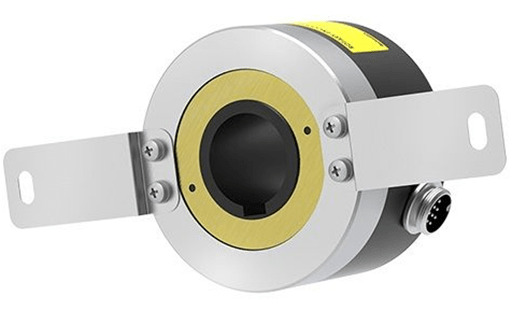

#Hollow shaft rotary encoder

Text

Jayashree Encoders provides hollow shaft encoder, hollow rotary encoder, hollow shaft rotary encoder at best price. It is the best hollow shaft encoder Supplier, Manufacturer, Exporter, Dealer company in Pune

0 notes

Video

analog encoder #rotaryshaftencoder #acmotorencoder #hollowencoder #shaftencoder #motionencoder

analog encoder, rotary shaft encoder, ac motor encoder, hollow encoder, motor shaft encoder, motion encoder www.roundssencoder.com [email protected]

0 notes

Text

Types of different motors and classification

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

Different types of motors and their use

What is motor?

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

How to Install Encoders - Best Practices

The wiring and installation of rotary encoders should be conducted in strict accordance with the instructions of each product. While for general encoder installation guidelines, you should pay attention to the following aspects during your encoder mounting work.

Figure 1: Romuon incremental encoder A2-CW5C installed on an equipment.

1. Installation of Different Types of Encoders

1.1 Solid Shaft Encoder

For solid shaft encoders, you need to pay attention to synchronous flange and clamping flange, which are different on the mounting bracket.

Here are 3 methods of fastening solid shaft encoders.

*Use the mounting hole on the end face of encoder flange directly to fasten the encoder and mounting brackets.

*Use the mounting boss of clamping flange to fasten encoder and mounting brackets by clamp.

*Use the clamping groove of synchronous flange to fasten encoder and mounting bracket by eccentric clamp.

1.2 Incremental Encoder

For incremental encoders, setting zero position through shaft or shaft sleeve and mark on flange will benefit the location assembly and use of the encoder. The fixed hole of the shaft sleeve on the through hole / blind hole hollow shaft encoder corresponds to the zero mark position, which is the mechanical zero position, on the flange surface.

The plat of the solid axis encoder shaft, in which the center line is aligned with the zero mark position on the flange, which is the mechanical zero position.

* About Couplings

*Keep the original state without any distortion when installing the coupling;

*The torque of the top screw on the coupling is generally 0.6Nm. Excessive torque will cause screw damage;

*The encoder and coupling shall be installed in concentric position. Any deviation may cause the mechanical load on the encoder shaft to exceed the rated range.

Figure 2: 3D model of cutaway structure of encoder couplings.

1.3 Hollow Shaft Encoder with Blind Hole

For hollow shaft encoder with blind hole, whether it is incremental or absolute encoder, note whether the length of shaft matches the depth of shaft sleeve. For example, dbs60, generally, the length of shaft shall not be less than 15mm and not more than 40mm. And atm60_ SSI, generally, requires that the length of the shaft is not less than 15mm and not more than 30mm.

1.4 Hollow Shaft Encoder with Through Hole

For hollow shaft encoder with through hole, if it’s incremental encoder, you can choose clamping ring and installation reed on the same side or different side. That is determined by the installation environment on site. Note whether it is more convenient to fix the clamping ring after the reed is fixed.

Figure 3: Sample of hollow shaft encoder with through hole, Autonics rotary encoder E100H35-10000-3-T-24

1.5 Installation of Absolute Encoders

The forms of mechanical installation of absolute rotary encoder includes high-speed end installation, low-speed end installation, and auxiliary mechanical device installation.

More information please visit https://okmarts.com/news/how-to-install-encoders-best-practices.html

1 note

·

View note

Text

Encoder Market is Expected to Grow With the CAGR of 8.7% in the Forecast Period of 2020 to 2027|Key Players Rockwell Automation, Inc., Dynapar (a subsidiary of Fortive), OMRON Corporation, Baumer, ifm electronic gmbh, Sensata Technologies, Inc

Encoder industry will relinquish an approximated estimate at a frequency of 8.7% for the projection space of 2020 to 2027 with factor such as growing adoption of encoders to push for industry 4.0 acting as major driver for the growth of the encoder market. Changing regulations of international markets is acting as major restraint to the encoder market. The encoder market has shown an exceptional penetration in countries such as the U.S., China, and Germany. Growing demand for industrial automation is increasing the penetration in developed countries. In developing countries, rising industrialization and the opportunity to integrate encoders in the wide range of applications is creating huge opportunity for the global encoder market.

Industry is offering new products for the improvement of the machine performance which is driving the encoder market growth. Increasing demand for compact size and advanced interface in encoder is augmenting the encoder market growth. Such new technological advancement is augmenting the encoder market growth. For instance, in August, 2020, FRABA B.V. Company introduced new encoder for the market with advanced interface. A new RTU communications interface based encoders is introduced for small to mid-sized control systems. Through this, the company has enhanced their product offering for the market. Market players have to meet the regulatory standards of each country in which they are selling their products which is limiting the encoder market growth. New product development is for a functional safety application and is creating opportunity for the encoder market to meet the new standards of the safety regulations. Few challenges are difficult to overcome while some market players are investing strongly to resolve the challenges which might help to overcome the technical issues in the encoder market.

Global Encoder Market, By Type (Rotary, Linear), Product Type (Non-Contacting, Contacting), Output (Digital, Analog), Size (31 mm - 70 mm, Less than 30 mm, 71 mm - 100 mm, More than 100 mm), Design (Hollow Shaft Encoders, Solid Shaft Encoders), End User (Industrial, Automotive, Aerospace, Medical, Printing, Food and Beverage, Oil and Gas, Consumer Electronics, Textile, Others), Country (U.S., Canada and Mexico, U.K., Germany, France, Spain, Italy, Netherlands, Switzerland, Russia, Belgium, Turkey, Rest of Europe, China, South Korea, Japan, India, Australia, Singapore, Taiwan, Malaysia, Indonesia, Thailand, Philippines, Rest of Asia-Pacific, South Africa, Saudi Arabia, U.A.E., Israel, Egypt, Rest of Middle East and Africa, Brazil, Argentina and Rest of South America) Industry Trends and Forecast to 2027 This encoder market report provides details of market share, new developments, and product pipeline analysis, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, product approvals, strategic decisions, product launches, geographical expansions, and technological innovations in the market. To understand the analysis and the encoder market scenario contact Data Bridge Market Research for an Analyst Brief, our team will help you create a revenue impact solution to achieve your desired goal.

Get Sample PDF of Encoder Market Report (including COVID19 Impact Analysis) @https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-encoder-market

Encoder Market Scope and Market Size:

The encoder market is segmented on the basis of type, product type, output, size, design and end user. The growth among segments helps you analyze niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of type, the encoder market has been segmented into linear and rotary. In 2020, rotary encoders are majorly adopted by the industrial, automotive, aerospace and other applications owing to continuous rotational movement which drives the segment growth. On the basis of product type, the encoder market has been segmented into contacting and non-contacting. In 2020, encoders itself are sensor which majorly performs by sensing the position as well as most of the rotary encoders are not able to form owing to speed and rotation due to which non-contacting encoders are dominating the encoder market growth. On the basis of output, the encoder market has been segmented into analog and digital. In 2020, the digital encoders are offering improved visibility and more accuracy for the motion control which is driving the segment growth. On the basis of design, the encoder market has been segmented into solid shaft encoders and hollow shaft encoders. In 2020, the hollow shaft encoders segment is dominating the encoder market as they offers enhanced load capacity and mounting flexibility for the encoder market.

Major Market Competitors/Players:

The major players covered in the encoder market report are Rockwell Automation, Inc., Dynapar (a subsidiary of Fortive), OMRON Corporation, Baumer, ifm electronic gmbh, Sensata Technologies, Inc., FAULHABER MICROMO, LLC, Pilz GmbH & Co. KG, YUEQING YUMO ELECTRIC CO.,LTD, Hans Turck GmbH & Co. KG, Hengstler GmbH (a subsidiary of Fortive), POSIC SA, Micronor LLC (a subsidiary of Photon Control Inc.), Wachendorff Automation GmbH & Co. KG, Renishaw plc, HEIDENHAIN, Celera Motion (a subsidiary of Novanta Inc.), maxon motor ag, HONTKO CO., LTD., FRABA B.V., Pepperl+Fuchs SE and SIKO GmbH among other domestic and global players. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

MAJOR TOC OF THE REPORT:

Chapter One: Encoder Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three: Encoder Market Competition, by Players

Chapter Four: Encoder Market Size by Regions

Chapter Five: Encoder Market Revenue by Countries

Chapter Six: Encoder Market Revenue by Type

Chapter Seven: Encoder Market Revenue by Application

Chapter Eight: Encoder Market Revenue by Industries

Chapter Nine: Encoder Market Revenue by Deployment Model

Chapter Ten: Encoder Market Revenue by End User

Get Table of Content on Request @ https://www.databridgemarketresearch.com/toc/?dbmr=global-encoder-market

Reasons for buying this Encoder Market Report:

Laser Capture Encoder Market report aids in understanding the crucial product segments and their perspective.

Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Laser Capture Encoder Market industry.

Even the Laser Capture Encoder Market economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

This report provides a more rapid standpoint on various driving facets or controlling Medical Robotic System promote advantage.

This worldwide Locomotive report provides a pinpoint test for shifting dynamics that are competitive.

The key questions answered in this report:

What will be the Market Size and Growth Rate in the forecast year?

What is the Key Factors driving Laser Encoder Market?

What are the Risks and Challenges in front of the market?

Who are the Key Vendors in Encoder Market?

What are the Trending Factors influencing the market shares?

What is the Key Outcomes of Porter’s five forces model

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-encoder-market

Browse Related Report:

Video Encoder Market

North America Encoder Market

Middle East and Africa Encoder Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Photo

360 CPR Incremental Rotary Encoder ABZ 3-Channel 8mm Hollow Shaft IHC3808

0 notes

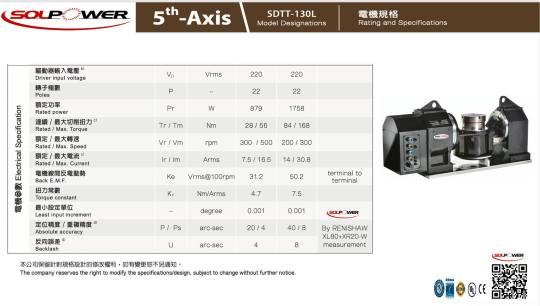

Photo

5 Axis Direct Drive Rotary Table

- Compact:

Direct connection to the load, Gear-less, Backlash-less, Low Noise. High over-load capacity(4x), High speed, High servo-response. Absolute encoders, High resolution(over 22- bits), High Precision. Hollow-Shaft structure, easy wiring and piping

- Customize

Customer-Supply-Encoder available.

Customize plate for mechanical fitting if needed.

- Cost-effective

Structure part moduli-zed, local tooling.

Supply non-hollow shaft type

#direct drive rotary table#5 axis direct drive rotary table#direct drive 5 axis rotary table#5 axis rotary table#5 axis machining#5 axis machine center#rotary table#direct drive#manufacturer#solpower#solpower taiwan#solpower motor#solpower 5 axis#solpower direct drive rotary table#end to end manufacturer#made in taiwan

0 notes

Photo

FORWARD & REVERSE WITH INTERLOCKING

DC TO AC SOLID STATE RELAY

(BACK TO BACK SCR)

INPUT : 7VDC TO 32VDC, 9mA – 16mA

OUTPUT : 24 TO 480VAC, 25Amp/50Amp/90Amp, 1200PIV

Visit For More Info: http://voxintech.com/71477-2/

0 notes

Text

[Hot] AEC Q100 qualified magnetic encoder ICs

[Hot] AEC Q100 qualified magnetic encoder ICs

The iC-MU200 and iC-MHL200 magnetic encoder ICs from iC-Haus are now qualified according to AEC Q100 (Grade 1) – for use in automotive applications in the temperature range from –40 to +125 °C.

The ICs are suitable for high-precision hollow shaft and off-axis rotary measurements and can be used, among other things, in electrically commutated motors, for measuring steering angles, in lidar…

View On WordPress

0 notes

Text

Do you really know the bearings used by industrial robots?

Industrial robot is a kind of multi-functional, multi-degree of freedom that can be repeatedly programmed under automatic control to complete certain operations or mobile work, which is an important engineering automation equipment in modern manufacturing industry. NSK lh25 Bearing

As one of the key accessories of industrial robot, industrial robot bearing is most suitable for the joint or rotating part of industrial robot, the rotating workbench of the machining center, the rotating part of the robot, the precision rotating workbench, the medical instrument, the measuring instrument, the IC manufacturing device, etc.

Characteristics of bearings of industrial robots:

1, can withstand the axial, radial, overturning and other directions of integrated load;

2, thin-walled bearings;

3, high swing positioning accuracy.

Industrial robot bearing classification:

Mainly includes two types of bearings for industrial robots, one is equal cross-sectionof thin-walled bearings, the other is cross-roller bearings. There are also harmonic decelerator bearings, linear bearings, joint bearings, etc., but mainly equal cross-sectionof thin-walled bearings and cross-roller bearings used more.

Cross roller bearing:

Cross roller bearing is a kind of vertical arrangement of cylindrical roller or tapered roller on the rolling surface of V-shaped groove with 90 degrees through isolation block, so it can bear radial load, axial load and moment load. The size of the inner and outer rings is miniaturized, the extremely thin form is close to the limit of the small size, and has high steel, and the accuracy can reach P5, P4, P2. Therefore, it is suitable for the joint and rotating parts of industrial robots, rotating tables of machining centers, precision rotating worktables, medical machines, calculators, military industry, IC manufacturing devices and other equipment.

Characteristics of cross roller bearing:

1. Excellent rotation accuracy

The internal structure of the cross roller bearing adopts the roller to be arranged in 90 ° mutually vertical cross arrangement, and the roller is equipped with a spacing keeper or an isolating block between them, which can prevent the inclined cargo roller of the roller from grinding each other and effectively prevent the increase of rotation torque. In addition, one side contact or locking phenomenon of roller will not occur; at the same time, because the inner and outer rings are divided structure, the gap can be adjusted, and even when preloading is applied, high-precision rotary motion can be obtained.

2. Simplified operation and installation

The outer ring or inner ring, which is divided into two parts, is fixed together after the roller and retainer are installed, so the installation is very simple.

3. Bearing large axial and radial loads

Because the rollers are arranged perpendicular to each other on the V-groove rolling surface of 90 °, the cross roller bearing can bear large radial load, axial load, moment load and other loads in all directions.

4. Save installation space

The inner and outer ring size of cross roller bearing is miniaturized to the minimum, especially the ultra-thin structure is close to the limit of small size, and has high rigidity, so it is most suitable for the joint or rotating part of industrial robot, the rotating table of machining center, the rotating part of manipulator, the precision rotating table, medical instruments, measuring instruments, IC manufacturing devices, etc General purpose.

Thin wall bearing with constant section:

The thin-walled constant section bearing is also called thin-walled ring bearing. It has high precision, very quiet and strong bearing capacity. Thin-walled ring bearings can be deep groove ball bearings, four point contact bearings, angular contact ball bearings, and the cross-section of thin-walled equal cross-section bearings are mostly square. In these series, the cross-section remains the same even for larger shaft diameters and bearing bores. These bearings are therefore called equal sections.

Advantages of thin-walled equal section bearing:

The Thin-walled bearing realizes the extremely thin bearing section, and also realizes the miniaturization and lightweight of the product. The diversity of products expands their range of uses.

Product characteristics of thin-walled equal section bearing:

In order to obtain the low friction torque, high rigidity and good rotation accuracy of the bearing, the steel ball with small outer diameter is used. The use of hollow shafts ensures lightweight and wiring space. Thin wall 6700, 6800 series have various dust cover forms, flange forms, stainless steel forms, wide forms, etc.

Main uses of thin-walled equal section bearing:

Stepping motor, medical equipment, office equipment, testing equipment, deceleration / speed change device, industrial robot, optical / imaging equipment, rotary encoder.

Thin cross roller bearing:

The internal structure of the thin-walled cross cylindrical roller bearing adopts the roller arranged in 90 ° mutually vertical cross arrangement. A single bearing can bear the combined action of radial force, bidirectional axial force and overturning moment at the same time. The roller is equipped with a spacing retainer or isolation block, which can prevent the inclination of the roller or the mutual abrasion between the rollers, and effectively prevent the increase of friction moment.

In addition, the roller vertical cross arrangement structure can avoid the roller locking phenomenon; at the same time, because the bearing inner and outer rings are divided structure, the gap can be adjusted, even if the pressure is applied, it can also obtain high rotation accuracy. Because of its light composite structure, high rotation accuracy, good rigidity and stable friction torque, cross roller bearing is widely used in the waist rotation of industrial robots, shoulder, arm, wrist and other rotating parts of articulated robots.

RV Reducer bearing:

RV Reducer, also known as precision joint reducer, is widely used in industrial robots because of its small size, strong impact resistance, large torque, high positioning accuracy and many other advantages. For RV Reducer, the shape structure and precise positioning of the bearing are the key factors such as compact structure, excellent rigidity and precise transmission. RV Reducer bearing includes a variety of Thin-walled bearing series and cylindrical roller cage assembly series.

Special bearing for harmonic reducer:

Harmonic reducer is a kind of flexible wheel with controllable elastic deformation by wave generator. It uses the controllable elastic deformation of flexible bearing to transmit motion and power. It is characterized by compact structure, high motion accuracy, large transmission ratio, and is mostly used for robot joints with small and medium torque.

Key technology of industrial robot bearing:

The development of modern industrial robots tends to be lightweight. If bearings are to be installed in a limited space, they must be small in size and light in weight, that is, lightweight. But at the same time, the robot's performance of high load, high rotation accuracy, high running stability, high positioning speed, high repetitive positioning accuracy, long life and high reliability requires that the supporting robot bearing must have the performance of high bearing capacity, high precision, high rigidity, low friction moment, long life and high reliability. Lightweight and high performance are a pair of contradictions.

Design technique:

The Thin-walled bearing for industrial robot should not only ensure enough bearing capacity, but also require accurate positioning and flexible operation. Therefore, bearing design analysis and determination of main parameters should not only take the rated dynamic load as the objective function, but also take the rated dynamic load, stiffness and friction moment as the objective function to carry out multi-objective optimization design. At the same time, it should adopt the ferrule and machine based optimization design The finite element analysis method of Thin-walled bearing with frame deformation.

Manufacturing technology:

(1) High precision detection technology for dynamic quality of robot bearing;

(2) Heat treatment process of Thin-walled bearing rings with micro deformation;

(3) The precision grinding technology of bearing ring based on the control of grinding modified layer;

(4) Precise control technology of negative clearance of Thin-walled bearing;

(5) The precise control technology of the protrusion of the thin wall angular contact ball bearing;

(6) Precision assembly technology of thin wall bearing;

(7) Non contact measurement technology of thin wall bearing rings;

0 notes

Text

Kuebler Inc - Now Manufacturing Incremental Encoders in Charlotte NC - Manufacturer of Rotary ...

Charlotte, N.C. (PRWeb) March 25, 2020 -- Kuebler Inc - Now Manufacturing Incremental encoders in Charlotte NC Kuebler is part of the global Kübler Group based in Villingen-Schwenningen, Germany with over 450 employees worldwide and sales in 50 countries, including 11 international subsidiaries. Kübler has 4 global production sites in Germany, India and in Charlotte, NC. Kübler is a leader in high quality rotary encoders, linear encoders, slip rings, as well as measuring...

This story is related to the following:

Sensors Monitors & Transducers

Test & Measuring Instruments

Search for suppliers of: Incremental Encoders

from Air Conditioning /companystory/kuebler-inc-now-manufacturing-incremental-encoders-in-charlotte-nc-manufacturer-of-rotary-encoders-for-shaft-and-hollow-bore-industrial-and-automation-applications-40034813

via http://www.rssmix.com/

0 notes

Text

Types of different motors

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

A motor encoder is a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Motor de refrigeração

Features of motor de refrigeração

Fan Cooling Fan Dual Fan Fan With Temperature Sensor Suit RC Mount Simulation Heating Motor Sink for Car Model RC

Feature

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5-10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

Kuebler Inc - Now Manufacturing Incremental Encoders in Charlotte NC - Manufacturer of Rotary ...

Charlotte, N.C. (PRWeb) March 25, 2020 -- Kuebler Inc - Now Manufacturing Incremental encoders in Charlotte NC Kuebler is part of the global Kübler Group based in Villingen-Schwenningen, Germany with over 450 employees worldwide and sales in 50 countries, including 11 international subsidiaries. Kübler has 4 global production sites in Germany, India and in Charlotte, NC. Kübler is a leader in high quality rotary encoders, linear encoders, slip rings, as well as measuring...

This story is related to the following:

Sensors Monitors & Transducers

Test & Measuring Instruments

Search for suppliers of: Incremental Encoders

from HVAC /companystory/kuebler-inc-now-manufacturing-incremental-encoders-in-charlotte-nc-manufacturer-of-rotary-encoders-for-shaft-and-hollow-bore-industrial-and-automation-applications-40034813

via http://www.rssmix.com/

0 notes

Text

Hollow Shaft Encoder Market: 2019-2025 Forecast Data

Hollow Shaft Encoder Market: 2019-2025 Forecast Data

Marketresearchnest.Com “Global Hollow Shaft Encoder Market Insights, Forecast to 2025” New Report to Its Research Database. The Report Spread across 113 Pages with Multiple Tables and Figures in It.

A hollow shaft rotary encoder is composed in a way so that the rotor portion of the encoder is tubular, with the inner diameter of the rotor tube sized to accept and clamp to most standard shaft sizes.

View On WordPress

0 notes

Text

Rotary Encoders Market by Players, Regions, Product Types & Applications 2017-2022

The global Rotary Encoders market is valued at XX million USD in 2016 and is expected to reach XX million USD by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

This report offers an overview of the market trends, drivers, and barriers with respect to the Rotary Encoders market. It also provides a detailed overview of the market of different regions across United States, Europe, China, Japan, India, Southeast Asia and Others. The report categorizes Rotary Encoders market by by Rotary Encoder Type, by Rotary Encoder Technology, by Output Signal, by Construction, and application. Detailed analysis of key players, along with key growth strategies adopted by them is also covered in this report on Rotary Encoders market is valued at XX million USD in 2016 and is expected to reach XX million USD by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

This report focuses Global market, it covers details as following:

Key Players

• AK Industries (USA)

• AMI Elektronik (Germany)

• Assun Motor Limited (Singapore)

• Autonics (Korea)

• Baumer Group (Brazil)

• DR. JOHANNES HEIDENHAIN GmbH (Germany)

• Dynapar (USA)

• ELAP (Italy)

• ELCIS ENCODER (Italy)

• Eltra S.p.a. (Italy)

• Gurley Precision Instruments (USA)

• Hengstler (Germany)

• Hohner Automaticos (Spain)

• HONEST SENSOR (China Taiwan)

• Johannes Hubner Giessen (Germany)

• KUBLER GmbH (Germany)

• LENORD + BAUER (Germany)

• Lika Electronic (Italy)

• Maxon Motor (Switzerland)

• MEGATRON Elektronik GmbH & Co. KG (Germany)

• Micronor (USA)

• Precizika Metrology (Lithuania)

• RENISHAW (UK)

• Scancon (Denmark)

• Sensata Technologies (USA)

• SICK (Germany)

• SIKO GmbH (Germany)

• TR-Electronic GmbH (Germany)

• W+S Mess-Sgsteme GmbH (Germany)

• Wachendorff Automation GmbH & Co. KG (Germany)

Request a Free Sample Copy of this Report @ https://www.radiantinsights.com/research/global-rotary-encoders-market-research-report-2017-2022/request-sample

Key Regions

• North America

• United States

• Canada

• Latin America

• Mexico

• Brazil

• Argentina

• Others

• Europe

• Germany

• United Kingdom

• France

• Italy

• Spain

• Russia

• Netherland

• Others

• Asia & Pacific

• China

• Japan

• India

• Korea

• Australia

• Southeast Asia

• Indonesia

• Thailand

• Philippines

• Vietnam

• Singapore

• Malaysia

• Others

• Africa & Middle East

• South Africa

• Egypt

• Turkey

• Saudi Arabia

• Iran

• Others

Download Full Research Report @ https://www.radiantinsights.com/research/global-rotary-encoders-market-research-report-2017-2022

Main types of products

Rotary Encoders Market, by Rotary Encoder Type

• Incremental Rotary Encoder

• Absolute Rotary Encoder

Rotary Encoders Market, by Rotary Encoder Technology

• Optical

• Magnetic

• Mechanical

• Potentiometer

Rotary Encoders Market, by Output Signal

• Fieldbus

• Analog

• Digital

• Sine Wave

• Other (Parallel, RS-422, RS-485)

Rotary Encoders Market, by Construction

• Solid-shaft

• Hollow-shaft

• Single-turn

• Multi-turn

• Other (Flange, Non-contact, Draw-wire)

Rotary Encoders Market, by Key Consumer

• Elevator

• Vector Motor and Servo Motor

• Construction Machinery

• Industrial Automation Control Production Line

• Other (Industrial Robot, Oil and Gas Industry)

About Radiant Insights

Radiant Insights is a platform for companies looking to meet their market research and business intelligence requirements. It assist and facilitate organizations and individuals procure market research reports, helping them in the decision making process. The Organization has a comprehensive collection of reports, covering over 40 key industries and a host of micro markets. In addition to over extensive database of reports, experienced research coordinators also offer a host of ancillary services such as, research partnerships/ tie-ups and customized research solutions.

Media Contact:

Company Name: Radiant Insights, Inc

Contact Person: Michelle Thoras

Email: [email protected]

visit our website: http://www.radiantinsights.com/

Phone: (415) 349-0054

Toll Free: 1-888-928-9744

Address: 201 Spear Street 1100, Suite 3036,

City: San Francisco

State: California

Country: United States

0 notes