#Magnetic rotary encoder

Photo

Optical rotary encoders can revolutionize your business facilities. Made by experts, these rotary encoders have integral bearings for separate coupling. Not only this, but they have a solid shaft. To know more about magnetic rotary encoders, visit the website today.

0 notes

Text

Top Six Sensors Provided By Pepperl+Fuchs

Pepperl+Fuchs is a world-known brand. It has a reputation for producing and delivering first-class industrial sensors and sensor systems for automation sectors. Their devotion to quality work performance is seen in their broad application products portfolio.

Their products include sensors for general purposes, and also custom solutions that are designed to suit specific area needs. Continue reading to learn more about the brand and the different types of sensors they produce.

Industrial Sensors For Factory Automation

The industrial sensors for factory automation of Pepperl+Fuchs stand out for the level of innovation and quality they have. This product range accommodates inductive, photoelectric, capacitive, magnetic, and ultrasonic sensors.

The company equips the system with features such as rotary encoders, positioning and identification systems. Pepper+Fuchs can show its concern with a complete automation solution by using industrial vision systems and vision sensors.

Sector-Specific Applications

Pepperl Fuchs supplier in UAE has set its eyes on different markets. It includes mechanical engineering, automotive, material handling, packaging, print, and paper industry. It is also applicable in doors and gates, elevator construction, process equipment, mobile equipment, and renewable energies.

The automation and sensors can be customized to meet the needs of each of the industry sectors. The brand name guarantees proper and continuous operation.

Different Types Of Sensors

Pepperl Fuchs supplier in UAE provides different types of sensors according to the needs of the customer. Some of the most demanded sensors are:

1. Photoelectric Sensors: These sensors function by using light beams for object detection. They are acknowledged for their high precision and reliability, which make them a choice for different industrial needs.

2. Ultrasonic Sensors: They are suitable for many applications that cannot be captured with other sensors. The ultrasonic sensors use sound waves to detect objects, hence offering accuracy and versatility.

3. Inclination and Acceleration Sensors: They are preferred for measuring the tilt angle or acceleration of an object. These sensors deliver accurate and reliable measurement data that offers the best performance in critical missions.

4. Distance Sensors: They have been engineered to measure the distance between the sensor and an object in a very reliable manner. These sensors are an integral part of applications that need accurate distance measurement. Some areas they are used in include robotics, AGVs and material handling systems.

5. Diffuse and Retroreflective Mode Sensors: Sensors in diffuse mode detect objects by reflecting light off of the object's surface. The retroreflective mode sensors use a reflector to bounce light back to the sensor. They are used in situations when the object to be detected is difficult to reach or precise positioning is demanded.

6. Double Sheet Sensors: The double sheet sensors are used to detect the multi-layer material passing through a process. These are usually employed in sectors including automotive, metal crafting, and printing among others. They minimize errors in material handling and processing.

Conclusion

Pepperl+Fuchs' quality, innovation, and customer satisfaction have made it a reliable partner for businesses. The wide range of products they offer teamed with their deep industry knowledge make them a choice for industries globally. They have maximised automation and efficiency in industrial processes.

0 notes

Video

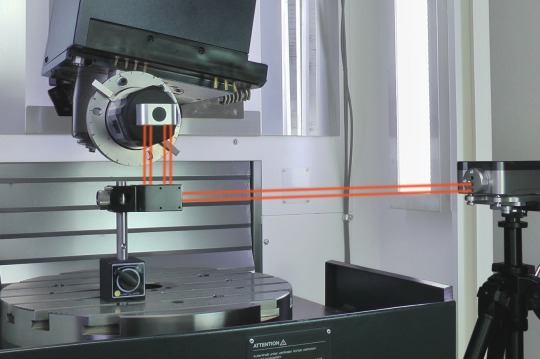

Machine Tool Encoders #magneticencoder #positionsensor #rotarytransducer #spindleencoder

Machine Tool Encoders, magnetic encoders,position sensor, rotary transducer, spindle encoder www.roundssencoder.com www.encoderchina.com [email protected]

0 notes

Text

Brushless DC Motors Working Principle and Applications

Brushless DC motors (BLDC) are a type of electric motor that operate on direct current (DC) power and use electronic commutation to switch the current direction in the armature windings. They have many advantages over traditional brushed DC motors, such as higher efficiency, longer lifespan, and lower maintenance requirements. They are widely used in various applications, such as electric vehicles, industrial automation, robotics, and power generation. This blog post will explain the basic structure, working principle, and applications of BLDC motors.

Structure of Brushless DC Motors

A Brushless DC motors consists of two main parts: the stator and the rotor. The stator is the stationary part of the motor that contains the armature windings. The armature windings are arranged in a sequence of coils that produce a uniform magnetic field when energized. The rotor is the rotating part of the motor that contains permanent magnets. The permanent magnets are attached to the rotor in a specific pattern that determines the number of poles of the motor. The rotor rotates around the stator due to the interaction of the magnetic fields.

The BLDC motor also requires a controller and a sensor to control the commutation of the armature current. The controller is an electronic circuit that switches the current in the armature windings according to the position of the rotor. The sensor is a device that detects the position of the rotor and sends a signal to the controller. The sensor can be either a Hall sensor or a rotary encoder. The Hall sensor is a magnetic sensor that detects the change of the magnetic field due to the rotation of the permanent magnets. The rotary encoder is an optical or mechanical sensor that detects the angular position of the rotor.

Working Principle of Brushless DC Motors

The working principle of a Brushless DC motors is based on the Lorentz force law, which states that a current-carrying conductor placed in a magnetic field experiences a force. The direction of the force is perpendicular to both the current and the magnetic field. In a BLDC motor, the current-carrying conductors are the armature windings, and the permanent magnets produce the magnetic field. The force acting on the armature windings causes them to rotate around the stator.

The commutation of the armature current is done electronically by the controller and the sensor. The controller switches the current in the armature windings in a specific sequence that ensures that the magnetic field of the stator is always perpendicular to the magnetic field of the rotor. This creates a maximum torque and a smooth rotation. The sensor provides feedback to the controller about the position of the rotor, so that the controller can switch the current at the right time.

Applications of Brushless DC Motors

BLDC motors are suitable for applications that require high efficiency, precision, and reliability. Some of the common applications of BLDC motors are:

Electric vehicles: BLDC motors are used to power electric vehicles, such as electric bikes, scooters, cars, and buses. They offer high performance, low noise, and long battery life.

Industrial automation: BLDC motors are used to drive various machines and equipment in industrial automation, such as conveyor belts, pumps, fans, and robots. They offer high speed, accuracy, and durability.

Robotics: BLDC motors are used to control the movement and operation of robots, such as humanoid robots, service robots, and drones. They offer high torque, responsiveness, and flexibility.

Power generation: BLDC motors are used to generate electricity from renewable sources, such as wind, solar, and hydro. They offer high efficiency, low maintenance, and environmental friendliness.

EMPPL is a company that specializes in providing high-quality Brushless DC motors for various applications. EMPPL offers a wide range of BLDC motors, such as brushless motors, brushless outrunner motors, brushless inrunner motors, and brushless hub motors. EMPPL also offers custom-made BLDC motors according to the customer’s specifications and requirements. EMPPL is your trusted partner for all your BLDC motor needs. You can visit their website here to learn more about their products and services.

0 notes

Text

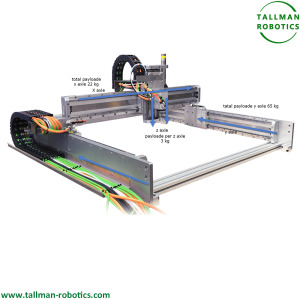

Linear electric motors for clients from Germany are under test

Linear electric motor is a type of electric motor that converts electrical energy into linear motion. It’s similar to a traditional rotary motor, but instead of producing a rotational motion, it generates linear movement.

Linear electric motors are commonly used in various industrial applications where precise and controlled linear motion is required. They offer several advantages over conventional mechanical systems, such as higher accuracy, faster response times, and increased reliability due to their simple design and absence of mechanical transmission elements like gears, belts, or screws.

The basic construction of a linear servo motor consists of a stator and a mover. The stator contains a series of coils that are energized with electric current, creating a magnetic field. The mover, typically a permanent magnet or a set of magnets, is attracted or repelled by the magnetic field, resulting in linear motion along a track or guide.

The movement of the mover is controlled by a feedback mechanism, usually involving position sensors such as encoders or linear scales. These sensors provide precise information about the position and speed of the mover, allowing for accurate control and positioning.

Linear electric motors find applications in various industries, including robotics, CNC machining, packaging, semiconductor manufacturing, medical devices, etc. They are used in systems requiring precise linear motion, such as linear stages, pick-and-place machines, cutting machines, and inspection systems.

It's worth noting that Linear electric motors are different from linear actuators, which are typically simpler devices that convert rotational motion into linear motion using mechanisms like lead screws or belts. While, Linear motors offer higher performance and are often preferred in applications where precise control and high-speed operation are critical.

You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data.

Read the full article

#ChinaLinearMotionStage#ElectricLinearMotor#IronlessMotors#Linearinductionmotor#LinearMotors#MotorizedLinearStages

0 notes

Text

Ferrite multistage ring magnets for magnetic encoders

ferrite multistage ring magnets for magnetic encoders

0 notes

Text

Encoders Market to amass significant gains by 2025

Encoders are devices or components used in various fields, including electronics, computing, communications, robotics, and automation. They are designed to convert physical or analog input signals into digital output signals for processing, measurement, or control purposes. Encoders play a crucial role in translating real-world data into a format that can be understood and utilized by electronic systems. Here are a few types of encoders:

For Download Sample Link : https://www.globmarketreports.com/request-sample/258207

Rotary Encoders: Rotary encoders are used to measure the position, speed, or angular displacement of a rotating object or shaft. They typically consist of a rotating disk with patterns or slots and a sensor that detects changes in the patterns as the disk rotates. Rotary encoders can be absolute (providing a unique digital code for each position) or incremental (providing relative changes in position or speed).

Linear Encoders: Linear encoders measure linear motion or position along a straight path. They are commonly used in applications such as machine tools, coordinate measuring machines, and robotics. Linear encoders can be optical, magnetic, or capacitive, depending on the technology used to detect and convert the linear displacement into digital signals.

Optical Encoders: Optical encoders use light and photodetectors to convert motion or position into digital signals. They typically consist of a light-emitting diode (LED), a codewheel or scale with patterns, and photodetectors to detect changes in the light patterns as the scale moves. Optical encoders offer high resolution, accuracy, and reliability.

Magnetic Encoders: Magnetic encoders use magnetic fields and sensors to detect changes in position or motion. They are often used in environments where dust, dirt, or liquids can affect the performance of other types of encoders. Magnetic encoders can be absolute or incremental and provide robust operation in challenging conditions.

Digital Encoders: Digital encoders convert analog signals into digital format. They are commonly used in audio and video applications for encoding analog signals into digital signals for processing, storage, or transmission. Digital encoders use various coding schemes, such as pulse code modulation (PCM), to represent analog signals digitally.

Encoder-Decoder (Codec): In the context of audio and video processing, an encoder-decoder, also known as a codec, is a device or software that converts analog or digital audio/video signals into a compressed digital format for efficient storage, transmission, or streaming. Codecs are widely used in applications such as video conferencing, multimedia streaming, and digital broadcasting.

Encoders are essential components in numerous systems and applications, providing accurate and reliable measurement, control, and data processing capabilities. The choice of encoder depends on the specific requirements of the application, such as resolution, accuracy, environmental conditions, and cost considerations.

0 notes

Text

Potentiometer Position Sensors Market Size, Share, Trends, Growth, Industry Analysis, Key Players, Revenue, Future Development & Forecast 2023-2032

The potentiometer position sensors market refers to the industry that involves the manufacturing, distribution, and sales of potentiometer-based position sensors. Potentiometers, also known as pots, are variable resistors that are commonly used as position sensors to measure the position or movement of various mechanical components in different applications.

Potentiometer position sensors typically consist of a resistive element and a sliding contact or wiper that moves along the resistive track. As the wiper position changes, the resistance of the potentiometer changes, allowing for position sensing and measurement. These sensors are widely used in various industries such as automotive, aerospace, industrial automation, robotics, and consumer electronics.

The market for potentiometer position sensors is driven by the increasing demand for accurate and reliable position sensing in various applications. These sensors offer advantages such as simplicity, cost-effectiveness, and ease of integration, making them a popular choice in many industries. Additionally, the growing adoption of automation and robotics in industries further fuels the demand for potentiometer position sensors.

Factors such as technological advancements, miniaturization of sensors, and the development of contactless potentiometer position sensors are expected to drive market growth. Contactless potentiometers use non-contacting methods such as magnetic, capacitive, or optical principles to measure position, eliminating issues related to wear and tear of mechanical components.

However, the potentiometer position sensors market faces competition from alternative position sensing technologies such as optical encoders, Hall effect sensors, and inductive sensors. These technologies offer advantages such as higher accuracy, longer lifespan, and resistance to environmental factors, which may limit the growth of the potentiometer position sensors market in certain applications.

Overall, the potentiometer position sensors market is expected to continue growing as industries seek reliable and cost-effective position sensing solutions. The market is characterized by ongoing technological advancements, increasing automation, and the need for precise position measurement in various sectors.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/potentiometer-position-sensors-market/723/

Market Segmentations:

Global Potentiometer Position Sensors Market: By Company

• SIKO

• ASM Sensor

• Honeywell

• BEI SENSORS

• NOVOTECHNIK

• ATEK SENSOR

• OPKON Optik Electronic

• MICRO-EPSILON

Global Potentiometer Position Sensors Market: By Type

• Potentiometer Rotary Position Sensors

• Potentiometer Linear Position Sensors

Global Potentiometer Position Sensors Market: By Application

• Aerospace & Defense

• Automotive

• Food & Beverage

• Pharmaceuticals

• Others

Global Potentiometer Position Sensors Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Potentiometer Position Sensors market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details : https://stringentdatalytics.com/reports/potentiometer-position-sensors-market/723/

Reasons to Purchase Potentiometer Position Sensors Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behavior: these research studies can offer insightful information about customer behavior, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/potentiometer-position-sensors-market/723/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Potentiometer Position Sensors Market#global Potentiometer Position Sensors Market report#global market insights#global research market report#global market report

0 notes

Text

Types of different motors and classification

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

Different types of motors and their use

What is motor?

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

Everything To Know About Incremental Shaft Encoders

Having a proper idea about the incremental shaft encoders is very important before starting work with such components. With a proper idea of the components, one would know how it works and where would be it’s ideal usage. Here it must be kept in mind that the incremental encoders fall undr the group of rotary shaft encoders. Hence, it can easily collect data and even offer feedback depending on the object rotation of a device.

What Are The Encoder Types?

Most of us might be aware of the fact that encoders are usually classified into four types, such as optical to magnetic, and mechanical to electromagnetic. All these types of encoders are usually available with the magnetic encoder distributors.

Shaft Encoders: Incremental

As we are well-aware of the fact that Rotary Encoders are often stated as Shaft Encoders. Also, Rotary Shaft Encoders are often referred to as Incremental Shaft Encoders. They can be used in a wide range of applications. But their main task is that they can easily measure speed, distance, and even the position.

However, one should keep in mind that the incremental encoders are able to offer information related to angle, position, as well as, on the rotation counts. The resolution gets defined as per the number of lines or even the pulses for every rotation. It must be kept in mind that the current position can be established by the control unit by taking help of the pulses.

Why Is It Referred To As Shaft Encoder?

In case, you are wondering why an incremental encoder is called as a shaft encoder then this post is right for you. For this style of encoder, the disk is usually mounted on the rotating shaft. The disk consists of a pattern of opaque as well as transparent sectors. As and when the disk starts tobrotate, the patterns will interrupt the light that gets emitted upon the photo detector. Thus, generating a pulse signal output.

Working Principle

Before consulting any magnetic encoder distributors for getting hold of any type of encoders, having an idea regarding the working principle of the encoders is important. For instance, the incremental encoder works as and when there is a change in the position of the shaft’s angular position into digital signal via the optical disk.

Hopefully, once you have a proper idea of the incremental shaft encoders, working with the component would be very easy one. But make sure the incremental encoder should meet the application device.

0 notes

Text

What Can The Music Industry Teach You About Animal Metal

MoYu is some of the dominant and senior speedcubes manufacturers available in the market, with a rich history of world-report breaking cubes. We cut out one nook of every heart sticker on the cube (see Figure 12), thus breaking rotational symmetry and permitting our model to find out absolute face angles from a single frame. The components from left to proper are (i) bottom center enclosure, (ii) lithium polymer battery, (iii) foremost PCBa with BLE, (iv) prime heart enclosure, (v) cubelet backside, (vi) compression spring, (vii) contact brushes, (viii) absolute resistive rotary encoder, (ix) locking cap, (x) cubelet top. For our hardness reduction, we develop two principal gadgets. The aim is to put 5 consecutive marbles within the center row of two adjacent quadrants (three in the middle row of 1 quadrant, two in the center row of one other quadrant) and then line them up. Section 2 introduces two manipulation tasks we consider here. See Section B.Four for particulars of their ADR parameterization. See Section E.1 for particulars. Make certain eye holes are large sufficient for little one to see out.

Contrary to well-liked perception, solving a Rubik’s cube isn’t all that arduous: all you might want to do is study the correct method, apply it a couple of times and - if your reminiscence is ok - you will quickly be able to do it blindfolded. While high quality quick turning cube will offer you exceptional velocity and provide you with sufficient control. For those with quality sound playing cards constructed into their computer systems, the allure is a little less potent. For these with horrendous-sounding laptops (yours actually included) the attraction of an outboard DAC is enormous; it could make an incredible distinction in sound quality. Should you had been to do a fast internet seek for “portable laptop computer speaker,” you’d be treated to a buffet of embarrassingly poor-sounding pieces of glorified plastic that, sadly, in all probability do sound higher than the audio system constructed into your common laptop computer. This is probably the commonest cube among world-class cubers, as a consequence of its wonderful performance, customizability, and high-high quality supplies, and is starring the highest world records list, with the 2nd fastest single clear up (4.16 s) and fastest common solve in the world, each set by Feliks Zemdegs.

It is a daunting task because of the complexity of Rubik’s cube and the interactions between it and the hand: in contrast to the block reorientation task, there isn't a means we can precisely seize the item in simulation. Since we train every coverage on only one particular activity (i.e. the block reorientation activity or solving the Rubik’s cube), we define meta-studying in our context as studying concerning the dynamics of the underlying Markov choice course of. Predicting the complete state of a Rubik’s cube is a tougher job and demands longer training time. Until of us get used to seeing such a factor, the Cube is certain to draw attention - it certainly did for us. Like a Rubik’s cube, each of these mirror cubes consists of three layers of blocks that you could rotate to get the specified configuration. That is the place speedcubes outperform the Rubik’s brand cubes as a result of most of the fashionable speed cubes permit for forty five levels nook cutting.

Proper corner chopping is executed effortlessly. The great corner slicing of the product makes it simple on the palm. Integrating magnets into speed cubes became more successful with time, and as of today it is broadly agreed as a typical for a great cube. Cubical graphs, not like grid graphs, will be conceptually associated to Rubik’s Cubes and Rubik’s Squares with little hassle. NASCAR has strict guidelines regarding how a lot nitrogen, or stress, might be in each shock. Back in the early days of NASCAR (which was integrated in 1948), the principles have been a bit beneath-evolved. rubik's cube with magnets have a bit more resistance when turning their layers, but will give you more control over your speed cube. They're quiet and don’t give the dry-scratchy feeling the quick turning ones do. Fast turning cube is poorly made if it merely provides no management. This supplies you with a brand new problem each time.

1 note

·

View note

Text

What Can The Music Industry Teach You About Animal Metal

MoYu is one of the most dominant and senior speedcubes manufacturers available in the market, with a rich historical past of world-report breaking cubes. We reduce out one corner of each heart sticker on the cube (see Figure 12), thus breaking rotational symmetry and permitting our mannequin to determine absolute face angles from a single body. The parts from left to proper are (i) backside heart enclosure, (ii) lithium polymer battery, (iii) predominant PCBa with BLE, (iv) high heart enclosure, (v) cubelet backside, (vi) compression spring, (vii) contact brushes, (viii) absolute resistive rotary encoder, (ix) locking cap, (x) cubelet high. For our hardness discount, we develop two fundamental devices. The purpose is to put five consecutive marbles within the center row of two adjacent quadrants (three in the middle row of one quadrant, two within the middle row of one other quadrant) after which line them up. Section 2 introduces two manipulation tasks we consider right here. See Section B.Four for details of their ADR parameterization. See Section E.1 for details. Be sure eye holes are large sufficient for youngster to see out.

Contrary to fashionable perception, solving a Rubik’s cube isn’t all that hard: all that you must do is study the right approach, apply it a couple of occasions and - if your memory is ok - you will soon be capable of do it blindfolded. While high quality quick turning cube will give you distinctive speed and offer you enough management. For those with quality sound cards constructed into their computers, the allure is rather less potent. For those with horrendous-sounding laptops (yours truly included) the enchantment of an outboard DAC is large; it can make a tremendous distinction in sound high quality. In the event you had been to do a fast web seek for “portable laptop computer speaker,” you’d be treated to a buffet of embarrassingly poor-sounding items of glorified plastic that, sadly, in all probability do sound better than the audio system built into your average laptop. This is probably the most common cube amongst world-class cubers, on account of its amazing efficiency, customizability, and excessive-high quality supplies, and is starring the highest world information listing, with the 2nd fastest single resolve (4.16 s) and quickest common remedy on the earth, both set by Feliks Zemdegs.

This is a daunting job as a result of complexity of Rubik’s cube and the interactions between it and the hand: in distinction to the block reorientation process, there isn't any means we are able to accurately capture the item in simulation. Since we prepare each coverage on only one particular process (i.e. the block reorientation task or fixing the Rubik’s cube), we define meta-studying in our context as learning about the dynamics of the underlying Markov decision process. Predicting the total state of a Rubik’s cube is a harder activity and demands longer coaching time. Until folks get used to seeing such a factor, the Cube is bound to draw consideration - it definitely did for us. Like a Rubik’s cube, every of those mirror cubes consists of three layers of blocks which you could rotate to get the desired configuration. That is where speedcubes outperform the Rubik’s model cubes because most of the fashionable speed cubes permit for 45 levels nook cutting.

Proper nook cutting is executed effortlessly. The good nook slicing of the product makes it simple on the palm. Integrating magnets into speed cubes became more profitable with time, and as of at present it's extensively agreed as a regular for an incredible cube. moyu meilong review , unlike grid graphs, can be conceptually associated to Rubik’s Cubes and Rubik’s Squares with little trouble. NASCAR has strict guidelines relating to how much nitrogen, or strain, will be in each shock. Back in the early days of NASCAR (which was integrated in 1948), the foundations had been a bit beneath-advanced. These have a bit extra resistance when turning their layers, however offers you extra control over your velocity cube. They're quiet and don’t give the dry-scratchy feeling the quick turning ones do. Fast turning cube is poorly made if it simply offers no management. This gives you with a new problem each time.

1 note

·

View note

Text

What are Encoders?

Encoders are motion control products that are used to make fine measurements and get feedback on various parameters like velocity, direction, speed, revolution, position, acceleration, count, and distance. The encoders use the motion under various technologies and translate them into electrical signals. These electrical signals are then sent to the control device like the PLC and then interpreted afterward to be used in the program to do a specific task. If you need superior quality encoders then Buy Autonics Encoder from us with supreme quality and reliability. For more information visit our website https://indusautomation.co/.

Some Important Information on Encoders

Different Types of Encoders: There are different types of encoders available in the market and the two most used are absolute encoders and incremental encoders. These are used in various applications like Servo or VFD control, measuring, counts, etc.

Technologies used: Different encoders use different technologies like magnetic, mechanical, resistive, and optical. Out of the four technologies the most used technology is optical technology.

Applications: These are used in various industrial applications like tool machinery, packaging machines, and general industrial machinery. These are mainly used with the motors and provide the finest measurements of various parameters like speed, revolution, and others.

These are mainly used in the sectors like automation, energy, additive manufacturing, medical, motors, textile manufacturing, robotics, and custom solution.

Our Products Offerings

We at Indus automation are a verified partner and distributor of Autonics encoders offering various models like the Autonics E50S8–100–3-T-1 Encoder, Autonics E50S8–1000–3-T-1 Rotary Encoder, Autonics E50S8–1024–3-T-1 Rotary Encoder, and Autonics E50S8–360–3-T-1 Rotary Encoder built for different applications.

Conclusion

The resolution and the accuracy are the two most important factors to consider while buying a rotary encoder. With our product offerings and the trust of Autonics brand, you can buy Autonics encoder online from our website with varied models and better resolution as well as accuracy. Get them now! And if you have any queries then mail us at [email protected] , [email protected], or call us at 022 4970 1186.

0 notes

Text

Two new instances of music gear with my soldering iron marks all over 'em.

First is my Korg Mini Kaoss Pad 2S. I noticed one day that the side button which turns on the internal microphone — to record things, or to feed your voice into the vocoder settings — wasn't clicking, or working at all. So I took it apart to find the tiny tactile switch was entirely missing.

You can see where it should be, there on the right under the plastic button, by the white silk-screened outline labeled SW7. There are two tiny holes in the board that mate with pegs on the underside of the switch, but the whole thing somehow got knocked clean off. For a while, I couldn't find it at all. These switches are tiny, and I really worried about being able to find a surface-mount tact switch in a compatible size. Fortunately, when I went to close the case back up, it turned out to have been stuck to the magnet in the internal speaker. I soldered it back on without major difficulty.

The second is a newer acquisition.

This is an older guitar pedal, BOSS's DD-20 Digital Delay. It's still quite powerful by today's standards, with up to 23 seconds of delay, 11 modes including reverse delay and a looper, and tap tempo. On the left is the manufacturer's photo, and my unit is on the right; there are some obvious differences. I picked it up in somewhat compromised condition. The four knobs on the left were missing, the button labeled "tap" wouldn't click, and — most importantly — the rotary encoder on the right would glitch in such a way that you couldn't reduce the time or BPM setting. If you rotated it slowly counterclockwise, the setting would click down a few times, and then count upwards. The tap tempo on the foot switch still worked, so it could be used, but it was definitely suboptimal.

So I took it apart. It's designed very nicely; the whole thing is in two PCBs, the main board and the control board. The non-working tap switch turned out to be a broken plastic switch actuator. The switch on the board still works, so I just removed the actuator until I can locate or print a replacement. I've stuck a short bit of dowel to the switch with fun-tak, so it can be pressed with the case on.

The rotary encoder turned out pretty lucky. I happened to have mostly-compatible replacements on hand, which I got a couple years ago for a project I haven't gotten to yet.

I desoldered the original, seen on the left, from the board. As you can see, it's shorter, both in the body and in the shaft, than the replacements, but they're exact matches electrically and in the footprint, so the new one dropped right in. You may or may not be able to tell from the photo above, but both the cup around the encoder and the knob ride higher from the enclosure's surface than they did with the original, but it's perfectly serviceable. Once back together, everything works just as it should. (The replacement knobs on the left-hand pots are ones l likewise had on hand.)

The two units are an awfully stark contrast in builds. The Korg device is all tiny surface mount devices on a single board in a plastic shell; the Boss switches and other controls are through-hole devices on their own board, and the case is, save the backplate and battery compartment, made of large hunks of die-cast aluminum. Then again, they're very different use cases. The Mini Kaoss Pad is for DJs and producers, and meant to be safe in a pocket or bag, where the delay pedal is meant to be stomped on, day after day, by boot-wearing guitar players.

At any rate, fixing things feels good.

3 notes

·

View notes

Text

Dubai Photoelectric Sensors, Proximity Sensors & Sensors brand

Future Sky Equipment has been helping customers in the United Arab Emirates and beyond to access a wide range of automation and instrumentation equipment. While focusing on the distribution of a variety of industrial automation products such as sensors, transducers, drives, diversified controllers, timers, and counters, the company has been a success in offering quality products.

All their equipment come with a 1 to 3 years guarantee hence ensuring that they are of the best standards. FSE currently prides in being among the best distributors of digital panel meters suppliers in Dubai, rotary magnetic encoders, and the best temperature controllers in the UAE.

The highly committed and friendly staff will ensure you get utmost customer satisfaction and get you the right equipment to cater to your needs. Unlike many other automation and instrumentation equipment suppliers in the UAE, Future Sky Equipment has a group of trained engineers who are ready to offer you any technical assistance regarding any of their equipment or offering advice on which product to purchase. Doing so is quite easy as they can offer their expertise to you either over the phone, internet, over the counter, and can also come to your site.

While it is now easier to shop for, order, and make payments online, FSE is targeting the global growing market and is ready to incorporate clients not only from Dubai and the UAE but also from all over the world.

The company is fully equipped with the financial resource which ensures that all their advertised items are always in stock and does not run out. If planning on purchasing automation equipment in the near future and looking for the best panel meter suppliers in Dubai, look no further than Future Sky Equipment. They can be reached 6 days week, open daily, except on Fridays.

Get comprehensive list of Photoelectric Sensors, Proximity Sensors & Sensors dealers in Dubai, Dubai Photoelectric Sensors

1 note

·

View note