#countersink hex

Text

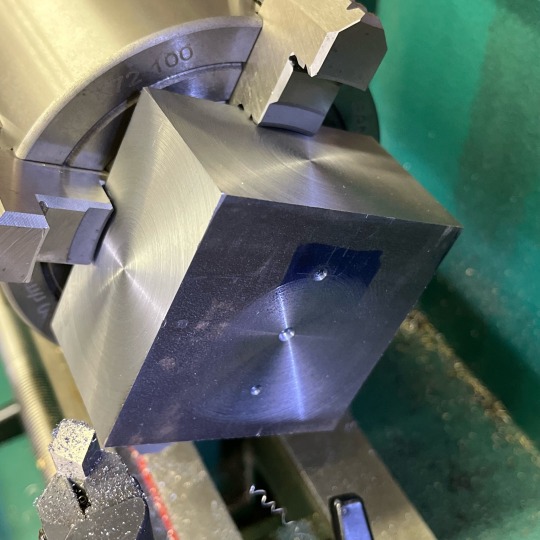

Finish cuts on that chunk of 1018 went well enough. Ended up lapping the top and bottom (1) for corrosion resistance, (2) to hone the surface characteristics in case I ever case harden or surface grind this, and (3) because I wanted to; the finish off the lathe was probably more than good enough, but eh. I don’t have a proper countersink for M6 socket head cap screws, so I reduced these heads to make what I have work.

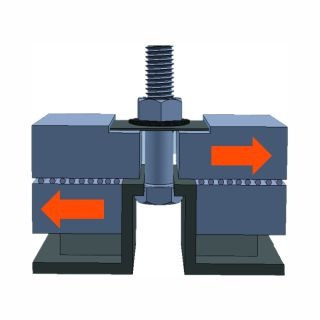

I did the same thing to the mounting screws on the milling adapter (below, left) way back when. Pictured here also (below, right) is the compound slide this’ll be partially replacing. The compound will still get use, certainly, but for most of what I do rigidity is at a premium and cutting tapers can be managed other ways. Especially since I finished the indicator holder/carriage stop, I expect this newest addition will get 80% of the workload.

I went through a lot of trouble to finish new brass gibs for that compound and lap the dovetails on both it and the cross slide last year. I’ve got pictures of the process, I think; still need to write that up. Should be easier now that it’s loose and easy to gesture at. Eventually.

Went ahead and primed and spray enameled the four vertical sides. More surface area for my dumb stupid fool idiot plan’s requisite accent painting, plus it means the headstock isn’t the only part of its color installed, plus it stands out less than turning marks.

For non-bearing surfaces that need semi-permanent protection, I tend toward bicycle chain lube. Hell of a lot cheaper than industrial corrosion prevention compounds, and for my relatively light use cases it’s fine. Good stuff in general — a little light waxy film goes a long way. It’s good for door hinges; passable for wooden and metal drawer slides; it’s a floor wax; it’s a dessert topping; if you can believe it, it does wonders for bike chains.

Cleaned the lathe itself and installed the thing before my giveashit went completely flat. Not gonna bother with test cuts yet, but soon enough. I’ll probably break it in by making some replacements for the plug screws in the headstock, knurling and all. Bit of a workout.

The mounting stud begs for an upgrade, for which task I’ve got a very clever (borrowed) scheme and a piece of 12L14 hex in the mail. That’ll be the real test of whatever rigidity gains I’ve won myself, but more on that when the time comes.

Had I a milling machine there’s a whole hell of a lot I’d have added to this design and executed differently — a corner to preload against, different mounting arrangement, some heavier side relief — but I can upgrade this upgrade down the line if the tooling arises. Good enough for the moment, I hope, and none of what I’ve done here precludes changes later.

22 notes

·

View notes

Text

Different Types of Screws, their uses and how to identify them

Introduction:

Fasteners are the unsung heroes of construction and DIY projects, providing the crucial link that holds everything together. Among these, screws play a pivotal role, and understanding the various types of screws and their applications is essential for any DIY enthusiast or professional. If you're new to measuring screws, you might want to start with this guide on how to measure a screw. Now, let's delve into the world of screws, exploring their different types, uses, and how to identify them. From wood screws to machine screws and beyond, let's demystify the intricacies of fasteners.

Anatomy of a Screw:

Before diving into the specific types, it's essential to understand the basic anatomy of a screw. A typical screw consists of three main parts:

Head: The top part of the screw, often designed for specific tools like screwdrivers or hex keys.

Shaft (Body): The cylindrical portion of the screw that penetrates the material.

Thread: The spiral groove along the shaft that provides grip and allows the screw to hold materials together.

Wood Screws:

Wood screws are perhaps the most common type, designed for use in wooden materials. They come in various sizes and designs, each serving a specific purpose:

Flat Head Wood Screws: Ideal for countersinking into wood surfaces, providing a flush finish.

Round Head Wood Screws: Known for their durability and resistance to pullout forces, suitable for heavy-duty applications.

Pan Head Wood Screws: Featuring a flat, rounded top with a slightly tapered bottom, offering a neat and clean appearance.

Wood Screw Sizes: Wood screws are available in different sizes, typically denoted by a gauge number. Understanding these sizes is crucial for selecting the right screw for your project.

Machine Screws:

Machine screws are designed for use with nuts or in pre-tapped holes in machine parts, making them versatile in a variety of applications:

Phillips Head Machine Screws: Commonly used in electronic and machinery applications, easily driven with a Phillips screwdriver.

Slotted Head Machine Screws: Traditional screws with a single groove on the head, requiring a flat-blade screwdriver.

Hex Head Machine Screws: Featuring a hexagonal-shaped head, these screws are tightened using a wrench or socket, providing a higher torque capability.

Machine Screw Sizes: Similar to wood screws, machine screws are also sized, with variations in length and diameter.

Specialty Screws:

Beyond wood and machine screws, there are numerous specialty screws tailored for specific applications:

Drywall Screws: Designed for attaching drywall to wooden or metal studs, featuring a coarse thread for better grip.

Deck Screws: Treated for outdoor use, resistant to corrosion, and designed for use in deck construction.

Self-Tapping Screws: Equipped with a cutting edge, eliminating the need for pre-drilling, suitable for various materials.

Sheet Metal Screws: Specifically designed for use in thin metal sheets, featuring sharp threads for easy penetration.

Identifying Screws:

Identifying screws is crucial for selecting the right one for the job. Consider the following aspects:

Head Type: Different screws have different head types, each serving a specific purpose. Recognizing these heads is the first step in identification.

Thread Pattern: The thread pattern varies between screws, affecting their holding power and application.

Material and Coating: Screws can be made of various materials and may have coatings for corrosion resistance.

Conclusion:

In conclusion, understanding the diverse world of screws is key to successful and secure construction and DIY projects. Whether you're working with wood, metal, or other materials, choosing the right screw for the job ensures a sturdy and reliable outcome. By demystifying the various types of screws, their uses, and how to identify them, you'll be better equipped to tackle any project that comes your way. So, next time you reach for a screw, do so with confidence, armed with the knowledge of a comprehensive guide to different types of screws.

1 note

·

View note

Text

Types of Screws and Their Uses

Screws are an essential component in various industries and everyday life. They come in different shapes, sizes, and materials, each designed for specific purposes. In this blog post, we will explore the different types of screws and their uses, helping you gain a better understanding of these tiny but mighty fasteners.

Introduction

Screws have been used for centuries, evolving from simple wooden pegs to the sophisticated fasteners we know today. They are versatile, reliable, and widely used in construction, manufacturing, and DIY projects. Understanding the various types of screws and their specific applications can save you time and effort when working on different projects.

Wood Screws

Wood screws are perhaps the most common type of screw. They have a tapered shaft and coarse threads that provide excellent grip in wooden materials. These screws come in different lengths and gauges, allowing them to be used in various woodworking applications. From furniture assembly to cabinetry and framing, wood screws are a go-to choice for joining wood pieces securely.

Machine Screws

Machine screws are designed to fit into pre-tapped holes or nuts. They have a uniform diameter along the entire length and are available in a wide range of sizes and head types. Machine screws are commonly used in metalworking projects, electronics, and machinery assembly. Their precise threading and compatibility with nuts make them ideal for creating strong and durable connections.

Sheet Metal Screws

As the name suggests, sheet metal screws are specifically designed for fastening metal sheets. They feature sharp self-tapping threads that can effortlessly penetrate thin metal surfaces. Sheet metal screws come in various lengths and head styles, including pan, flat, and hex heads. They are extensively used in HVAC installations, roofing, and automotive applications.

Drywall Screws

Drywall screws are specially designed for fastening drywall panels to wooden or metal studs. They have a bugle-shaped head that helps to countersink the screw into the drywall surface. The threads of drywall screws are spaced farther apart, allowing for quick and efficient installation. These screws are not suitable for load-bearing applications but are perfect for securing lightweight materials.

Self-Tapping Screws

Self-tapping screws are a versatile type of screw that can create their own threads when driven into a material. They are commonly used in plastic, metal, and wood applications. Self-tapping screws come in different styles, including flat, pan, and hex heads, catering to various project requirements. Their ability to create threads eliminates the need for pre-drilling, making them a convenient choice for quick installations.

Screws play a vital role in countless applications, holding things together and ensuring structural integrity. By understanding the different types of screws and their specific uses, you can choose the right fastener for your projects, ensuring a secure and long-lasting result. Whether you're a professional tradesperson or a DIY enthusiast, having knowledge about screws empowers you to tackle various tasks with confidence.

So, the next time you embark on a woodworking project, assemble furniture, or work with metal sheets, remember to select the appropriate screw type to achieve the best results. Happy fastening!

0 notes

Text

Essential Tools Needed for Garage Door Installation

Garage door installation is a big job, and it pays to be prepared with the right tools. You don't want to start the job only to find out you're missing a key tool or part. Fortunately, if you have a basic tool kit at home, you may already have the essential tools needed for garage door installation; otherwise, you’ll need to rent or purchase them. This may include a drill, level, stud finder, pliers, measuring tape, torque wrench, and a variety of screwdrivers. Additionally, you may need wedges, clamps, a hacksaw, and a variety of other items to help you install the garage door properly. If you're uncertain if you have the right tools, you can call a professional and ask what you'll need before starting the job.

Basic Hand Tools

Hand tools are essential for any DIYer or home handyman or handywoman, as they are the tools you use most often when making repairs or working on projects around the house. The most basic tools will include a hammer, a screwdriver, some pliers, a set of wrenches, an adjustable wrench, and a pair of scissors or snips. A set of tool boxes, a sorting tray, and a first aid kit are also necessary for any tool kit. Hand saws, levels and a handsaw are also necessary for any serious DIY project. Additionally, a screwdriver set, drill bits, and hex keys are also important pieces of hand tools. When beginning any DIY project, it is important to have the appropriate hand tools, as they are the foundation of any work you may do around the house.

Measuring Tape

Measuring is necessary for many DIY projects around the house and a quality measuring tape is essential. Measuring tapes have come a long way since they were first invented. They are now made from durable yet lightweight materials for easy portability, are accurate and offer modern features such as locking mechanisms, metric and imperial measurements, and outstanding accuracy. When using a measuring tape, it is important to keep the measuring tape as perpendicular to the surface as possible. It should be firmly pressed to the surface to avoid any inaccuracies in the measurements.

Electric Drills

Electric drills are a must for any DIY project, as they provide the power and precision for skillful work. A good drill should have enough power for the task at hand, be comfortable for extended use, and have the ability to handle different bits and attachments. Drills are an important part of any handyman's toolkit, as they are the key to drilling, driving, countersinking, sanding, polishing, ripping, and more.

Ladders and Step Stools

Ladders and step stools are essential tools for any home handyman or handywoman. A good ladder should provide a stable base, have an additional stabilizing bar for extra support, and should be adjustable to fit different requirements. A step stool should provide enough stability and traction to allow the user to reach higher, and also be lightweight enough to carry around. safety should also be considered, as ladders and step stools can be at risk for slips and falls.

Safety Gear

Safety gear is essential for any handyman or handywoman. Safety gear such as gloves, protective eyewear, hard hats, and steel-toed boots should be worn when working around the house and should always be the first thing you grab when beginning your project. It is also important to have a first aid kit on hand in case of any accidents that may occur.

Socket and Wrench Sets

Socket and wrench sets are important tools that are necessary for a variety of projects. Most sets include multiple sizes of sockets and wrenches, including hex keys, as well as adapters and extensions. It is important to pick the right set for the job, as each set will provide different sizes of sockets and wrenches.

Garage Door and Parts

Garage doors are essential to keep your home secure and provide access to the outside. When something goes wrong with a garage door, it can be difficult to deal with it, so having the right tools on hand is key. A garage door opener kit, screwdriver, adjustable wrench, hammer, chisels, drill bits, and a lubricant are all necessary for most repairs. It is important to be cautious when dealing with garage doors and parts, as some of these parts may be under tension and can be dangerous.

Conclusion

In conclusion, essential tools for garage door installation consist of an adjustable wrench, socket extensions, a socket driver, wire strippers, level and tape measure, a drill, and drill bit set. It is important to ensure that these tools are all the correct sizes and of good quality to guarantee that the garage door installation goes smoothly. Having the proper tools on hand makes the process of installing a garage door much easier, and with the right care and maintenance, these tools will last you for years to come.

0 notes

Text

Stranded in bittercold without food or drink...

Though the following

twittering scenario quite absurd,

methought diehard adherents of mine

(intimation also quite far-fetched),

some unnamed readers insomnia

nevertheless could benefit courtesy

a thought provoking tweet

east of Eden heard.

Dire straits necessitated

yours truly to be atypical and think

outside the box (literally outdoors

of squarish structured nested dwelling),

where blinding albedo effect

forced me to blink,

additionally also ruffled tail feathers

of this sole surviving male bobolink

(North American songbird,

Dolichonyx oryzivorus)

pushing survival species

to extinction brink,

thus series of unfortunate events

woke resident chewink

(North American bird,

Pipilo erythrophthalmus

also called: towhee

or ground-robin),

tweeted from within

his cozy armoire chink

polar vortex froze habitat,

whereby arctic wind found

brushy areas to clink

unwittingly brambles ferocious

waving circular rotation

wrought minuscule countersink

eh, no bigger than a cufflink

his ornate bejeweled complex edifice

compliments of sizable income

allowed, enabled, and provided

opportunity in tandem

with significant other

to create acronym named DINK

(dual income no kid)

acquiring handsome combined income

rendering and selling stylized goldfinch

also known as distelfink

common motif in

hex signs and fraktur,

which interpretive native folk art

eye state meaningless

without rhyme nor reason,

superfluous gibberish by George,

and/or...well... courtesy

following purposeless gobbledygook

defying poetaster to incorporate doublethink

intelligently nsync with downlink

playfully, jauntily, and deliberately

creating confounding badinage eye wink

at thee, no doubt many

an anonymous innocent

reader calling me rat fink

(Ed “Big Daddy” Roth's child)

under their breath or more

colorful brutal appellation

inducing cheeks of unknown followers

turning fifty plus shades of firepink

moost definitely concurring gink

perfectly apropos description

concluded individually versus

collectively, quickly, and

unanimously i.e. (think) groupthink

I approve this entire message, which

most likely tinders pet peeve,

concluding GoDaddy

go tell Aunt Rhody

yours wittily, truly,

quirkily, nervously, jokingly

attempted to hoodwink.

0 notes

Photo

Prototype #4 for the Desk Castor Bracket. Note I've changed the through bolt from M10 to M8 (which may still be overkill). Also flipped the M4 fasteners, so no longer need the Hex countersink, but just a circular sink for the cap screws. Also, hard to spot but the uprights are thinner too. Now just waiting for delivery of the nuts and bolts and I'll print off the final four and complete this project. . . #3DPrinter #3DPrintADay #crealityender3v2 #livingrocks #nokillswitch https://www.instagram.com/p/Cgt3wZmvVps/?igshid=NGJjMDIxMWI=

0 notes

Text

The Common Type of Fastening Tools You Should Know About

Fasteners are crucial when it comes to the construction of all kinds. If you are searching for industrial bolting project solutions, you would likely have heard of fasteners being tightened or assembled with the use of a torque wrench and even used them to complete the job at hand. But before we jump into the most common types of fastening tools that you should know about, let us check out what fasteners actually are.

What Are Fasteners?

Fasteners encompass a broad category of tools such as nuts and bolts, screws, washers, hydraulic nuts etc. that are used in different industries for a purpose i.e. to hold objects together mechanically. Although super strong glue, welding and similar things can fulfill the same purpose, glue is not one of those types of fasteners. Hence, to add to the earlier definition, fasteners consist of hardware that holds objects together mechanically.

It is noteworthy that fasteners typically form a non-permanent joint. To put it simply, fasteners connect two components and can be removed to separate the pieces without them going through any kind of damage. For instance, the same would not happen with welded joints. The only exception to this rule is a rivet which is a fastener, but it creates permanent joints.

Although fasteners form non-permanent joints, they are not used only when you would like to take things apart. In the same vein, this does not mean that the joint in question is by any means weak. Fasteners can hold objects together in a reliable manner without putting them under a lot of stress. This makes them a great alternative for permanent as well as non-permanent joints, offering versatility for all kinds of projects.

Most Common Types of Fasteners

Screws

Screws are essentially the first type of tool that comes to mind when one thinks of fastening tools. Screw fasteners are super versatile as their threaded shafts allow them to have durable holding power. Moreover, unlike a bolt, screws do not demand anything to stay in place. A drill is typically used to create a pilot hole in a specific material, and then a screwdriver is used to put the screw in its place. It is noteworthy that screws come in several sizes and types. Some of the common types of screws are as follows:

Wood screws have a tapered head and coarse threads.

MDF screws do not split the material because they can self-tap.

Deck screws are quite similar to wood screws. However, they are corrosion resistant and include self-tapping designs for outdoor applications.

Masonry screws come with a flat tip. Moreover, they usually have a hex-head design.

Drywall screws have a self-tapping head. Hence, they can easily countersink, avoiding any damage to drywall.

Machine screws do not taper off and feature a uniform thickness.

Sheet metal screws come in sharper threads so that they can connect metal to different materials.

Nails

One tool that has stood the test of time and has been used for centuries is nails. Nails are an everyday household item and can easily be identified because they do not have any threading. Although a nail does not really provide the strong holding power of a screw, it definitely has higher shear strength. This makes it a better alternative for some projects. Several types of nails derive their names from the specific applications they are used for. This makes it easy to choose the right nail for a particular job.

Washers, Bolts & Nuts

Washer, bolts, and nuts are other types of common fasteners. Nuts and bolts work with each other in order to hold the components of an object together by using a torque wrench. The bolts are inserted through the parts that you wish to combine. They are then fastened at the end using a nut. Bolts and nuts can function by themselves, but they are sometimes combined with a washer in between them. Washers are flat discs that have an opening in the center. A washer can contribute towards distributing a load of a fastener more evenly across a material’s surface.

Anchors

Anchors are called by this name because their purpose is similar to that of an anchor of a boat that embeds itself into the bed of the sea in order to hold a ship in place. People generally use anchors to connect an item to another material like concrete or drywall. They hold the object by embedding themselves in a specific material, thus affixing the object in place.

Rivets

Rivets create permanent joints between two different objects. They include a cylindrical shaft and a tail on both ends. The tail can be expanded using a unique tool to ensure that the rivet stays in place. Moreover, rivets are extremely durable as far as fastening tools go.

Wrapping Up

These are some of the most common types of fastening tools you should know about for your projects. So, the next time you work on a maintenance or assembly project, you will know which fastener to use for which application.

Content Sources :- ABSGroup

0 notes

Video

Titanium Combination Drill Tap Bit Screw Tapping #drillbit #tool #Manufacturer Titanium Combination Drill taps are made of HSS , which can ensure sharp, fast execution and retain strength and efficiency. The surface is treated with a titanium alloy, which greatly improves the cutting performance of the drill, is more wear-resistant and prolongs the service life. Three in one operation provides hole drilling, tapping, deburring and countersinking for a quick and complete job on copper, brass, aluminum, sheet metal and plastic It has high versatility. Each tap drill is engraved with a label, which is convenient for you to choose the size that suits you. The convenient ¼-inch (6.35mm) quick change hex shank has a tapered end to prevent excessive knocks. Back taper exceeds the tap to prevent over-drilling and damage to the thread. Storage case is lightweight and durable for easy storage and is portable for all job environments https://www.instagram.com/p/CUHpJk2FIHV/?utm_medium=tumblr

0 notes

Photo

R$ 42,41 7%de desconto | Binoax 6 pçs titânio hss combinação broca torneira bit countersink hex shank M3-M10 https://a.aliexpress.com/_mr7haJL https://www.instagram.com/p/CQpl87Ng_c_/?utm_medium=tumblr

0 notes

Text

Generic 3Pcs 12mm 16mm 19mm 1/4" Hex Shank Wood Plastic Chamfer Bit Drill Bit Tools Countersink Bore Set Wholesale

Generic 3Pcs 12mm 16mm 19mm 1/4″ Hex Shank Wood Plastic Chamfer Bit Drill Bit Tools Countersink Bore Set Wholesale

Price: (as of – Details)

1X Generic 19mm : New 1pc Drill Bits Hinge Open Hole Drill Professional Forstner Wood Working Hole Saw Wood Cutter 15-60mm Multi

Brand Name: JETTING, Type: Countersink Drill Bit, DIY Supplies: WoodworkingModel Number: Hex Countersink Boring Set, Material: Other, Use: Wood Drilling1X Generic 3Pcs 12mm 16mm 19mm 1/4″ Hex Shank Wood Plastic Chamfer Bit Drill Bit Tools…

View On WordPress

0 notes

Photo

✨ Slide New 4/5pcs set Woodworking Countersink Drill Bit Set 1/4 Quick change Hex Shank Screw Carpe

0 notes

Text

Rocaris 23-Pack Woodworking Chamfer Drilling Tool, 6pcs 1/4" Hex 5 Flute 90 Degree Countersink Drill Bits, 7pcs Three Pointed Countersink Drill Bit with L-wrench, 8PCS Wood Plug cutter, and Automatic

Your Online Shopping center at

[Read More ...]

woodworking

* This article was originally published hereCheck us out at https://healthproductsshopping.blogspot.com

source https://healthproductsshopping.blogspot.com/2021/01/rocaris-23-pack-woodworking-chamfer.html

source https://marianrmonaco.blogspot.com/2021/01/rocaris-23-pack-woodworking-chamfer.html

0 notes

Text

Rocaris 23-Pack Woodworking Chamfer Drilling Tool, 6pcs 1/4" Hex 5 Flute 90 Degree Countersink Drill Bits, 7pcs Three Pointed Countersink Drill Bit with L-wrench, 8PCS Wood Plug cutter, and Automatic

Your Online Shopping center at

[Read More ...]

woodworking

* This article was originally published hereCheck us out at https://healthproductsshopping.blogspot.com

source https://healthproductsshopping.blogspot.com/2021/01/rocaris-23-pack-woodworking-chamfer.html

0 notes