#Rotary encoders

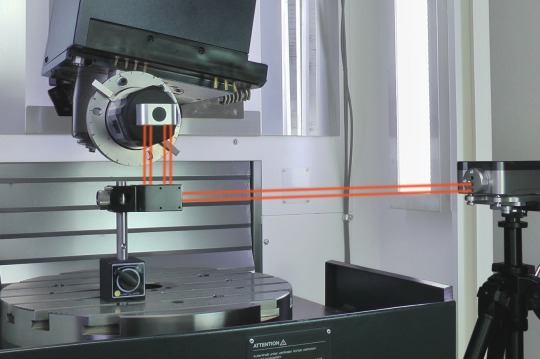

Photo

Optical rotary encoders can revolutionize your business facilities. Made by experts, these rotary encoders have integral bearings for separate coupling. Not only this, but they have a solid shaft. To know more about magnetic rotary encoders, visit the website today.

0 notes

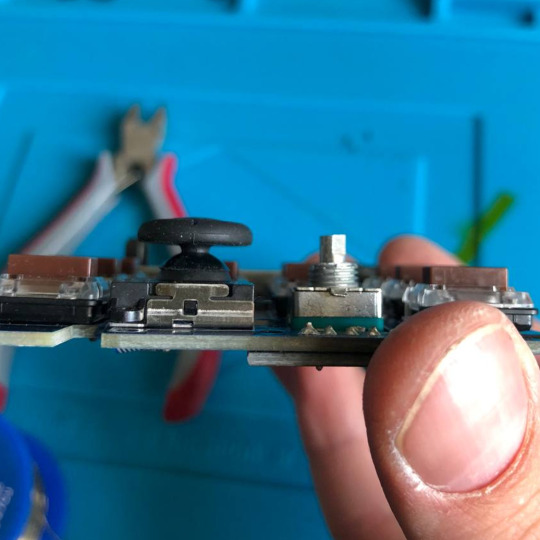

Photo

Modifying KY-040 rotary encoder to low-profile

By cutting its shaft and re-shaping its stem, I decreased its height from 28 mm to 13 mm

from WaifuPad

#rotary encoder#encoder#low-profile#slim#mod#modification#electronic#electronics#craft#diy#file#saw#arduino#pcb#module#component#ky040#ky-040#rotary#macropad#keypad#keyboard#geek#waifu#waifupad#adobe illustrator#illustrator#macro#soldering#controller

19 notes

·

View notes

Text

Jayashree Encoders provides ip65 rotary encoder, photoelectric rotary encoder, rotary encoder 1024, rotary encoder 600 pulse, rotary encoder pins at best price. It is the best rotary encoder Supplier, Manufacturer, Exporter, Dealer company in Pune.

0 notes

Text

Rotary Encoder Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “Rotary Encoder Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitor’s analysis and a detailed overview of the global rotary encoder market in terms of market segmentation by type, product, application, end-user industry, and by region.

Increasing Industrialization and Digitization to Promote Global Market Share of Rotary Encoder

The market is predicted to increase moderately as a result of the Industry 4.0 revolution and digitization, which have further expedited the adoption of automation across a number of industries. Industry 4.0 persuaded OEMs to include IoT in their operations due to the consistent increase in IoT usage and digital transformation occurring across several industries. For instance, according to the International Data Corporation's (IDC) Worldwide Semiannual Internet of Things Expenditure Guide, European investment in the Internet of Things (IoT) exceeded USD 202 billion in 2021. It is expected to increase by double digits through 2025.

Request Report Sample@

In addition to these, Governments everywhere are promoting the adoption of various automation technologies to support the structural expansion of industrial firms. Governments across the globe focus on the manufacturing sectors since they are essential to this progress. This is expected to promote market expansion overall by increasing the usage of industrial robots.

Some of the major growth factors and challenges that are associated with the growth of the global rotary encoder market are:

Growth Drivers:

Surge in Technological Developments and High Accuracy Could Strengthen Market Growth

Rising Automotive Industry

Challenges:

Lack of product differentiation is one factor hindering the growth of the rotary encoder market. Because rotary encoders are used in such large quantities in the electronics, aerospace, automotive, and other industries, customers purchase them in bulk. Rotary encoders can have a wide range of functions and applications. Due to the wide variety of huge enterprises offering similar technology items, consumers have many options. In order to compete with larger manufacturers for the high volume of these products, manufacturers are under pressure to reduce their pricing. This is troublesome because it puts pressure on manufacturing prices. Encoders encounter a number of issues and constraints that reduce their capacity to endure competition because of their few brittle parts and possible complexity and potential error causes that could lead to the inaccuracy are some of the major factors anticipated to hamper the global market size of rotary encoder.

By application, the global rotary encoder market is segmented into metal forming & fabrication, servo motor, elevator industry, machine tool and material handling. The machine tool segment is to garner the highest revenue by the end of 2036 by growing at a significant CAGR over the forecast period. In machine tool applications, rotary encoders are used to accomplish precise sensing and positioning. A machine can determine the exact commutation angle and axis alignment. Rotating encoders improve system precision and enable optimal machine performance. It is heavily used in this application for these reasons. It is anticipated that the robust adoption rate and increasing demand will drive the robotics segment's notable expansion. The International Federation of Robotics (IFR) projects that between 2020 and 2022, factories globally will deploy close to 2 million industrial robots. These factors should boost demand for rotary encoders because of their widespread application in robotics.

By region, the Europe rotary encoder market is to generate the highest revenue by the end of 2036. Industrial robotic applications are one of the many potential markets for encoders, and this increase is projected to boost the market growth in the region. Automation in many industries in Europe may eventually lead to a rise in the need for robots, which will also raise the need for rotary angle sensors. Another dynamic area that has a lot of promise for the increase in encoder demand over the course of the projection period is the electronic sector.

Access our detailed report at:

0 notes

Text

Pepperl+Fuchs FVM58 ABSOLUTE ROTARY ENCODER

Manufacturer: Pepperl+Fuchs

Product no. : FVM58N-011AEA3GN-0813

Product type : Multiturn absolute encoder

Data format : F = Fast parallel

Shaft version : V = Solid shaft

Principle of operation : M = Multiturn

Housing material : N = Aluminium, powder coated

Shaft dimension/flange version : 011 = Shaft ÿ10 mm x 20 mm with clamping flange

Connection type : AE = Plug connector type 9426,…

View On WordPress

#Absolute Rotary Encoder;#P+F बैरियर#P+F ปัญหาและอุปสรรค#P+F halangan#P+F hambatan#P+F rào cản#P+F الحواجز#Pepperl+Fuchs Absolute Rotary Encoder;#Pepperl+Fuchs Barriers#pepperl+fuchs encoder#pepperl+fuchs sensor

0 notes

Text

Explore the world of miniature rotary encoders, where precision meets compact design. Learn how these versatile devices provide accurate rotational sensing for a wide range of applications. Find out more about the benefits and uses of miniature rotary encoders today.

1 note

·

View note

Text

Rotary Encoder FAQs (Frequently Asked Questions)

Explore our informative blog series on Rotary Encoder FAQ! Gain a comprehensive understanding of working principles, types, and practical applications. From robotics to manufacturing, rotary encoders are crucial in various industries. Whether you're a novice or an expert, join us on this engaging journey of discovery!

0 notes

Photo

Hubner encoders ,Level switch ,Hubner techogenerators ,Pilz Safety relay ,Pnoz pilz safety systems

link:https://www.shreejimkt.com/burkert.html

0 notes

Text

Retrofit and Controller/VFD Up-Gradation

Machine retrofits are possible in various levels. A retrofit can be as basic as replacing old axes motors and drives with new AC digital servo technology.

A comprehensive retrofit for example would include an all new machine electrical system such as CNC control, AC digital servo motors and drives, complete machine wiring, linear and rotary encoders for closed loop positioning feedback, new operator pendent, and new electrical cabinet. Machine operation Training and Manufacturers Warranty are also provided.

#Machine retrofits are possible in various levels. A retrofit can be as basic as replacing old axes motors and drives with new AC digital ser#A comprehensive retrofit for example would include an all new machine electrical system such as CNC control#AC digital servo motors and drives#complete machine wiring#linear and rotary encoders for closed loop positioning feedback#new operator pendent#and new electrical cabinet. Machine operation Training and Manufacturers Warranty are also provided.#palletizing company india

0 notes

Text

Roomba Silver (models 4150, 415) by iRobot, Bedford, MA (2005). This model has a distinctive silver finish, and was sold via Amazon.com and Target. It’s one of the first models to sport the two-tone swivel caster wheel. This passive caster located at the front of the Roomba provides a third point of support in addition to the two drive wheels. This half black & half white caster is also a rotary encoder, with an optical sensor detecting the alternating contrast as it rotates. This detects if the Roomba is stuck or beached, when the drive wheels are spinning, but the Roomba isn't moving.

20 notes

·

View notes

Text

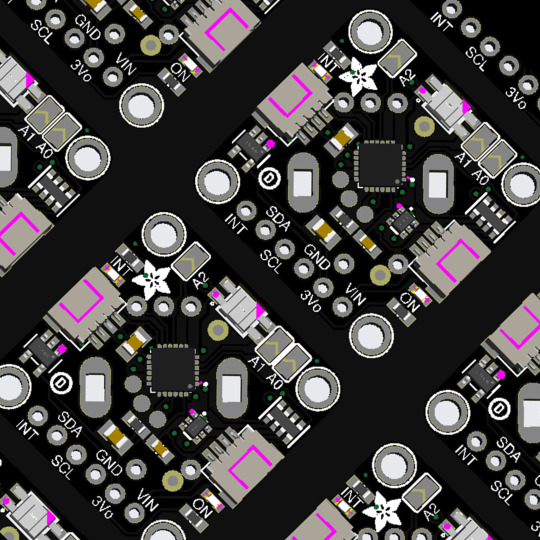

PCB of the day! Adafruit I2C Stemma QT Rotary Encoder Breakout with NeoPixel - STEMMA QT / Qwiic 🔧🔄🎛️

Rotary encoders are soooo much fun! Twist them this way, then twist them that way. Unlike potentiometers, they go all the way around and often have little detents for tactile feedback. But, if you've ever tried to add encoders to your project, you know they're a real challenge to use: timers, interrupts, debouncing…

This Stemma QT breakout makes all that frustration disappear - solder in any 'standard' PEC11-pinout rotary encoder with or without a push switch. The onboard microcontroller is programmed with our seesaw firmware and will track all pulses and pins for you and then save the incremental value for querying over I2C. Plug it in with a Stemma QT cable for instant rotary goodness with any microcontroller from an Arduino UNO up to a Raspberry Pi.

You can use our Arduino library to control and read data with any compatible microcontroller. We also have CircuitPython/Python code for use with computers or single-board Linux boards.

#adafruit#electronics#pcb#opensource#opensourcehardware#pcboftheday#arduino#raspberrypi#circuitpython#python#linux#rotaryencoder#stemmaqt#neopixel#i2c#breakoutboard#engineering#hardware#microcontroller#diy#technology

35 notes

·

View notes

Text

yesterday I got in the mail:

arduino nano every

rotary encoders (basically a dial that you can keep turning and doesn't have a start/stop)

plastic knobs that DON'T FIT THOSE ROTARY ENCODERS REEEEEE

some new, different EEPROMs that aren't single-wire and are clock-driven instead

I found an addressable RGB (well, BGR) LED strip that I bought like 6 years ago and hey presto it still works!! back in 2018 I had it hooked up to a Teensy, and the Teensy would take commands over serial to display colors on the LED strip, and I would have a Python program watching pulseaudio on my PC and change the colors based on something that @earthnuker wrote (that I'm trying to decipher again) so that bass would show up as red and high notes would show up as blue. ish. I have a video on tumblr of this from that point but siikr is still down so I can't find it. this is all to say that I bought the Nano for this purpose, or at least prototyping putting this into a compact package so it Just Werks (TM). I am remiss about using an entire breakout board to do this though, I've got a handful of STM32F030 chips sitting around and they may be better suited for this idk. it'll probably be good for a prototype so I can reuse the Arduino at a later date since that sucker was $20 and the STM32 chips are like $1 (but are literally just the microchips that you have to solder on to a PCB yourself)

Rotary encoders are for that dumb Arcblip game that I want to turn into a device. I want to use that as the peripheral to control spinning the little circle around, rather than using buttons to do that. I also discovered that it has a push-to-click functionality too, so I don't even need an external button if I go this route. looks cool, datasheet is horrible. the knobs I bought for the encoder have the D-shaped holes, rather than a knurled circle - they didn't fucking have this on the mouser.com page, you literally had to LOOK AT THE DATASHEET FOR A PIECE OF PLASTIC. I am still salty about this. so they're basically useless, I will take them to canada for @party-slug to use instead.

finally the EEPROMs are 24AA02IDs, they are clock-driven instead of single wire. the AT21CS01 device I was trying to get working previously was really cool but it depended on microsecond precision, some operations literally needed to last 1-2µs maximum which the STM32F030 couldn't quite handle. it felt very loose and I couldn't ever get it to work, so I think I needed a faster processor (also, it would start in "high speed mode" instead of the lower "standard" speed, wtf). so now I'm going to try out using this device where I define how fast the clock goes, it can handle ranges from 100khz-400khz which is a lot easier to manage. it's not quite I2C, but it should be more reliable than the stupid time-and-edge based chip I was using before.

thanks for reading my blog

4 notes

·

View notes

Text

"idk if ill be able to come up with uses for three rotary encoders" was quitter talk. one of them is volume, one of them is undo/redo, and one of them is left/right arrow+shift for individual character highlighting for editing. i feel like a god.

18 notes

·

View notes

Text

Choosing the Right Bearingless Encoder for Your Application

Bearingless encoders are available in a wide range of types and configurations, making it challenging to select the right one for your specific application. In this article, we will provide an overview of the different types of bearingless encoders available and their applications. We will also discuss the key factors to consider when choosing a bearingless encoder, such as accuracy, resolution, signal output, and environmental considerations. By the end of this article, you will have a better understanding of how to choose the right bearingless encoder for your application.

0 notes

Text

#Omron Proximity Sensor#Omron Photoelectric Sensor#Omron Rotary Encoders#P&F Proximity Sensor#P&F Photoelectric Sensor#P&F Rotary Encoders.

1 note

·

View note

Text

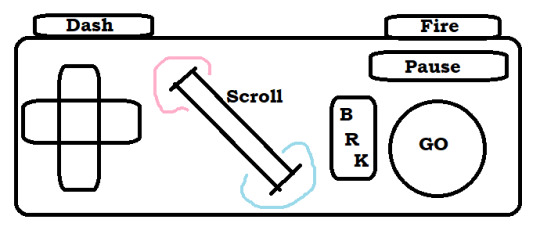

A controller with a scroll wheel, you say?

Well this is a little funny. Yesterday I posted the first part of a series of post on the fine details of how computers work, mentioning how I've been looking into this as part of a personal project I've been working on, and today I wake up to see Masahiro Sakurai posting a youtube video lamenting the lack of... this exact thing I'm working on.

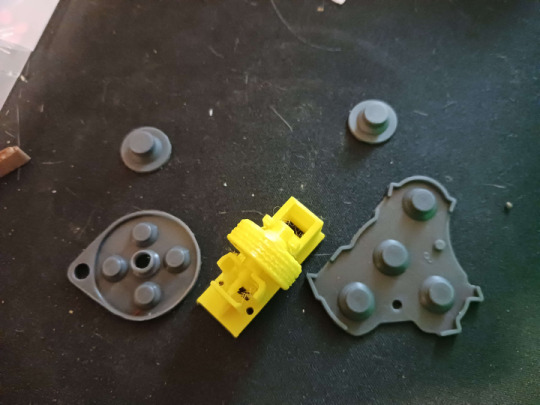

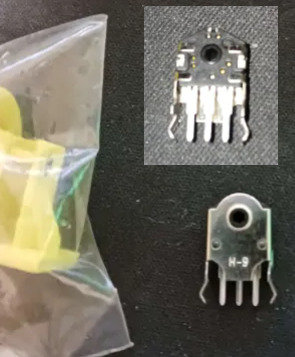

Apologies for how much cat hair is in this photo, that's a bit of an occupational hazard, but this here is a photo I took back in September when most of the parts I had to order were in for the prototyping of this thing:

That's a really bad MS Paint mockup, but yeah. I'm designing my own game console, and one of the key features is a big ol' scroll wheel right in the center of the controller. Another is that I'm planning to just put all the designs of the circuit boards and 3D printer files for the casing/buttons up online for free, making it this totally open DIY thing where anyone who's a big enough nerd can just make a couple downloads, order some dirt cheap components, and build their own copy of the system (or people with better setups than me can build and sell them, whatever). So I'm not super worried about anyone stealing my ideas or whatever, but I WOULD like to establish a standard and all that, and figured it was worth noting that this is something I've been slowly working towards for like a year or two now, and didn't just get the idea from this video:

youtube

But yeah, now that the idea's out in the public consciousness, here's the plan for the controller (that I was planning to keep under my hat until I had a working prototype and some demo software sometime next year).

First off, the plan is that this is to be the standard controller for a whole console I'm also plucking away at designing, which is a bit more ambitious of a project, so I figure I might as well make it compatible with something that's already out there. So specifically, I'm designing this so that you can take one, plug it right into an SNES (or with a different connector at the end, an NES, because turns out they use the exact same input handling standard and it's just the shape of the plastic on the end that differs), and have it just work. Or mostly work anyway. I'm hoping I can process a signal out of the scroll wheel in a way that it either just needs the 3 extra bits of the input signal I don't have buttons for in my design (more on that later) or failing that, I can get it to output the same sort of signal as one wheel in the SNES mouse, which just rides along the second data line very few things use. I think that plan might break multitap compatibility and require an extra chip on the controller PCB, but it would leave this slightly more compatible with existing games on the same hardware. I might also do something weird with the button mapping to be sure NES select is on a shoulder and it works right out of the box with that whole library.

Working out exactly how to handle signals from the scroll wheel happens to be the point I'm currently stuck on by the way. I got this baggie full of rotary encoders for just a few cents which... almost fit in my first draft 3D printed wheel housing, but I have NO documentation on them, not even a part number/manufacturer besides "H-9," the pins don't fit a breadboard, and I've kinda been scrambling for rent so I can't afford a nice multimeter or oscilloscope to poke around with. Plus again I need to redesign this wheel print to even get it to spin right, and... this was a gift from a friend with a printer who is Not Local. Solvable problem, just needs more time and/or outside expertise.

But yeah, once I have those kinks worked out, it should be easy enough to get a custom board design made, replicas of end-cap of the controller cord are another problem easily solved by ordering a 1 dollar part or 3D printing something. The actual cord might be tricky since I don't know where you actually order something like that from, but it should be easy enough for anyone who doesn't mind a little assembly work to put one of these together and have it good to go for any software made with it in mind, or retrogames where you don't mind a weird button count. So... what's the pitch on this scroll wheel anyway?

Well for starters, there's the stuff Sakurai got into this morning. Any sort of RPG or text heavy game can use it to quickly scroll through menu options, or stuff in a text-heavy game. You could also pan the screen with it, something a lot of early 16-bit games assigned to the shoulder buttons or holding up and down while getting used to the new options the hardware was giving them.

Past that, you'll notice in my design it's at a 45 degree angle. I might have to tweak it a little, but my thinking is for a game that uses it heavily, one thumb or the other can slide over easily enough (I'm going for a pretty compact overall design) so we can have some games where you take your thumb off the D-pad, and have this nice analogue steering wheel. Nice for fine control in a racing game, or if you want some little radio-tuning/safe-cracking sorta deal.

Alternatively, move your right thumb over, use the D-pad to steer, shoot and dodge or whatever with shoulder buttons, and use the wheel to rotate a turret for a twin-stick sort of game maybe.

Or just use it for the sort of stuff mouse based games stick on the scrollwheel. Changing weapons, changing powerups... I'm planning to officially label the directions "hot" and "cold" to encourage weird gimmicky things like... I dunno, a platformer where you have a thermostat in your controller you can always mess with, freeze water coming out of pipes, crank up flame jets? Have a shot charging mechanic where you just really crank it to get to max strength? Weird minigame stuff. There's some fun space to explore with it.

Then we have the rest of the design here... which basically comes down to me being just plain sick of how every controller made by anyone in the past... 20 years give or take has kind of the exact same layout? 4 good face buttons, a D-pad, 4 shoulder buttons, 2 sticks, and 1-4 annoying to reach tiny awkward middle buttons, and we're just kind of overdue for a change-up?

Like first of all, hey, this is just too many buttons. There's a ton of games that really only need a D-pad, and maybe 3 buttons (attack jump pause) and the two things that aren't fully standardized is how awkwardly placed the D-pad is and how awful and awkwardly placed the pause button is. Shoulder buttons can be nice, but I've never really felt like 4 of them awkwardly crammed on the rim has been really useful or ergonomic, and that's coming from someone who's been playing a ton of FF14, which gets more use out of them than anything else I could name. And really, aside from games doing fake twin-stick stuff and using the whole grid like a second D-pad, I'm having a really hard time thinking of any game I've ever played that really makes good use of 4 good face buttons? Like people will use them if they've got'em sure, but unless you do that keyboard style thing where you lay the controller on a table and use all your fingers, you can really only comfortably hit 2 face buttons without sliding your thumb away from them, maybe comfortably make a quick pivot to a third.

Also, really, a lot of designers just sort of feel compelled to map SOMETHING to every button, even if it's clear the design didn't really need them. So basically I figure I'll try kinda just taking a "less is more" approach here. Here's the buttons that it's comfortable to rest your thumbs and fingers on, here's a dedicated pause/menu button where people often stick a kind of redundant menu button, here's my gimmicky scrollwheel. That's it, work around that.

I'm also going a little Gamecube inspired (literally using replacement membranes for one in my prototype design, even). Gonna make a great big primary button and use different shapes for the other two. Trying to label these in a less arbitrary fashion than most. If shooting a gun is a thing you do in this game, and there isn't a real good reason not to, default it to this nice right trigger you can hold down all the time. If we're advancing through menus or jumping or holding down gas in a car, here's the big GO button. Need brakes, need to break stuff with a melee attack? Go back in a menu system? There's your other face button. Have a quick dash move or a run you hold down, let's just use the other shoulder.

So yeah. That's my controller. Need to work out the kinks on the scroll wheel, source a cord, and hopefully I can slap things together and this will be something you can just order bits for piecemeal and put together for like, $5-10 after shipping? Maybe less? The parts are shockingly cheap so far.

But yeah if anyone has any insight to the scroll wheel or cord issues, let me know. Also the whole thing is presently a tad back-burnered because I am in a serious financial crisis and I don't want to have electronics spread all over my table if I have to abruptly find a new place to live if I can't scrape next month's rent together. So as usual, donations are incredibly welcome.

2 notes

·

View notes