#Demag crane

Photo

🏗️ TEREX-DEMAG AC500 DE BRANDT 📸 ZEMST BELGIUM 🗓️ 2006/09/21 #photographedbyhermanwalraet© #hewapic© #terex #demag #terexdemag #ac500 #crane #cranes #cranespotting #debrandt #zemst #dendermonde #water #instaphoto #instaphotography #photogram #photo #instagram #insta #hewapic #instafoto #fotografie #fotografia (bij Sluis Zemst) https://www.instagram.com/p/CmEbMhGoIZc/?igshid=NGJjMDIxMWI=

#photographedbyhermanwalraet©#hewapic©#terex#demag#terexdemag#ac500#crane#cranes#cranespotting#debrandt#zemst#dendermonde#water#instaphoto#instaphotography#photogram#photo#instagram#insta#hewapic#instafoto#fotografie#fotografia

0 notes

Text

Plain Text

RUNWAY BEAM INP UNTUK CRANE - UNLOADING INP 450 DARI TRUK https://www.youtube.com/watch?v=af8UATZCcDk

youtube

#Inp beam#sparepartpabriksawit#Inp 450#Crane runway beam#Inp beam demag crane#Inp beam swf crane#Inp 450 ready stock#Demag crane pabrik sawit#sparepartdemag#sparepartcrane#sparepartpks#Youtube

0 notes

Link

Lifting and moving products is hard work. For those who specialize in overhead cranes, the parts that make it all happen are optimized to give top performance in almost every working condition.

#overhead cranes#Overhead Travelling Cranes In Malaysia#overhead cranes parts Philippines#MHE-Demag#Dock Leveller Singapore#Electric Overhead Travelling Crane#Telehandler manufacturer Singapore#Wheel Loader Singapore#shipyard cranes Singapore#Explosion proof crane supplier

0 notes

Text

The collapsed northern wall of the reactor building of Chernobyl Reactor 4.

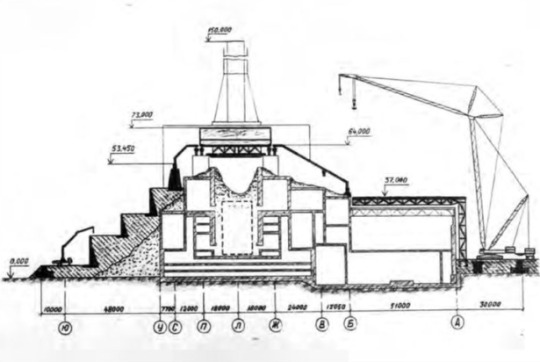

A cross section diagram of the final design of the Sarcophagus.

The Cascade Wall (seen on the left of the diagram above) was one of the most difficult sections of the Sarcophagus to build, but it was one of the most important. It covered the partially collapsed northern wall of the reactor building, as well as the pile of highly radioactive debris left by the explosion. The wall was composed of four stepped tiers, and topped out at 54 meters above the ground.

This was the first part of the Sarcophagus to begin construction. To begin, the men of Sredmesh Unit US-605 installed "Pioneer Walls" (I will make a post on these later) to lessen the gamma radiation at the site. They then filled the space between the Pioneer Walls and the reactor with concrete. On top of this base, they placed huge prefabricated metal wall sections, like the one seen below.

Demag 21 prepares to lift a section of the Cascade Wall into place.

The first tier of the Cascade Wall during installation.

Once the wall sections were all in position, remote controlled concrete pump trucks (seen on the left of the above image) filled the space between the wall and the reactor building, in a similar manner to the area between the Pioneer Walls and the reactor building. This process was repeated until the Cascade Wall was completed.

Crews help to position a section of the third tier of the Cascade Wall before it is lifted into place by crane. These sections weighed more than 120 tons.

Note the white cabin on the crane. These were built similarly to the bathyscaphes used to survey the reactor building during construction of the sarcophagus, with air filters and thick lead sheeting.

The first and second halves of the fourth and final tier of the Cascade Wall, on the left and right respectively.

The men of Sredmash Unit US-605 Shift Four, who installed the fourth tier of the Cascade Wall.

I could not find their names, but I felt compelled to share this photo in their honor.

Without the Cascade Wall, radiation levels would have remained dangerously high and radioactive debris would have been left exposed to the atmosphere. Additionally, it shored up the collapsed northern wall of the reactor building, which had to support some of the weight of the roof section of the Sarcophagus. The men who participated in the project are some of the worst affected amongst the liquidators in terms of sickness.

Men of US-605 fourth shift celebrate the completion of the Cascade Wall with a ceremonial flag raising.

[Image descriptions:

First image: This black and white photo shows the partially destroyed northern wall of the reactor building. Twisted metal and piles of concrete rubble sit on various ledges within the collapsed wall. A network of pipes is visible about three fourths of the way up the wall. The main circulation pumps of the reactor sit partially covered by rubble at the bottom of the wall. Burns cover much of the concrete. An even gravel surface makes up the foreground of the photo, and a large crane is on the right. The striped circular stack of the plant rises in the top left of the image.

Second image: A cutaway diagram of the sarcophagus viewed from the west side of the reactor building. It shows the original structure of the power plant and the plans for the structure of the sarcophagus. From left to right it consists of the four steps of the Cascade Wall, then a slight incline up to the roof section over the reactor hall, then another more gradual slope down to the section covering the turbine hall.

Third image: A black and white photo showing a large crane on the right preparing to lift a large section of metal wall on the ground in front of it. The wall has a small section to help it stand on its own protruding at ninety degrees at its bottom, with angular pipes bracing it against the wall. The crane is lifting it via its hook, which is attached in the shape of an uppercase A. A large metal brace holds the two halves of the lifting section apart above the wall section.

Fourth image: A black and white photo showing the early construction of the cascade wall. The collapsed northern wall sits above the newly placed first section of the cascade wall. The wall is on a raised embankment, below which sit a concrete pump truck sticking its spindly white boom into the wall to add concrete and help build the structure.

Fifth image: The same large crane is lifting another section of the cascade wall just off of the ground. The first and second tiers of the wall can be seen in place in the background of the photo. Nine men, dwarfed by the section of wall they are working on, pull on ropes attached to the wall to angle it correctly for placement on top of the previous sections. The heavy protective cabin of the crane can be seen mounted on the crane chassis, a large white metal box with thick windows to protect the driver from radiation.

Sixth and seventh images: these twin images show the lifting of the two final sections of the cascade wall into place. These sections are both shown in the air on the way to their destination.

Eighth image: A group photo of about forty men in front of the destroyed reactor during the construction of the cascade wall. The wall is only partially finished, but the men are posing in two rows for a photo (crazy!). The men are dressed in dark khaki/deep blue clothes, and white sanitary caps that cover their hair and prevent contaminated. Some of them are also wearing masks or respirators.

Ninth image: this color image shows another gathering of liquidators around a blue concrete pump with a red banner attached to the end of its pump arm. The arm is fully extended about a hundered feet into the air. The group is a lot more informal. The cascade wall is seen fully completed behind the men, but several white and orange concrete pumps still work on other parts of the Sarcophagus. The large yellow crane used to lift the wall sections into place sits idle on the right of the image. Also in this image is the iconic red and white striped chimney of the plant.

#chernobyl#chernobyl hbo#nuclear#nuclear power#radiation#accidents and disasters#history#reactor#autism#disaster#concrete#remote control#concrete pump#construction equipment#construction#welding#heavy lifting#chernobyl disaster#collapse#explosion#cleanup#soviet#soviet union#ussr (former soviet union)#ussr#ussr history#reactor 4#sarcophagus#chnpp#nuclear disaster

5 notes

·

View notes

Text

Shanit Global world leader in light crane system supplier in India & kbk rail crane system suppplier in India. Shanit Global offer tailor made like; X Y Friction Free customized Rail cranes systems/KBK rail cranes systems as per requirements of customers.

0 notes

Text

Best eot crane manufacturers in India

EOT (Electric Overhead Traveling) crane manufacturers design and produce industrial lifting equipment used in various applications. These cranes are vital in manufacturing, construction, and logistics. Prominent manufacturers include Konecranes, Demag, and Street Crane, known for their innovative designs and robust construction. They offer a wide range of EOT cranes, from single girder to double girder, with varying lifting capacities. Customization options are available to suit specific industry needs. EOT crane manufacturers prioritize safety features, efficient operation, and durability, complying with international standards. These cranes enhance productivity by facilitating the efficient movement of heavy loads within factories, warehouses, and construction sites.

0 notes

Text

Scissor Lift Manufacturers in Singapore: Elevating Your Efficiency and Safety

Introduction

Singapore, known for its remarkable infrastructure and rapid industrial growth, has always prioritized efficiency and safety in its various industries. Among the essential equipment used across different sectors, scissor lifts play a pivotal role in enhancing productivity and ensuring the well-being of workers. Scissor lift manufacturers in Singapore have risen to the challenge, providing innovative solutions that meet the high standards of this dynamic city-state.

This article explores the world of scissor lift manufacturers in Singapore, shedding light on their contributions to the local economy, the advanced technologies they employ, and their commitment to safety and sustainability.

The Significance of Scissor Lifts in Singapore

Scissor lifts are versatile machines that are used extensively in Singapore across multiple industries. They are instrumental in construction, maintenance, warehousing, and other sectors where working at elevated heights is necessary. Scissor lifts offer several advantages that make them indispensable:

Safety: Scissor lifts provide a secure platform for workers, reducing the risk of falls and accidents. This is of paramount importance in Singapore, where stringent safety regulations are in place to protect workers.

Efficiency: These lifts allow for efficient access to heights, improving productivity. In industries like construction and maintenance, time is money, and scissor lifts help save both.

Versatility: Scissor lifts come in various configurations, including indoor and outdoor models, electric and diesel-powered versions, and rough-terrain options. This versatility ensures they can be used in a wide range of environments.

Compactness: Many scissor lifts have a compact design, making them suitable for use in tight spaces, a common challenge in Singapore's urban environment.

Scissor Lift Manufacturers in Singapore

Singapore boasts a thriving manufacturing sector, with several companies specializing in scissor lift production. These manufacturers are known for their commitment to quality, innovation, and safety. Here are some of the leading scissor lift manufacturers in Singapore:

SkyLift Pte Ltd: SkyLift is a renowned manufacturer of scissor lifts in Singapore. They offer a wide range of scissor lifts designed for various applications, including indoor and outdoor use. SkyLift's products are known for their durability and reliability, making them a preferred choice for many industries in Singapore.

Sin Heng Heavy Machinery Limited: Sin Heng is a well-established heavy machinery manufacturer in Singapore. They produce a range of construction equipment, including scissor lifts. Sin Heng's scissor lifts are designed to meet the demands of the construction industry, where safety and efficiency are paramount.

MHE-Demag Singapore Pte Ltd: MHE-Demag is a leading materials handling equipment manufacturer in Singapore. While they are known for their cranes and hoists, they also produce scissor lifts. Their scissor lifts are engineered for both indoor and outdoor use and are characterized by their advanced technology and safety features.

Technological Advancements

Singapore's scissor lift manufacturers are at the forefront of technological advancements in the industry. They continuously invest in research and development to improve the performance, safety, and environmental impact of their products. Some notable technological innovations in scissor lifts include:

Electric Power: Many scissor lifts in Singapore are now powered by electric motors, reducing emissions and making them suitable for indoor use. These electric lifts are energy-efficient and produce lower noise levels, contributing to a greener and quieter work environment.

Advanced Control Systems: Manufacturers are incorporating advanced control systems that enhance operator safety and precision. These systems include features like self-leveling platforms, load sensors, and real-time diagnostics.

Telematics: Telematics systems are becoming increasingly common in scissor lifts, allowing remote monitoring of machine performance, maintenance needs, and location. This data-driven approach improves fleet management and reduces downtime.

Lithium-ion Batteries: Some scissor lifts in Singapore are now equipped with lithium-ion batteries, which offer longer operating times and faster charging. This extends the productivity of the lifts while reducing the need for frequent recharging.

Eco-Friendly Designs: Manufacturers are focusing on eco-friendly designs by using sustainable materials, reducing energy consumption, and incorporating features like regenerative braking to minimize environmental impact.

Safety and Training

Safety is paramount in Singapore's industries, and scissor lift manufacturers play a crucial role in ensuring the well-being of workers. They provide comprehensive training programs for operators and maintenance personnel to ensure safe and efficient use of their equipment. These programs cover topics such as:

Equipment Operation: Proper operation techniques are taught to operators, including how to maneuver the scissor lift safely, raise and lower the platform, and use safety features effectively.

Fall Protection: Training includes guidelines for fall protection, emphasizing the importance of wearing appropriate safety gear like harnesses and helmets while working at heights.

Maintenance and Inspections: Operators are trained to conduct pre-shift inspections and basic maintenance tasks to ensure the equipment's reliability and safety.

Emergency Procedures: Training programs also cover emergency procedures, such as what to do in the event of equipment malfunctions or accidents.

Regulatory Compliance

Singapore has stringent regulations governing the use of scissor lifts and other lifting equipment. Scissor lift manufacturers are well-versed in these regulations and ensure that their products comply with local and international standards. This commitment to regulatory compliance not only ensures the safety of workers but also helps businesses avoid legal and financial repercussions.

Sustainability Initiatives

Singapore is increasingly focusing on sustainability and environmental conservation, and scissor lift manufacturers are following suit. Many manufacturers are adopting eco-friendly practices in their production processes and product designs. This includes reducing carbon emissions through the use of electric-powered lifts, using sustainable materials, and implementing recycling and waste reduction measures in their operations.

Conclusion

Scissor lift manufacturers Singapore are instrumental in supporting the city-state's thriving industries by providing essential equipment that enhances productivity and safety. Their commitment to technological advancements, safety training, regulatory compliance, and sustainability reflects the high standards and values upheld in Singapore's business landscape. As Singapore continues to grow and evolve, these manufacturers will play a pivotal role in shaping the future of work at heights and contributing to the overall success of the nation's industries.

0 notes

Text

Robotic Parking Systems Market Will Hit Big Revenues In Future | Biggest Opportunity Of 2022

Robotic Parking Systems Market Comprehensive Study is an expert and top to bottom investigation on the momentum condition of the Global Robotic Parking Systems industry with an attention on the Global market. The report gives key insights available status of the Global Robotic Parking Systems producers and is an important wellspring of direction and course for organizations and people keen on the business. By and large, the report gives an inside and out understanding of 2021-2027 worldwide Robotic Parking Systems Market covering extremely significant parameters.

Some key Players in This Report Include

Parkplus (United States)

Serva Transport Systems (Germany)

Shenzhen Yeefung Automation Technology (China)

MHE-Demag (Singapore)

Stanley Robotics (France)

AIM Inc. (United States)

Fata Automation (United States)

A.P.T. Parking Technologies (United States)

LoDige Industries (Germany)

Smart City Robotics (Abu Dhabi)

The rising unavailability or the limited availability of parking spaces coupled with the increasing number of vehicles have resulted in heavy traffic congestion in several regions and countries. Moreover, it is observed that the drivers searching for vacant parking spaces account for approximately 40% of the total traffic congestion. Thus enhancing the need for a robotic Parking system across the countries. In addition to that, the main reason people want this parking space is that the time spent in finding parking space, results in wastage of fuel and increased emission. As per the study done in the market, it is seen that the German driver spends, on average, 41 hours on searching parking spaces each year. Hence causing the country to cost around USD 45 billion which included the cost of wasted time, fuel, and emission. Hence all the aforementioned reasons are sufficient to drive the market forces.

Market Trends: The adoption of smart cities with high-rise buildings has grown significantly. Thus implementing the need for smart parking. As per the Council on Tall Buildings and Urban Habitat, the developers are focusing on reducing emissions and offering low emission sustainable homes. For example, the Beacon residential facility in London offers zero-emission sustainable homes with a fully automated parking system with 320 parking spaces. Hence, increasing the trend in this market space.

Market Drivers: The Growing Population in Urban Areas has put Enormous Pressure on Parking Infrastructure and Necessitated the Expansion of the Available Infrastructure

Increasing per Capita Income, Improved Lifestyle, and Increasing Demand for Personal Mobility has Increased the Sales of Vehicles in Metropolitan Cities

Market Challenges: High Capital Requirement

Market Opportunities: The rising benefits and advantages of the robotic parking system coupled with the increasing number of vehicles are providing an opportunity in this market. For example, global automotive sales reached a record-breaking 90 million in 2017 which was 2.7 percent growth since 2016. In addition to that, the advantages of the automated parking system over conventional parking systems are increased efficiency by 35%-40% and have increased capacity by 40%-50%.

The Global Robotic Parking Systems Market segments and Market Data Break Down by Type (Robotic Parking Systems Using Standalone AGVs, Robotic Parking Systems Using AGVs With Peripherals), Application (Commercial, Residential, Other End Users), Component Type (Software, Hardware), Automation Level (Semi-Automated, Fully-Automated), Technology (Sensor Technology, Mobile Technology, Radio Frequency Identification (RFID) Technology, Other technologies), System Type (Rail Guided Cart (RGC) System, Crane System, Tower Systems, Puzzle System, Silo System, Automated Guided Vehicles (AGV) System, Multi Parking, Rotary Carousel, Speedy Parking, Shuttle System, Optima Parking), Design Model Type (Electro-Mechanical, Hydraulic), Platform Type (Non-Palleted, Palleted), Service Type (Vehicle Detection Solutions, Monitoring & Reporting Services, Integrated Payments, Space Reservation Services), Number of Levels (More Than Level 15, Level 5-Level 10, Less Than Level 5)

Presented By

AMA Research & Media LLP

0 notes

Text

FOR SALE SALE

Demag AC 80-1

Capacity 80 ton

Boom length 50m

Jib 17m

Used Import Crane

Excellent condition

Please kindly contact us for more information

91+8070317878/8070327878

0 notes

Text

Maximizing Efficiency with an Overhead Traveling Crane, Hoist Crane, and Gantry Crane

Wire rope hoist

A wire rope hoist is a type of lifting equipment that utilizes wire rope to lift and move heavy loads. Wire rope hoists are commonly used in various industries such as construction, manufacturing, and transportation due to their advanced lifting capabilities, ease of load handling, and repeated duty cycles.

They are available in a variety of designs and functionalities, including basic hoist units for integration into plant and machinery, as well as lifting units for hazardous environments and spark resistance. Some of the leading manufacturers of wire rope hoists include Demag Cranes and Components, ACCO Material Handling Solutions, Yale, Harrington Hoists, and McMaster-Carr.

Overhead traveling crane

An overhead traveling crane, also known as a bridge crane or suspended crane, is a type of crane that is used to lift and move heavy loads horizontally. It consists of a bridge that spans the width of the work area and moves along rails mounted on a runway beam. The hoist and trolley are mounted on the bridge and move along the length of the bridge to lift and transport the load. Overhead traveling cranes are commonly used in manufacturing, construction, and transportation industries for heavy-duty material handling operations.

Hoist crane

A hoist crane, also known as a chain hoist, is a type of crane that is used to lift and move heavy loads vertically. It consists of a hoist unit that is mounted on a frame or stationary structure and a chain or wire rope that is used to lift and lower the load. Hoist cranes are commonly used in industries such as automotive, construction, and logistics for material handling operations that require lifting and lowering of heavy loads.

Gantry crane

A gantry crane is a type of crane that is used to lift and move heavy loads horizontally and vertically. It consists of a bridge that spans the work area and is supported by two or more legs that run on rails or wheels. The hoist and trolley are mounted on the bridge and move along the length of the bridge to lift and transport the load.

Gantry cranes are commonly used in shipyards, construction sites, and manufacturing plants for material handling operations that require lifting and transporting heavy loads over a wide area.

In summary, each type of crane has its unique features and applications. Overhead traveling cranes are suitable for heavy-duty material handling operations that require horizontal movement of heavy loads. Hoist cranes are ideal for lifting and lowering heavy loads vertically. Gantry cranes are versatile and can be used for both horizontal and vertical movement of heavy loads over a wide area.

Jib crane Singapore

Jib cranes are a popular type of lifting equipment used in Singapore. Shin Guan Singapore offers wall-mounted and pillar jib cranes, which have a load capacity of up to 2,000 kg and a slewing motion that can reach up to 300 degrees with a pillar jib and 270 degrees with a wall-mounted jib.

The cranes have multiple designs for jib arms based on customer requirements. Shin Guan also provides slewing jib cranes that are efficient for spot-loading activities, such as assembling and repairing pumps, valves, and motors.

Shin Guan Cranes offers Jib cranes that provide lifting in a single workstation for compact and easy installation. These cranes can be used as a small capacity cranes for workstation lifting systems for maintenance, assembly, or QC type of operation.

Overhead crane

Overhead cranes are another commonly used type of lifting equipment in Singapore. These cranes are installed on the ceiling or roof of a building and are used to lift and move heavy loads in a horizontal direction.

Overhead cranes are commonly used in manufacturing plants, warehouses, and construction sites.

Shin Guan Singapore provides a range of overhead cranes, including single-girder, double-girder, and underslung cranes.

These cranes have a load capacity of up to 10,000 kg and can be customized to meet specific customer requirements. The company also offers automated cranes that can be programmed to perform repetitive tasks, which can improve productivity and reduce labor costs.

Another company that provides overhead cranes in Singapore is Street Crane. They offer a range of overhead cranes, including single-girder, double-girder, and underslung cranes.

The company also provides automated cranes that can be programmed to perform specific tasks, such as material handling and assembly line operations.

Several other companies in Singapore provide overhead cranes, including Hitachi Industrial Equipment Systems, Mitsubishi Electric Asia, and Demag Cranes & Components. These companies offer a range of cranes with different specifications and features, allowing customers to choose the crane that best suits their specific needs.

Overall, overhead cranes are an important type of lifting equipment used in Singapore, and several reputable companies provide these cranes to customers.

0 notes

Photo

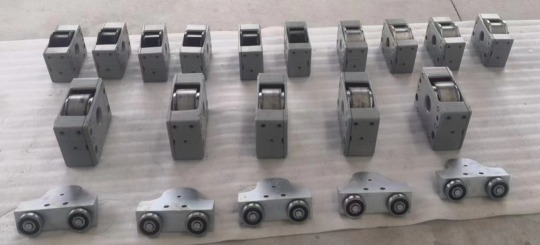

DRS crane wheel block DRS125 DRS160 DRS200

Factory supply replacement demag same size.

whatsApp +86-15038267159

#demag #cranewheelblock #cranewheel #crane

0 notes

Photo

🏗️ TEREX-DEMAG AC650 sarens 📸 Antwerp 🗓️ 2006/08/22 #photographedbyhermanwalraet© #hewapic© #terex #demag #telescope #crane #ac650 #ac700 #sarens #kranen #hijskranen #lift #photography #photo #foto #fotografie #august #augustus #2006 #08 #22 #hisser #aout #hewapic #antwerpen #antwerp #anvers (bij Antwerp, Belgium) https://www.instagram.com/p/CkvTlt1IsaT/?igshid=NGJjMDIxMWI=

#photographedbyhermanwalraet©#hewapic©#terex#demag#telescope#crane#ac650#ac700#sarens#kranen#hijskranen#lift#photography#photo#foto#fotografie#august#augustus#2006#08#22#hisser#aout#hewapic#antwerpen#antwerp#anvers

0 notes

Text

Plain Text

DEMAG CRANE DH1025 - Menuang Lori Isi Buah Sawit di PKS 30Ton/Jam https://www.youtube.com/watch?v=eqtbaDqHsl4

youtube

#Dh1040#Dh1025#Demag crane pks#Demag crane pabrik sawit#Sparepart demag crane#Demag kbh180 b2/12#Demag dh1025 poc#Demag dh1040 poc#Youtube

1 note

·

View note

Photo

At Avezaat Cranes we have a large stock of crane boom sections and jibs in stock of many brands like: Kobelco, Liebherr, Hitachi, Sumitomo, Liebherr, Demag, Grove, Faun, etc.

This way we can supply fast. Our boom sections or jibs from stock are ready to use, and can be supplied in any colour and with inspection certificates.

previous

0 notes

Text

The Sarcophagus constructed around Reactor 4 after the accident was built by Sredmash, the Soviet ministry responsible for building nuclear weapons and power stations.

Sredmash unit US-605 was formed with the specific task of constructing the Sarcophagus. The personnel in the unit rotated out in two month shifts to minimize radiation exposure, as the worst radiation conditions in the zone were found in the area immediately surrounding the husk of the reactor, known as the “Special Zone”. Radiation levels only allowed liquidators mere minutes-or just seconds in some areas-to complete their assigned tasks. Especially dangerous was the pile of debris on the north side of the reactor, a tangled mess of concrete, pipes, fuel, and graphite, all dangerously radioactive.

The work of clearing debris and contaminated soil had to be conducted remotely by robotic bulldozers or armored combat engineering vehicles normally used to clear mines. The two large cranes in the first image are DEMAG cranes, imported from West Germany at enormous cost specifically for the construction of the Sarcophagus. Operators for these cranes sat in their cabins protected by lead sheets 15 centimeter thick. They worked in total darkness, lifting the enormous prefabricated pieces of the Sarcophagus into place using only CCTV footage from a camera mounted on the hooks and radio instructions from Sredmash commanders sitting in a nearby command bunker.

It was far too dangerous to send up welders or riveters to join the pieces, so concrete pumps were used to cement the prefabricated metal parts of the Sarcophagus in place. Parts of the Sarcophagus would arrive from foundries, then be lifted into place by the cranes. Concrete was poured into and on them by concrete pump trucks until the section was considered to be adequately secured. Engineers then detonated remote control explosive bolts attaching the crane wires to the section, and work would begin on the next section. Construction was conducted 24 hours a day, floodlights illuminating the site at night. The frantic pace was set by insane Communist party deadlines and concern over continued emissions of radionuclides. The Soviet government was eager to restart the other three reactors to regain some of their tarnished reputation and show the world that Chernobyl had been made safe. Ultimately, the Sarcophagus would be officially completed on November 30th, 1986, seven months and four days after the explosion.

[Image description: the Sarcophagus, an angular construction of black metal, sits completed over the gaping maw of the hole left by the explosion. It has three sides; a northern and western wall, as well as a roof. The Cascade Wall, the southern wall, is a series of four terraces. It covers a pile of debris blown out of the reactor as well as a sizable hole in the wall of the reactor hall. The western wall is a reinforcing structure for the reactor hall walls, with several buttresses running up its face. The roof is slightly sloped and covers the hole left in the roof by the explosion and prevents the emission of more radionuclides from the remains of the reactor. The area around the reactor is level earth, brought in to cover up the contaminated soil. Heavy construction machinery is scattered throughout the image, with two enormous tracked cranes on either side of the reactor. They tower over the twenty story reactor building.]

#chernobyl#chernobyl hbo#nuclear#accidents and disasters#disaster#nuclear power#autism#tomb#prefab#concrete#radiation#history#heavy machinery#construction#construction equipment#reactor#chernobyl disaster#engineering

4 notes

·

View notes

Text

MEA Rough Terrain Cranes Market to Witness a Healthy Growth by 2032

Rough terrain crane comes across as a kind of hydraulic crane used to move, lift, load, and unload heavy materials all across construction and the other industry verticals.

MEA rough terrain cranes market stands at ~US$ 302.5 Mn as of now and is expected to reach US$ 641.9 Mn by the year 2032 at a CAGR of 7.3% from 2022 to 2032.

MEA rough terrain cranes market emphasizes on 6 regions – Northern Africa, GCC countries, Turkey, South Africa, Israel, and the rest of MEA.

Rough terrain cranes are a preferred choice as far as off-road uses are concerned. This could be credited to their robust construction. Also, continuous improvisation is being done, so that they turn out to be apt for the rough terrain.

The features like easy handling, flexibility on the count of placing on hard sites, the way they could be easily moved from a work site to the other, and ease with which they could be stored when they are not in use compel the key market participants to use them over lift trucks. Also, majority of rough terrain cranes have been designed such that both – labor and time are saved by minimization of operational costs. Emergency rescue features are also included herein, which simplify the task of lifting people from collapsing or dangerous work sites.

Automated technologies are being implemented with the objective of reducing human interaction in the manufacturing facilities. This factor is expected to bolster MEA rough terrain cranes market’s growth in the next decade. Several industry verticals have begun with adoption of automatic cranes due to the reason mentioned above. For example – Manitowoc, in February 2020, put forth Grove GRT8120 rough-terrain crane.

Plus, the transportation and construction verticals are growing at a rapid pace.

One of the trends is also that of an ever-increasing demand for rental rough terrain cranes. Adoption on their part has actually taken over the new units. This could be reasoned with higher cost of the rough terrain cranes.

Telematics is also in its advanced stage. This is another factor expected to provide business opportunities. The end-consumers are asking for advanced rough train cranes with automation and diagnosis at advanced levels.

Initially, rough terrain cranes used to comprise 2 exclusive engines to transmit power for transportation and cranes’ operations. That used to be actually proportional to requirement of load. However, now the manufacturers prefer usage of a powerful engine that could efficiently perform both the functions. Along these lines, TADANO has come up with new-fangled models of cranes that enclose an eco-made system and a fuel-monitoring system that lessens fuel consumption and provides a much better control over the engine when it’s idle.

At the same time, the fact that higher capital investment could hamper MEA rough terrain cranes market can’t be ignored. Also, the market is facing dearth of skilled professionals over here.

Key Takeaways from the MEA Rough Terrain Cranes Market

1 – 75 tons rough terrain cranes are holding the largest market share. They account for more than 30% of the overall market revenue. This could be attributed to growing demand for lifting operations along with the versatility with respect to performing off-road and on-road construction projects.

GCC countries account for close to 60% of the overall market share. Turkey and South Africa follow suit.

“With urbanization increasing at an alarming rate, the demand for rough terrain cranes is bound to substantiate in the forecast period”, says an analyst from Future Market Insights.

Competitive Arena

The Manitowoc Company, Inc., in February 2020, came up with Grove GRT8120 rough terrain crane.

TADANO, in February 2019, completed acquisition of Demag mobile crane business from Terex Corporation for close to US$ 215 Mn.

Liebherr, in February 2019, signed a contract with AI Faris Equipment Rentals. It implied delivering 12 cranes from novel LRT rough terrain cranes series worth close to US$ 25.8 Mn.

XCMG, in July 2020, did launch 750 tons XCA750 eight axle all-terrain crane, which has a 7-section, 92-meter main boom, topped by heavy-duty hydraulically erected wind turbine extension. Its purpose is to undertake maintenance and repairs of wind turbine.

Johnson Arabia, in May 2020, inducted 10 novel Grove rough terrain cranes into the fleet for targeting lifting projects in oil & gas sector.

Thunder Cranes, in September 2022, announced reopening the operations in Middle East with new-fangled base in the UAE.

Dubai Cranes & Technical Services LLC, in December 2020, tabled 8 novel models of the wire rope hoists that range from 3.2 to 40 tons.

Liebherr, in July 2022, announced launching H2 direct injection for the heavy-duty combustion engines as it’s conducive to heavy applications.

Terex Corporation has inked an agreement with Galadari Heavy Equipment Division to distribute rough terrain cranes all over the Middle East.

Browse Detailed Summary of Research Report with TOC: https://www.futuremarketinsights.com/reports/mea-rough-terrain-cranes-market

Key Segments Covered in MEA Rough Terrain Cranes Market Analysis

By Lifting Capacity:

Upto 25 Tons

25.1 to 50 Tons

50.1-75 Tons

75.1-100 Tons

More than 100 Tons

By Boom Length:

Upto 25 Meters

25.1-35 Meters

35.1-50 Meters

More than 50 Meters

By Sales Channel:

New Sales

Equipment Rental

By Country:

GCC Countries

Israel

Turkey

South Africa

Northern Africa

Rest of the Middle East and Africa

What does the Report Cover?

Future Market Insights offers an exclusive perspective and various real-time insights on the dermatology devices market in its latest study, presenting historical demand assessment of 2016 – 2021 and projections for 2022 – 2032.

The research study is based on lifting capacity (up to 25 tons, 25.1 to 50 tons, 50.1 to 75 tons, 75.1 to 100 tons, and more than 100 tons), by boom length (upto 25 meters, 25.1 to 35 meters, 35.1 to 50 meters, and more than 50 meters), and by sales channel (new sales and equipment rental).

0 notes