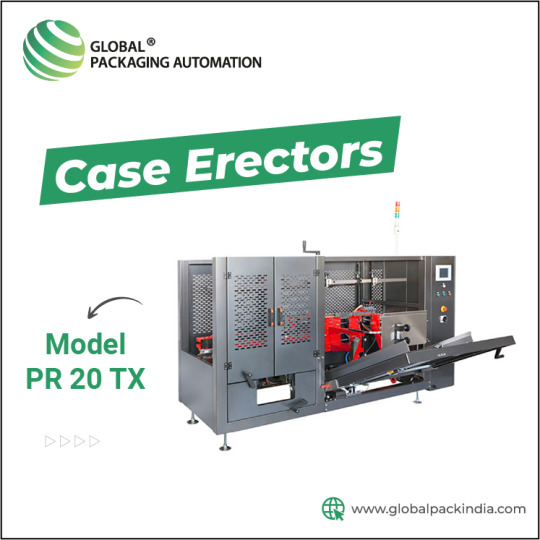

The PR 20TX is an automatic case erector machine. The machine is used for forming boxes from their collapsed corrugated form.

This machine is built for heavy usage and can achieve speeds of up to 12 boxes/min. The machine can also be customized as per your requirements of carton dimensions or tape size.

0 notes