#cnc machine company

Text

How Can JGW Machine Help in Scaling Your Business?

Scaling a business can be a challenging task, especially when it comes to manufacturing. Contracting your metal manufacturing can offer many benefits to businesses looking to scale up their operations. Now the question is: how can we help?

Customization and Flexibility

Metal manufacturing allows for customization and flexibility in the production process. Manufacturers can tailor their products to meet the specific needs of their customers. This is important for businesses looking to scale up as they can create unique products that differentiate them from their competitors. Visit us here: “JGW Machine Limited”.

Cost-Effective Production

Metal manufacturing is a cost-effective way to produce goods at scale. This is due to the economies of scale that are achieved when producing larger quantities of products. Additionally, metal is a durable material that can be reused and recycled, reducing waste and production costs.

High-Quality Products

Metal manufacturing produces high-quality products that are strong and durable. This is important for businesses looking to scale up as they need to ensure their products are of a high standard and can withstand heavy usage.

Speed and Efficiency

Metal manufacturing processes are generally faster and more efficient than other manufacturing methods. This means that businesses can produce more products in less time, allowing them to meet the demands of their customers and scale up their operations quickly.

Versatility

Metal manufacturing is versatile and can be used to produce a wide range of products, from small components to large structures. This means that businesses can expand their product range as they scale up, allowing them to target new markets and customers.

Automation and Robotics

Metal manufacturing is an industry that has embraced automation and robotics. This means that businesses can automate many of their production processes, reducing costs and increasing efficiency. This is particularly useful for businesses looking to scale up as they can increase production without increasing their workforce.

If you are looking to scale your business and need a contract metal manufacturer, JGW Machine is here to help.

0 notes

Text

Using CNC Machining Process To Manufacture Customized Products

CNC (computer numerical control) machining now provides more adaptability. Machines are used to create smaller and more intricate components since there are more dimensions and machine kinds accessible. The industrial business has only advanced thanks to the growth of CNC machining. CNC machines are used to manufacture toys, home furnishings, medical equipment, automobiles, and other goods. Metal fabrication is a flexible and cost-effective production technique. Several materials may be utilized with this technique. Therefore, CNC Machining Manufacturing is beneficial for a variety of businesses and uses. Various methods are employed by manufacturers and machinists to complete this operation. It encompasses production that occurs directly, indirectly, or concurrently.

How CNC Machining Is Done

The size of the material being utilized has to be calculated and programmed. This prevents the bit from straying too far from the material or missing it entirely. Instead of asking you to manually enter each measurement and curvature code, computers like Aspire can do it.

Programming has the benefit of allowing machines to save codes so they may continue accurately mass-producing items.

For setup, the centre of the material must be located. Create an "X" with a sharp razor from one corner to the next to identify the centre of a square or rectangular item. The material must next be flattened and securely fixed on the CNC table.

Ways Manufacturing Is Being Improved Via CNC Machining.

Sustainability- The technique produces less waste since it doesn't need as many extra materials. Additionally, it is less likely to make mistakes, which prevents the need to discard supplies and components and lose valuable manufacturing time.

Convenience: Automated performance moves more quickly than labour done by humans. Additionally reducing human mistakes, automated production is available all days of the week. You can unwind knowing that CNC Machining Manufacturing won't take the place of your personnel but rather will empower them and make their jobs more fun.

Fewer processes: The key components of controlling a CNC machine are computers & technology. Another advantage of such tech is that practically all production processes may be completed by it without the need for extra personnel.

Manufacturers employ subtractive processes throughout the CNC machining process to create bespoke components by removing a workpiece's or blank's material layers. Machining prototypes can help you better understand the product and prevent mistakes from occurring later in the production process. CNC Machine Company has made prototyping more affordable and accessible. The development of more complete designs is made possible by the new technology, which simplifies production. Despite being subtractive, the CNC machining method excels at manufacturing products with superb surface qualities.

The CNC Machine Company remarkable abilities in the processing of metal components are a result of RPWORLD significant experience in the processing of plastics. Using dozens of CNC machines, they can handle a wide range of goods and parts made of various materials.

1 note

·

View note

Text

Premier CNC Machining Services: Precision Engineering at its Finest

Need high-quality, precision-machined parts in Dubai? Our expert CNC machining services deliver exceptional results for all your engineering needs.

0 notes

Text

📦Unlocking Business Opportunities: ARRK’s Comprehensive Services📦

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

📈About ARRK: Get the best Product Development Services 📈

ARRK is a global company offering comprehensive product development services from design, and prototype to production. Our innovative technologies and engineering expertise help our customers deliver the highest quality products to the market.

ARRK offers a wide range of services aimed at supporting businesses in bringing their products from conception to market. These services include:

3D PRINTING

Our 3D printing service and additive manufacturing solutions cover any requirement with the help of advanced technology and a variety of high-quality materials, as well as our signature design and engineering expertise. Our capability is a prototype ready for evaluation or production, and the differentiation relies on the various processes we manage.

VACUUM CASTING

Easily reproduce your design with the vacuum casting process by using a 3D printed or machined master to create RTV silicone rubber molds. This is a cost-effective solution with consistent prototypes, be it in small quantities or in the region of hundreds.

CNC MACHINING

Computer Numerical Control (CNC) machining is when software controls machinery to make precision cuts by removing material from a workpiece to create unique parts. Plastic and metal components can be prototyped or produced with our medium or low-volume CNC machining

MICROWAVE MOLDING

Microwave Molding is a quick manufacturing process that works by micro pelletizing a thermoplastic resin to create prototypes. The fine particles are heated and melted in a silicone mold similar to our Vacuum Casting solution. The result is a lot faster and ready for the evaluation process.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

LIGHTING PROTOTYPE

As prototyping experts, we rely on our engineering skills and manufacturing technology to make lighting prototype models that reach high-quality standards and accomplish design guidelines. Optics, electronics, mechanics, and analysis convene to produce excellence.

INJECTION MOLDING

Our high to low-volume injection molding services allow companies to get as many custom parts as needed since this process’s main features are repeatability and competitiveness. Injection molding works by injecting melted plastic into a mold, cooling it afterward, and solidifying it. It’s generally a mass-production solution. If you want to get more information about product development, you can navigate to this website.

DIE CASTING

Die casting is a process that inserts molten metal under high pressure into reusable molds called dies to produce high-quality components for multiple purposes. ARRK can create complex, accurately dimensioned parts with this low-cost and effective solution as a die casting manufacturer.

By emphasizing their global reach, comprehensive services, innovative technologies, and engineering expertise, you convey a strong message about their commitment to assisting customers in delivering top-tier products. It's concise and highlights ARRK's strengths effectively.

💼 Connect with Us Today! 💼

From concept to creation, ARRK is your one-stop destination for comprehensive product development services. Reach out to us via our official channels:

🏢 Business Address: Block E-10-01, Oasis Ara Damansara, Jalan PJU 1A/7, Ara Damansara, Petaling Jaya, Selangor, 47301 Malaysia

📞 Phone: +60 377347692

🌐 Website: ARRK Official Website

🕘 Hours of Operation: Monday-Friday: 8:30 am-5:30 pm

Social Media: Don't forget to follow us on social media for the latest updates, tips, and success stories:

👍 Facebook: ARRK Business

🔗 LinkedIn: ARRK

🕊️ Twitter: ARRK

Choose ARRK and embark on a journey where innovation meets precision, ensuring your ideas are not just realized, but perfected at every stage of the product development process.

#rapid manufacturing company#rapid prototyping and manufacturing#3d printing prototype service#cnc cutting machine supplier

1 note

·

View note

Link

#market research future#cnc machine products#cnc machine market revenue#cnc machine companies#cnc machine market trends

0 notes

Text

Maximizing Value: Cheap CNC Machining Excellence

Our Cheap CNC Machining Service offers cost-effective precision manufacturing solutions without compromising on quality. Utilizing advanced technology and skilled technicians, we deliver accurate and reliable machining at competitive rates. From prototyping to production, our affordable services cater to various industries, providing efficient solutions for your manufacturing needs. Experience the benefits of precision machining without breaking the bank with our Cheap CNC Machining Service.

#Cheap CNC Machining Service#CNC Machine Repair Near Me#CNC Machine Service Near Me#CNC Machine Specialist#CNC Machining Services UK#CNC Specialist Machining Services#Large CNC Machining Services#CNC Machining Company#CNC Milling Company

0 notes

Text

#cnc-machining#best-prototype-companies#prototype-machining-services#cnc-components-manufacturers#custom-cnc-aluminum-parts#stainless-steel-cnc-machining-services#cnc-machining-services#cnc-machining-companies-near-me

0 notes

Text

Boost Performance with CNC machining Car Parts: What You Need to Know

In this post, we'll check out how automotive precision machining helps make car parts. We'll talk about small parts in cars that are made from Falcon CNC Machines, and why they're so good. We will discuss all these in our blog post.

#automotive precision machining#cnc machining car parts#micro machining companies#screw machining services

0 notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

1 note

·

View note

Text

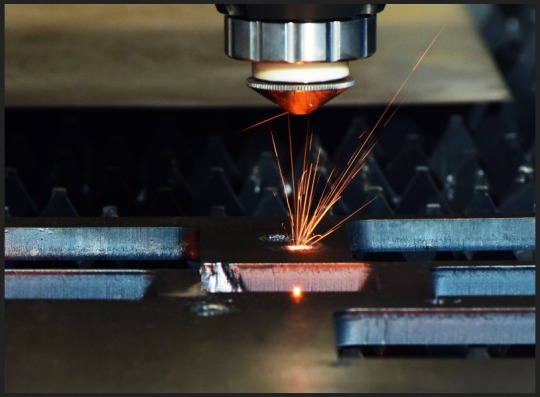

The Unmatched Precision of Laser Cutting and CNC Cutting Services

In today’s fast-paced industrial landscape, precision is paramount. Enter laser cutting services in London – the pinnacle of modern manufacturing technology. Laser cutting and CNC cutting services offer a myriad of advantages, from unparalleled accuracy to versatility across materials, making them indispensable in various industries.

Precision Redefined: At the heart of laser cutting services…

View On WordPress

0 notes

Text

CNC Machine Company- Help From JGW Machine in Business Scaling

Scaling a business can be a challenging task, especially when it comes to manufacturing. Contracting your metal manufacturing can offer many benefits.

0 notes

Text

A Brief History Of CNC Machining Manufacturing

Today, CNC machines are very popular in different industries. These machines have a wide range of applications. From workshops to large industrial plants, CNC machines have become vital parts of production, as well as manufacturing industries. These machines had their origins when they were considered numerical control. But this was an older system, which did not involve programmable computers. But nowadays, CNC machining systems are based on programmed computer systems. This is why these machines are known as Computer Numerical Control machines. Due to the evolution of CNC machines, many companies deal in the manufacturing of these machines.

The best CNC Machine Company can provide you with quality and affordable CNC machines according to your utilization and preferences.

Know The History

The history of CNC machining dates back to John Parsons, who was responsible to invent the first CNC machine. This technology has developed for several decades. In the past times, there were punch-tape-controlled devices, which are now evolved into computer-programmable machines. Engineers produce pieces of CNC machinery, which are equipped with better speed and accuracy via automated precision.

The concept of the modern CNC first evolved in the 18th century. The invention of the turning machine was done in 1751 to replace handcrafted techniques by enhancing precision in mechanical operations. This technique of machining marked the commencement of industrialization.

After that, in the 1940s, John T. Parsons who was a computing pioneer started researching the prospects of controlling machines with the help of computers and was successful in his research work. This led to the creation of numerically controlled milling. He figured out how to calculate the coordinates of the airfoil using an IBM 602A multiplier. This development would later assist in the production of helicopter parts for the Sikorsky Helicopter Company. The best part is that it was considered the first numerical control machine that was operated by inputting punched cards into a system.

The evolution of CNC machines has taken to the next level in the 1950s, 1960s, 1970s, and so on. From 1980 to 1990, programs were used to create numerical control open-source, which included the Enhanced Machine Controller project. This is how CNC machines became more accessible for product manufacturers. In 2000, CNC machining units turned out to be more cost-effective as proprietary machine software was removed by the Enhanced Machine Controller System.

This is how CNC Machining Manufacturing has evolved a lot. Today, there are CNC milling machines and machine lathes are popular in the manufacturing businesses. RPWORLD is a reputed CNC machining service provider, where you can get the best suggestions and solutions for manufacturing businesses.

0 notes

Text

Advanced CNC Machines in Oman: Precision Engineering Solutions

Discover advanced CNC machines in Oman for precision engineering solutions. Explore our range of cutting-edge CNC technologies for your manufacturing needs.

0 notes

Link

#market research future#cnc machine products#cnc machine market revenue#cnc machine companies#cnc machine market trends

0 notes

Text

Engineering Excellence: CNC Birmingham's CNC Machining Services

CNC Birmingham specializes in precision machining solutions for diverse industries. With state-of-the-art equipment and experienced technicians, we offer high-quality CNC machining services tailored to meet your specific requirements. From prototyping to production runs, our team ensures precise, reliable results with quick turnaround times. Trust CNC Birmingham for efficient and cost-effective machining solutions to bring your projects to fruition.

#CNC Machining Birmingham#CNC Birmingham#CNC Milling Birmingham#CNC Machining Companies Near Birmingham#CNC Turning Birmingham

0 notes