#billet technology

Text

#41 Le slam et l'IA

La question est sur toutes les lèvres depuis quelques mois.

Des répliques d’Arnold Schwarzenegger finiront-elles par remplacer les artistes ? Plutôt qu’hurler avec les loups, j’ai préféré prendre un peu de distance et passer le sujet au prisme de ma modeste pratique : le slam poésie.

En septembre dernier, j’ai donc suivi un atelier aux JIRAFE (Journées de l’Innovation, la Répétition, l’Accompagnement, la Formation et l’Environnement) des musiques actuelles à Paris intitulé « Intelligences artificielles (IA) génératives : des outils pour la création musicale ? » et animé par Jérôme Pons, sympathique producteur de spectacles rennais.

Jéjé a poussé le vice en utilisant l’IA pour concevoir sa présentation. L’objectif ? Nous présenter les possibilités de la machine en matière de conception de visuels, de génération de vidéos, de production d’instrumentales et surtout en ce qui nous concerne…d’écriture de textes.

Premier constat (objectif) : la plupart des outils sont payants par abonnement et donc chers. Les versions gratuites étant volontairement limitées, modèle économique oblige.

Deuxième constat (subjectif) : les résultats actuels ne sont pas extraordinaires. Si certains visuels générés pourraient faire office de pochette d’album surréaliste potable, que certaines vidéos frôlent les cinématiques d’un Final Fantasy VIII (1999 quand même), les instrumentales se révèlent médiocres (moins sur les arrangements que la qualité du son) et les textes clichés voire incompréhensibles. Codée en anglais, la machine galère avec la langue de Molière. Bref, il faut repasser derrière.

« Mais tout dépend du prompt » assure Jéjé. C’est-à-dire des instructions transmises pour arriver au résultat souhaité.

Piqué mais pas Gérard, je décide donc de tester le fameux félin à trois lettres (ChatGPT) en lui demandant de m’écrire un slam à la manière de Grand Corps Malade, Kery James ou encore Hippocampe fou. Puis de m’écrire un slam sur X sujet en trois parties.

Là encore, les résultats sont peu probants et une évidence me saute aux yeux. La machine se contente de recracher un mix de données digérées. Elle ne peut pas innover. Alors que la quête de formes nouvelles est l’essence même de la poésie.

Mon approche aurait pu en rester là. C’était sans compter le mois de février. Je suis en plein cycle d’atelier slam, troisième séance quand un soupçon s’éveille en moi. Deux collégiens qui peinaient encore à écrire hier reviennent avec deux textes achevés, spatialement bien structurés sur le papier. L’un avance l’aide de sa sœur, l’autre le soutien de son voisin de table qui ne semble pas assumer tant de maturité.

Je n’ai pas de preuves mais ça sent l’entourloupe. Je suis pris de court sans avoir pu réfléchir au problème. Alors je vais me permettre de reproduire ici la réponse que j’ai tenu à la classe entière :

Je n’ai pas d’avis tranché sur l’IA dans le slam. Pour le moment. C’est un outil. Il peut donner des idées, inspirer, même si je trouve qu’il est limité et qu’a priori, il utilise le travail de créateur.e.s sans leur consentement. Pour le moment. Cela changera peut-être. En revanche, je pense que cela doit rester un outil et ne pas devenir un prolongement de la créativité humaine. Ne laissons pas ChatGPT devenir à l’imagination ce que la calculatrice est devenu au calcul mental et le GPS au sens de l’orientation. Cela passera peut-être en atelier. Pas sur une scène slam tout public. Pas lors d’un examen oral. Pas lors d’un entretien d’embauche. Pas pour faire rire ses potes. Pas pour séduire l’élu(e) de son cœur. C’est comme un muscle. Si on laisse l’effort à la machine, le muscle fond. Alors gardons la forme. Surtout en milieu scolaire.

Le reste n’appartient qu’à l’avenir.

- Image : ©kung_tom/Shutterstock

- Musique : « Savages » - AlttA

0 notes

Text

Mending a Family 22/?

Prev | Next

Father and son day out!

Danny vibrated with excitement as dad put on a leather jacket. (He didn’t know why his dad put one on; it was the middle of summer.)

The sun hadn’t risen yet, and the stars were in full view. Today, it would be a father-son trip to the planetarium.

“Have fun, you two,” Jazz said. She wore a robe, and her hair was all over the place.

“We will, Jazz,” Danny said, excited.

His dad put Danny in the booster seat. He didn’t even complain because the sooner they left, the sooner they would get there. It would take almost six hours to get there. (Danny suggested flying, but his daddy said it was too dangerous.)

Danny watched as the sun rose in the sky and read the pamphlet his dad had printed out over and over again.

“Can we go to the gift shop at the end,” Danny asked.

“Of course, chum. What’s a trip to a planetarium if we don’t go to the gift shop afterward?”

“Yay,” Danny yelled in excitement.

Danny spent the car ride giving his dad facts about space. Anything he could think of, from constellations to black holes to galaxies. Danny talked about it all. He even talked about how gravity differed in Space from Earth and the equations used to determine how far anything was. Danny was afraid his dad would get bored after a while but could feel his dad’s enthusiasm.

Danny cheered when he saw the “Welcome to Montreal” sign in French and English.

“How much longer, daddy?”

“Half an hour,” Jason said, smiling at the excited little boy.

How did he get so lucky to have Danny in his life?

Jason parked and carried a vibrating Danny into the planetarium.

Danny’s overwhelming happiness and excitement hit Jason like a freight train when they entered the planetarium.

Jason put his little boy down but held on to his hand so he wouldn’t run off.

“Bienvenue à le planétarium du Montréal. Comment je peux veux aider?” (Welcome to the Planetarium of Montreal. How can I help you?)

“Daddy, what did she say,” Danny asked while tugging on Jason’s shirt.

“Bonjour, j’ai besoin du deux billet, mais je suis américain. Je puis obtenir des services in anglais?” (Hello, I need two tickets, but I’m American. Can I get English services?)

“Of course, sir. How many tickets?”

“I need one for an adult and one for a child, please.”

Danny had tuned out the two adults and stared at the ships they had hanging on the ceilings. It had been so long since he had the chance to come to a planetarium. He had been ten the last time. (He ignored that he was five this time around. It was too confusing to think about.)

“Okay, chum, I got our tickets to enter and for the shows. Ready to go in.”

“Yeah, yeah!” Danny jumped up and down excitedly.

“Have a good time,” the lady said before turning to the next family.

Danny led his daddy deeper into the building. He stared and drooled over the exhibits. There was alien technology that would never exist on his Earth.

The Metropolis Space Museum had recently lent the planetarium its Krypton exhibit. There was a model of Superman’s baby spaceship. A few imitation kryptonite rocks and part of the meteor Superman had been in during his ride to Earth.

Next, there were smaller exhibits on Tamarian and Martian technology and culture. Danny ate it all up. Jason had to remind Danny to be careful with his eyes as he stared at the new technology he had never seen in his dimension.

It was nothing new or exciting to Jason, who had met Superman and Starfire. He had fun watching his son’s adorable face.

They caught a show of Clark’s passage through space when he was a baby. He had donated the images when he found them in his spaceship. They went to another about every known sun with civilization and how each culture interacted.

(This was thanks to the Green Lantern Corps.)

Then, they watched a few shows that were closer to home. As much as Danny enjoyed learning about alien culture and technology, there was just something fun watching about the phenomena that happened on their turf.

Danny enjoyed the one that showed all the planets and different constellations from the Earth’s perspective while playing orchestra in the background.

Jason took them to eat and then to an activity room where children could replicate satellites and space telescopes with Lego.

Finally, at the end, Jason took Danny to the gift shop. Danny bought a plush of Martian Manhunter, a rocket he would build, and a lamp with planets orbiting the sun. He also got a keychain for Jazz and a starry blanket for Ellie, all with daddy’s money, of course.

Jason had to carry his little boy to the car. Danny’s sleep contentment enveloped Jason, and he reveled in it.

“Did you have fun, lad,” Jason asked as he buckled his baby boy in.

“I had the funnest day ever! We don’t have aliens in my world, so learning about the different cultures was the best!”

“I’m glad you liked it. What was your favorite part?”

“Learning about Superman and Martian Manhunter. I think Martian Manhunter is my favorite Justice League member!”

Jason laughed.

“Remind me to tell you stories about Uncle Clark later.”

“Who’s Uncle Clark?”

“I’ll tell you a secret: Uncle Clark is Superman.”

Danny woke up a bit hearing that tidbit of information.”

“Y’know Superman? He’s your uncle?”

Jason laughed while feeling a ping of guilt; he hadn’t told Danny much about his time as Robin.

“Yeah, he’s da—Bruce’s best friend, so he came around the Manor a few times. Plus, I met him in the Watch Tower in space.”

“You’ve been to space? Have you met Martian Manhunter?”

Jason regaled his son of his time as Robin on the ride home. Danny fell asleep to his daddy’s voice as he told his stories.

Jason couldn’t wait to have another day out with his precious boy.

I've never been to a planetarium, but then I thought to myself, this DCU, they have aliens. I can put whatever I want. Anyway, if anyone has actually been to the Planetarium of Montreal, sorry for it not being accurate.

@itsberrydreemurstuff @idontgetpaidenoughforthisshit @skulld3mort-1fan @theauthorandtheartist @emergentpanda-blog @jaggedheart11 @fisticuffsatapplebees @booberrylizard @fantasticbluebirdfan @thegatorsgooseoose @cyrwrites @kjoboo91 @crystallicedart @amaramizuki666 @spekulatiusmuffin @meira-3919 @kilasmess @bubblemixer @lexdamo @wonderland-daisy @mj-arts-n-stuff @amyheart19 @dolfay @the-church-grimm @undead-essence @aph-mable @lizisipancardo @purrloin77 @writer-extraodinaire @charlietheepic7 @sinfulloccultist @nootherusernameworked @coruscateselene @chaoticchange @itsberrydreemurstuff @gmkelz11 @feral-bunny31 @paroovian @thatonegaybitch68 @d4ydr34min9 @overtherose @fandomwandererer @vipower001 @thordottir45 @blackrabbitt3t @rosecinnamonbun @bianca-hooks123 @epilepticnerd @dat1angel @consouling @flamingenchiladadragon @all-mights-asscheeks @ender-reader @fuyu-bitch @ravenswife

61 notes

·

View notes

Text

15k Words (2) Masterlist

part one

A-Lister (ao3) - tastefulcucumber

Summary: Phil’s Dad owns a small photography business. Daniel Howell, academy-award winning actor decides that Lester’s Portraits is the best place to get his head-shots for his portfolio. He expects to get his pictures taken, but what he doesn’t expect is the photographer’s son to be so captivating. No one else has treated Dan this normal since the beginning of his acting career. Maybe that’s just what Dan needs, a friend who is there for him, and not for his status.

A Little Bit Of Magic - dxnhowell

Summary: Dan is the new potions teacher at Hogwarts and is muggleborn, this is his first year teaching and whilst he’s excited, he has to get used to being in the castle with absolutely no muggle technology. Phil is the herbology teacher and is clumsy and likes puns and likes to help Hagrid with his magical creatures. Dan and Phil eventually meet and become rather close, some of the students realize this and try to get them together before the end up of the year.

Amaryllis (ao3) - bokeae

Summary: In which Dan has to wed Princess Alice when he would much rather marry her brother, Philip.

Ardour (There’s a World Outside These Walls) (ao3) - centroid

Summary: Dan’s facade crumbled. His breathing was the first to go, leaving his lungs with short gasps of air. He brought his hands up to press the heels of his palms into his eye sockets as tears trekked down his cheeks. Dan’s romantic life was always covered in a veil of sorrow, but never once had he cried over it. Never once did he let his walls down and just weep. Dan was relieved, so relieved but at the same time he was in despair. It was as if his fate had been set in stone, finalizing that he was and would forever be alone. In a world with its foundation dug heel toe into romance, he was someone who had to go without.

billet-doux (ao3) - Tarredion

Summary: Dan and Phil, gang leaders and rivals to the highest degree, harbor big secrets they want no one to see

Coffee and Calligraphy (ao3) - brookwrites

Summary: Dan’s a barista at the local cafe, where writer!Phil decides to sit with his journal. Dan likes Phil. A lot. But things change when Dan finds something out about Phil that breaks his heart.

Colour Me Blue (ao3) - orphan_account

Summary: What if a boy, whose heart was so full of darkness, that he couldn’t believe in colours anymore, met someone so full of light who slowly painted his world bright again?

Demons In My Head (ao3) - kae_karo

Summary: An unconscious demon mysteriously shows up on Dan's property, and Dan heals it, promising he'll send it back to where it came from as soon as he finds out why it's there. Finding the will to banish a charming demon is harder than he thought.

for you I’d wait (til kingdom come) (ao3) - blueshirt

Summary: The time that Dan misunderstands one little conversation—which he still maintains is PHIL’S FAULT, not his—and it leads to six years of unrequited pining.

going the wrong way home (ao3)- moonlightmusings

Summary: the almost-college au where dan and phil take a summer road trip.

I heard the March birds singing, and oh, what a beautiful sound. (ao3) - emonerd_io

Summary: Inspired by the anime 四月は君の嘘 (Your Lie in April)!

The piano initiated the opening chords, and she drew the melody out in simple, yet alluring and complex lines. It’s a tune Dan did not recognise, but fell in love with immediately. Deep, and filled with a certain longing, yet tragically beautiful.

It’s the type of music that allows you to fathom why exactly some people practise for years and for decades, trying to master their craft, just to play something so modest and stark, yet so exquisite.

This is the story of two young musicians, Dan and Phil, and how their lives became entwined over the course of one year in high school.

In Faded Holograms They Speak (ao3) - artdeficient

Summary: They’re in japan and nothing seems to make sense, so they hide in hotel rooms and pretend they can’t see what’s right in front of them, and it works, for a while. (badlands au based off of halsey’s album)

no longer feel alone (ao3) - natigail

Summary: who'd have known that a random act of kindness from a stranger could lead to this.

refraction (ao3) - indistinct_echo

Summary: (To be read after completing Monochrome by intoapuddle.)

Dan doesn’t want to wait any longer: it’s time to share with Angie and PJ his Fall Whisperer identity.

This really isn’t so scary… oh, who is he kidding, it’s terrifying.

Cue supportive-boyfriend Phil, amateur-therapist Dan, and a healthy dose of luck (+ bonus smut).

Teach Me to Fly (ao3) - thesleepdeprived

Summary: Soulmates!AU, Wings!AU. People had always told him that wings were the solution to everything, the key to your love life, your friend circle, who you are as a person, even. Yet somehow, Phil just can’t bring himself to see it that way. Who would want a soulmate that would never fly? (or, as my planning outline so eloquently puts it, kiss kiss fall in love you emotionally repressed motherfuckers) COMPLETE

These Violent Delights Of Love (ao3) - cyanica

Summary: Dan is hopelessly in love, Phil’s seemingly oblivious and they’re on a world tour just to make things more chaotic.

And yet, the Gods, or the Ruler of the Universe, or whoever the hell was in charge decided Dan needed to die in the end, too. Currently, leaning over the porcelain throne of shit and piss was the Gods’ human voodoo doll, throwing up the contents of his unfortunate Indian dinner – and significantly more alarming than that: black tulips. Fucking flowers. This wasn’t real life.

waiting to be found (ao3) - dizzy

Summary: Dan and Phil meet at a club.

(And then a coffee shop.)

Who’s Taking You Home Tonight? (ao3) - whatkindoffanfics (orphan_account)

Summary: October, 1944. While World War II rages on, Dan Howell finds himself thrown into the secretive world of Bletchley Park, a headquarters for intercepting and breaking the codes of encrypted German messages.

12 notes

·

View notes

Text

If Carroll Shelby were to build the Cobra today. The team at Classic Recreations built their new Diamond Edition Shelby Cobra to demonstrate what the legendary Cobra would be, if built with all of the benefits of modern technology. It’s powered by a 5.0L Ford Performance Gen3 Coyote Aluminator engine that can be tuned to make 1000+HP mated to a Tremec T56 Magnum 6-speed manual transmission and rides on a race-inspired Schwartz Performance chassis (with cantilever suspension and billet CNC-machined aluminum assembly components), Baer brakes, 295/35ZR18 & 335/30ZR18 Michelin Pilot Super Sport tires, and 18x10/18x12 Forgeline forged three piece HL3X wheels finished with Matte Bronze centers & Polished outers! See more at: https://forgeline.com/customer-gallery/classic-recreations-4

🇺🇸🇺🇸🇺🇸

#forgeline#forgelinewheels#forgedwheels#customwheels#HL3X#ForgelineHL3X#notjustanotherprettywheel#doyourhomework#madeinUSA#classicrecreations#diamondedition#shlebycobra#csxcobra

24 notes

·

View notes

Text

Une bonne alchimie entre la science et l'art !!

« L'art et la science ont en commun de questionner le monde en rendant visible l'invisible »

Durant les semaines précédentes, j’ai pu aller visiter deux expositions marquantes mettant en lien l’art et la science. En effet le 15/02, je suis allé visiter l’exposition « bestiole électronique » de Marylou où l’on pouvait y retrouver plusieurs types d’ampoules s’allumant quand les capteurs s’activaient, plusieurs types de capteurs (ex : capteur de présence, capteur sonore, etc…) permettant de collecter des données et vis-à-vis de ses données, retransmettre des sonorités de bestioles et d’oiseau. Puis le 07/02, je me suis rendu à Chamarande , j’ai pu assister à l’exposition de Karine Bonneval qui se prénomme « se planter ! ». Cette exposition vise à associer la technologie et la nature comme Marylou mais d’une manière différente. En effet, dans cette exposition, nous devions dans un premier temps effectuer un parcours à l’aveugle permettant de de dissocier la vision du ressenti. L’artiste avait décidé d’y faire dans l’orangerie du domaine de Chamarande des formes reconnaissance avec le touché et des bruits sonores. Nous devions décrire à notre binôme qui était masqué ce que l’on pouvait y apercevoir. Puis dans le reste de la visite nous avions pu observer plusieurs types d’œuvres liant des thèmes impactant la nature.

Par exemple nous avions une œuvre où l’on pouvait y voir un moteur de voiture, celui d’une mustang et au-dessus des graines de colza, démontrant alors l’absurdité de la transformation d’une matière première en un objet polluant qui impacte donc la nature.

Ou bien comme autre exemple nous avions une œuvre où nous devions être pieds nu et entrer dans un trou, puis se connecter à la plante par le billet d’une feuille en cuivre. Cela me permettait donc de ressentir les vibrations entre la plante et moi, qui me permettait donc d’avoir un certain point de communication avec la plante.

Après avoir effectué ces deux sorties, j’en ai donc conclu un lien entre les deux artistes. Tout d’abord, les deux artistes basent leurs œuvres en mettant en lien l’art et la nature. Chacune d’elles retranscrit de manière artistique les « ressentis de la nature » dut à l’impact de la présence de l’Homme dans la nature. L’une sensibilise par des capteurs et des lumières, l’autre utilise de même ces technologies mais en ajoutant ce côté humain, ce qui rends plus réaliste et plus vivant son exposition.

En sommes, les deux artistes ont su retransmettre grâce à leur art, l’impact de l’homme sur la nature, plus précisément l’impact de la technologie sur la nature.

A.N

Bibliographie : consultés le 14/03/2024

informations :

centretignousdartcontemporain.fr/marylou-bestioles-electroniques/

photos :

A la prochaine pour un nouveau blog !!!

2 notes

·

View notes

Text

Review: Iron Documents

Iron Documents began as the PhD thesis of Matthias Goll under the title Interdisciplinary studies on the technology of late medieval European plate armour production between 1350 and 1500, which was submitted and approved in 2013. This work was intended to fill a perceived void in scholarship regarding the production processes of plate armor in the late medieval period. The author states that “the limitation of this study to the years from 1350-1500 is due to this period showing the first zenith of the art of armour making” [30]. Additionally, due to issues of time and space in the document, tournament and horse armor were both omitted. Instead, the author focuses this study exclusively on armor made for man for use in the field.

This study is divided into nine chapters, the first of which serves as an introduction. In this chapter Goll touches upon the dearth of scholarship regarding the production of European plate armor, remarking that only three major works (those written by Ffoulkes in 1912, Price in 2000, and Williams in 2003 which will be reviewed next week) have been written on the subject. Additionally, the author outlines that, due to the nature of this study, the vast majority of the primary sources utilized are the objects themselves being examined. Written documents do serve to bolster the study, however, which Goll divides into five groups: guild regulations, orders, payments, legal disputes, and accounts/stock lists.

The second chapter is entitled “Terminology and Typology of Plate Armour.” Here the author summarizes issues of terminology in modern scholarship, with particular regard to the inconsistent use of terminology across arms and armor scholarship in different languages. As a consequence, the author suggests abandoning traditional armor terminology, and suggests a simplified typology of his own design, which he outlines in this chapter. These terms are what he uses throughout the remainder of the study.

The third chapter, called “A Brief History of Plate Armour from a Technological Point of View,” examines the development of armor and armor making techniques over the 150 year period covered by this study. This chapter is arranged according to parts of the body covered by armor, proceeding from Arms to Hands, Head, Legs, Neck, and finally Torso.

Chapter four is entitled “Summarizing Technological Features.” The longest chapter in the study, this section is divided into four subsections: “Metalwork on the Plates,” “Joints and Applications,” “Dimensions,” and “The Serial Production of Armour.” The metalwork subsection discusses the general techniques of shaping iron from both the billet and the plate into the desired shape, and covers the marks of these techniques left behind on surviving elements of armor. This section also includes decorations which are forged into the plate, both through embossing and non-embossing techniques. “Joints and Applications” examines the various forms of joining together separate plates as well as decoration which are applied to the plate rather than forged from it (for instance a strip of brass riveted to the edge of a plate rather than the edge of the plate being rolled and filed.) The third subsection covers the measurable dimensions of surviving elements of plate armor, including not only the typical dimensions of width, height, and length, but also weight, and plate thickness. The fourth and final subsection considers the question of armor produced not on an individual basis, but rather mass produced cheaply and quickly. In this subsection the author examines four case studies of helmets found at the medieval Venetian colony at Chalkis on the Greek island of Euboea which have traditionally been assumed to be serially produced.

Chapter five explores the questions of “Supplying Crafts.” These the author defines as crafts which supply materials necessary for the armorer to complete his own craft. These include wire drawing (which is necessary not only for the production of mail armor but also for the rolling of the edges of plates), tool production, tailoring (plate armor includes many textile elements), etching (typically for decoration), bellows (a necessary tool for any smith), tanners (who produce leather for straps and for ties to pass through), and finally the production of lace (braided laces were used to attach many pieces of armor which needed to “float” rather than being held tightly to the body.)

In the sixth chapter, Goll addresses the “Problem of Authenticity.” Here the author provides notes on the history of armor preservation and a commentary on the history of armor reproduction and restoration, issues which are central to the question of armor authenticity. Goll then moves on to discussing methods of distinguishing wholly authentic armor from armor which has been “restored” in the past 200 years and from wholly fake pieces.

Chapter seven provides a discussion on “The Metallurgy of Armour Production.” Brief summaries on medieval methods of producing iron and steel are provided, as well as a history of the production of iron plates. The author also comments on medieval plate quality as well as recent studies which have been conducted to examine the metallurgical structures of medieval iron plates. The author ties this discussion back to the question of authenticity, mentioning how it has been hoped that this manner of metallurgical analysis could help distinguish modern from medieval armor.

The eight chapter is entitled “Suggestions for New Approaches to the Mapping of Plate Armour.” By the “mapping of plate armour,” the author means the dating of surviving pieces as well as attributing them to particular sites of production, and even to particular armorers. In this chapter the author discusses the use of stylistic dating criteria (the most popular method typically used to map armor production,) as well as the use of marks attributed to both makers and cities. The author then examines some newly identified marks which help to map the pieces more specifically. The author then utilizes these new suggestions, as well as the tools he provided in chapter six, to examine a few specific pieces and suggest both their authenticity and to where and when they may be attributed. The ninth chapter serves as a summary.

An index and bibliography are both provided. Throughout the study the author refers to works previously written on the subject of arms and armor, stating where he agrees and disagrees with their findings as it relates to this study. These works include English, German, Italian, and French scholarship.

Iron Documents was originally written in German, and the English translation which this reviewer read is rather clumsy. The translation is rife with writing errors, and many sentences require several readings before the reader can work out exactly what the author intended to say. More troubling, however, is the author’s apparent inability to provide a clear answer to the problems raised in this study. The author spends a great deal of time deconstructing and criticizing popular methods for mapping and examining the authenticity of plate armor, but rarely provides his own opinion on how best to accomplish these tasks.

Despite these criticisms, Goll’s examination of the process of armor making is unparalleled. Additionally, the author provides a truly extraordinary number of references, including images from multiple angles of over 5,000 surviving pieces of armor. These images are not included in the body of the text, but instead in a separate file accessible on computer, and while this system is somewhat inelegant, this reviewer understands it as a necessary concession given the sheer volume of images the author chose to include. This work will be inaccessible to most enthusiasts of the field of arms and armor, however, it should not be neglected by any specialist in the field.

52 notes

·

View notes

Photo

The Hispano-Suiza H6C “Tulipwood” Torpedo (with A Wooden Body)

The Hispano-Suiza H6 was introduced in 1919, just a year after the First World War. It was powered by an advanced new all-alloy inline-six cylinder engine that was closely based on Marc Birkigt’s V12 aero engine.

Unusually for the era the H6 engine had a single overhead camshaft, rather than the more common flathead or overhead valve/pushrod design. The engine’s aluminum construction helped ensure it was far lighter than its iron counterparts, and its seven-bearing crankshaft was milled from steel billet to ensure strength.

Apart from the engine, one of the other major notable features of the Hispano-Suiza H6 was its advanced power-assisted braking system – a world first. The car was fitted with light-alloy drums on all four corners with a brake servo that provided additional braking power.

This technology was so revolutionary that the patent was licensed by a number of other manufacturers, most significantly by their arch rivals over at Rolls-Royce in England.

The H6 was built in three major variants between 1919 and 1933. The first was simply known as the H6, this was succeeded by the H6B in 1922, which in turn was replaced with the H6C in 1924.

The original H6 and H6B were powered by a 6,597cc displacement version of the company’s straight-six, which was followed by an enlarged 7,983cc version in the H6C. All engine variants used a 3-speed manual transmission sending power back to a live axle rear end.

This car is one of the lower surbaissé Type Sport variants with a lowered radiator and a 52 imperial gallon (236 liter) fuel tank designed for long rallies.

Engineer Henri Chasseriaux developed an ultra-lightweight body consisting of 1/8th inch thick strips of mahogany laid over inner 3/4-inch ribs, all secured in place by thousands of aluminum rivets.

It’s not exactly where the “Tulipwood” name originated given that the car is bodied in mahogany, however the name has followed the car its entire life.

Once completed the body was weighed, tipping the scales at just 160 pounds (72.5 kgs) – extremely light compared to similarly sized steel bodies.

24 notes

·

View notes

Text

5 Latest Manufacturing Process of Heavy Wall Thickness CS Seamless Pipes

Heavy wall thickness CS seamless pipes are used in various applications, from oil and gas to construction and infrastructure. These pipes are known for their high strength, durability, and resistance to corrosion, making them an ideal choice for harsh environments.

The manufacturing process for heavy wall thickness CS seamless pipes involves several steps, each critical to the final product's quality.

Raw Material Selection: The first step in the manufacturing process is the selection of high-quality raw materials. Heavy wall thickness CS seamless pipes are typically made from carbon steel, which is known for its strength and durability. The steel is selected based on its chemical composition, mechanical properties, and other factors to meet the required specifications.

Billet Production: The next step is the production of billets and cylindrical steel pieces that serve as the starting point for the pipe-making process. The steel is heated to a high temperature and then rolled into a cylindrical shape. The resulting billet is cut to the desired length using a saw or other tool.

Piercing and Rolling: Once the billets have been cut to the desired length, they are ready for piercing and rolling. The billets are heated to a high temperature and then pierced with a mandrel, which creates a hollow tube. The tube is then rolled using a series of rollers to reduce its diameter and increase its length.

Heat Treatment and Finishing: After the piercing and rolling process, the tube is heat treated to improve its mechanical properties. The tube is heated to a high temperature and then quenched in water or oil to harden the steel. This process helps to improve the pipe's strength and durability. Once the heat treatment process is complete, the pipe undergoes finishing. This involves cutting the pipe to the desired length and removing excess material or burrs. The pipe is then inspected for quality control to ensure it meets the required specifications.

Testing and Certification: Before the heavy wall thickness CS seamless pipes are shipped to the customer, they undergo testing and certification. The pipes are subjected to various tests, including hydrostatic testing, ultrasonic testing, and visual inspection, to ensure they meet the required quality standards. Once the pipes have passed all required tests, they are certified and shipped to the customer.

In addition to the steps mentioned above, several other important factors must be considered in manufacturing heavy wall-thickness CS seamless pipes.

One of the key considerations is the quality of the equipment used in the production process. Modern equipment and technology, such as advanced rolling mills and heat treatment furnaces, can significantly improve the efficiency and quality of the process.

Another important consideration is the quality control measures throughout the manufacturing process. Strict quality control measures ensure that the pipes meet the required strength, durability, and corrosion resistance standards.

These measures can include regular inspections and testing throughout the production process and comprehensive final testing and Certification.

It is also worth noting that the manufacturing process for heavy wall thickness CS seamless pipes can vary depending on the specific application and customer requirements.

For example, some applications may require additional steps, such as surface treatment or coating, to enhance the pipe's corrosion resistance.

Overall, the manufacturing process for heavy wall thickness CS seamless pipes requires careful attention to detail and a commitment to quality at every step. By selecting high-quality raw materials, using modern equipment and technology, and implementing strict quality control measures, manufacturers can produce pipes that meet the most stringent requirements for strength, durability, and corrosion resistance.

For more such stories, kindly follow Tumblr.

#metal industrial#construction#stainless steel#architecture#alloy#buildings#carbon steel pipe#seamless pipe#heavy wall pipe#CS Seamless Pipes#Carbon Steel#SEAMLESS CARBON STEEL HEAVY WALL THICKNESS PIPES#ASTM A53 Heavy Wall Thickness Seamless Pipes#ASTM A106 Gr B Steel A53 Heavy Wall Thickness CS Seamless Pipe

2 notes

·

View notes

Note

Un être sans âme... C'est pas faux. Mais faut pas hésiter à parler de bêtise, de stupidité, de connerie. Parce qu'il est franchement très très con. Je ne vois rien d'intelligent dans la manière qu'il a eut de te traiter. J'en reviens au fait qu'il t'ai dit qu'il t'aimait pour te larguer 5 minutes plus tard. Ce mec est un gros con. Il a été bercé trop prêt du mur hein. C'est le cas de beaucoup de belges apparemment. Bref, Dieu merci, c'est de l'histoire ancienne ! Bisou bella

Hahaha ! Et bien je ne te contredirais pas ! C'est incontestablement un vrai con. Les belges peuvent être très gentils. Mais opportunistes avec nous. Ils veulent tout de nous, jusqu'à notre identité. Ils nous flattent avec de belles paroles comme "pays frère", alors qu'ils n'hésitent pas à la première occasion à nous poignarder dans le dos. Ils veulent avoir accès à tous nos médias, comme si ça parlait d'eux, ils ont exigé de pourvoir regarder nos chaines de télévision sans payer un centime, au frais des contribuables français, ils veulent lire tous nos écrivains, écouter tous nos chanteurs, s'habiller et parler comme nous, mais je note que par exemple, pendant des années, la France donnait systématiquement à la Belgique 12 points (le maximum) à l'Eurovision tandis qu'eux donnaient les 12 points à d'autres pays. Un jour, très récent, la France, a enfin cessé son aveuglement : depuis 2 ans, c'est zéro vote pour la Belgique ! Pas trop tôt. Ils veulent toutes nos technologies mais achètent des F-35 aux américains alors qu'ils sont censés acheter européen, donc français, donc Dassault, donc le Rafale. Dassault vient de les éjecter de son titanesque projet avec ces mots : "Pourquoi j'inclurais des traitres comme les belges dans mon projet ? Qu'ils continuent à acheter américains !". Les belges ultra vexés et culottés, se plaignent, depuis lors, de ne plus faire partie du projets Dassault malgré leur indéniable trahison.

Jacques Brel a été rejeté par presque toutes les maisons de disques belges et il ne trouvait pas le succès. Il débarque en France, vit à Montmartre, tente sa chance en bouffant les pissenlits par la racine jusqu'à ce qu'une maison de disque française le prenne en charge. Là, l'immense succès que l'on connait. Et bien dès que les étrangers se trompent en disant de Brel "french singer", les belges rappliquent en clamant super énervés "He was NOT french he was a belgian man". Même chose avec Stromae, qui, sans la France n'aurait jamais percé et ils continuent avec leur agaçante Angèle. Les frites ont été inventées en France, précisément à Paris. Ils s'attribuent la recette alors que des preuves historiques existent. Et cetera, et cetera... Opportunistes, pas sincères, traitres et ingrats.

C'est un peu ça le Ô, un vieux con belge aux belles paroles, lâche comme pas deux et traitre. Et puis il est germanophile. Sauf quand ça l'arrange. je remarquais qu'il s'identifiait aux allemands mais se servait généreusement dans l'art français pour ses billets. Un vrai con quoi !

Baptiste, lui, est bien français ;-) bisou douceur.

1 note

·

View note

Text

TMT Bar Manufacturer and Distributor in Kanpur | RHL Profiles limited

Savings & Other Benefits to Construction in Use of High Strength TMT Steel Bars

Steel is an essential element of any civil or construction activity like Houses, Multi Storey, Townships, Malls, Airports, Ports, Dams, Bridges, etc. Steel not only provides strength to any construction but also provides durability and long life.

Each transformation of the steel industry was driven by the growing market need for steel bars with higher strength and elongation. The 21st century has witnessed a rapid increase in the cost of steel products and also brought greater focus on safety and quality norms of construction. This has spurred the demand for the development of TMT bars with properties of high strength and elongation to provide cost savings in the construction by reducing consumption.

Steel researchers across the world have been working hard to develop steel products to meet these specific market needs. This research has led to the development of TMT steel Bars with yield strengths of 500 N/mm 2, 550 N/mm2, and 600 N/mm2. These bars, because of their higher strength than traditional steel bars, are required in lesser quantities, thus, reducing the overall cost of the structure significantly.

The BIS code for IS 1786 (High Strength Deformed Steel Bars And Wires for concrete Reinforcement Specification), IS 13920 (Ductile Detailing of Reinforced concrete structures subjected to Seismic forces - Code of Practice), and IS 456 (Plain And Reinforced Concrete – Code of Practice) incorporated necessary changes to include these latest developments in the field of steel technology.

IS 1786 under its latest revision groups the Steel Bars under the following grades:

Fe 415, Fe 415D, Fe 415S

Fe 500, Fe 500D, Fe 500S

Fe 550, Fe 550D

Fe 600

Reinforcing steel is produced through one or a combination of processes like hot rolling after microalloying, hot rolling followed by cold working, or hot rolling followed by Thermo Mechanical Treatment (TMT process).

TMT Technology

TMT technology involves rapid cooling of hot-rolled bars rolled out of a finishing rolling mill from a temperature of 950-1050°C to 550-600°C using a high-pressure cool water spray system. The bars after quenching are cooled under controlled atmospheric conditions to impart properties based on the size and grade being rolled. The three major steps of the TMT process are as under :

1. QUENCHING: The hot rolled bar coming out of the finishing rolling mill stand is passed through a quenching box where it is rapidly quenched using a high-pressure cool water spray system. The surface of the bar gets hardened to the depth optimized for each section through the formation of a 'Martensitic' rim while the core remains hot and 'Austenitic'.

2. SELF TEMPERING: The bar coming out of the quenching box thus has a hot core compared to the cool outer surface thus allowing the heat to flow from the inner core to the outer surface causing tempering of the outer martensitic rim into "Tempered Martensitic" structure. The core remains "Austenitic" at this stage.

3. ATMOSPHERIC COOLING: The bar is then finished on an Automatic rake type controlled Cooling Bed where uniform atmospheric cooling of each bar takes place under controlled conditions resulting in the transformation of the hot "Austenitic" core of the bar into "Ferrite Pearlite" structure. The resultant final structure of the Bar thus produced consists of a hard and strong outer layer (Tempered Martensitic) with a soft and ductile inner core (Ferrite Pearlite) structure.

Importance of branded steel manufacturer -

Steel Billet of appropriate chemical composition - Right raw material procurement and selection.

Accurate rolling within close tolerances - Robust and Accurate manufacturing equipment.

Quenching under appropriate water pressure, water temperature, and water volume depending on finishing mill speed, chemical parameters, size, and grade of finished steel - Trained manpower.

Uniform atmospheric cooling on Automatic rake type cooling bed - Right technology.

Testing for Mechanical, and Physical properties in the laboratory - Quality Assurance.

Bundling, tagging, and dispatch as per grade and size of finished TMT Steel - Complete customer service and satisfaction.

2 notes

·

View notes

Text

Navigating Market Dynamics in the Long Steel Products Industry

The global long steel products market size is expected to reach USD 1,012.11 billion by 2030, expanding at a CAGR of 5.1% from 2024 to 2030, according to a new report by Grand View Research, Inc,. Products such as rebars and wire rodsare of vital importance in today’s world with their growing emphasis in the building and construction industry. Based on product, the market is segmented into rebars, wire rods, sections, and tubes, of which rebars are extensively used in the construction of infrastructure and buildings. Wire rods are manufactured by drawing hot metals through shafts to develop wires with reduced diameters. Wire rods represent the most ductile form owing to their high ductility and easy availability in different diameters. They are widely used in construction and fencing applications which is positively impacting their growth.

Long Steel Products Market Report Highlights

Based on product, rebars held a revenue share of more than 34.0% in 2023 of the global market. Rebars are embedded in the concrete or used along with it so that the concrete can withstand the compressive forces in the structure and sustain against the tensile forces formed in the structure. The demand for rebars is expected to propel in developing nations owing to the growing construction activities

In terms of revenue, wire rods is anticipated to register a CAGR of 5.9% across the forecast period owing to their rising use in the automotive industry

Asia Pacific accounted for the highest share of over 66.0% in 2023, in terms of revenue, and this trend is anticipated to continue over the forecast period. As the region is characterized by a growing population and surging housing requirements, countries such as China and India, are witnessing an increasing number of residential construction projects. This is expected to result in significant product demand in the Asia Pacific in the coming years

The market is characterized by intense competition. Several of players are entering into long term supply contracts with end-users. ArcelorMittal, Emirates Steel Arkan and Emirates Rebar Limited are among the leading players of the market in the world

For More Details or Sample Copy please visit link @: Long Steel Products Market Report

Based on region, Asia Pacific is one of the leading markets in the world. The growth is attributable to China which is the largest producer and consumer of long steel products in the Asia Pacific. Other major markets in the region include Japan, South Korea, India, and Southeast Asian countries such as Indonesia, Vietnam, and Thailand. In recent years, the Asia Pacific market has faced challenges due to a global oversupply of raw materials, increased competition from other steel-producing countries, and the impact of the COVID-19 pandemic on the region's economies.

Further, various growth strategies such as new product development and capacity expansions by the market players are likely to benefit the industry growth. For instance, in February 2023, ArcelorMittal introduced a new blast oxygen furnace LD (Linz-Donawitz) converter in Bosnia with a capacity of 125 tons. This converter has been supplied by Primetals Technologies. Thus, this investment ramps up the production and processing of steel into billets, bars, blooms, and ingots.

#LongSteel#SteelMarket#ConstructionMaterials#BuildingIndustry#SteelIndustry#Manufacturing#SteelProduction#IndustrialMaterials#StructuralSteel#MarketAnalysis#SteelDemand#Metallurgy#BuildingMaterials#ConstructionTrends#SteelPrices#IndustryInsights

0 notes

Text

Copper Rod Continuous Casting and Rolling Line, Global Market Size Forecast, Top 10 Players Rank and Market Share

Copper Rod Continuous Casting and Rolling Line Market Summary

The copper rod continuous casting and rolling production line is a piece of equipment used for the continuous production of copper rods. It consists of a continuous casting machine and a continuous rolling mill, which can continuously cast the molten copper into a copper billet, and then continuously roll the copper billet into the required copper rod through the continuous rolling mill. This unit has the characteristics of high efficiency and continuous production, which can greatly improve the production efficiency and quality of copper rods.

Figure. Copper Rod Continuous Casting and Rolling Lines Product Picture

Source: Secondary Sources and QYResearch, 2024

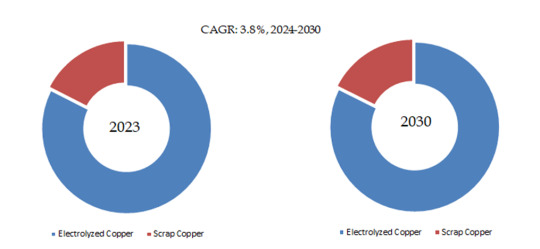

According to the new market research report “Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030”, published by QYResearch, the global Copper Rod Continuous Casting and Rolling Line market size is projected to reach USD 0.22 billion by 2030, at a CAGR of 3.8% during the forecast period.

Figure. Global Copper Rod Continuous Casting and Rolling Line Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global Copper Rod Continuous Casting and Rolling Line Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Copper Rod Continuous Casting and Rolling Line include Southwire Company, LLC, SMS group, Chengdu Shuhong Equipment Manufacturing, Continuus-Properzi spa, Xuzhou New Dongdian Electrotechnical Machinery, etc. In 2023, the global top four players had a share approximately 89.0% in terms of revenue.

Figure. Copper Rod Continuous Casting and Rolling Line, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030.

In terms of product type, Electrolyzed Copper is the largest segment, hold a share of 82.5%,

Figure. Copper Rod Continuous Casting and Rolling Line, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030.

In terms of product application, Electric Power is the largest application, hold a share of 55.3%,

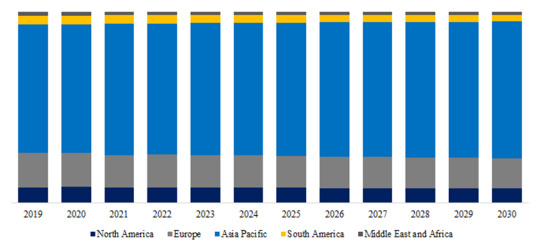

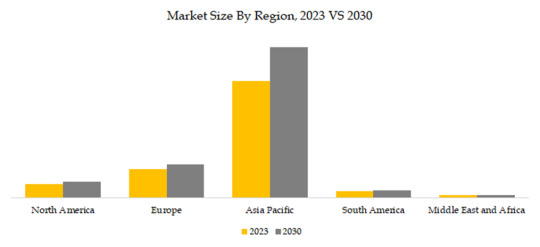

Figure. Copper Rod Continuous Casting and Rolling Line, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Copper Rod Continuous Casting and Rolling Line Market Report 2023-2030.

Market Drivers:

D1: Increasing Demand for Copper Products: The demand for copper products, including copper rods, is influenced by sectors such as electrical and electronics, construction, automotive, and telecommunications. As these industries grow, the demand for high-quality copper rods produced by continuous casting and rolling lines increases.

D2: Efficiency and Cost Savings: Continuous casting and rolling processes are known for their efficiency in producing uniform and high-quality copper rods. These systems offer cost savings by streamlining the production process and reducing material waste compared to traditional methods.

D3: Automation and Industry 4.0 Integration: The trend towards automation and the integration of Industry 4.0 principles in manufacturing processes drive the adoption of advanced equipment like continuous casting and rolling lines. Smart manufacturing technologies enhance efficiency, reduce downtime, and improve overall production capabilities.

Restraint:

R1: High Initial Investment: The capital expenditure required for setting up a Copper Rod Continuous Casting and Rolling Line can be significant. The high upfront costs may act as a deterrent for some manufacturers, particularly smaller enterprises or those with budget constraints.

R2: Operational and Maintenance Costs: While continuous casting and rolling lines are efficient, there are ongoing operational and maintenance costs associated with these systems. Regular maintenance and occasional repairs can add to the overall cost of ownership.

R3: Technical Complexity: Operating and maintaining continuous casting and rolling lines require specialized knowledge and expertise. Some manufacturers may find it challenging to recruit or train personnel with the necessary skills, potentially leading to operational challenges.

Challenges:

C1: Market Competition: In regions where, multiple manufacturers have already adopted continuous casting and rolling technology, there may be intense market competition. This can lead to pricing pressures and may make it challenging for new entrants or existing manufacturers to differentiate themselves.

C2: Global Economic Conditions: Economic downturns or uncertainties can impact investments in manufacturing equipment. During periods of economic instability, companies may delay or reconsider their plans to invest in new technologies, including continuous casting and rolling lines.

C3: Customization Challenges: Meeting the diverse and evolving requirements of different industries may pose challenges. Some manufacturers may face difficulties in customizing their continuous casting and rolling lines to accommodate specific production needs.

About the Authors

Wei Qin

Lead Author

Semiconductor and Electronics

Email: [email protected]

About QYResearch

QYResearch founded in California, USA in 2007. It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Séance #14 — Trop sur les réseaux, fais attention à ton coco!

Chers lecteurs,

Les réseaux sociaux nous apportent plusieurs bienfaits : divertissement, cercle social, espace de partage, information. Toutefois, les inconvénients sont nombreux. On a qu’à penser à la comparaison, la cyberintimidation, l’anxiété, la solitude, la dépendance ou même la crainte de rater quelque chose (FOMO). On en retire un grand questionnement par rapport aux réseaux sociaux : leurs inconvénients deviennent-ils plus importants que leurs bienfaits ?

Selon moi, oui.

Il suffit d’observer notre propre utilisation. Sommes-nous réellement heureux, rivés sur nos écrans ? Je crois qu’il est important de garder un équilibre dans notre usage des réseaux sociaux. Pour ma part, depuis l’arrivée de l’application TikTok, je vois une grande différence dans mon quotidien. Ce réseau social est très addictif. Il est très facile de faire défiler les vidéos pendant des heures sans s’en rendre compte. Je pense sincèrement que de ne pas utiliser cette application, ou du moins contrôler son usage serait bénéfique sur ma productivité et, ultimement, sur ma santé mentale.

Une étude publiée par le journal Technology Mind and Behavior et rapportée dans un article de La Presse a démontré que réduire le temps de consommation des réseaux sociaux est responsable du bien-être psychologique des jeunes. Les participants ont limité leur utilisation des réseaux à une trentaine de minutes par jour. Ils ont ensuite eu des résultats plus positifs sur des tests d’anxiété, de dépression, de solitude et de crainte de manquer quelque chose que sur ceux faits avant la réduction du temps d’utilisation (Legault, 2023).

Ce qui est le plus difficile c’est d’agir. Voici quelques trucs pour aider à restreindre notre temps sur les réseaux :

Mettre une limite de temps par application via les réglages du cellulaire

Se mettre en mode « Ne pas déranger » ou désactiver les notifications

Évaluer la quantité de temps passé sur les médias sociaux chaque jour

Le meilleur truc : avoir la volonté de le faire pour sa santé mentale (!!!)

Je pense que nous sommes tous conscients de notre surutilisation des réseaux sociaux. Alors, pourquoi ne changeons-nous pas nos habitudes ? J’espère que ce billet vous aura motivé à changer vos habitudes autant que moi. Sur ce, je ferme mon ordinateur !

À bientôt !

Bibliographie

Legault, J-B. (2023, 15 juin). Moins de réseaux sociaux, meilleure santé mentale. La Presse. https://www.lapresse.ca/societe/2023-06-15/etude/moins-de-reseaux-sociaux-meilleure-sante-mentale.php

Réseaux sociaux, comment tisser sa toile et préserver sa santé mentale? (2023, 10 octobre). Minds. https://www.minds-ge.ch/ressources/reseaux-sociaux-comment-tisser-sa-toile-et-preserver-sa-sante-mentale

0 notes

Text

If Carroll Shelby were to build the Cobra today. The team at Classic Recreations built their new Diamond Edition Shelby Cobra to demonstrate what the legendary Cobra would be, if built with all of the benefits of modern technology. It’s powered by a 5.0L Ford Performance Gen3 Coyote Aluminator engine that can be tuned to make 1000+HP mated to a Tremec T56 Magnum 6-speed manual transmission and rides on a race-inspired Schwartz Performance chassis (with cantilever suspension and billet CNC-machined aluminum assembly components), Baer brakes, 295/35ZR18 & 335/30ZR18 Michelin Pilot Super Sport tires, and 18x10/18x12 Forgeline forged three piece HL3X wheels finished with Matte Bronze centers & Polished outers! See more at: https://forgeline.com/customer-gallery/classic-recreations-4

🇺🇸🇺🇸🇺🇸

#forgeline#forgelinewheels#forgedwheels#customwheels#HL3X#ForgelineHL3X#notjustanotherprettywheel#doyourhomework#madeinUSA#classicrecreations#diamondedition#shlebycobra#csxcobra

8 notes

·

View notes

Text

Subtractive Manufacturing Mastery: CNC's Role in Rapid Prototyping

Many innovators and manufacturers turn to rapid prototyping to speed up product development. Through subtractive manufacturing, these professionals can streamline their time to market without compromising the strength and quality of their parts. This fast-evolving technology delivers CNC machined parts and helps businesses cut manufacturing and development costs.

Subtractive manufacturing is set to drive the growth of the rapid prototyping market by 14.9% from 2022 to 2031, with the aerospace industry likely being the largest contributor. Moreover, the increased availability of CNC machining services in China should encourage more industries to adopt and benefit from this rapid prototyping solution. Continue reading to learn more about CNC machining’s role in rapid prototyping.

A great way to make physical models

CNC machining is a subtractive manufacturing solution that helps manufacturers, product engineers, production planners, and designers make a tangible model, prototype, or sample of their product. These professionals can save time and money by using CNC machined parts to test and review their products in the real world.

Subtractive manufacturing creates a prototype by removing material from a block or billet of metal or plastic. That said, the process is fully automatic and computer-controlled, making it more reliable and capable of delivering results faster than hand-carving and other manual processes. Some service providers can even reduce lead times to 4 business days with CNC machining.

Ensuring accurate, high-quality parts

Rapid prototyping with CNC machining delivers robust, high-precision parts, especially when service providers apply industry-standard tolerances. The best CNC machined parts are controlled to DIN-2768-1 Medium for plastics and Fine for metals to ensure accurate-to-CAD results. In addition, manufacturers use the latest and proven equipment and tools, such as sink and wire EDMs, CNC mills, and surface grinding machines, to deliver CNC milling and turning solutions.

How it benefits rapid prototyping

CNC machining supports rapid prototyping because of the following reasons:

Quick and repeatable, making it ideal for low-volume manufacturing.

Delivers on high tolerance and precise specifications.

Service providers offer a wide range of rapid prototyping materials.

Master CNC machining with the experts

Learn more about subtractive manufacturing and get high-quality CNC machined parts from the experts at HLH Proto. The rapid prototyping and low-volume manufacturing company has extensive experience in providing custom solutions to various industries, including automotive, aerospace, electronics, industrial automation, robotics, oil and gas, and medical. Request a quote now to see how they can help your next project!

0 notes

Text

Innovations in Forging Technology: What's on the Horizon?

In the dynamic landscape of industrial processes, forging technology stands as a cornerstone in the manufacturing sector. As the industry continues to evolve, it is crucial to explore the innovations that are shaping the future of forging. From advancements in the forging process to the integration of cutting-edge equipment, this blog delves into the exciting developments on the horizon.

The Current State of Forging Technology:

Before we venture into the future, let's take a brief look at the present state of forging technology. Traditional forging methods have been refined over the years, ensuring durability and precision in the production of essential components for various industries. However, the need for efficiency, sustainability, and enhanced capabilities has fueled the exploration of new frontiers in forging.

Advanced Processes Revolutionizing Forging:

In the world of forging, innovation is key to moving forward. We understand how important it is to use the latest technologies to improve what we do and get great results. Among these advancements, the use of an infrared pyrometer stands out as a notable tool for temperature measurement in billet heating processes.

With their non-contact measurement capabilities and rapid response time, infrared pyrometers contribute to the efficiency and accuracy of our operations. However, alongside these advancements, we leverage several other advanced processes to revolutionize forging:

Precision Forging:

One of the emerging trends in forging technology is precision forging. This process involves the use of advanced simulation and control systems to achieve unparalleled accuracy in shaping metal components. The result is a reduction in material waste, improved product quality, and enhanced overall efficiency. Precision forging is becoming increasingly popular in industries where tight tolerances are crucial, such as aerospace and automotive manufacturing.

3D Simulation: Enhancing Forging Efficiency

Our utilization of 3D simulation software, such as 3D SIMULATION DEFORM 3D and FORGE NxT 2.1 Transvalor, enables us to develop parts offline. This approach optimizes the forging process, enhancing the utilization of forging equipment and materials. With our commitment to advanced engineering solutions, we strive to deliver superior quality and efficiency across all aspects of our operations. By harnessing the power of cutting-edge technology, we ensure that every component produced meets the highest standards of precision and performance.

Automation in Forging Processes:

Automation has become a game-changer in the forging industry, streamlining processes and improving overall efficiency. Happy Forgings Limited embraced automation in their forging plants, automating repetitive tasks and allowing skilled workers to focus on more intricate aspects of the production process. This has not only increased productivity but also improved worker safety.

Sustainable Forging Practices:

Green Forging:

Sustainability is a growing concern in the manufacturing sector, and forging is no exception. Green forging practices focus on minimizing environmental impact by optimizing energy usage, reducing emissions, and using renewable sources like solar energy. Innovations in energy-efficient heating technologies and closed-loop forging processes contribute to forging's evolution toward a more sustainable future.

Recyclability and Circular Economy:

The forging industry is exploring ways to contribute to the circular economy by designing products with recyclability in mind. Materials that can be easily recycled or repurposed after their lifecycle reduce the environmental footprint of forging operations. The adoption of eco-friendly materials and forging techniques aligns with global efforts to create a more sustainable and circular approach to manufacturing.

Collaborative Efforts and Industry Initiatives:

Industry Association Initiatives:

Forging industry associations play a pivotal role in driving innovation. Collaborative efforts within the industry foster the exchange of knowledge and best practices. Industry associations often organize conferences, workshops, and knowledge-sharing platforms to facilitate discussions on the latest technologies, ensuring that the entire forging community stays informed and aligned with advancements.

Equipment Digests:

Staying updated on the latest equipment innovations is crucial for forging manufacturers. Equipment digests, industry publications, and technology showcases provide insights into the newest machinery and tools available. Manufacturers can leverage this information to invest in state-of-the-art equipment that enhances their forging capabilities, ensuring they remain competitive in the market.

Conclusion

As we peer into the future of forging technology, it's evident that innovation is driving the industry forward. Precision forging, additive manufacturing, smart equipment, sustainability initiatives, and collaborative efforts within the industry are shaping a new era for forging. Manufacturers embracing these advancements are not only ensuring their competitiveness but also contributing to a more sustainable and efficient future for the forging industry. The horizon is bright, and the evolution of forging technology continues to be a fascinating journey into uncharted territories.

0 notes